Rolling diaphragm pump

a diaphragm pump and diaphragm technology, which is applied in the direction of flexible wall reciprocating engines, positive displacement liquid engines, etc., can solve the problems of increasing the differential pressure, and reducing the life of the diaphragm, so as to achieve variable control of the diaphragm stress and increase the pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

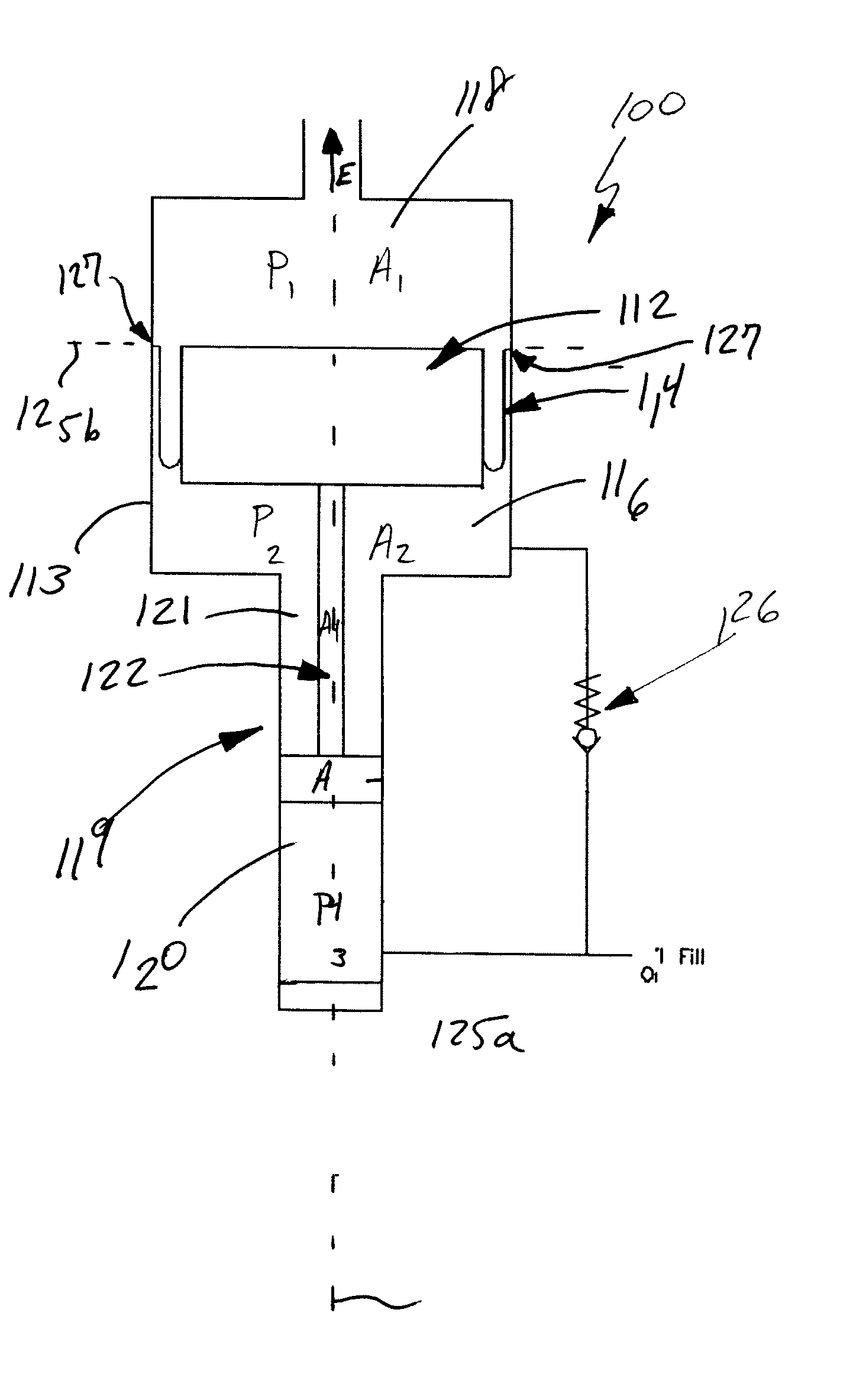

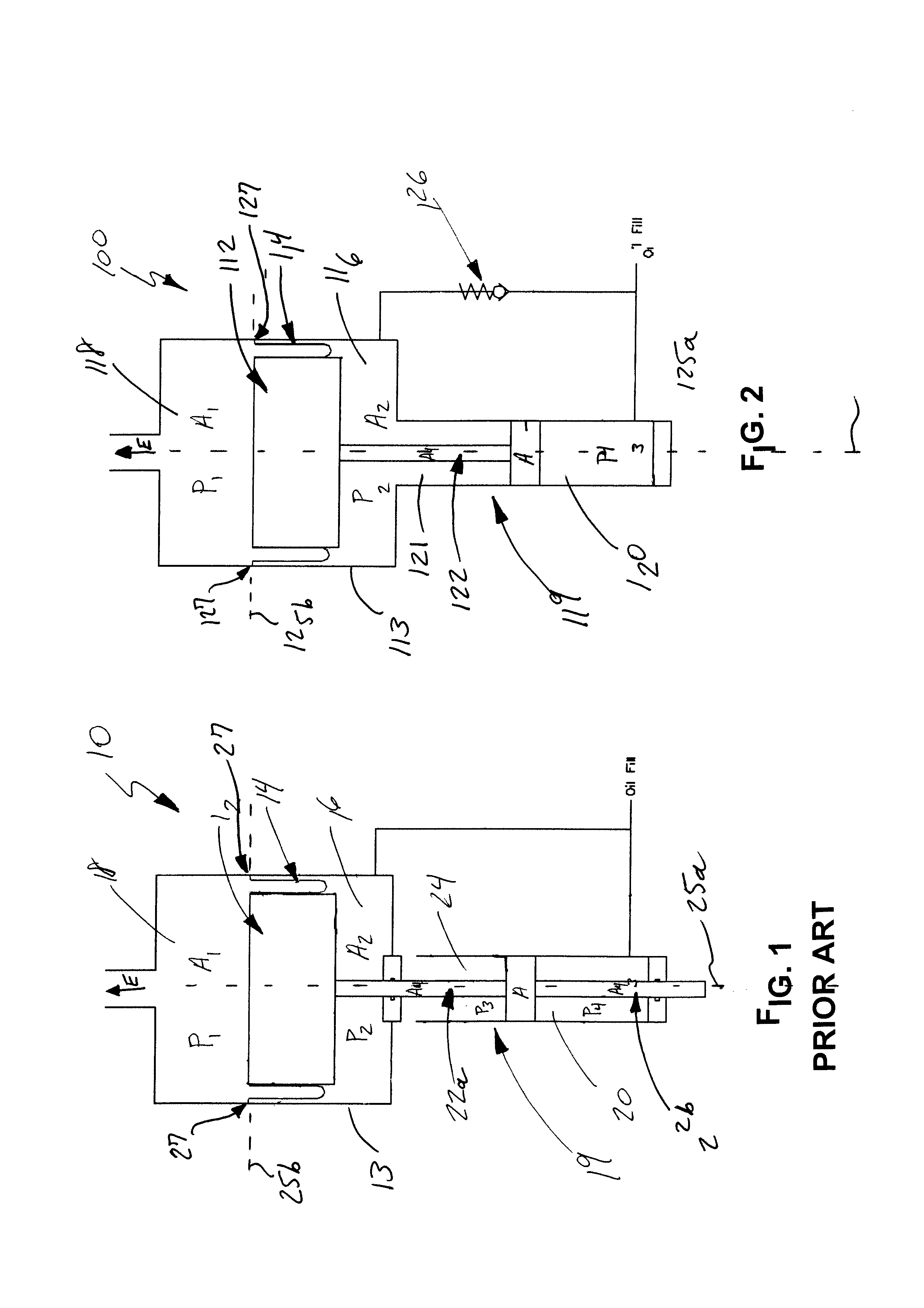

[0021]Turning to FIG. 2, an exemplary embodiment of an inventive rolling diaphragm pump 100 is shown. Pump 100 is suitable, for example, for use in pumping mine roof bolt anchoring compositions, water-bearing explosives, food products, concrete, fraccing fluids for oil and gas wells, coal / water slurries, nuclear waste slurries, asphalt, paint, and filled epoxy resins. However, this list is non-exhaustive and a variety of high viscosity liquids and slurries are amendable to pumping in accordance with the exemplary embodiment.

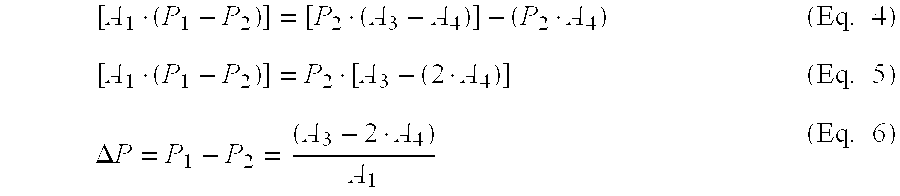

[0022]Inventive rolling diaphragm pump 100 includes a piston 112, which for example may be formed of nylon, is disposed within a cylindrical housing 113, and is seated with respect to a rolling seal diaphragm 114 such as a top-hat shaped rubber diaphragm. A working medium 116 such as oil fluid and a discharge medium 118 (the medium that is being pumped) are shown. A standard hydraulic cylinder 119 (such as a single-rodded cylinder) includes a fluid region 120 suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com