Magnetorheological fluid flexible die forming device and magnetorheological fluid flexible die forming method for plates

A technology of magnetorheological fluid and rheological fluid, applied in the direction of presses, manufacturing tools, stamping machines, etc., to achieve the effects of broadening application fields, improving forming quality, and optimizing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

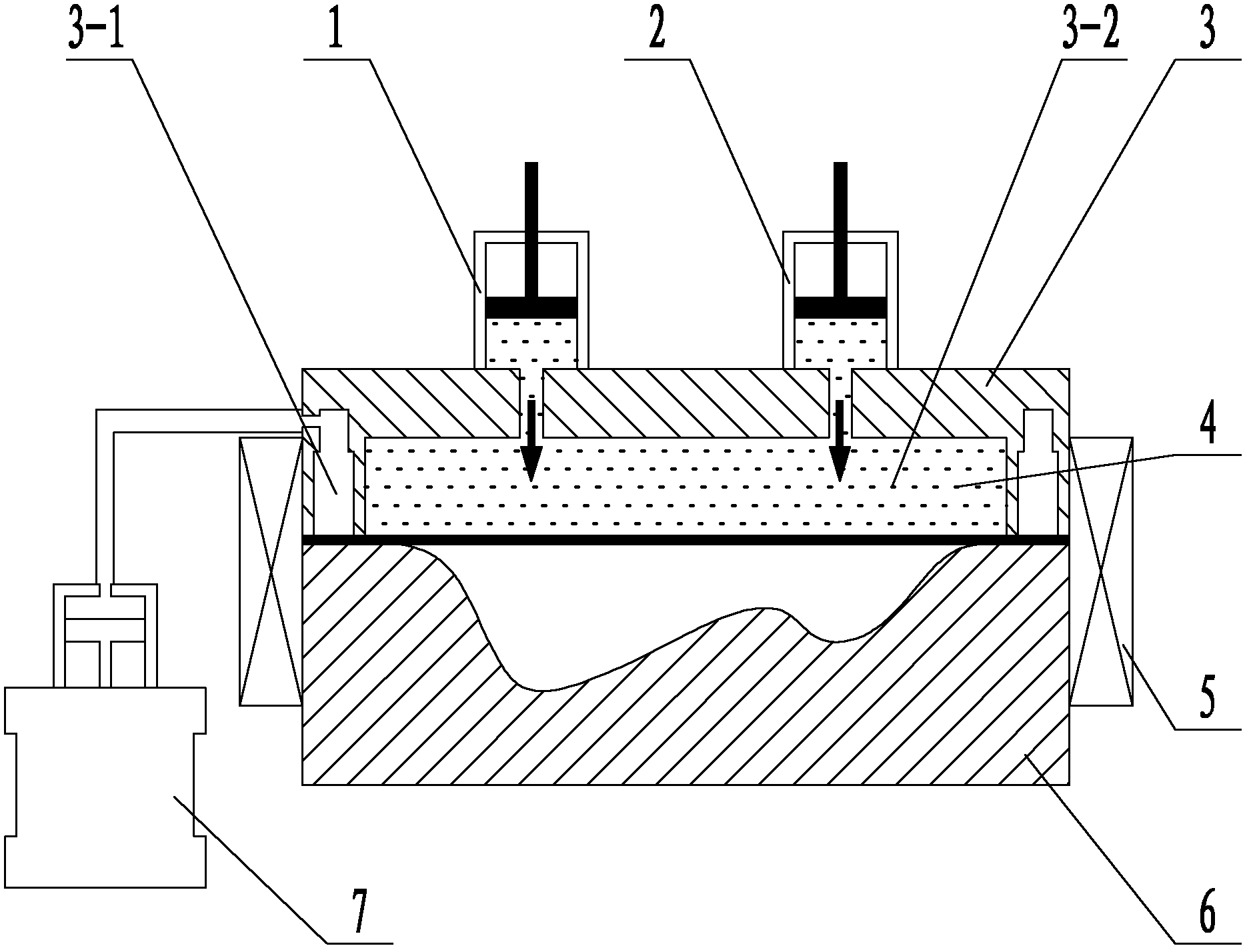

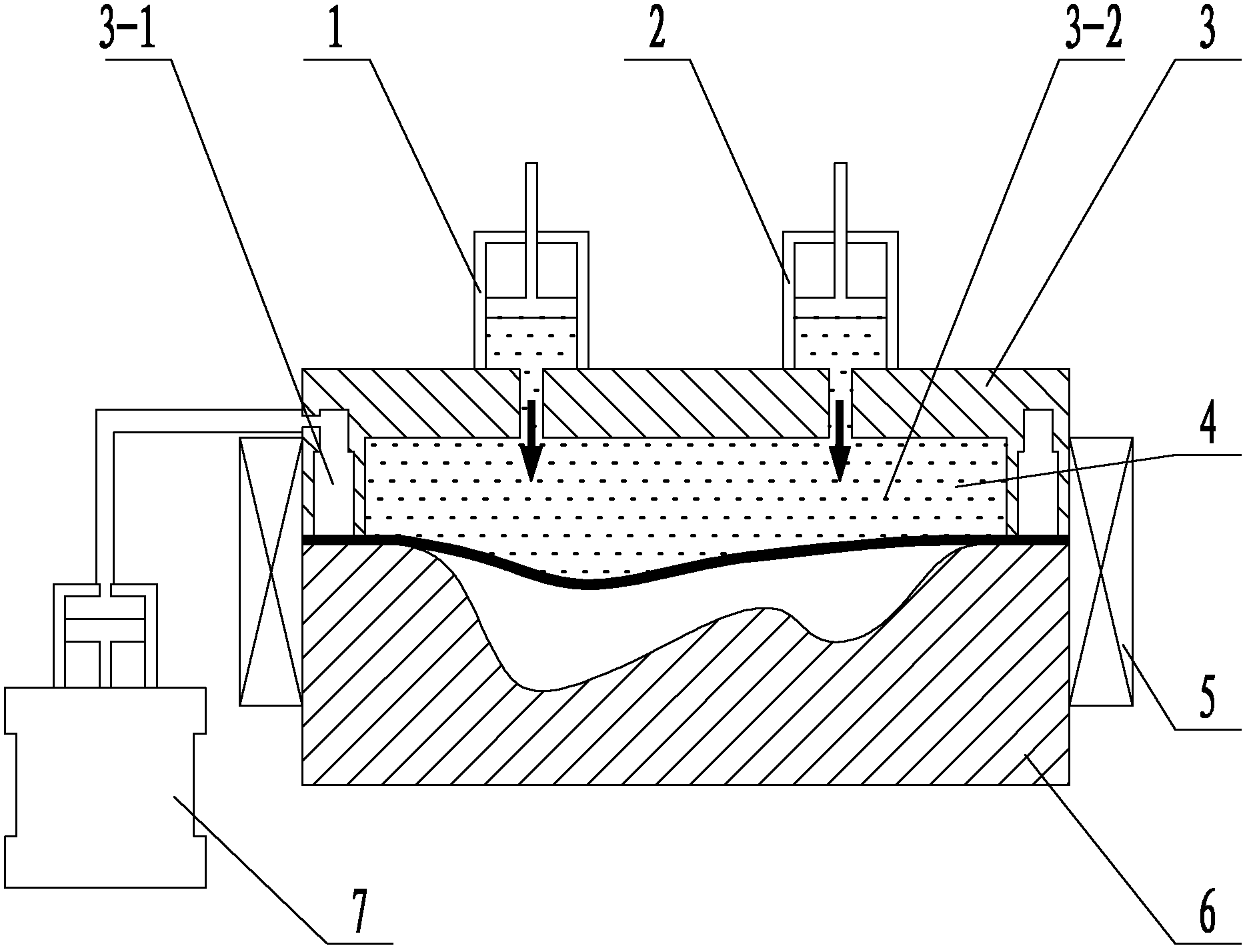

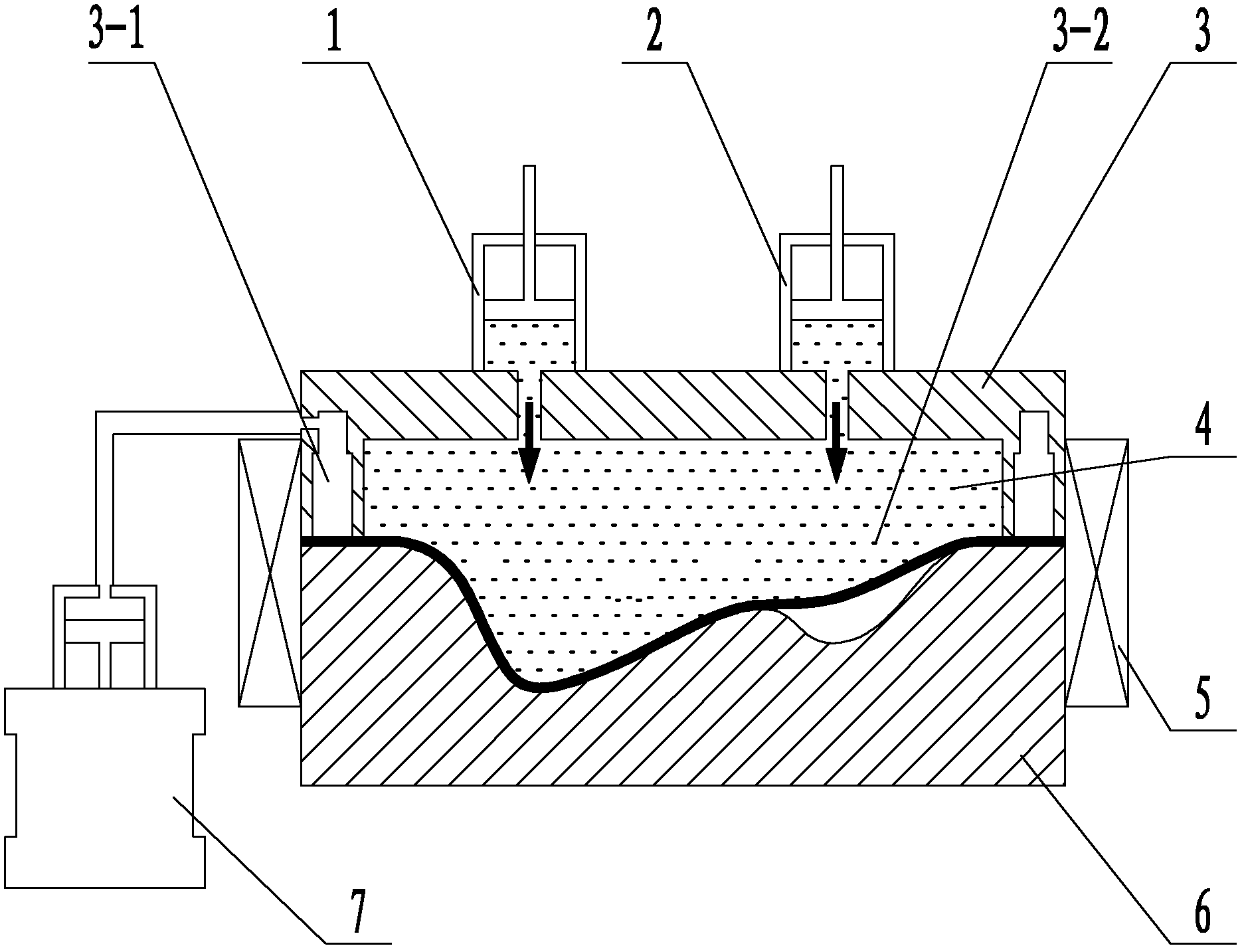

[0028] Specific implementation mode one: combine Figure 1 to Figure 8 This embodiment is described. A sheet material changing physical state soft mold forming device described in this embodiment includes a first magnetorheological fluid injection cylinder 1, a second magnetorheological fluid injection cylinder 2, a magnetorheological fluid container frame 3, a magnetic Rheological fluid 4, solenoid 5, die 6, blank holder cylinder 7, third magnetorheological fluid injection cylinder 8 and fourth magnetorheological fluid injection cylinder 9, magnetorheological fluid container frame 3, die 6 Arranged from top to bottom, the plate is located between the lower surface of the magnetorheological fluid container frame 3 and the upper surface of the die 6, the upper surface of the plate, the lower surface of the magnetorheological fluid container frame 3, the magnetorheological fluid container frame 3 The inner side walls of the two frames form a closed first inner cavity 3-2, the lo...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination Figure 1 to Figure 8 To illustrate this embodiment, the magnetorheological fluid container frame 3 and the concave mold 6 of the plate magnetorheological fluid soft mold forming device described in this embodiment are both made of non-magnetic steel or austenitic stainless steel. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 1 to Figure 4 To illustrate this embodiment, the specific steps of a soft mold forming method for sheet metal magnetorheological fluid with magnetorheological fluid loaded on one side using the device described in Embodiment 1 described in this embodiment are as follows:

[0031] Step 1. Clamp the plate to be formed between the upper surface of the die 6 and the lower surface of the magnetorheological fluid container frame 3;

[0032] Step 2: Fill the first inner cavity 3-2 with the magnetorheological fluid 4. During the forming process, the first magnetorheological fluid is injected into the cylinder 1 and the second magnetorheological fluid is injected into the cylinder 2 into the first inner cavity 3-2. Inject magnetorheological fluid 4 into it;

[0033] Step 3. Determine the magnetic field strength B in the working area according to the shape of the plate to be formed and the action form of the soft mold.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com