Patents

Literature

49results about How to "Reduce the number of tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

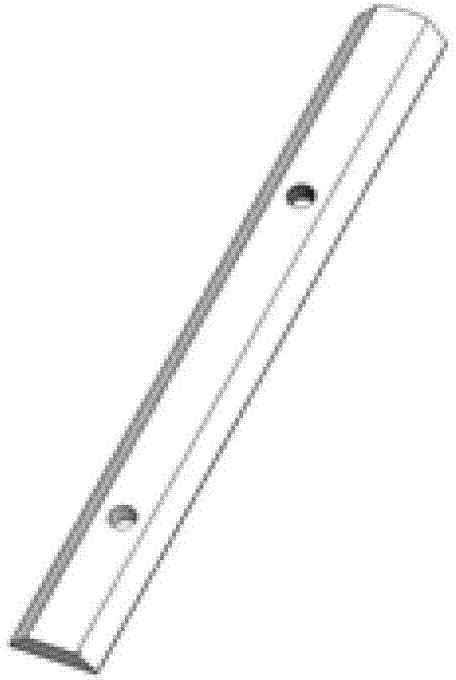

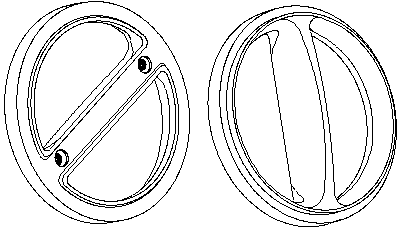

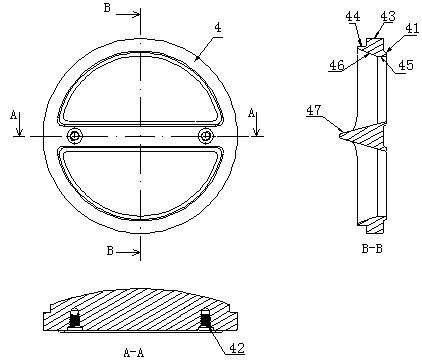

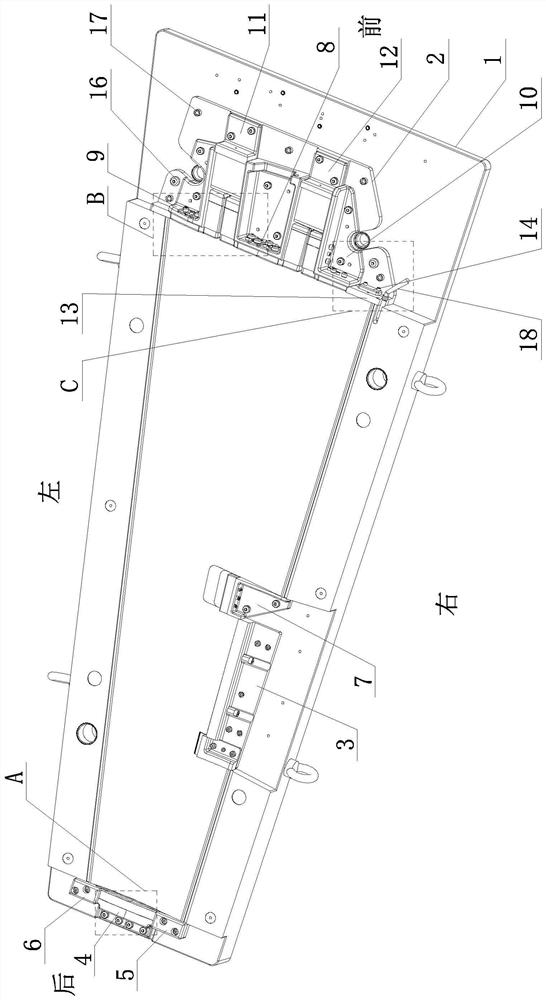

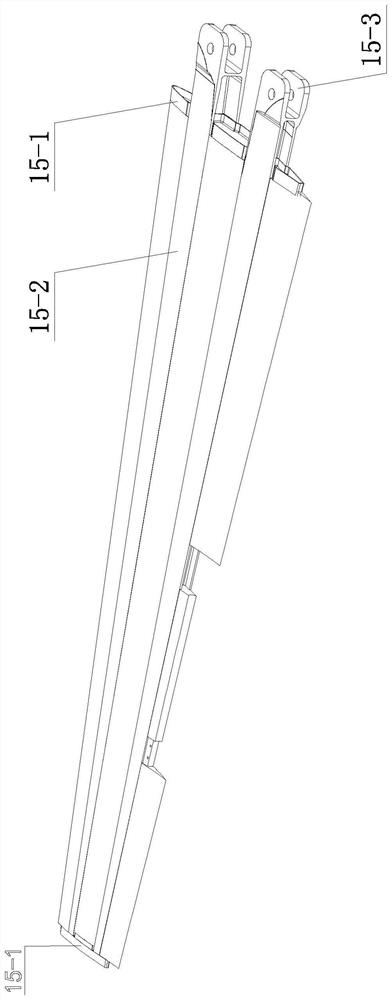

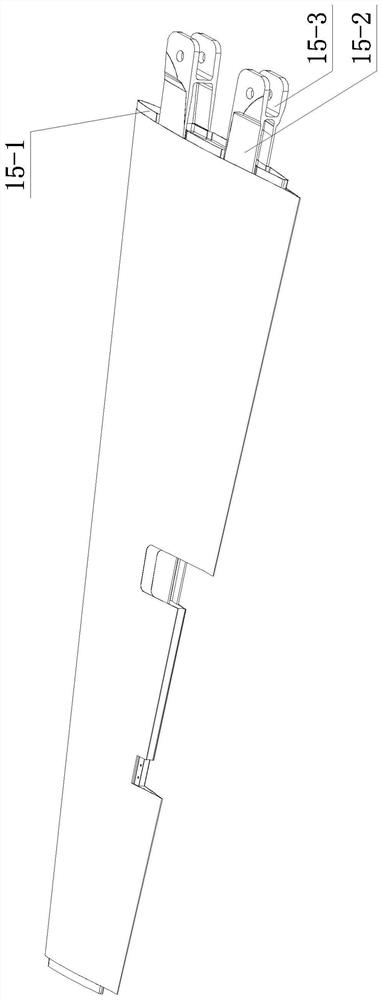

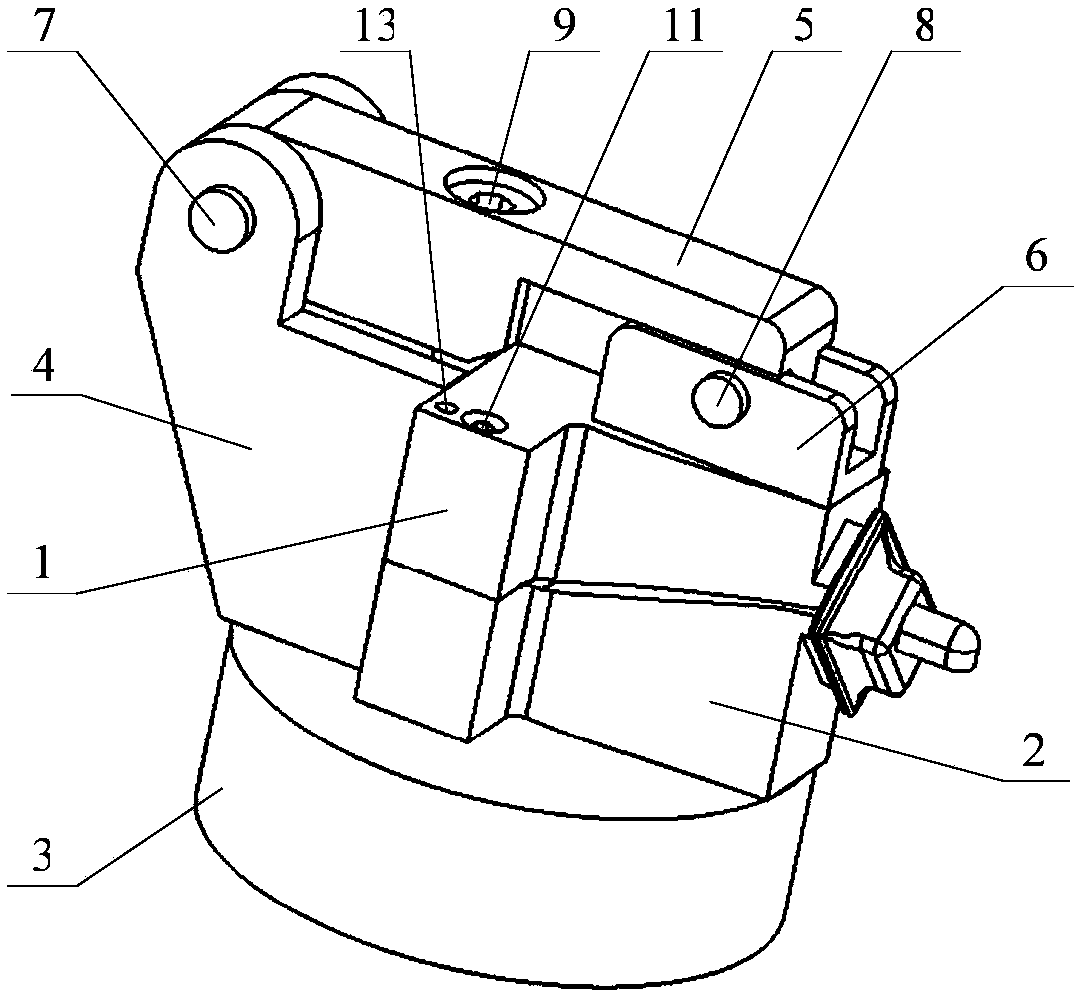

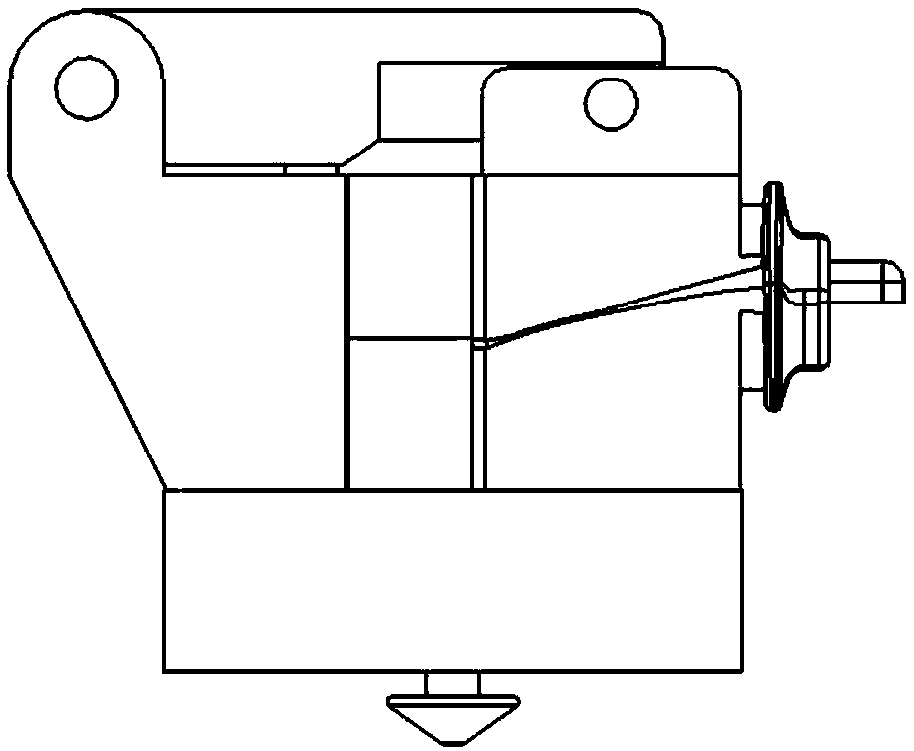

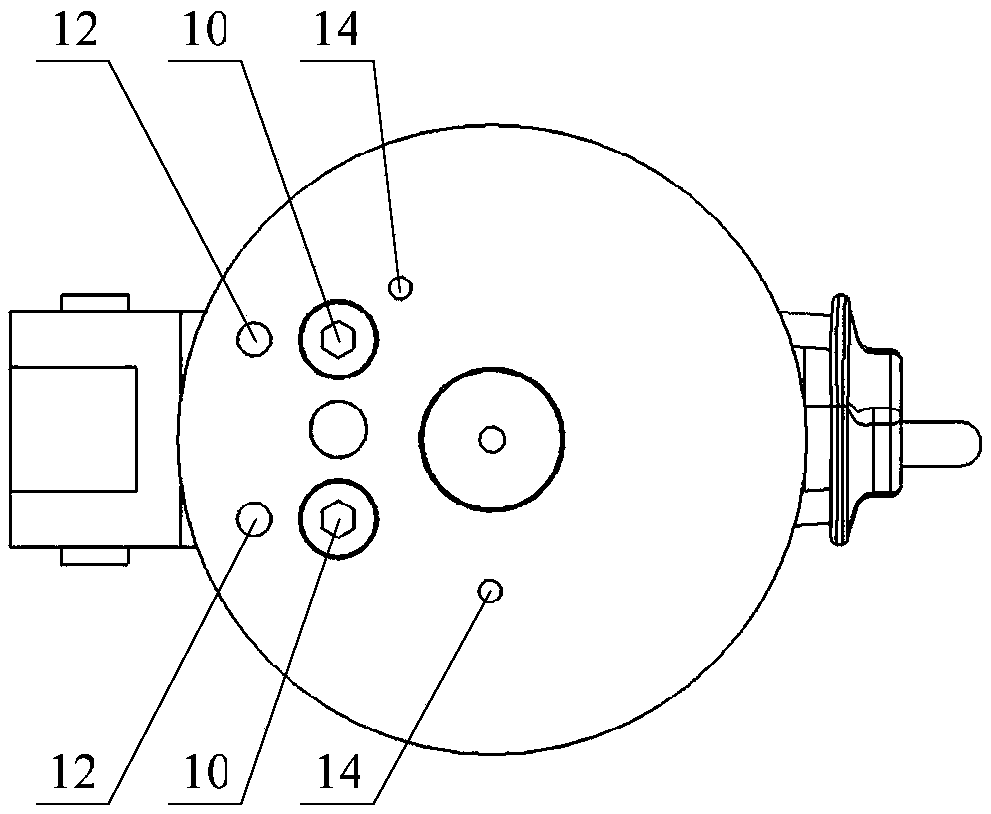

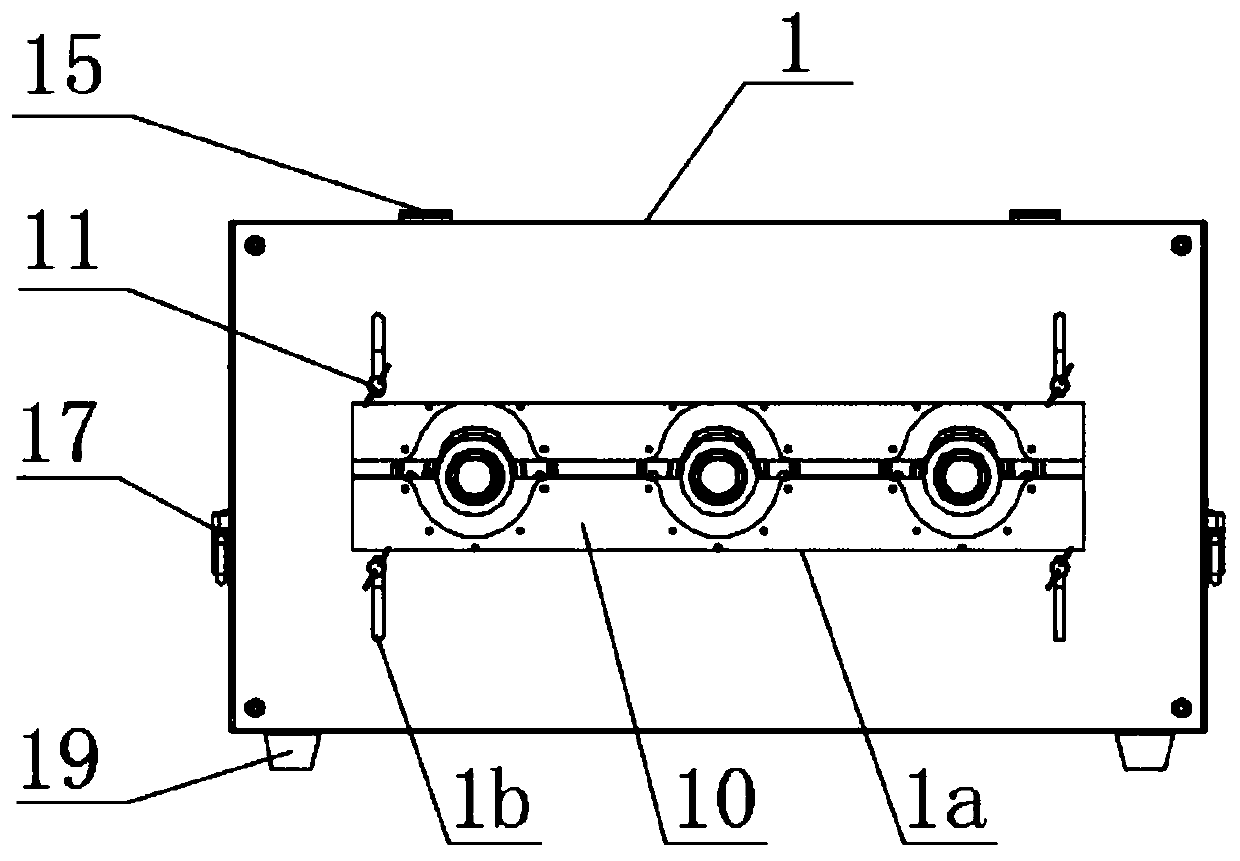

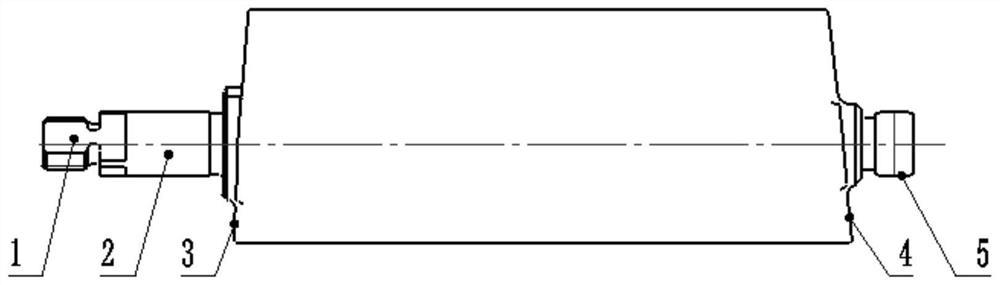

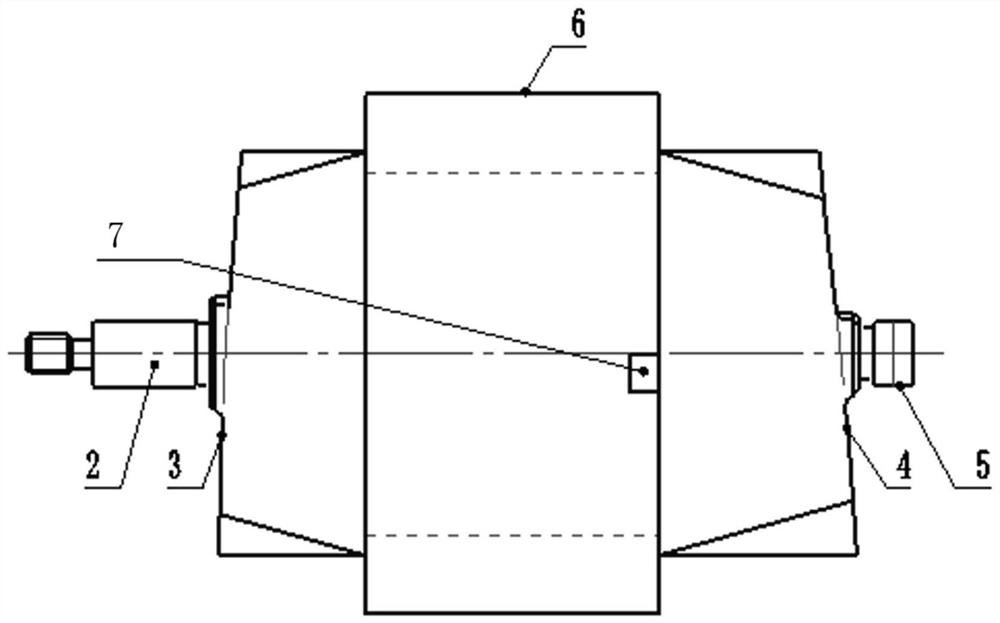

Bidirectional location thin-walled workpiece welding clamp

ActiveCN106425256APrevent oxidationEliminate positioning gapsWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

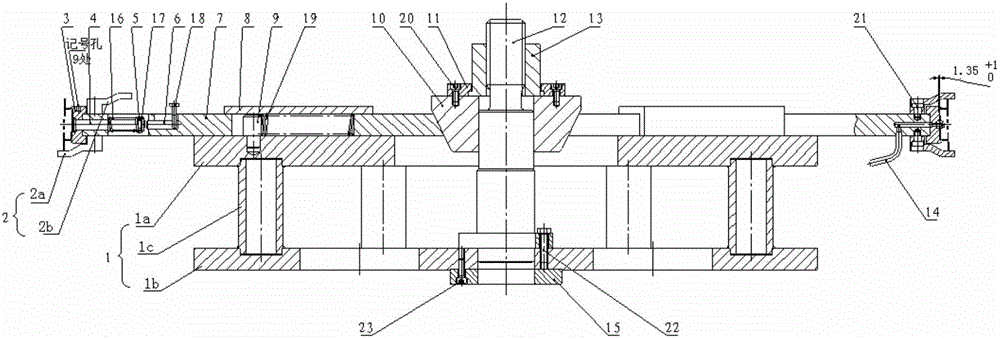

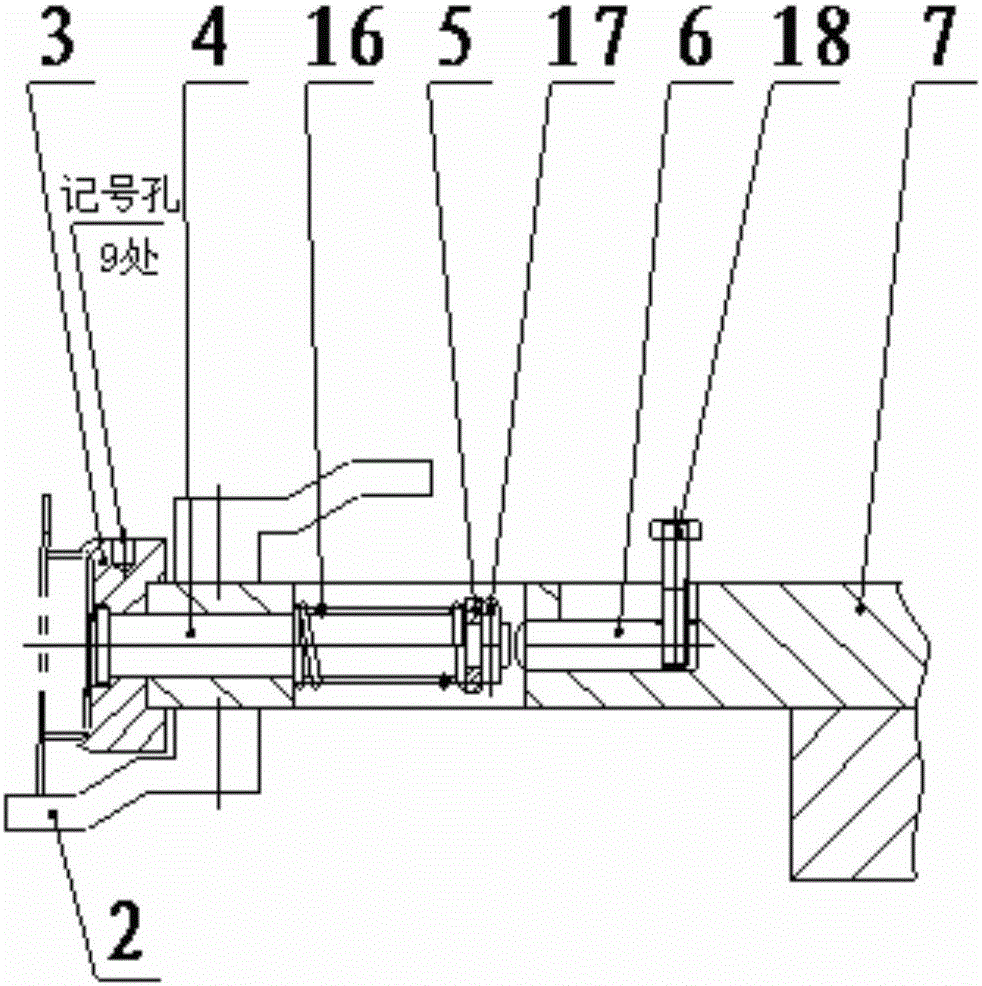

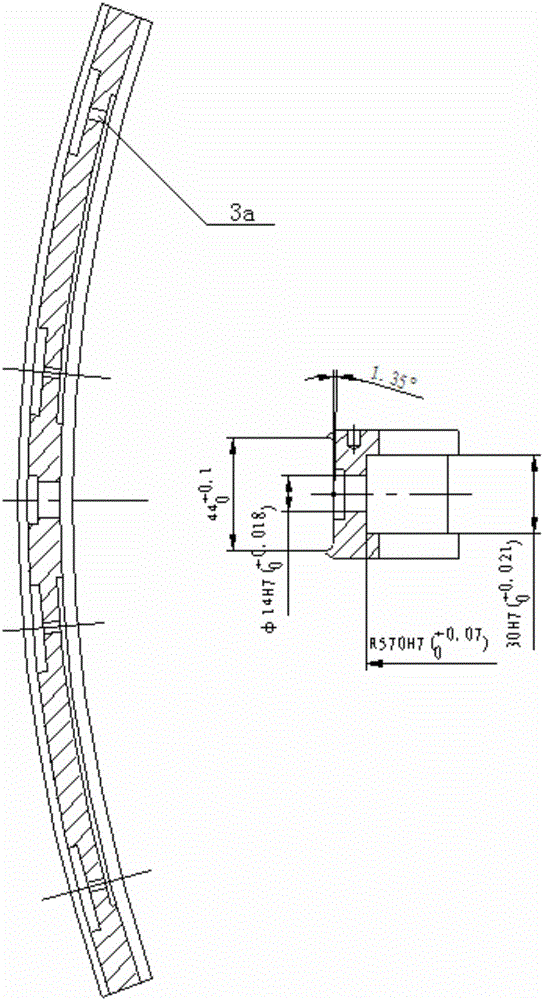

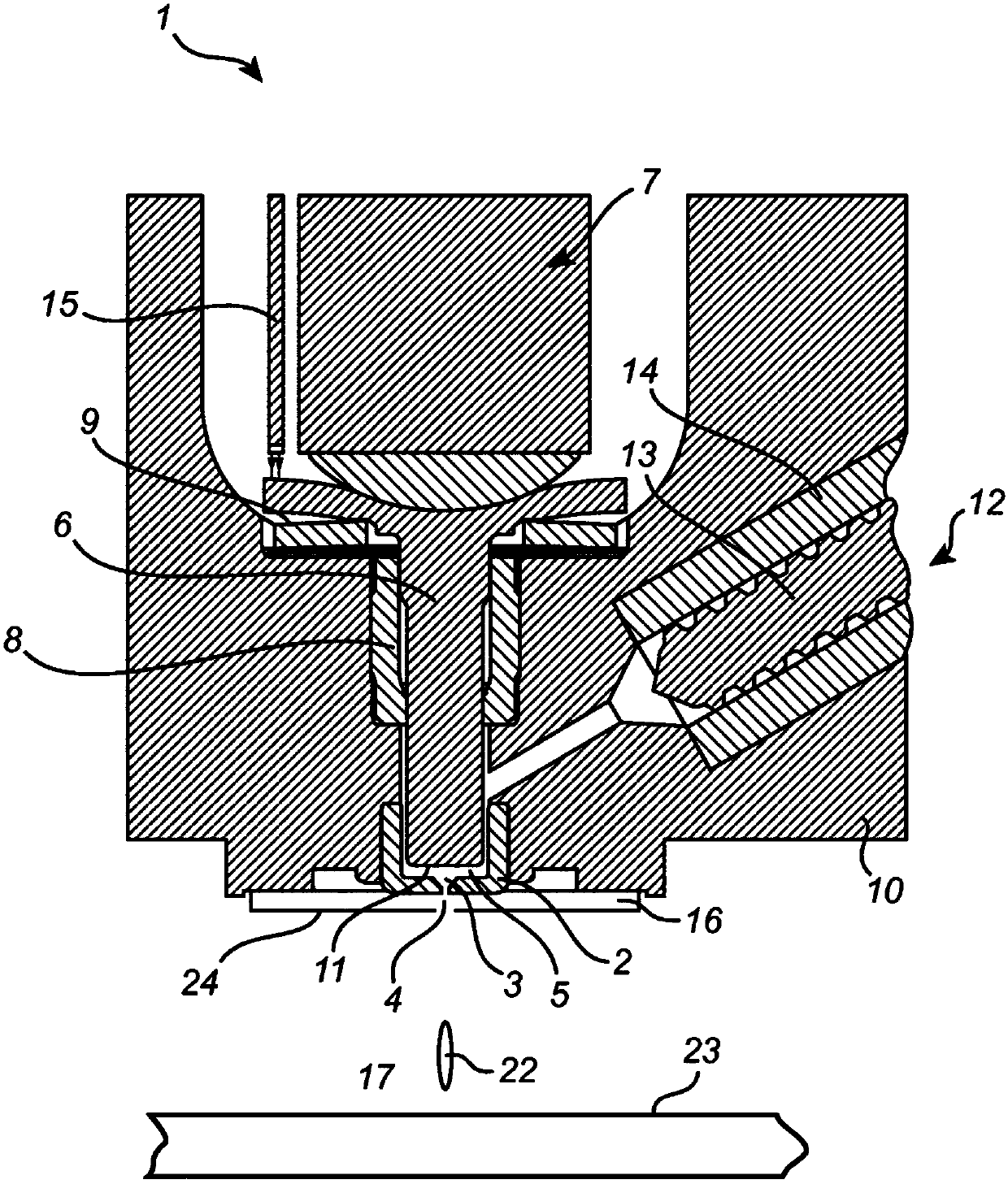

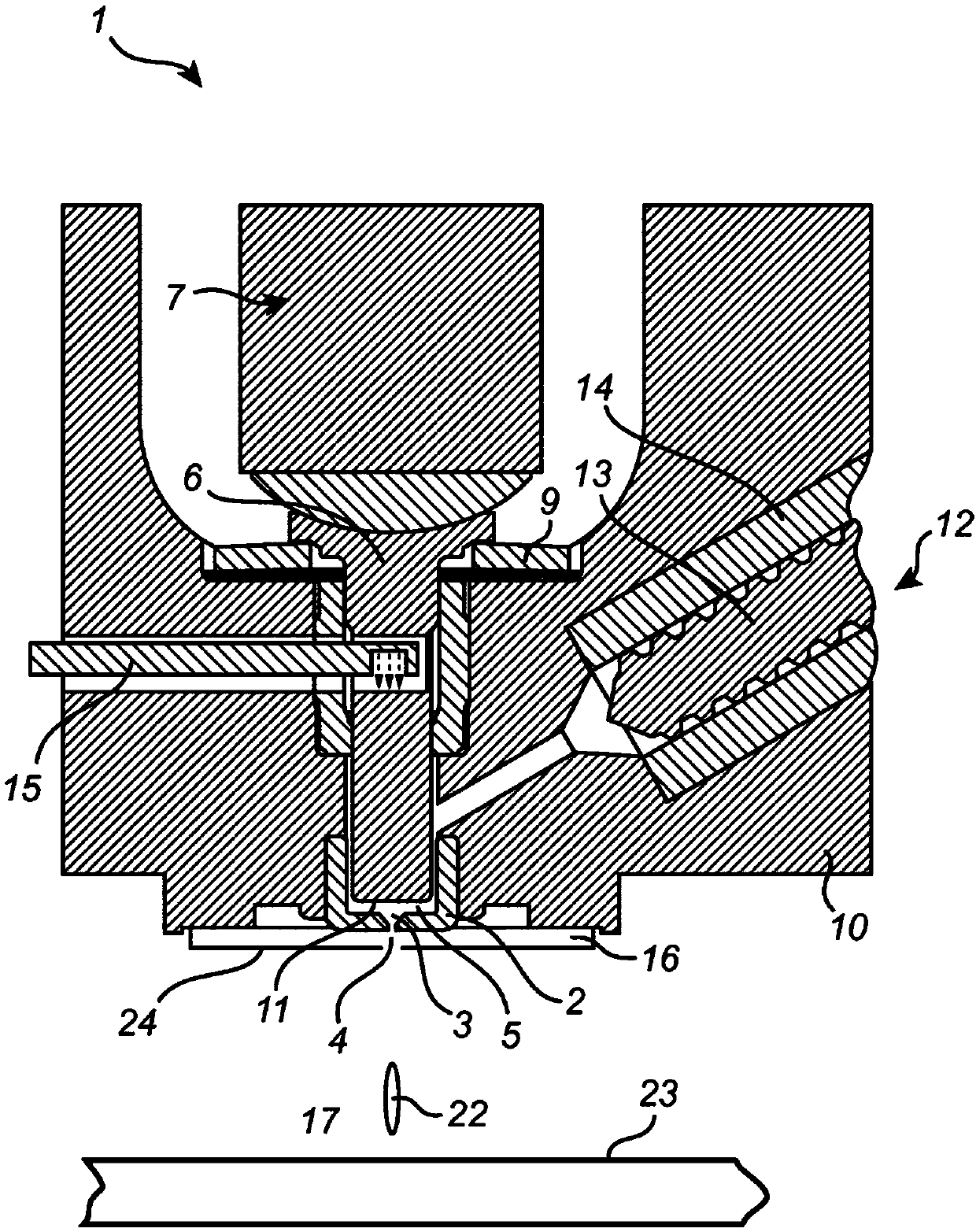

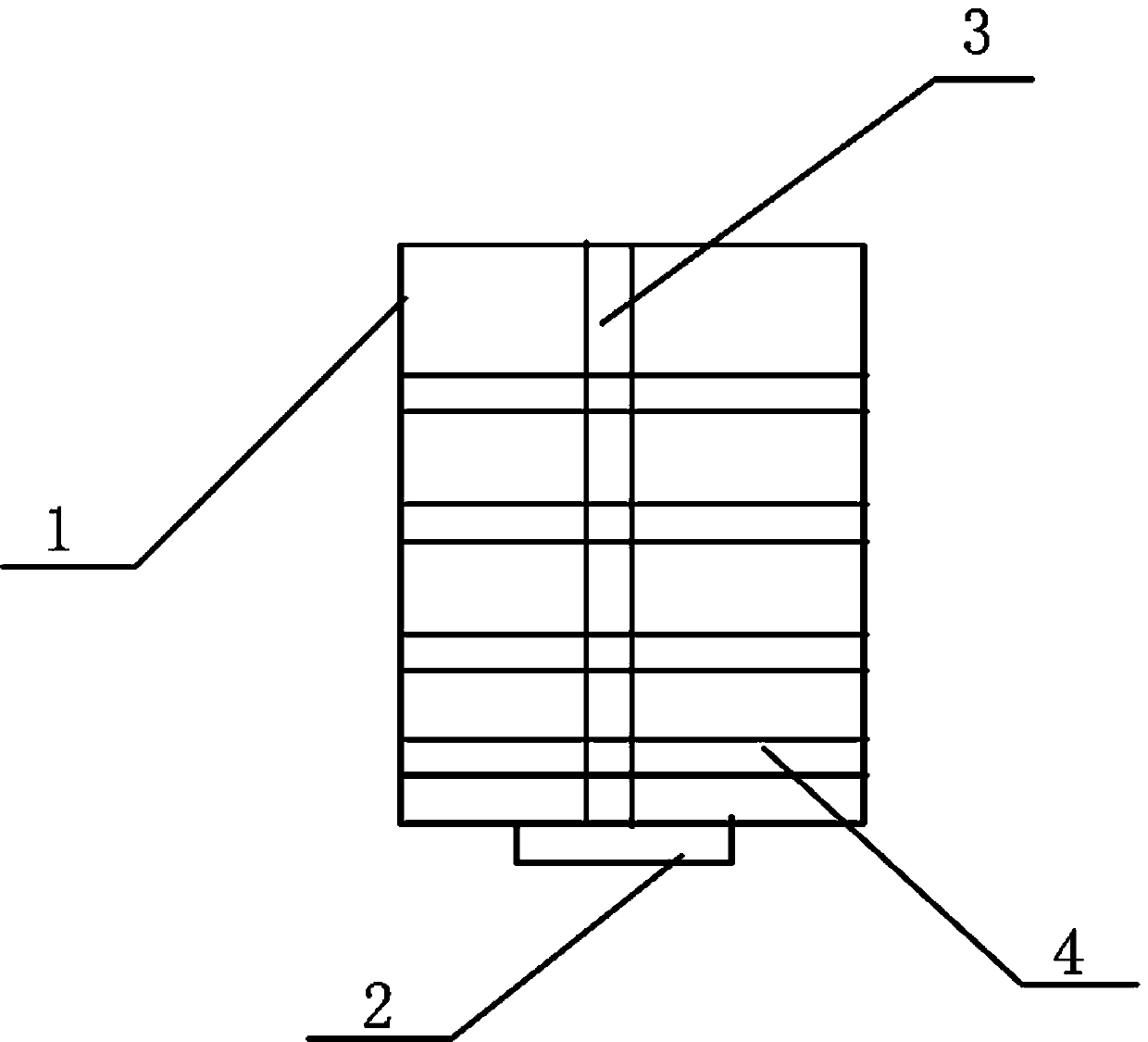

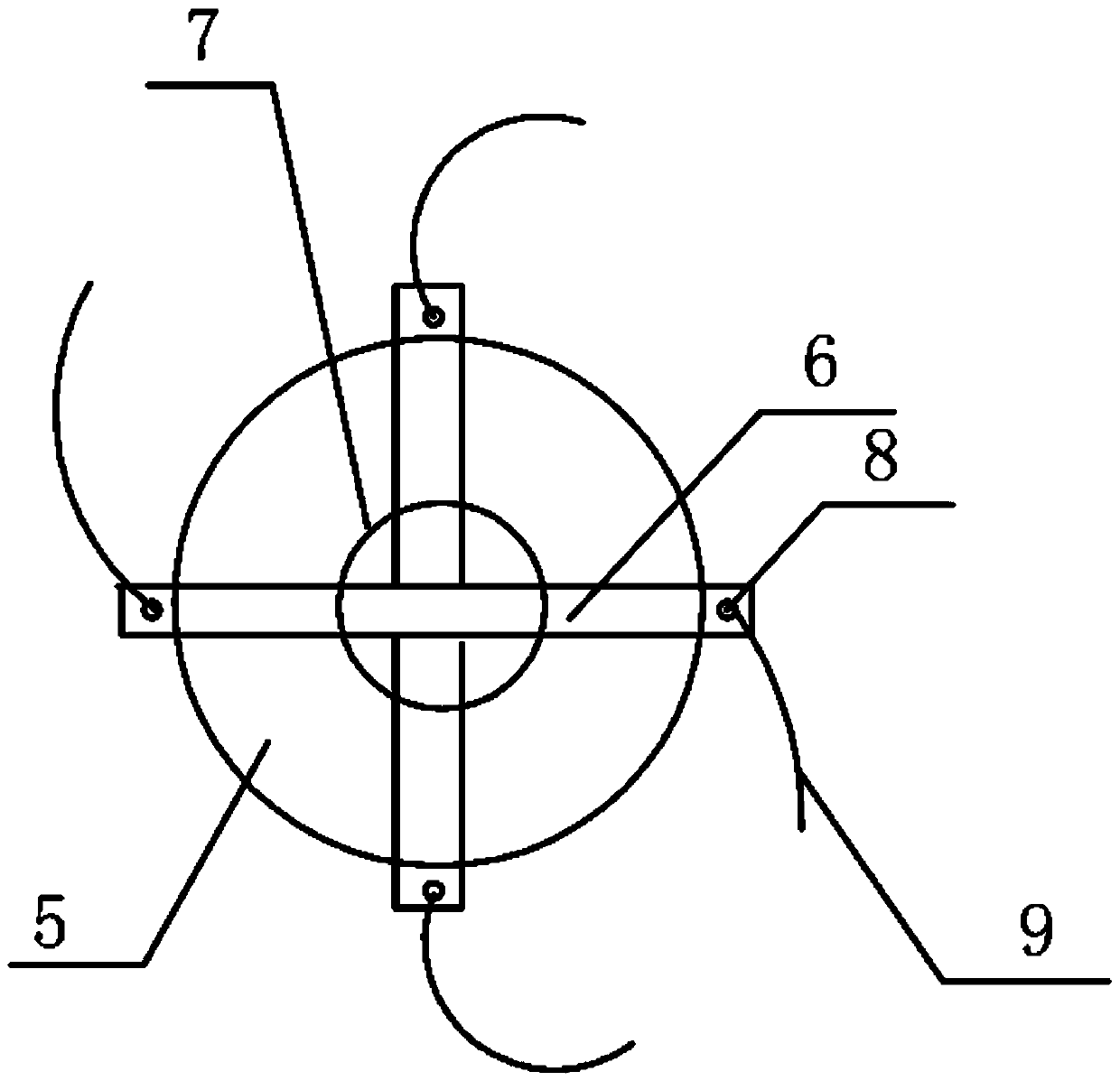

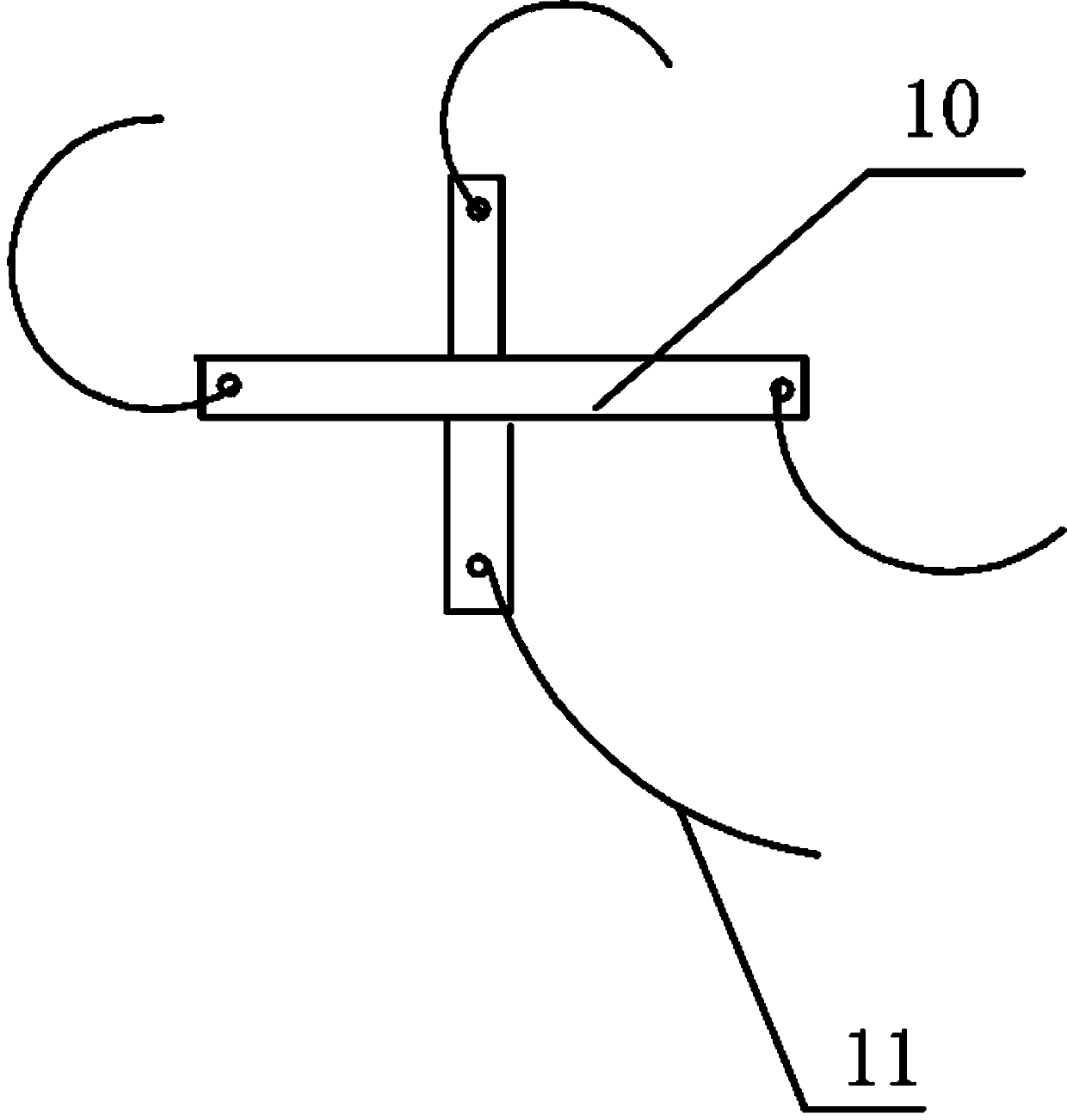

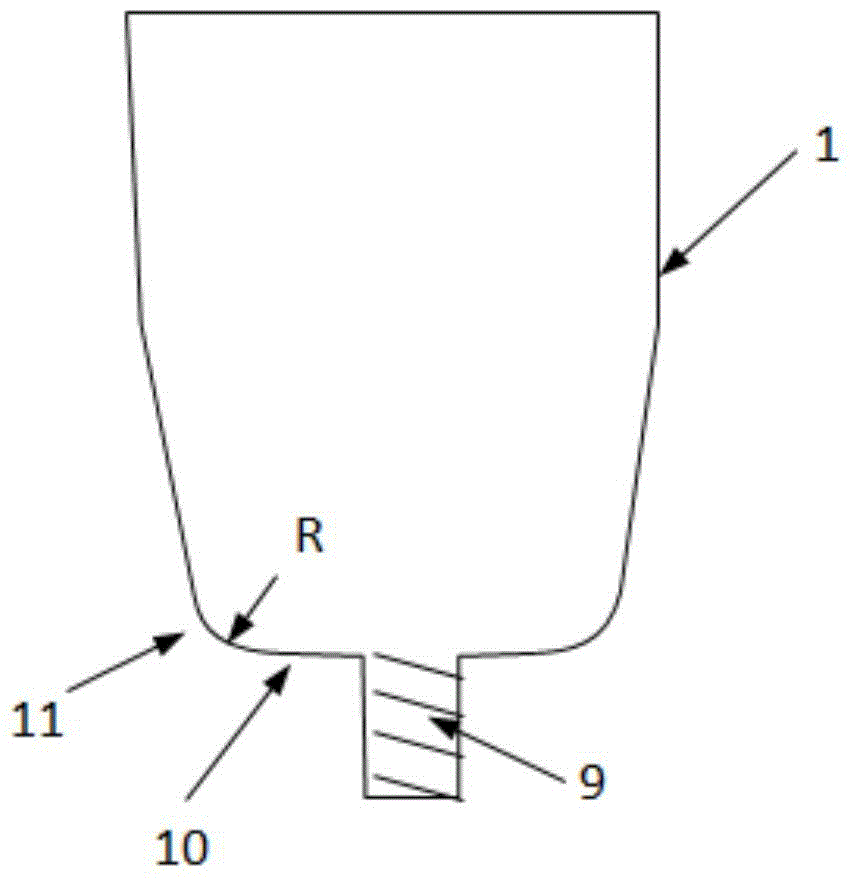

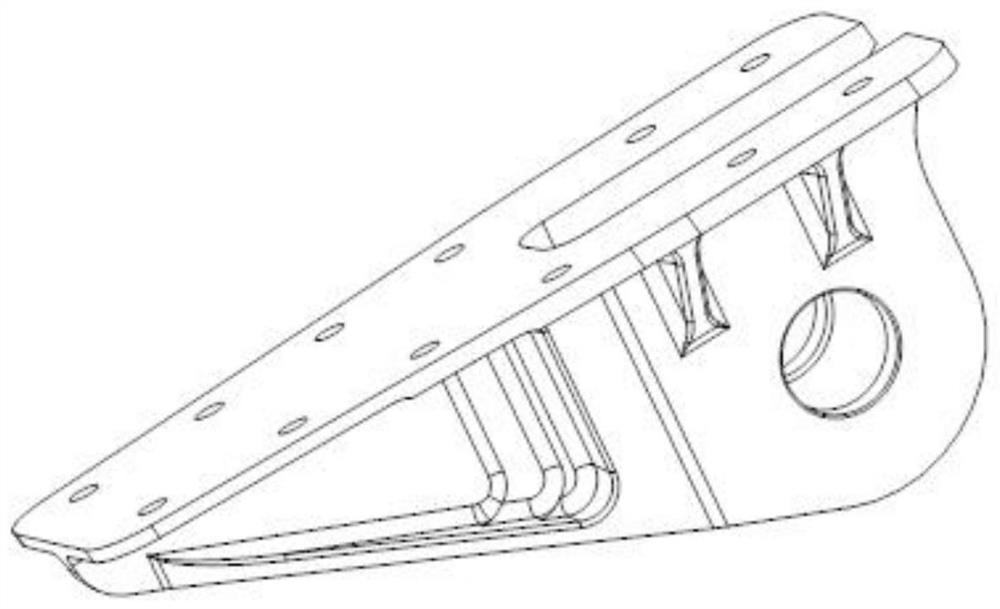

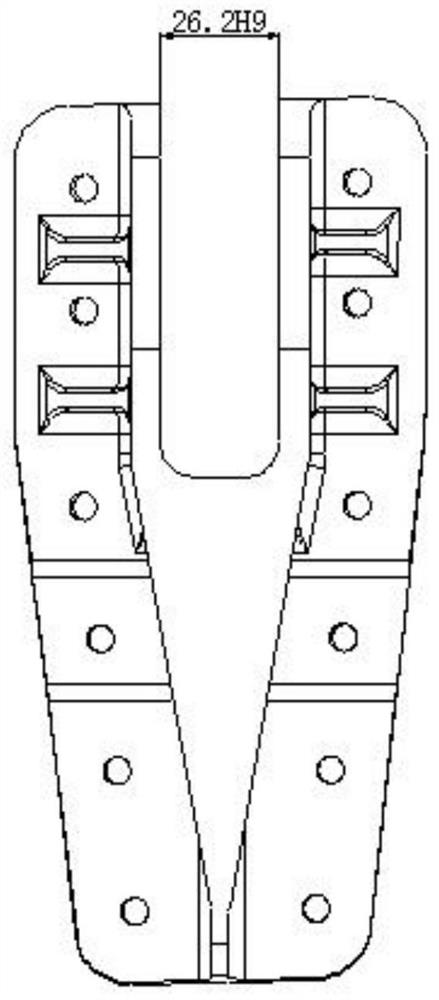

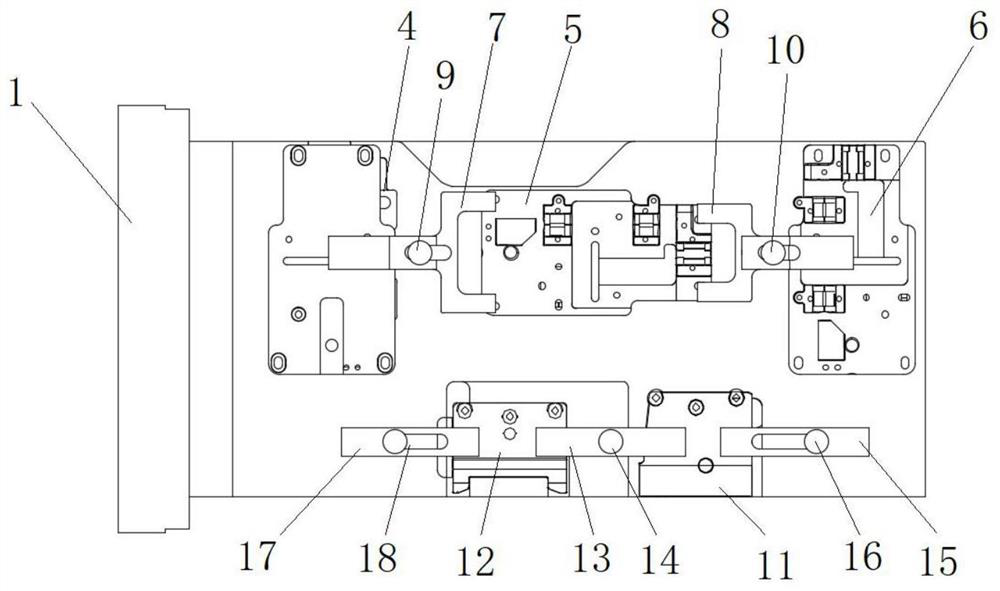

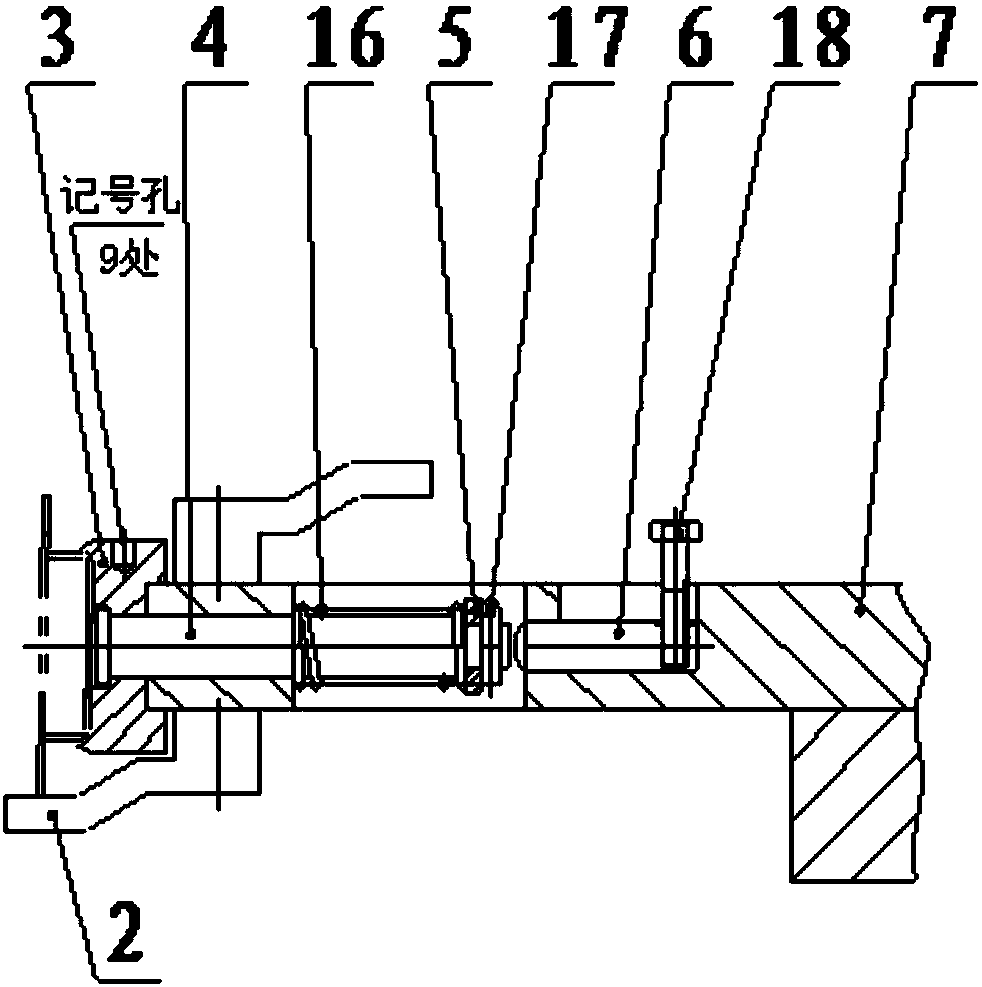

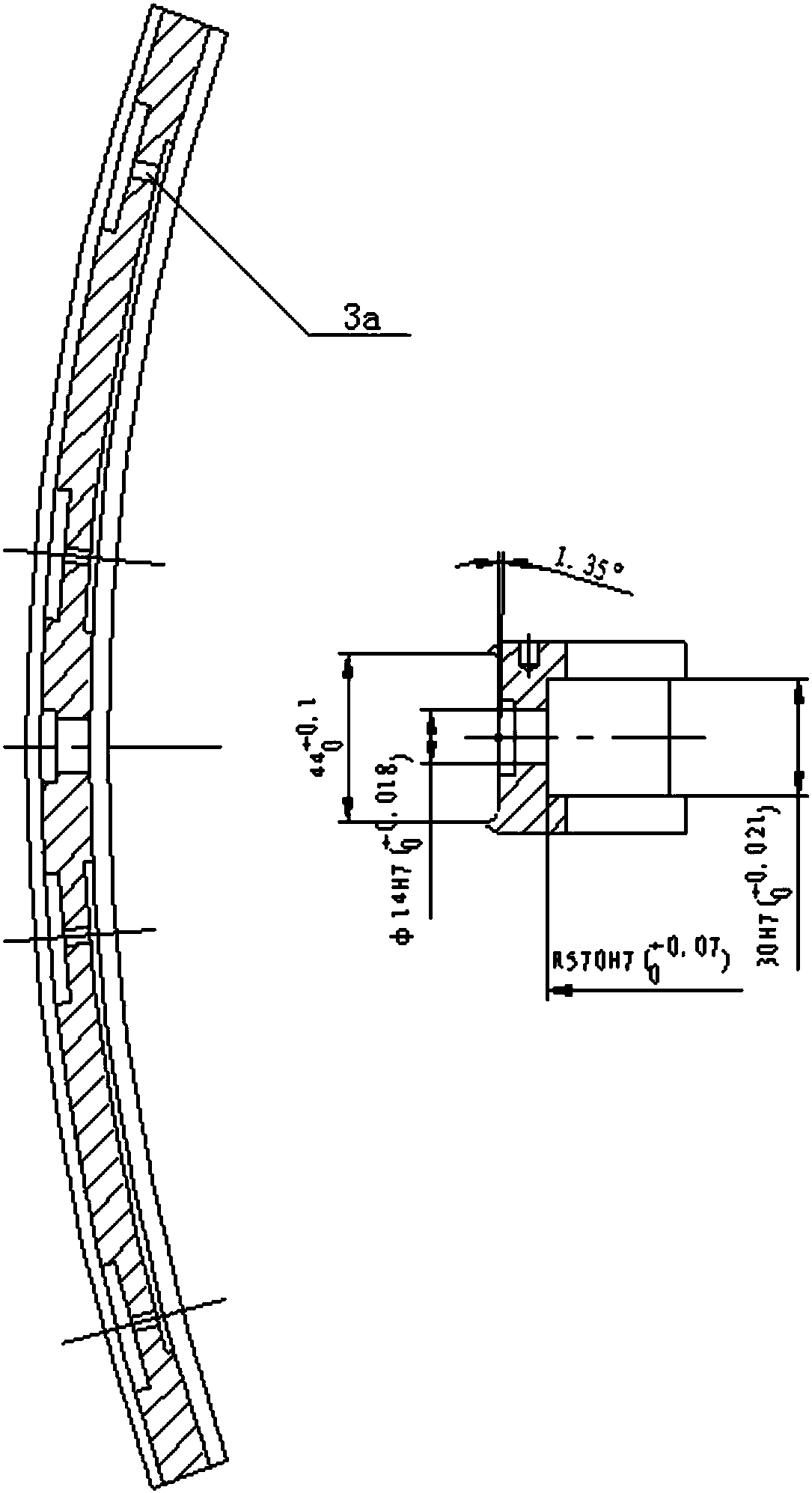

The invention discloses a bidirectional location thin-walled workpiece welding clamp. The bidirectional location thin-walled workpiece welding clamp comprises a body base, a clamping plate, overturnable locating blocks, small shafts, gaskets, push pins, expansion blocks, guide plates, stop pins, a conical body, a cover plate, a mandrel, a nut, a ventilation pipe, a locating plug, springs I, split pins, bolts I, springs II, screws I, screws II, bolts II and screws III. By means of the bidirectional location thin-walled workpiece welding clamp, location clearance can be effectively eliminated, welding deformation can be resisted, and a welding seam zone is prevented from metal oxidation; and due to the fact that a locating face can be overturned, a support ring can be welded to a tool, and the number of tools and tool replacement time are reduced. When the bidirectional location thin-walled workpiece welding clamp is used practically, the problems that welding deformation of the support ring is large, and dimensions and angles are out of tolerance are solved; tool cost is saved; labor intensity is lowered; the qualification rate of products is increased; and production efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method and apparatus for controlling jet dispensing by displacement measurement

PendingCN109644560ADetect and compensate for rheological differencesReduce the number of toolsLiquid surface applicatorsSpray nozzlesSpray nozzleEngineering

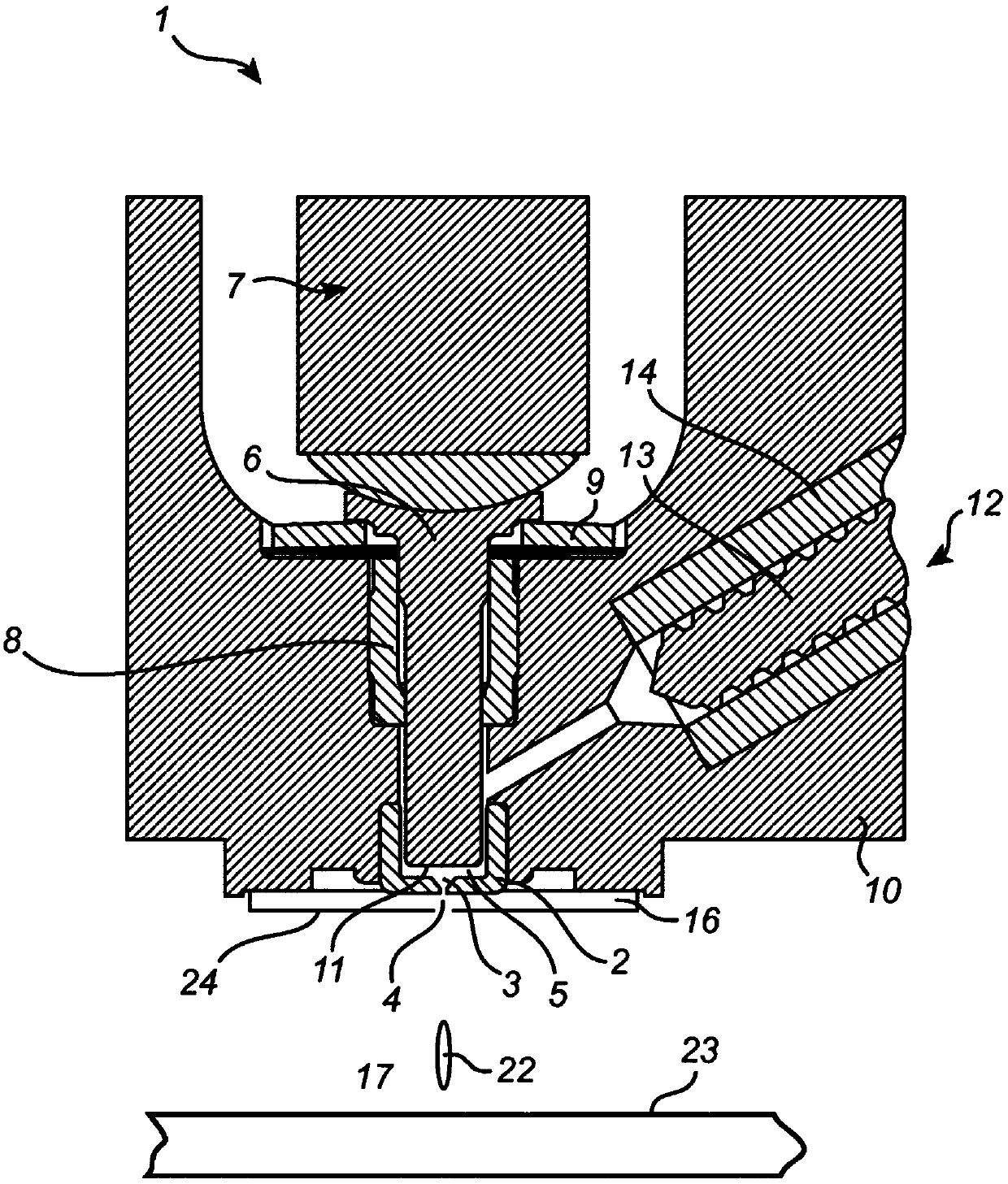

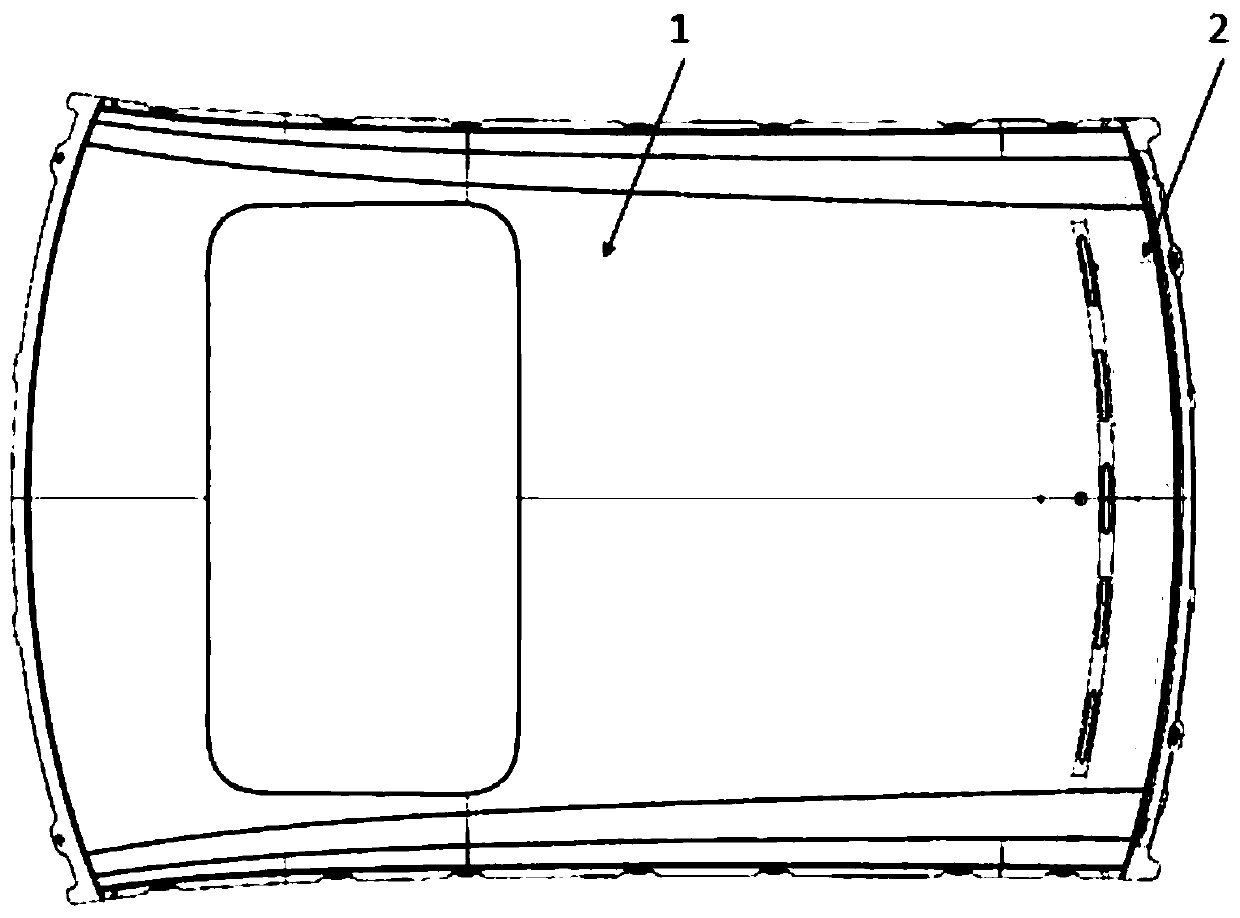

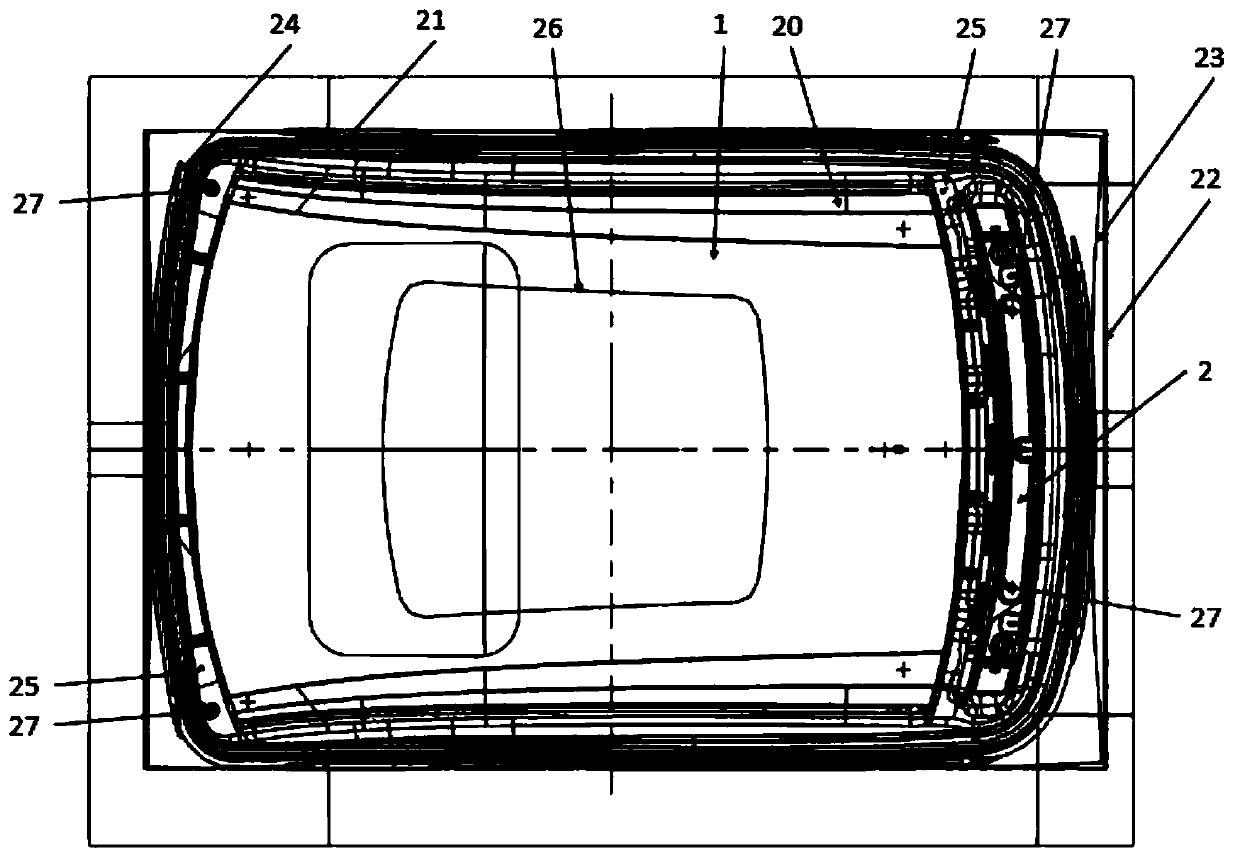

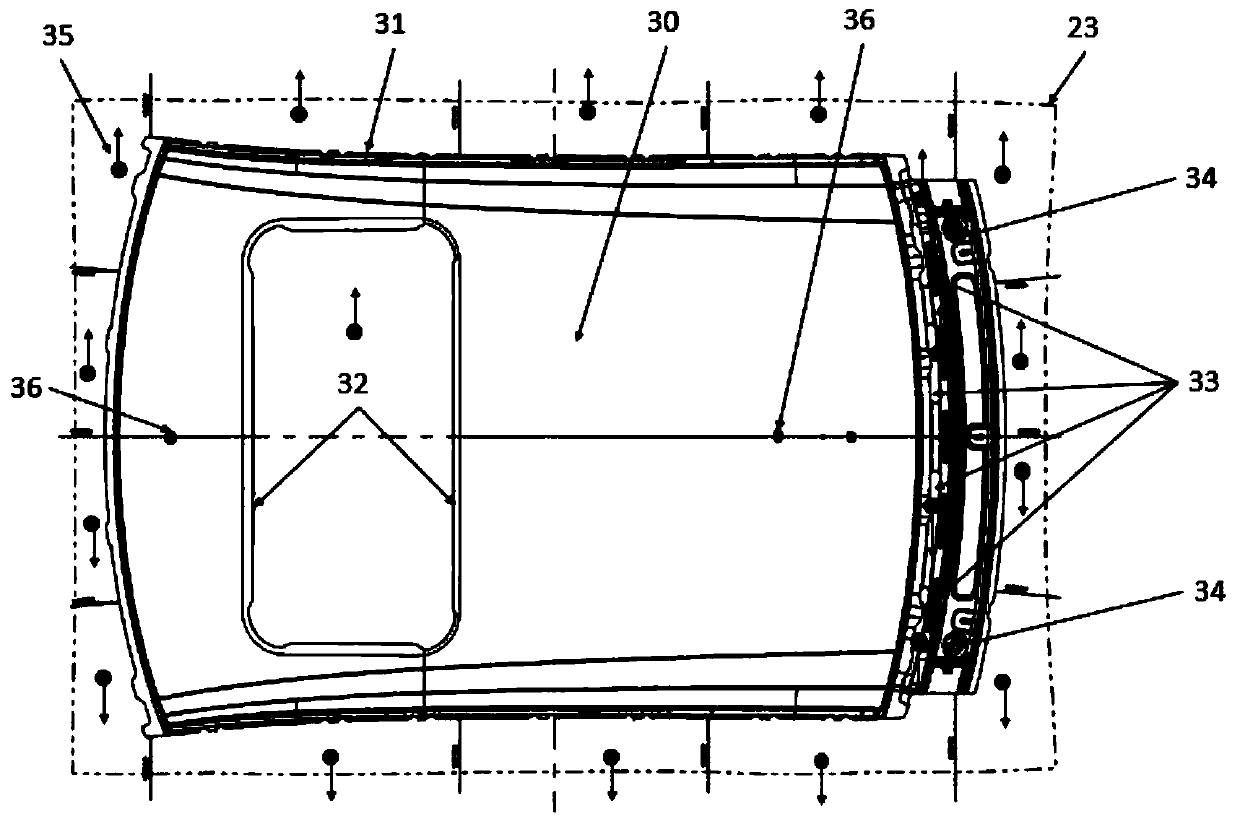

A method for jetting a viscous medium onto a substrate (23) is disclosed. The method comprises providing (110) viscous medium to a jetting chamber (5) of an ejector (1), operating (120) an impacting device (6, 7) to impact a volume of the viscous medium in the chamber such that viscous medium is jetted through a nozzle (4), connected to the chamber, towards the substrate, and monitoring (130) a displacement of the impacting device during the impact. An ejector and a system comprising such an ejector and a control unit (32) is also disclosed. The monitoring of the displacement allows for the operation of the impacting device to be controlled accordingly, thereby providing for an improved control of the jetting process.

Owner:MYCRONIC

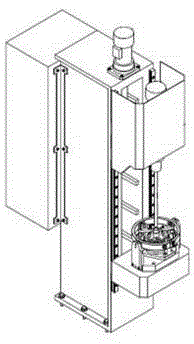

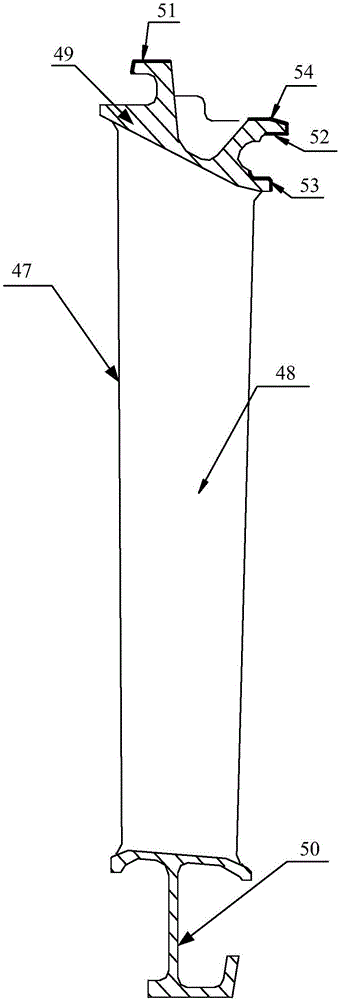

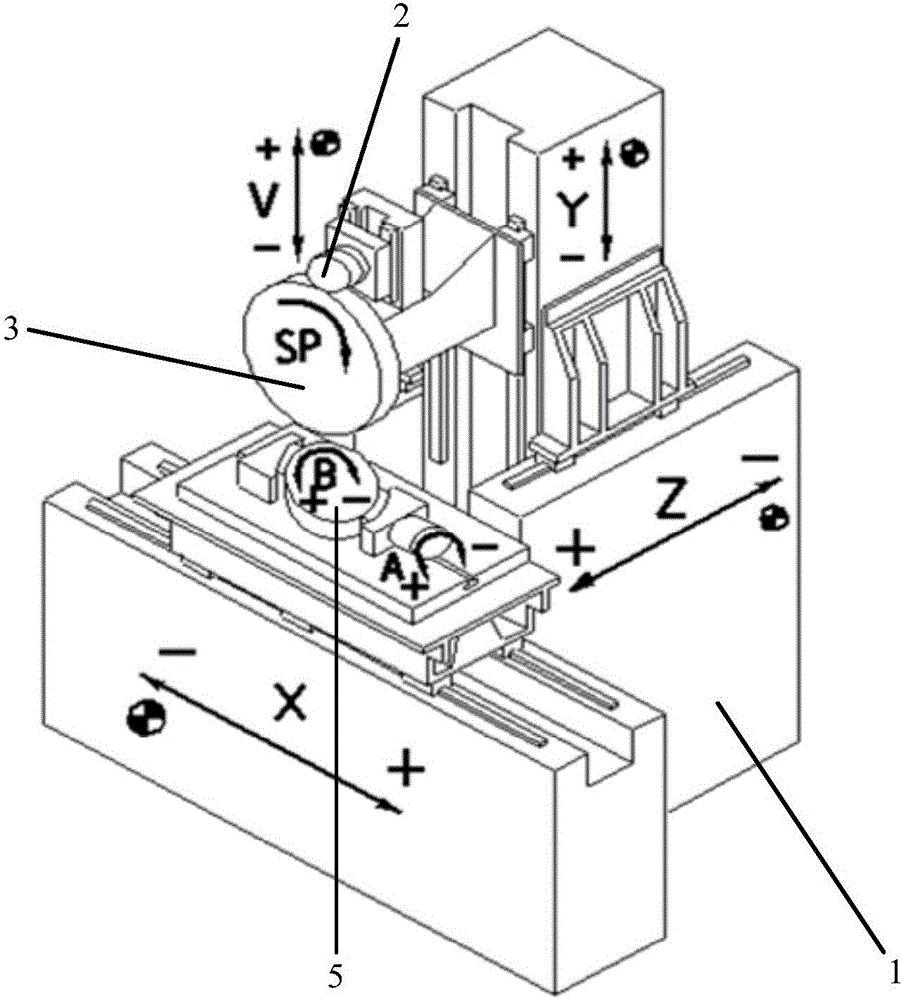

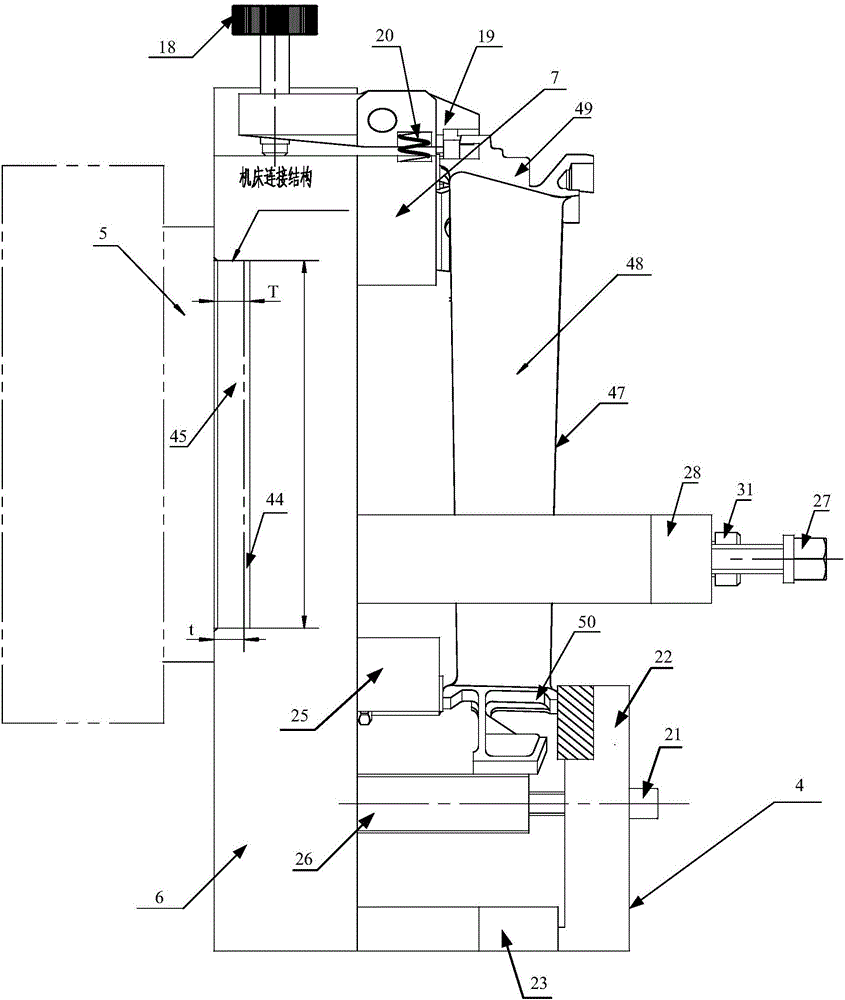

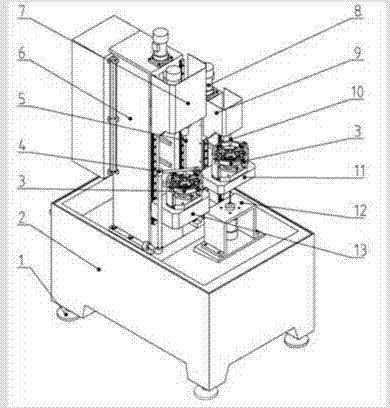

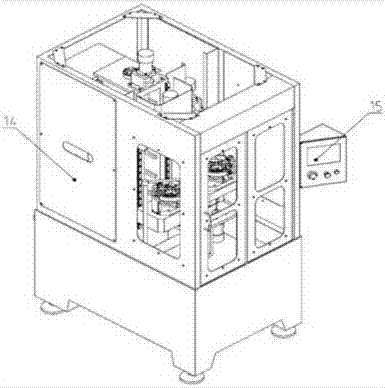

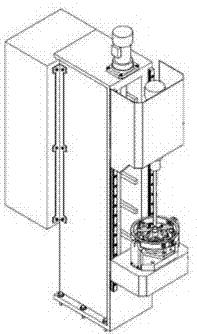

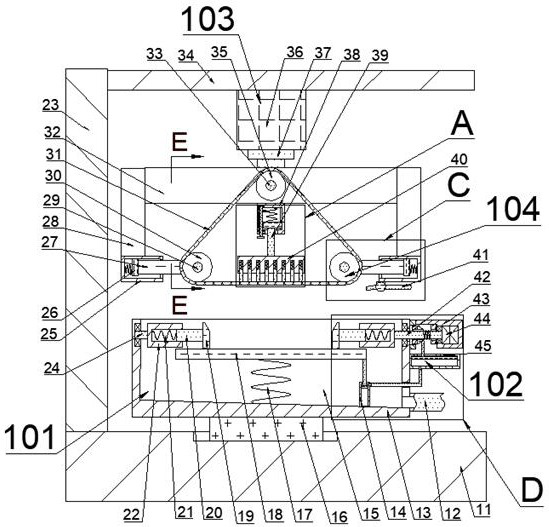

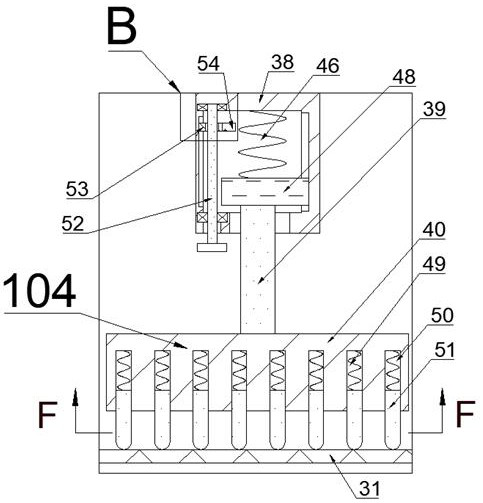

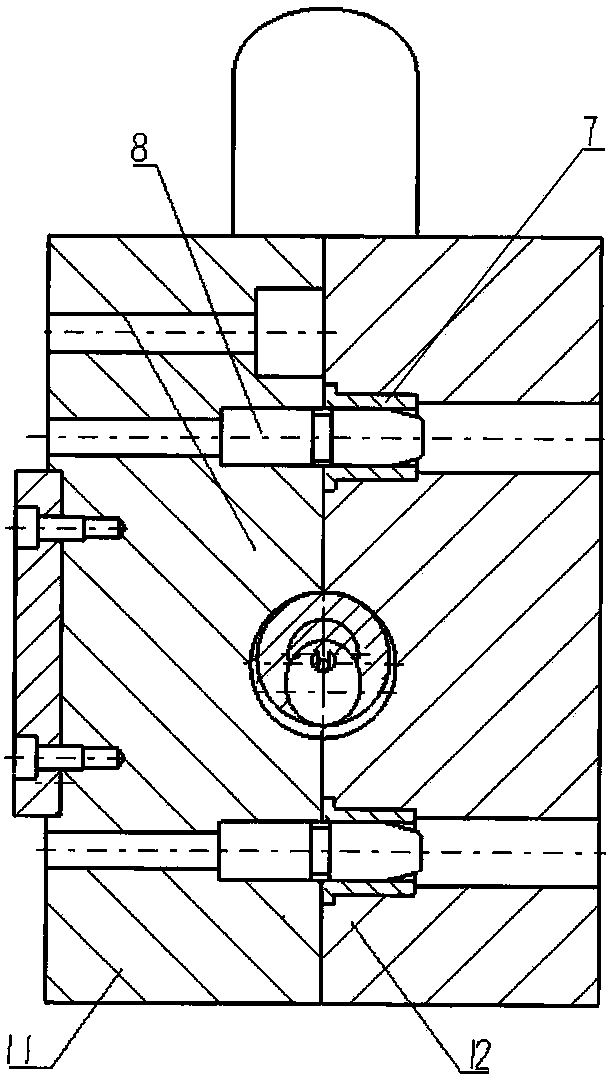

Numerically controlled vertical high-precision honing machine and honing method thereof

ActiveCN104385110AImplement Surface TexturesHigh geometric accuracyHoning machinesSurface roughnessMachine tool

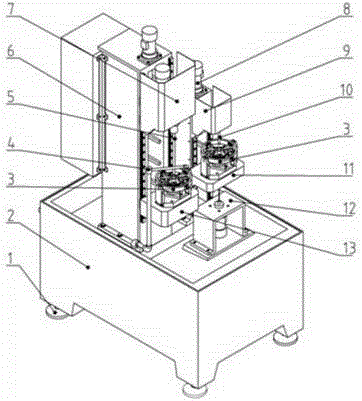

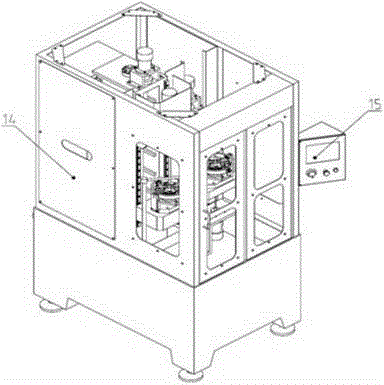

The invention relates to a numerically controlled vertical high-precision honing machine and a honing method thereof. The honing machine comprises a processing station upright post component, and a main shaft supporting plate screw rod and a processing station clamp supporting plate screw rod which are parallel are vertically arranged in the processing station upright post component; a main shaft supporting plate and a processing station clamp supporting plate are arranged outside the processing station upright post component; the main shaft supporting plate is connected with a screw rod nut on the main shaft supporting plate screw rod through a main shaft supporting plate connecting plate; the processing station clamp supporting plate is connected with a screw rod nut on the processing station clamp supporting plate screw rod through a processing station clamp supporting plate connecting plate; the contact surfaces of the supporting plates and an upright post are glidingly fixed by a guide rail and a guide block respectively; the lower end surface of a machine tool main shaft component is connected to a honing tool; full-floating honing tools are fixed to the upper surface of the processing station clamp supporting plate to be opposite to the honing tool, and the screw rods are controlled and connected by a stroke motor. When the honing machine and the honing method provided by the invention are used for precisely honing the inner surface of a hole-like part, the size precision, the surface roughness and the geometrical shape precision of a hole can be greatly improved.

Owner:上海善能机械有限公司

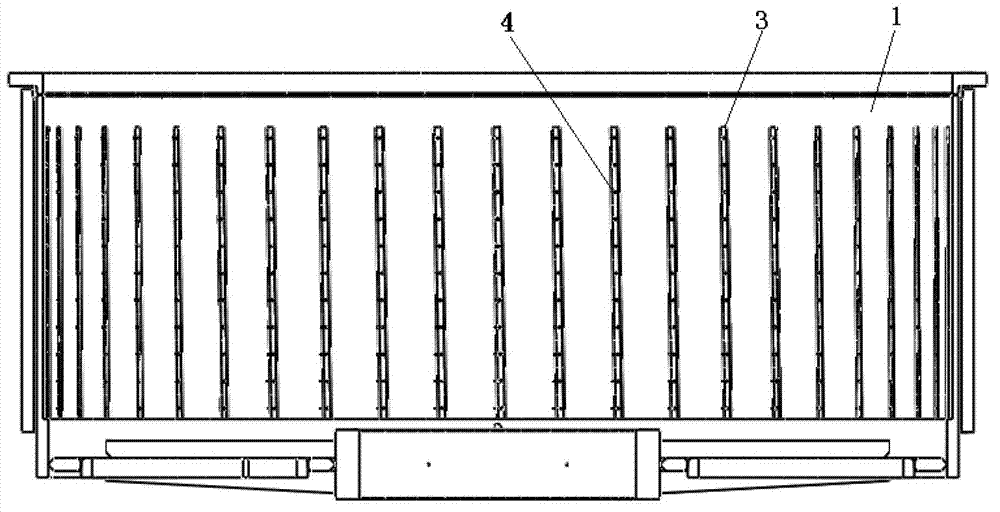

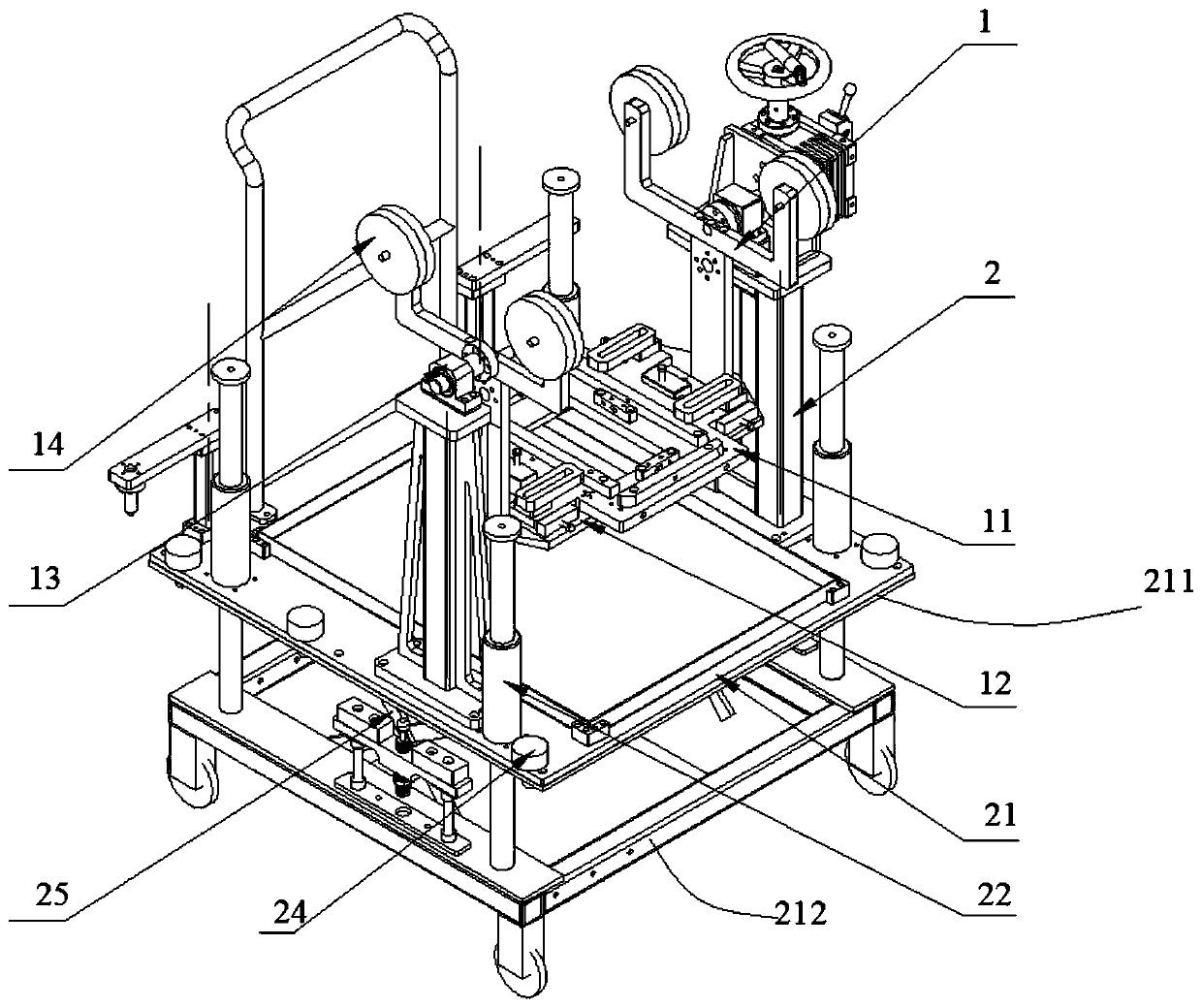

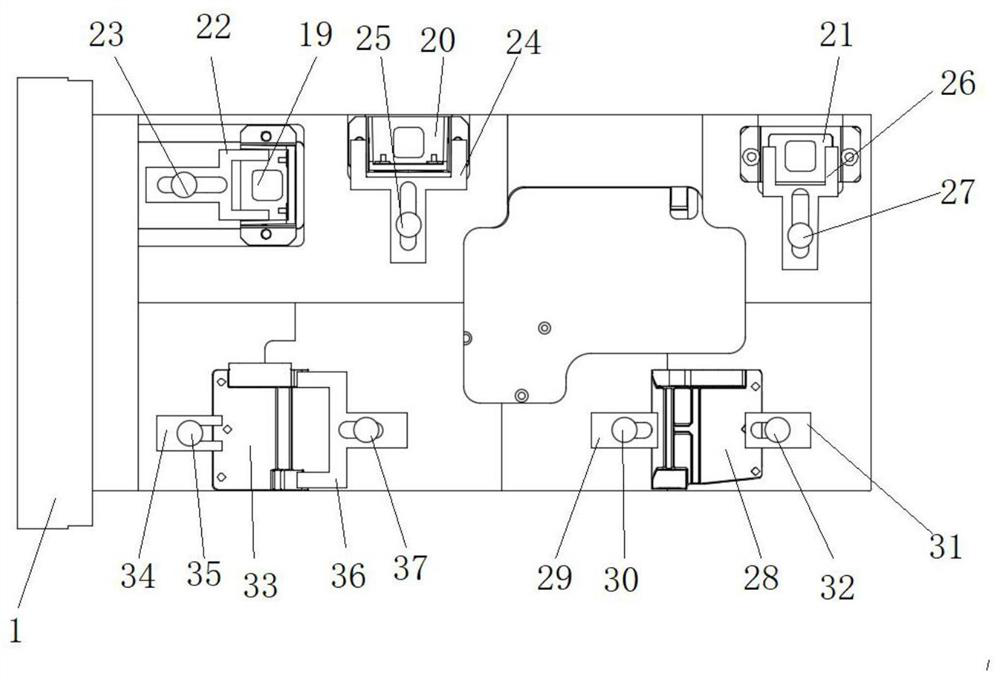

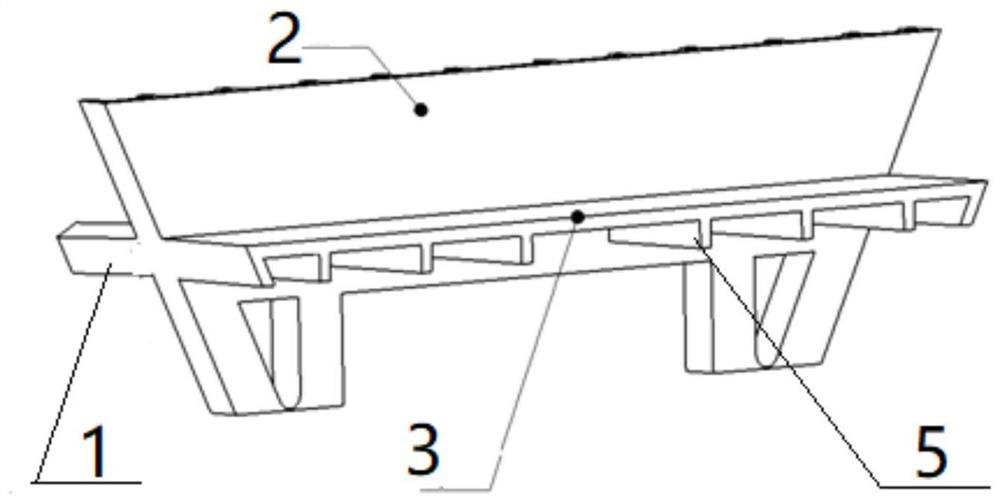

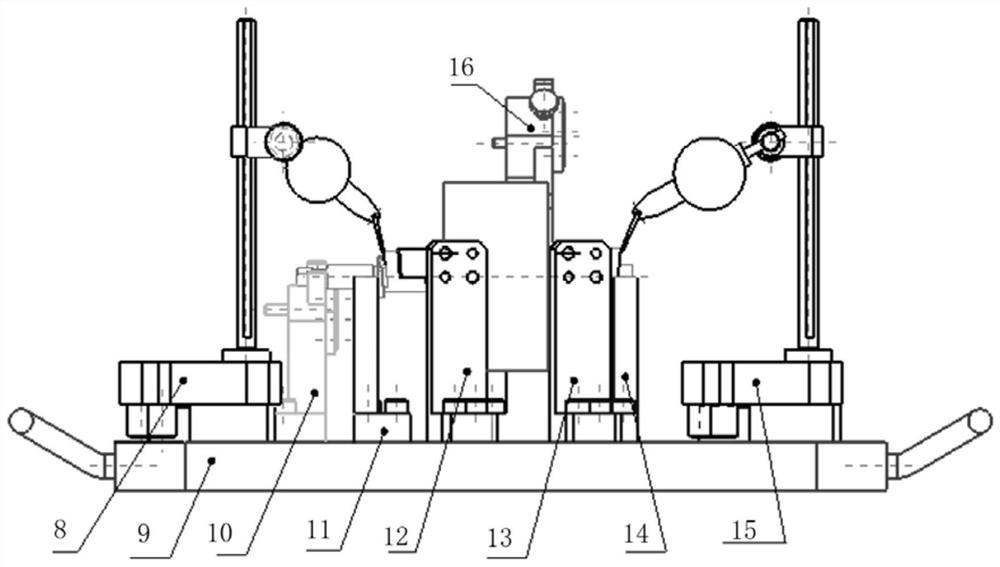

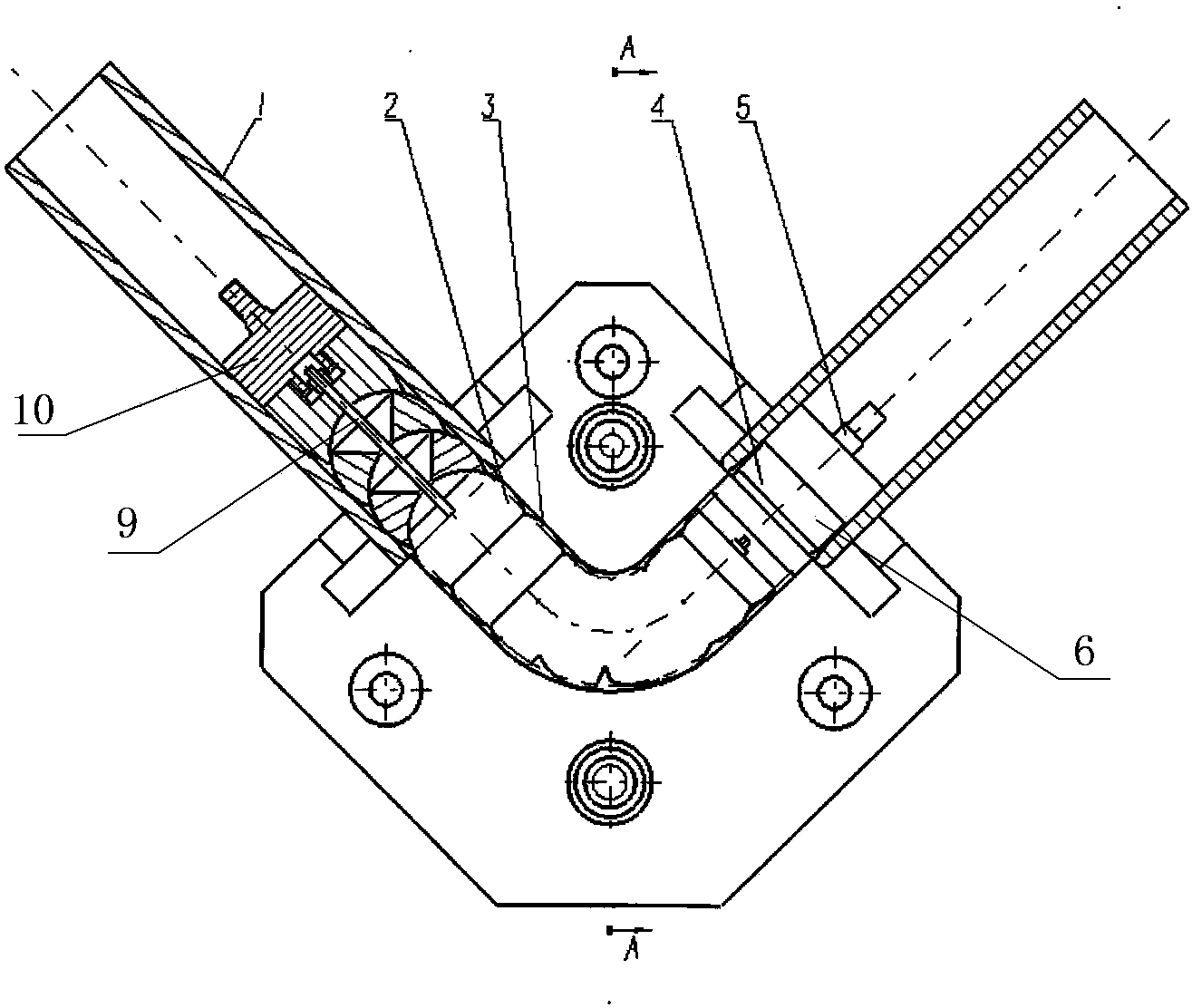

Multi-station continuous grinding device and method for guide vane

ActiveCN106695499AReduce the number of toolingSave time during process changeoverGrinding machinesGas turbinesConvex structure

The invention discloses a multi-station continuous grinding device and method for a guide vane and belongs to the technical field of gas turbine vane machining. The multi-station continuous grinding device for the guide vane comprises a four-shaft linkage slow feeding grinding machine, a rolling wheel, a grinding wheel and a clamp; the rolling wheel is installed on a rolling wheel shaft of the four-shaft linkage slow feeding grinding machine; the grinding wheel is installed on a grinding wheel shaft of the four-shaft linkage slow feeding grinding machine; the clamp is installed on a rotating table of the four-shaft linkage slow feeding grinding machine; the side face of the rolling wheel comprises four grinding areas; the structure of the four grinding areas is the same as the structure of four machining areas of an installing plate of the guide vane; a structure ground by the side face of the rolling wheel and opposite to the concave and convex structure of the side face of the rolling wheel is formed on the side face of the grinding wheel; and the clamp comprises a bottom plate which is provided with an upper installing plate positioning and clamping mechanism, a lower installing plate positioning and clamping mechanism, a vane body tight pressing mechanism, a radial positioning and clamping mechanism and a pot back positioning and clamping mechanism. By means of the device and method, four to-be-machined stations of the guide vane can be subjected to continuous grinding.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

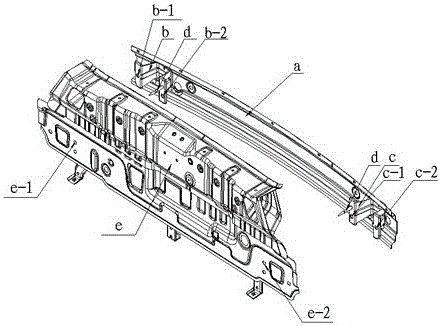

Automobile top cover and top cover rear cross beam nesting drawing forming method and die

ActiveCN110976691ASimple structureEasy to operateShaping toolsPerforating toolsStructural engineeringStamping process

The invention discloses an automobile top cover and a top cover rear cross beam nesting drawing forming method and die. According to the method, the top cover and a top cover rear cross beam forming cavity are nested in a drawing molding die, so that the top cover and the top cover rear cross beam are simultaneously formed in one stamping process. According to the method, the top cover and the topcover rear cross beam can be nested together to be produced, die toolings can be saved, and stamping production batches are reduced.

Owner:DONGFENG MOTOR CORP HUBEI

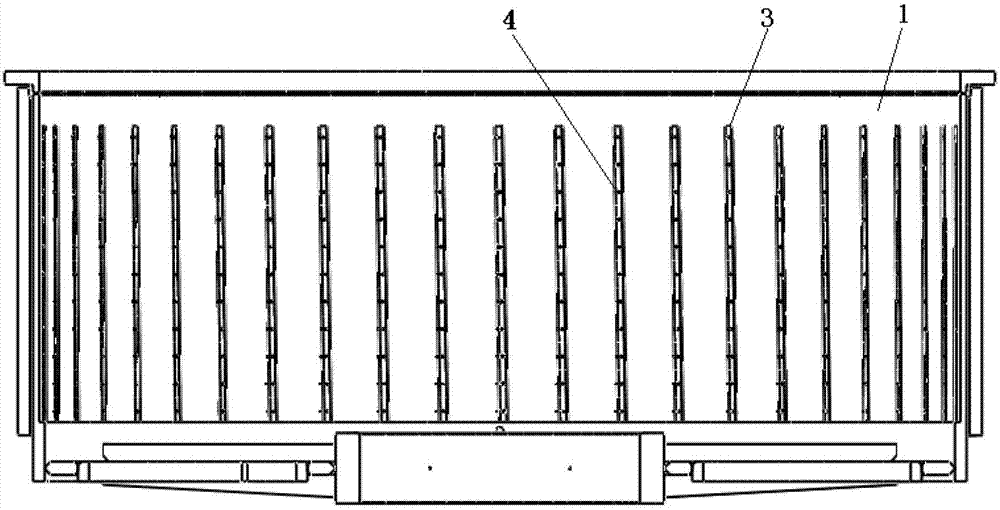

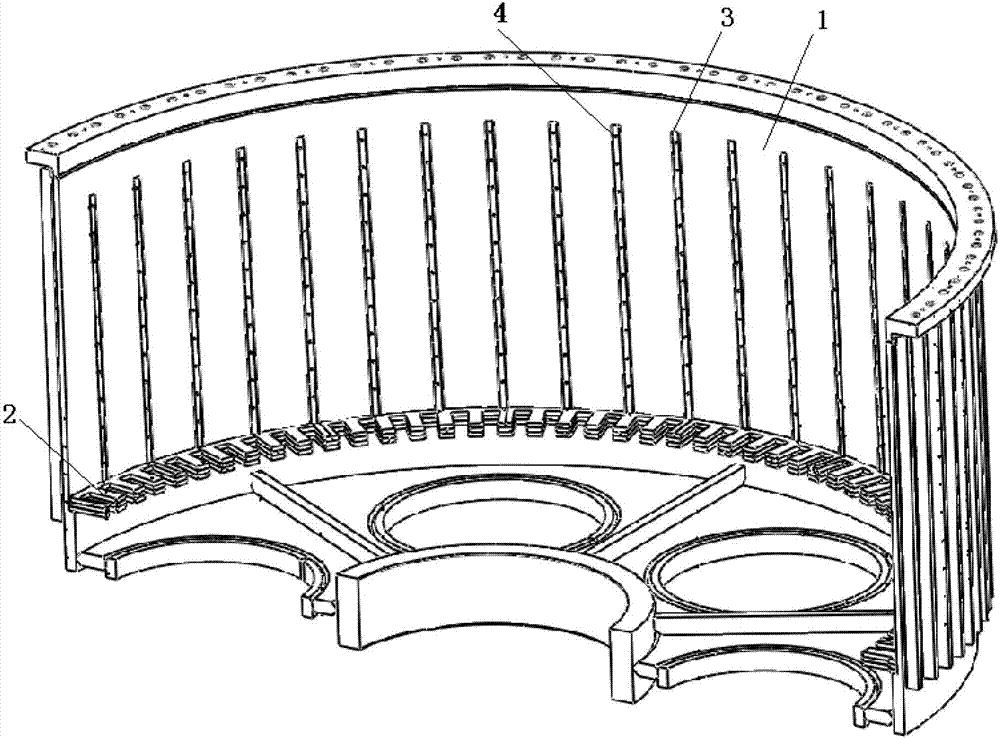

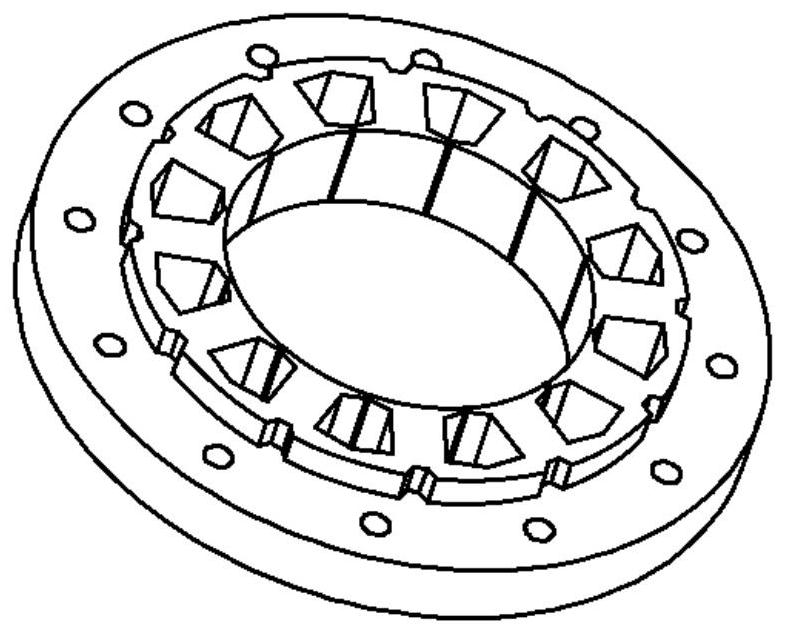

Permanent magnet generator with stator inclined grooves and inclined groove realization method of permanent magnet generator

ActiveCN103051077ASmall torqueHarmonic reductionMagnetic circuit stationary partsManufacturing stator/rotor bodiesPunchingPermanent magnet synchronous generator

The invention discloses a permanent magnet generator with stator inclined grooves and an inclined groove realization method of the permanent magnet generator. The permanent magnet generator comprises a generator stator, wherein the stator comprises a stator casing and a stator iron core punching sheet and also comprises a plurality of convex strips, the convex strips are arranged on the inner wall of the stator casing according to a certain inclination, clamp grooves used for being clamped with the convex strips are arranged at the back side of the yoke part of the stator iron core punching sheet, the stator iron core punching sheets are overlapped onto the convex strips in a laminated way through the clamp grooves, and in addition, the clamp grooves have the same inclination as the inclination of the stator inclined grooves and the installation inclination of the convex strips after the lamination. The stator inclined grooves of the permanent magnet generator can be realized, the tooth groove torque is effectively reduced, meanwhile, the harmonic waves are reduced, in addition, few toolings are required by the stator inclined groove realization method, the cost is low, and the process is simple.

Owner:GUODIAN UNITED POWER TECH

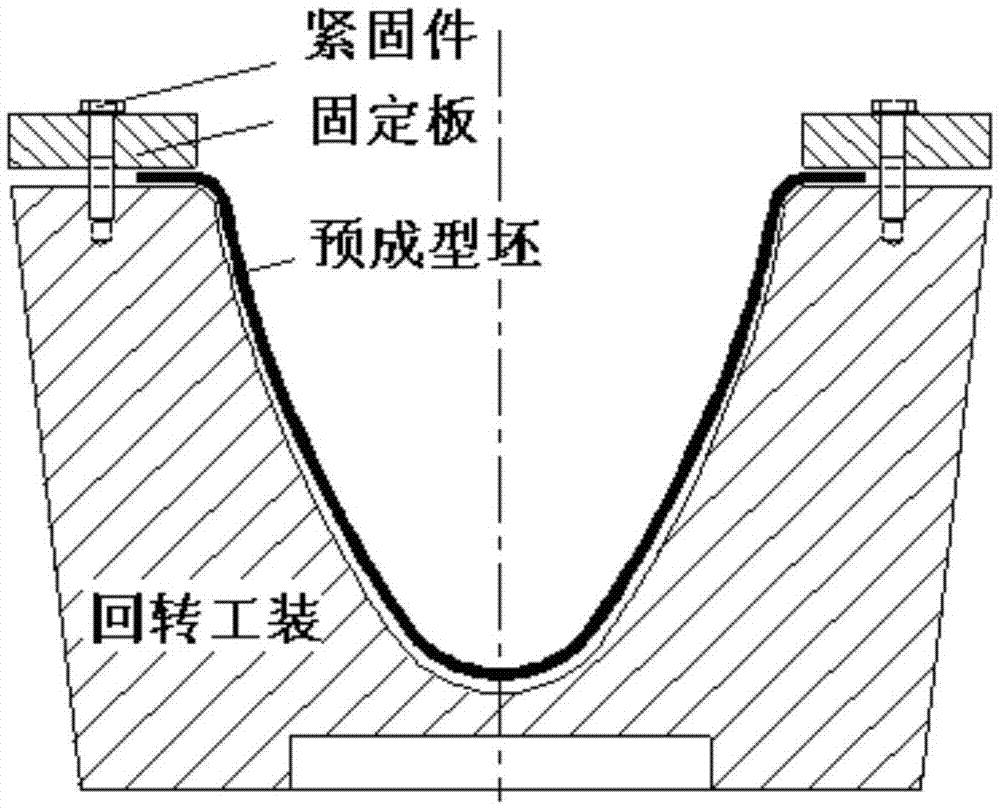

Rolling and machining composite processing device and method for rotating deep-cavity curved surface member

InactiveCN106903512AAchieve sharingReduce the number of toolsOther manufacturing equipments/toolsMechanical engineeringEngineering

The invention discloses a rolling and machining composite processing device and method for a rotating deep-cavity curved surface member. The rolling and machining composite processing device for the rotating deep-cavity curved surface member comprises a rotary tooling, a feeding platform, a rolling module and a machining module, wherein during processing, a preformed blank is fixed to the rotary tooling; the feeding platform has a freedom degree in the horizontal direction relative to the rotary tooling; the rolling module and the machining module are fixed to the feeding platform; and the rolling module and the machining module separately have a freedom degree rotating around a vertical shaft. Through the adoption of the scheme of the rolling and machining composite processing device provided by the invention, the finished product rate and the processing efficiency can be improved, and besides, the cost is reduced.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

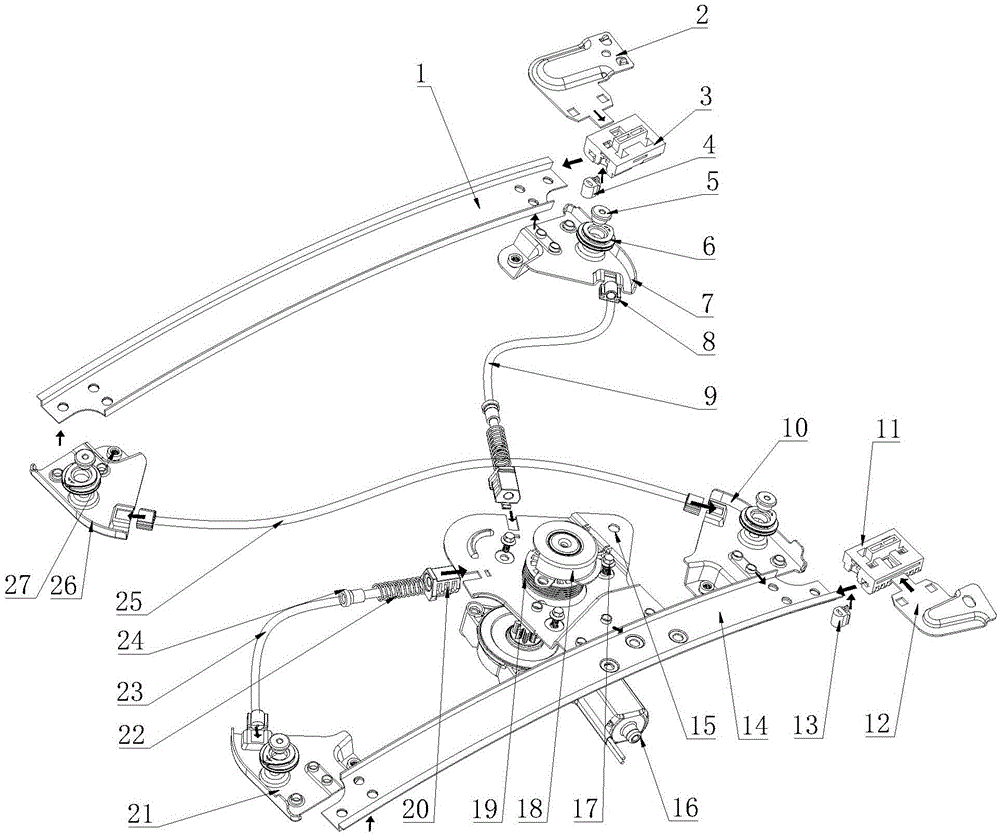

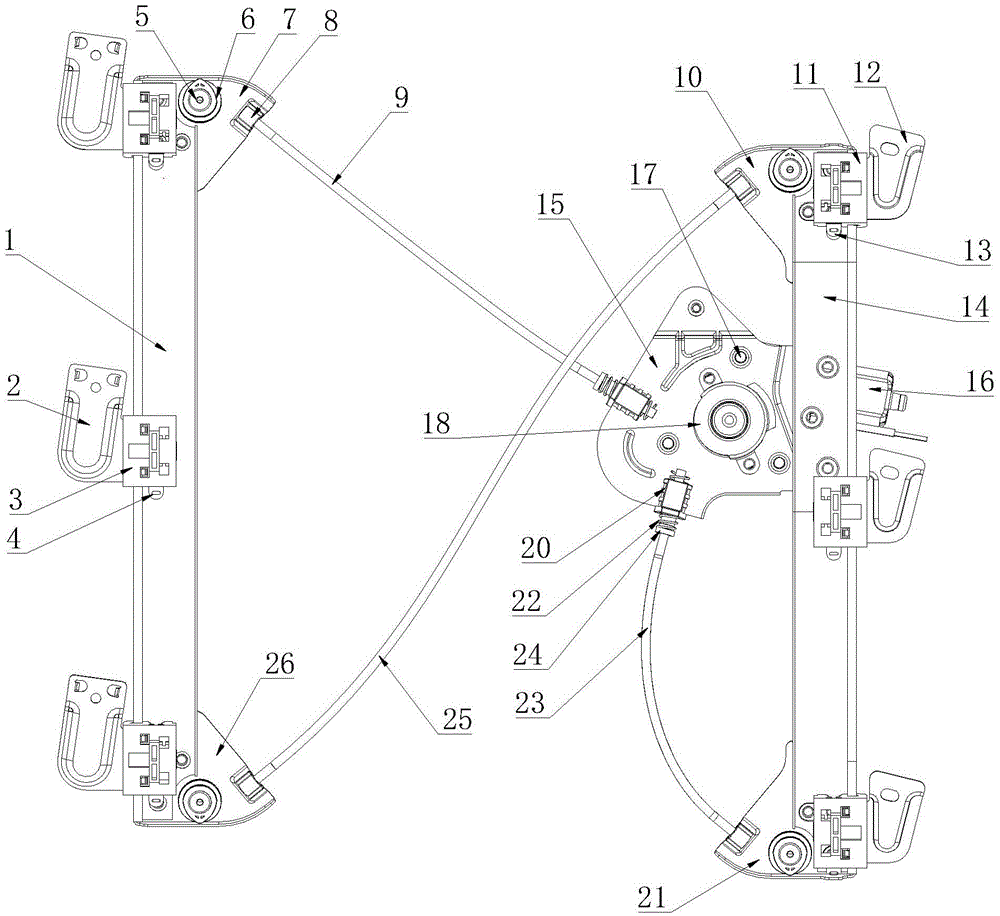

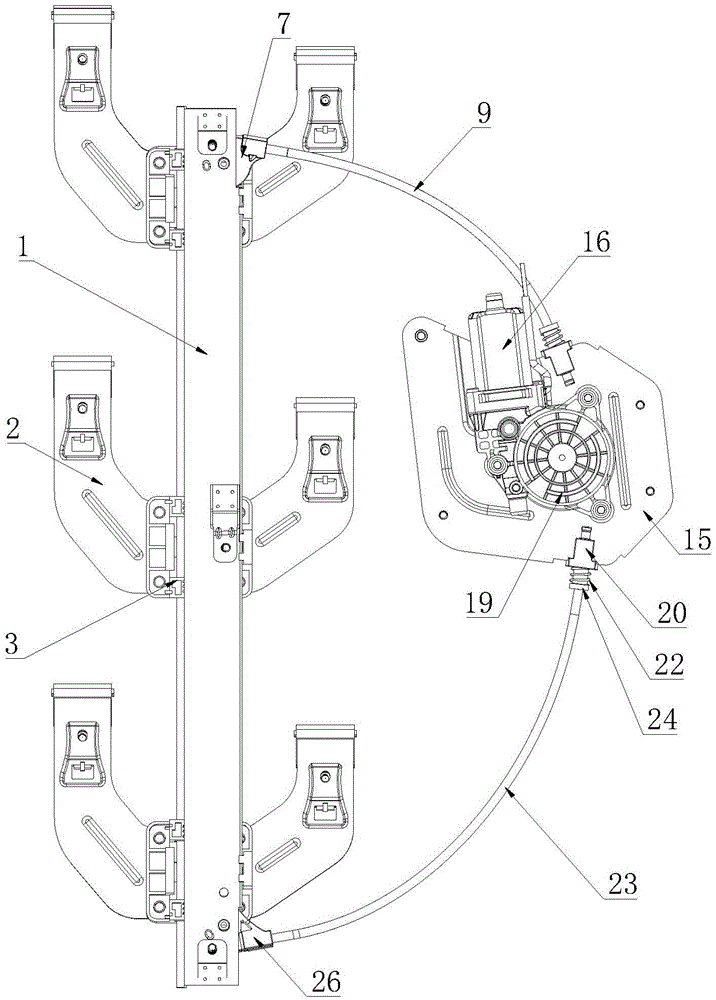

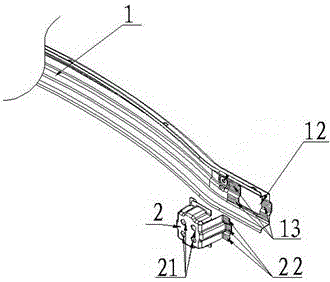

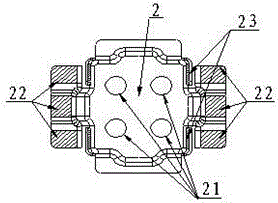

Rope wheel type glass lifter with modularized structural design and design method for rope wheel type glass lifter

InactiveCN105525825AReduce manufacturing costReduce management costsPower-operated mechanismMathematical modelElectric machinery

The invention discloses a rope wheel type glass lifter with a modularized structural design and a design method for the rope wheel type glass lifter. Four rolling guide rails with different sections and four standard slide blocks matched with the rolling guide rails are designed; various angle-adjustable slide wheel assemblies suitable for application of the rolling guide rails are designed; three thread rolling barrels which can meet various stroke needs and corresponding thread rolling barrel housings are designed; six motors are determined; other universal parts and standard parts are designed, and the parts are stored into a module base for use after being modeled; during design, according to vehicle type needs, proper rolling guide rails, slide blocks, slide wheel assemblies, motors and other standard universal parts are selected from the module base, so that only slide block bottom plates, guide rail upper brackets, guide rail lower brackets and motor fixing bases are required to be designed, and each part is combined and assembled into a product assembly mathematical model. According to the invention, the modularized design scheme is adopted, so that the problem that the rope wheel type glass lifter product is relatively long in development period is completely solved.

Owner:WONH IND

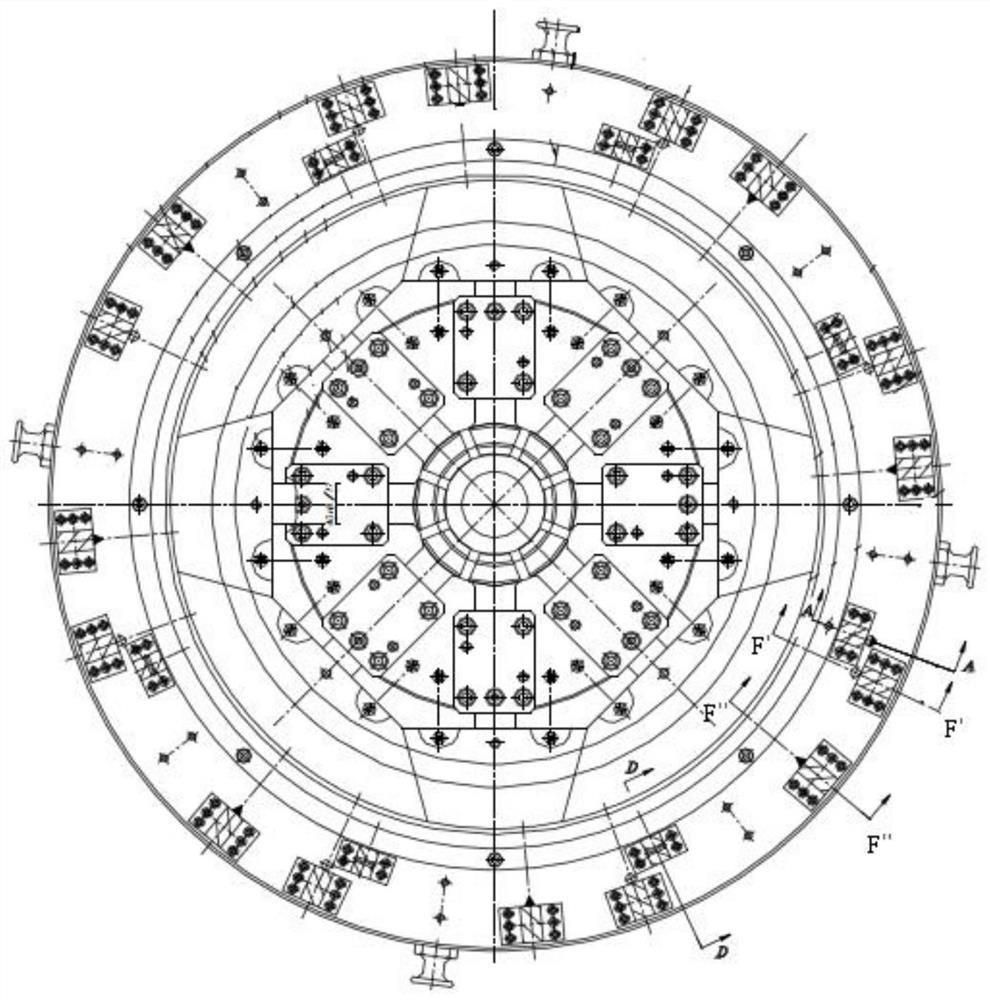

Mounting and adjusting device for pouring of solid propellant combustion chamber

ActiveCN107687377AGuaranteed stabilityAccurate entryRocket engine plantsLoad-engaging elementsCombustion chamberEngineering

The invention discloses a mounting and adjusting device for pouring of a solid propellant combustion chamber. The mounting and adjusting device comprises a pouring cylinder which is cylindrical and isprovided with the hollow interior, and the bottom of the pouring cylinder is provided with a hydraulic lifting platform. A plurality of guiding grooves are uniformly distributed in the side wall of the pouring cylinder in the axial direction, a plurality of annular grooves are distributed in the side wall of the pouring cylinder in the radical direction, and the guiding grooves and the annular grooves are vertically formed in the inner side of the side wall in a staggered mode. The mounting and adjusting device further comprises a bearing disc, the bottom of the bearing disc is connected witha bearing beam, and the center of the bearing beam is provided with a bearing. The mounting and adjusting device is reasonable in structure, reliable in work and easy to operate, various potential safety hazards are completely eliminated, the number of tools is decreased, and the production cost and management cost of enterprises are greatly reduced.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

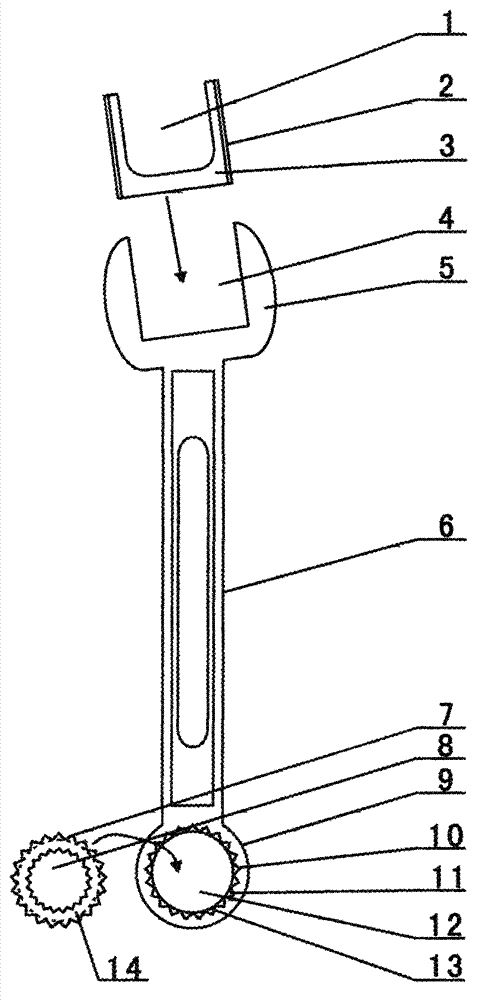

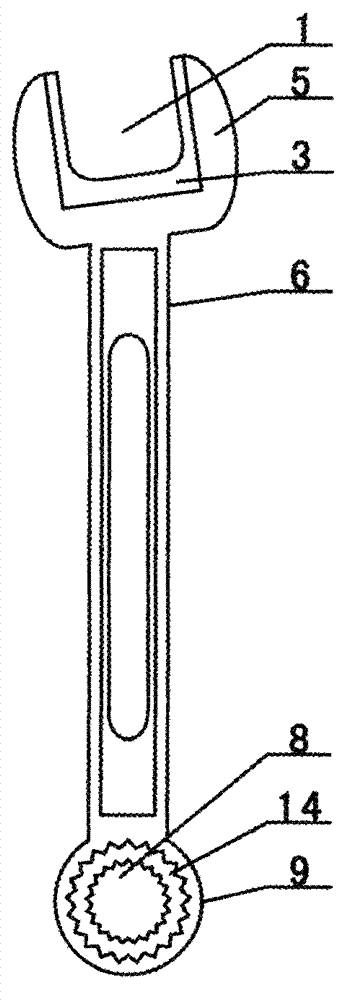

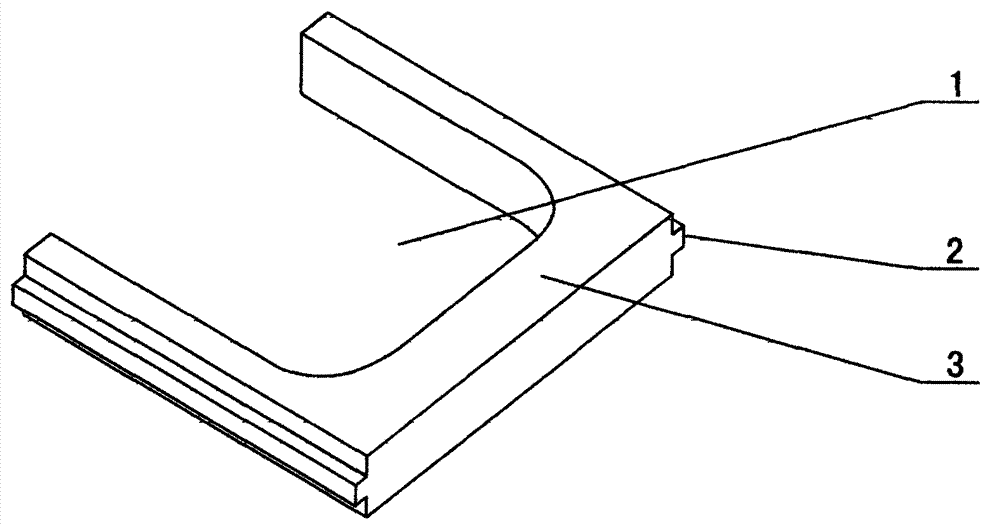

Anti-explosion combination wrench with replaceable bayonets

The invention discloses an anti-explosion combination wrench with replaceable bayonets and relates to an anti-explosion wrench. An opening end (5) and a plum blossom end (9) are respectively arranged at two ends of a handle (6). The opening end (5) is provided with a jack (4). Raised lines (2) arranged on outer walls of two sides of a U-shaped connector clip (3) are connected with grooves (15) of the jack (4) in an inserting mode. A plurality of bayonets (1) of the U-shaped connector clip (3) are respectively in various sizes. The plum blossom end (9) is provided with a placing inlet (12). The periphery surface of an insertion cover piece (14) is connected with the placing inlet (12) in an inserting mode. A plurality of plum-blossom-shaped covering ports (8) of the insertion cover piece (14) are respectively in various sizes. Aluminium bronze or beryllium bronze is adopted as manufacture material quality. By the adoption of the plurality of the bayonets, in various sizes, of the U-shaped connector clip and the plurality of cover ports, in various sizes, of the insertion cover piece, the fact that the tool quantity is effectively reduced in operation is achieved.

Owner:STATE GRID CORP OF CHINA +1

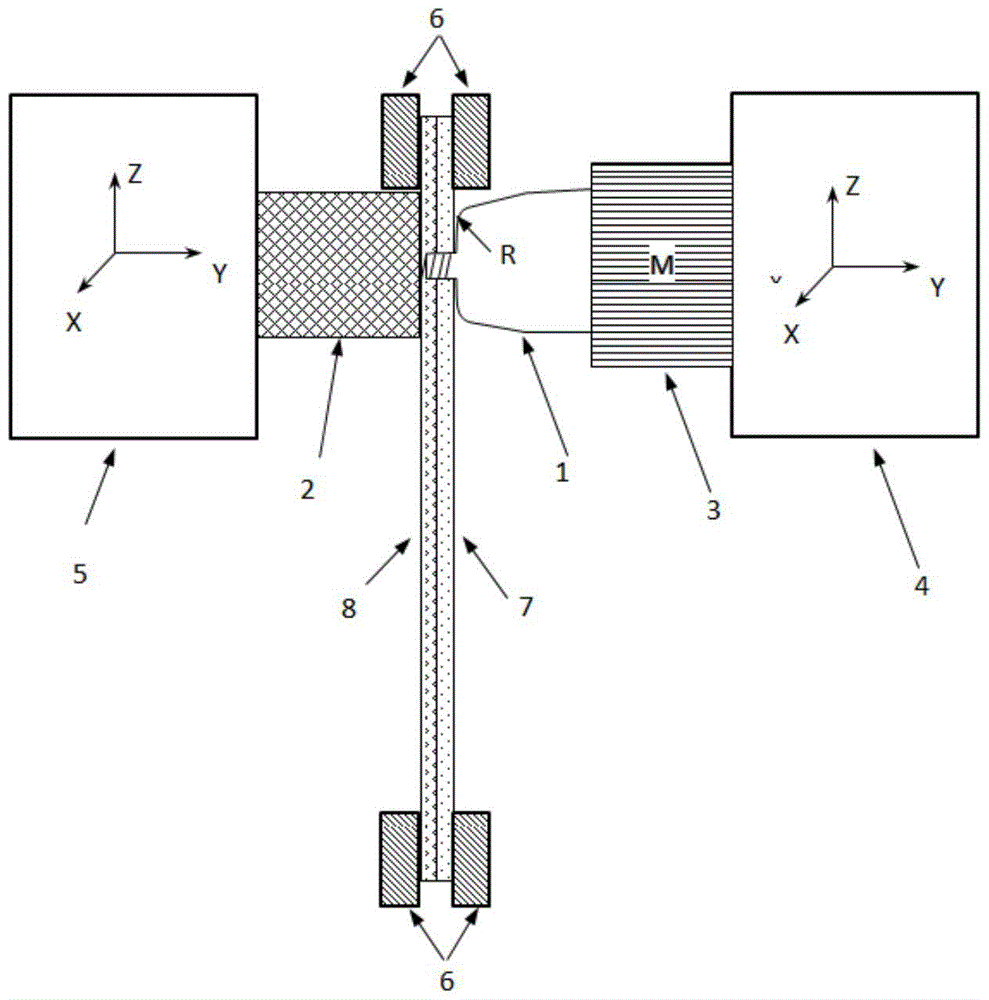

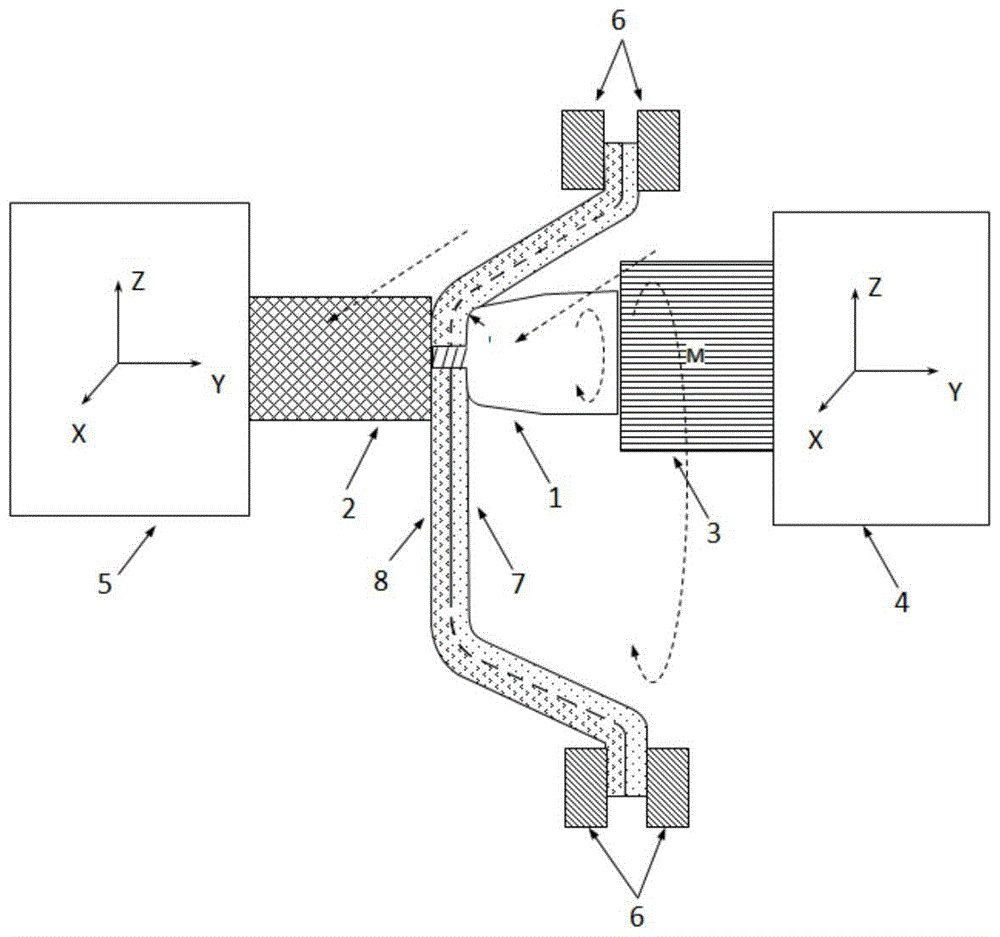

A device and method for progressive composite forming of sheet metal stirring

The invention relates to an incremental sheet metal stirring composite forming device and method. The forming device comprises an incremental stirring forming tool head, a reverse roof pressure head, a spindle motor, a main drive unit, an auxiliary drive unit and a sheet metal fixture. The forming method includes: generating an incremental forming track according to a three-dimensional model of a machining part to be machined to serve as a synchronous movement track of the main drive unit and the auxiliary drive unit; controlling the spindle motor to rotate, allowing the incremental stirring forming tool head to be driven to rotate by the spindle motor to be inserted in the interior of a sheet metal to be machined, and the reverse roof pressure head and the incremental stirring forming tool head pressing the sheet metal; respectively controlling the incremental stirring forming tool head and the reverse roof pressure head to move synchronously according to the synchronous movement track to complete incremental sheet metal stirring composite forming. Compared with the prior art, the incremental sheet metal stirring composite forming device and method has the advantages that functionally graded materials can be integrated in welding and forming, the manufacturing process is shortened, the number of tools is reduced, and the problem that traditional functionally graded materials are poor in extension and cannot be formed can be avoided as well.

Owner:SHANGHAI JIAOTONG UNIV

Floating and overturning type motor pressing assembling trolley and assembling method for assembling gearbox on trolley

ActiveCN110762196AReduce usageSmall footprintGear lubrication/coolingElectric machineryStructural engineering

Owner:无锡明恒混合动力技术有限公司

Permanent magnet generator with stator inclined grooves and inclined groove realization method of permanent magnet generator

ActiveCN103051077BSmall torqueHarmonic reductionMagnetic circuit stationary partsManufacturing stator/rotor bodiesPunchingPermanent magnet synchronous generator

The invention discloses a permanent magnet generator with stator inclined grooves and an inclined groove realization method of the permanent magnet generator. The permanent magnet generator comprises a generator stator, wherein the stator comprises a stator casing and a stator iron core punching sheet and also comprises a plurality of convex strips, the convex strips are arranged on the inner wall of the stator casing according to a certain inclination, clamp grooves used for being clamped with the convex strips are arranged at the back side of the yoke part of the stator iron core punching sheet, the stator iron core punching sheets are overlapped onto the convex strips in a laminated way through the clamp grooves, and in addition, the clamp grooves have the same inclination as the inclination of the stator inclined grooves and the installation inclination of the convex strips after the lamination. The stator inclined grooves of the permanent magnet generator can be realized, the tooth groove torque is effectively reduced, meanwhile, the harmonic waves are reduced, in addition, few toolings are required by the stator inclined groove realization method, the cost is low, and the process is simple.

Owner:GUODIAN UNITED POWER TECH

Machining fixing tool for special-shaped valve seat part

InactiveCN109894898ASimple structureEasy to usePositioning apparatusMetal-working holdersMating connectionEngineering

The invention discloses a machining fixing tool for a special-shaped valve seat part, and belongs to the field of tool clamps. The tool comprises a clamp base body and a pressing ring sleeve; the clamp base body comprises a positioning seat and a clamping part arranged at the end, far away from the part, of the positioning seat; a shallow groove which just contains two semicircular bosses on the front surface of the part is formed in the end surface of the front end of the positioning seat; a positioning pin corresponding to a threaded hole in the part is arranged on the surface of the shallowgroove; a circle of limiting boss is arranged on the inner wall of the top end of the pressing ring sleeve; a hole which is in clearance fit with a part back step outer circle is formed in the centerof the limiting boss; and the pressing ring sleeve and the positioning seat are in matched connection to fasten the part between the positioning seat and the pressing ring sleeve. The machining fixing tool is simple in structure and convenient to use, the whole part can be machined through twice clamping, the number of tools can be reduced, technological process can be shortened, the positioningerror is small, and the processing efficiency is high.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

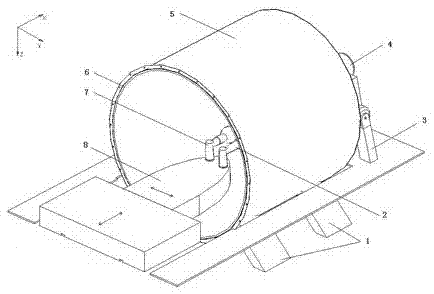

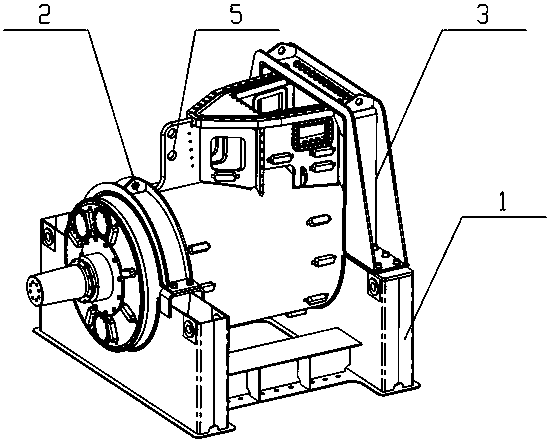

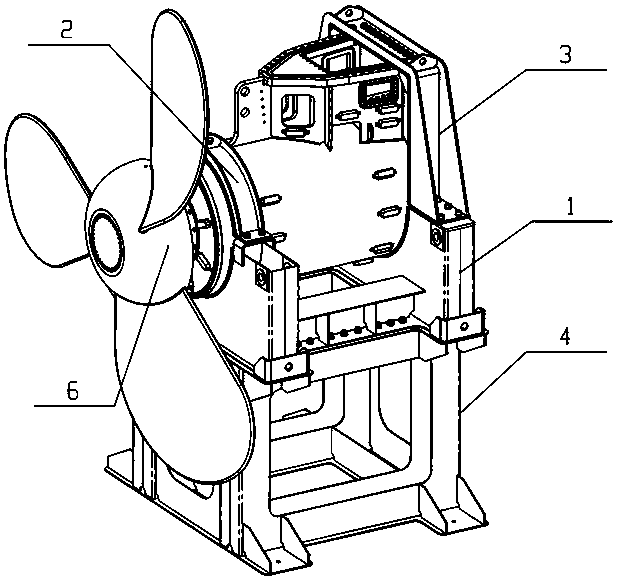

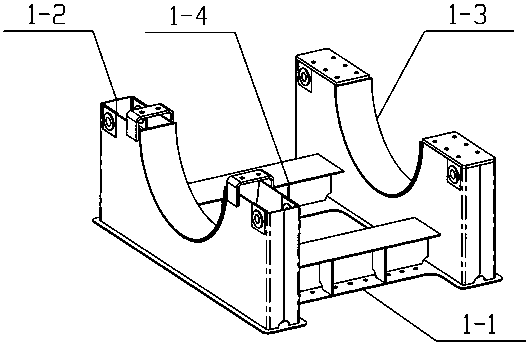

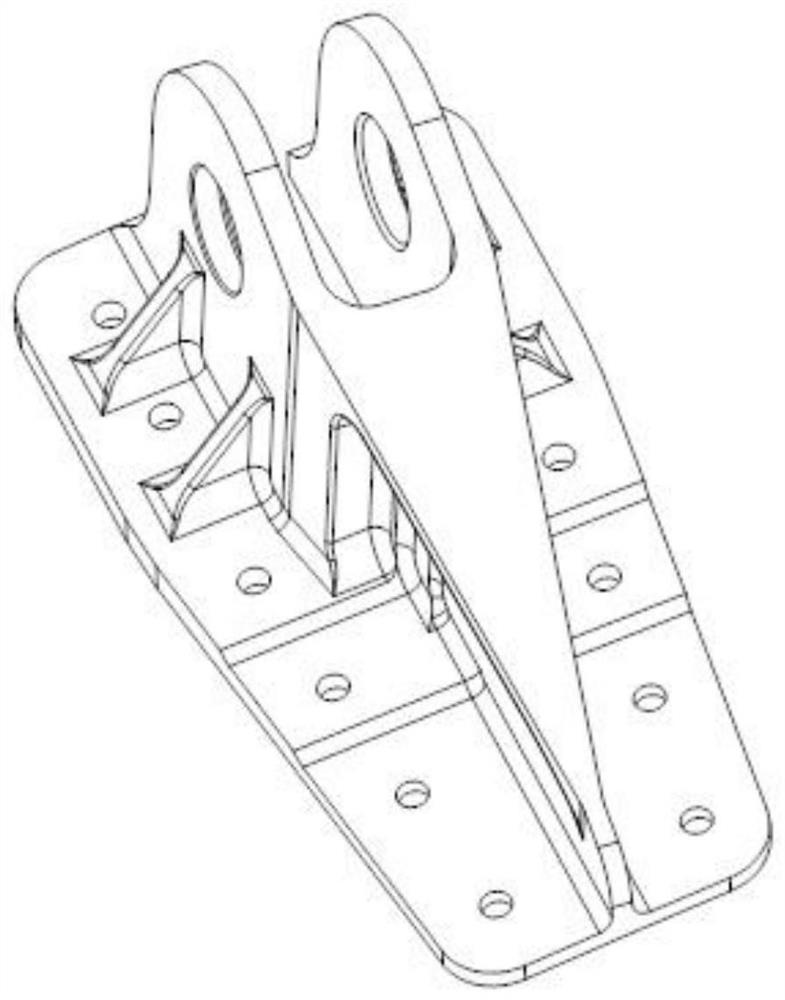

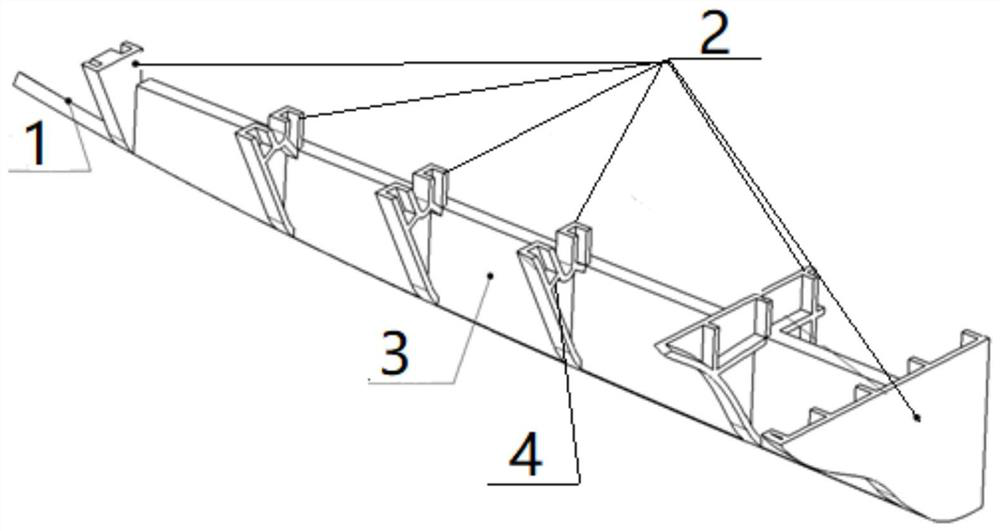

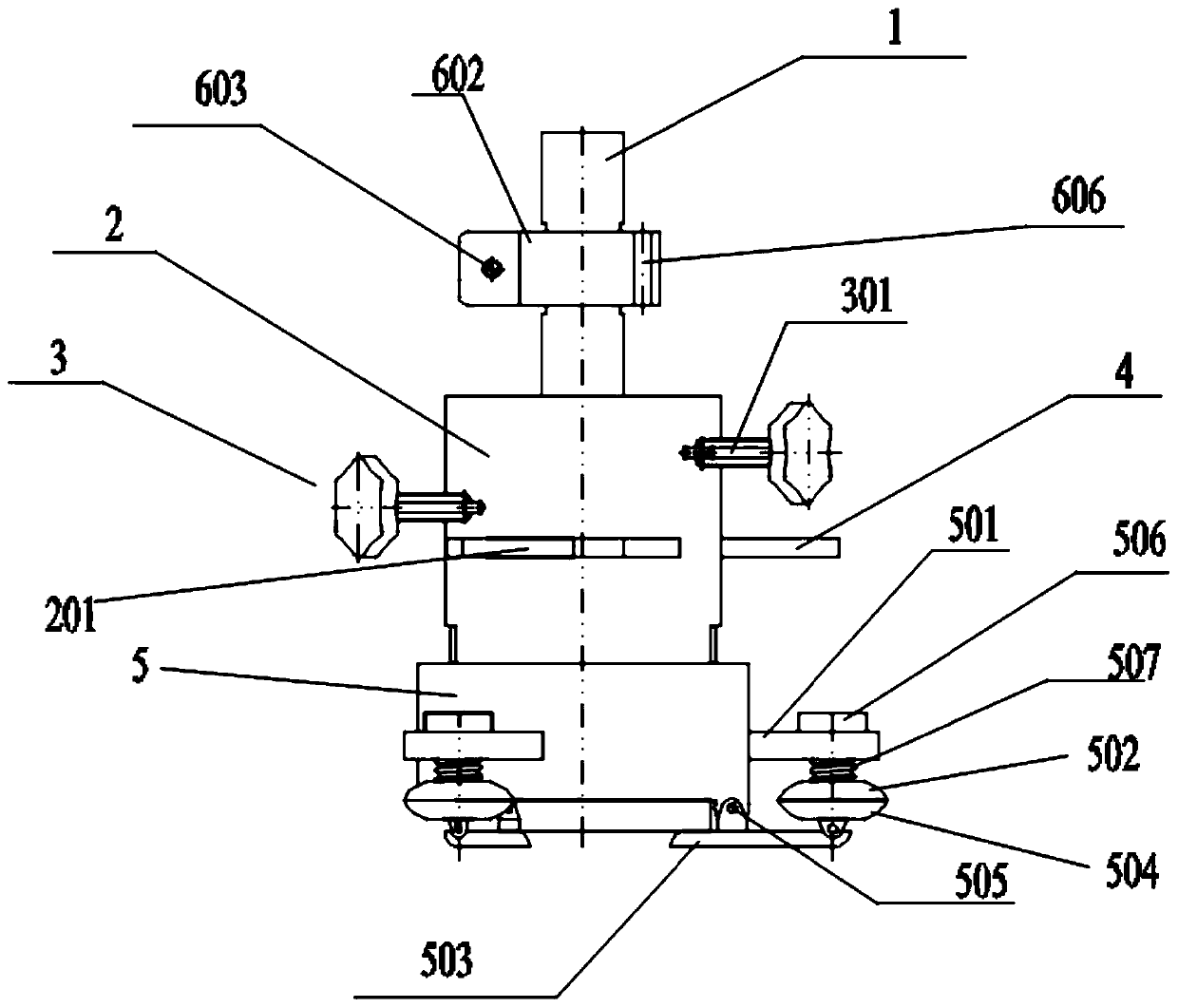

Pod propeller combination tooling

PendingCN107672739AReduce the number of toolsReasonable structureVessel designingPropulsive elementsPulp and paper industryFlange

The invention relates to a pod propeller combination tooling. The pod propeller combination tooling comprises a base, a near propeller end locking part and a far propeller end locking part, and the base comprises a near propeller end wall frame, a far propeller end wall frame and a base bottom plate; the near propeller end wall frame and the far propeller end wall frame are symmetrically arrangedon the two sides of the base bottom plate, and the two ends of an arc bending plate of the near propeller end locking part are connected with the near propeller end wall frame through fasteners; and the two ends of a U-shaped bending steel plate of the far propeller end locking part are fixedly connected with the far propeller end wall frame, and the top of the U-shaped bending steel plate is connected with a flange face of the top of a pod body. The pod propeller combination tooling is reasonable in structure and convenient to combine, and can simultaneously meet requirements of shipping, assembly and test in the whole manufacturing process of a pod propeller. The number of toolings required in the manufacturing process of the pod propeller is simplified, the production cost is reduced, and the manufacturing efficiency is improved.

Owner:CSSC NANJING LUZHOU MACHINE

A Flexible Fixture with Adaptive Support and Multi-point Compression

ActiveCN111673496BSimple structureEasy to usePositioning apparatusMetal-working holdersControl engineeringEngineering

The invention discloses a flexible fixture with self-adaptive support and multi-point pressing, which comprises a fixture base and a first self-adaptive clamping device, a second self-adaptive clamping device, an self-adaptive support device and a fixture arranged on the fixture base. Supporting boss; the first self-adaptive clamping device and the second self-adaptive clamping device are respectively slidably connected to the clamp base, and the two ends of the first self-adaptive clamping device and the second self-adaptive clamping device are respectively connected to the The part A surface and the part B surface are pressed tightly; the self-adaptive support device is attached to the part C surface; the opening slot of the part is inserted into the fixture support boss, and the main positioning sleeve of the part is inserted into the part positioning hole, the fixture support boss and is connected with the press Tighten bolted connections. The invention designs multiple clamping points, and the clamping force can be evenly distributed on the parts, so that the rigidity of the parts during processing is well guaranteed, the machining accuracy and surface quality of the parts are guaranteed, the process flow and production preparation time are shortened, and the Improve processing quality and production efficiency.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Numerical control vertical high-precision honing machine and its honing method

ActiveCN104385110BImplement Surface TexturesHigh geometric accuracyHoning machinesSurface roughnessMachine tool

The invention relates to a numerically controlled vertical high-precision honing machine and a honing method thereof. The honing machine comprises a processing station upright post component, and a main shaft supporting plate screw rod and a processing station clamp supporting plate screw rod which are parallel are vertically arranged in the processing station upright post component; a main shaft supporting plate and a processing station clamp supporting plate are arranged outside the processing station upright post component; the main shaft supporting plate is connected with a screw rod nut on the main shaft supporting plate screw rod through a main shaft supporting plate connecting plate; the processing station clamp supporting plate is connected with a screw rod nut on the processing station clamp supporting plate screw rod through a processing station clamp supporting plate connecting plate; the contact surfaces of the supporting plates and an upright post are glidingly fixed by a guide rail and a guide block respectively; the lower end surface of a machine tool main shaft component is connected to a honing tool; full-floating honing tools are fixed to the upper surface of the processing station clamp supporting plate to be opposite to the honing tool, and the screw rods are controlled and connected by a stroke motor. When the honing machine and the honing method provided by the invention are used for precisely honing the inner surface of a hole-like part, the size precision, the surface roughness and the geometrical shape precision of a hole can be greatly improved.

Owner:上海善能机械有限公司

A method for integral co-curing molding of UAV wings

ActiveCN110481811BSimple molding processAvoiding Hole Sealing ProblemsWeight reductionAircraft assemblyAviationUncrewed vehicle

An integral co-curing molding method for an unmanned aerial vehicle wing belongs to the field of aviation composite material molding. The method steps are: step 1: assembling the wing frame; step 2: assembling the lower mold; step 3: making the lower wing surface skin of the wing in the assembled lower mold mold, and reserving the upper wing surface skin when paving step 4: positioning the wing frame; step 5: making the upper wing surface skin; step 6: assembling the upper mold; step 7: curing and demoulding. The wing prepared by the method of the present invention can be molded at one time, which improves the strength, saves the cost, and improves the manufacturing speed.

Owner:GUANGLIAN AVIATION IND CO LTD

A precision forging blade tenon root and front and rear edge processing jig

ActiveCN106181468BEasy to processImprove machining accuracyPositioning apparatusMetal-working holdersNumerical controlEngineering

Owner:NORTHWESTERN POLYTECHNICAL UNIV

CNC multi-station machining auxiliary clamping jig

InactiveCN113118809AReduce manufacturing costReduce the number of toolsPositioning apparatusMetal working apparatusBeam splitterElectric machinery

The invention discloses a CNC multi-station machining auxiliary clamping jig. The CNC multi-station machining auxiliary clamping jig is used for being installed on a CNC constant-speed shaft to machine an emitting plate, a beam splitter prism seat, a transverse shaft motor seat and a vertical shaft motor seat, and the CNC multi-station machining auxiliary clamping jig comprises a vertical flange plate and a multi-station horizontal fixing plate. A rectangular positioning sliding groove is formed in one side of the vertical flange plate, one side of the multi-station horizontal fixing plate is fixed in the rectangular positioning sliding groove through a connecting piece, and the multi-station horizontal fixing plate is provided with a clamp mechanism used for fixing the emitting plate, the beam splitter prism seat, the transverse shaft motor seat and the vertical shaft motor seat. The vertical flange plate is further provided with a positioning pin hole matched with an installation pin on the CNC constant-speed shaft and a locking screw A connected with a threaded hole in the CNC constant-speed shaft in a locking mode correspondingly. The CNC multi-station machining auxiliary clamping jig is convenient to disassemble, fix and adjust, the problem that in the prior art, a CNC machine tool can only machine one part at a time is solved, the number of tools is greatly reduced, the machine adjusting time is greatly shortened, the production efficiency is improved, and the product quality is guaranteed.

Owner:苏州艾徕优光电科技有限公司

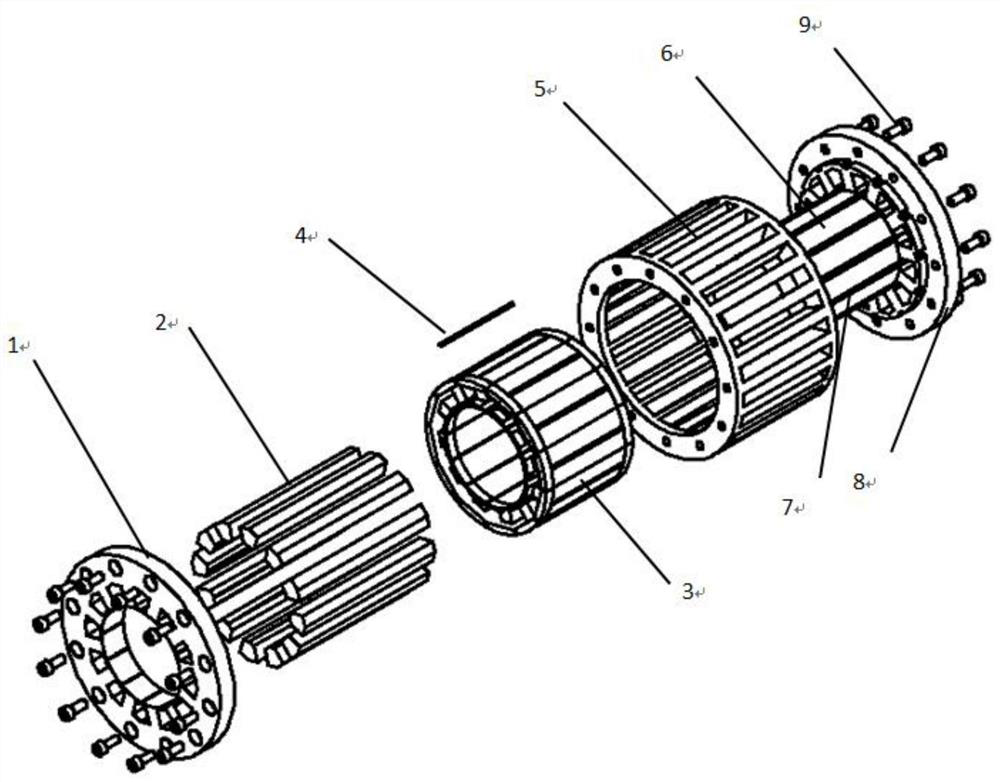

Forming method of block stator, block stator and motor under full-scale control

ActiveCN113364228BFull size controlEasy to switchWindingsMagnetic circuit stationary partsManufacturing technologyPunching

The invention belongs to the technical field of motor block-type stator manufacturing technology, and discloses a block-shaped stator forming method under full-size control, a block stator and a motor. The inner circle, outer circle and groove shape of the sheet iron core are positioned, and then the punching sheet is pressed and compacted by tightening the screws on the tool, and then the V-shaped buckle is used to crimp the iron core into a whole; then install the stator iron core After the skeleton is completed, the winding is carried out. After the winding is completed, the tooling is used again for full positioning, and then laser welding is used to weld into a full-circle stator. According to the invention, the four parts of the mandrel and the inner circle of the stator iron core, the slot positioning rod and the stator slot, the toothed positioning rod and the outer circle fixing hoop cooperate with each other and the stator iron core. size control. The invention saves the number of tooling, facilitates switching of the tooling, enables reliable forming of the stator iron core and can maintain the size of each part of the stator iron core.

Owner:WUHAN HUADA NEW TYPE MOTOR CO LTD

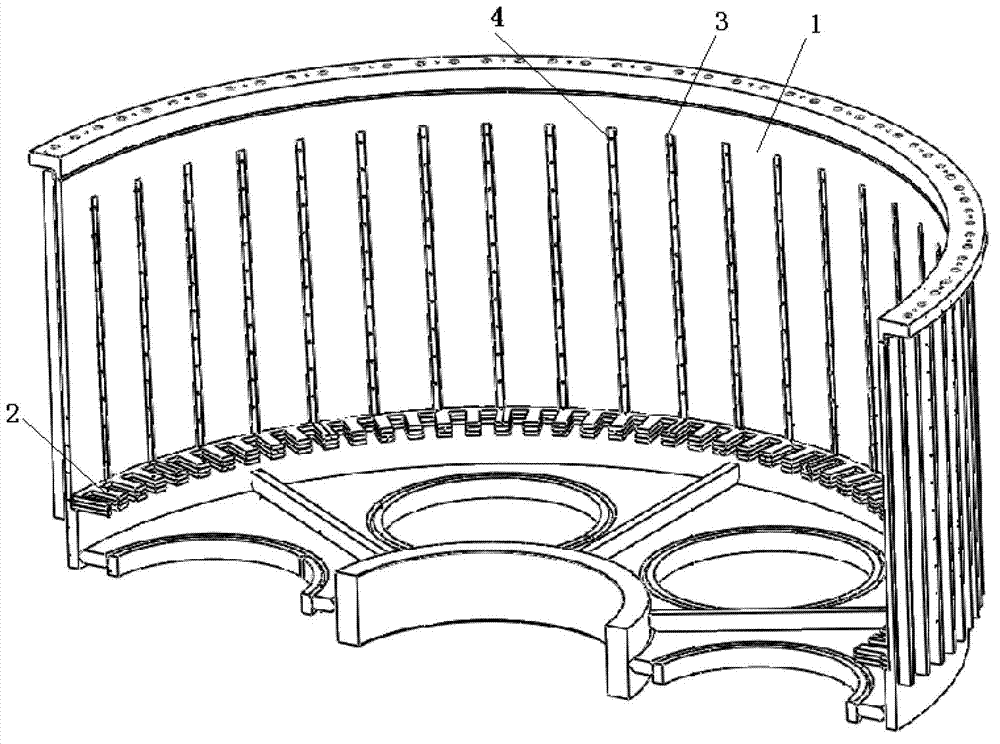

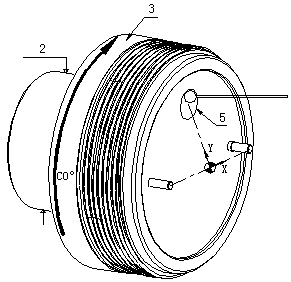

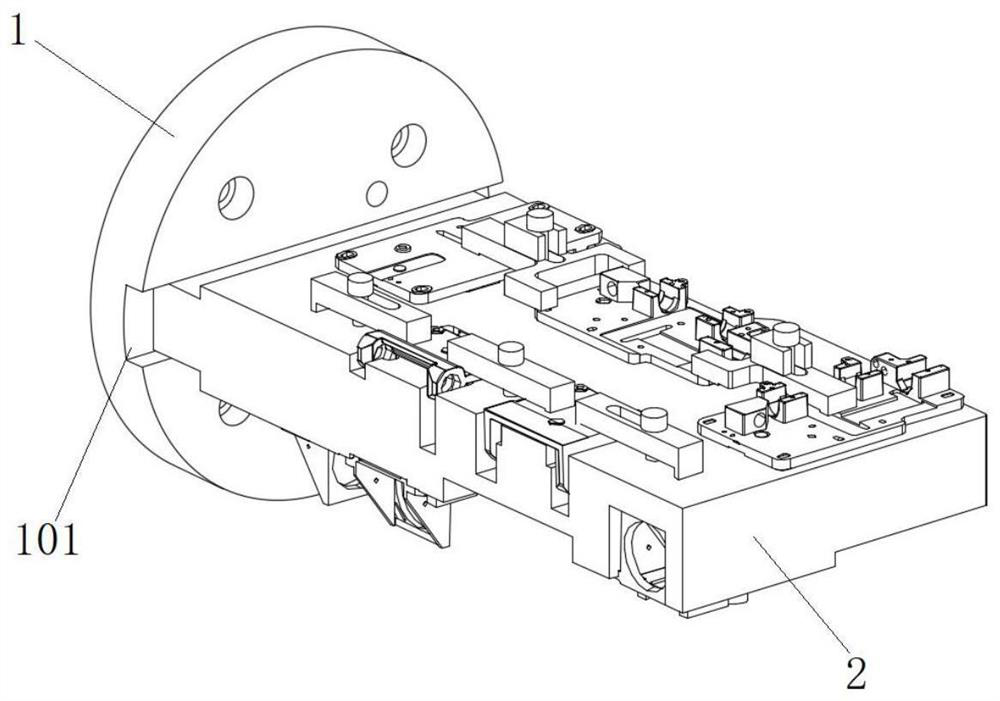

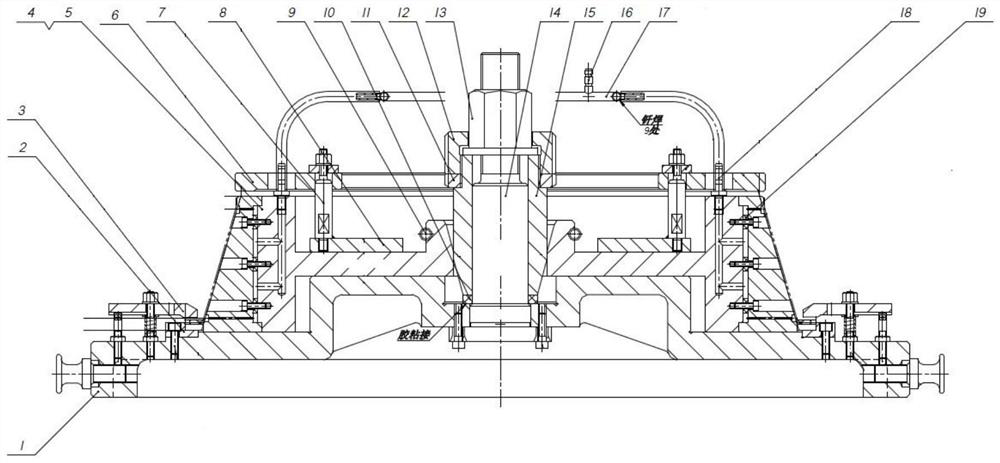

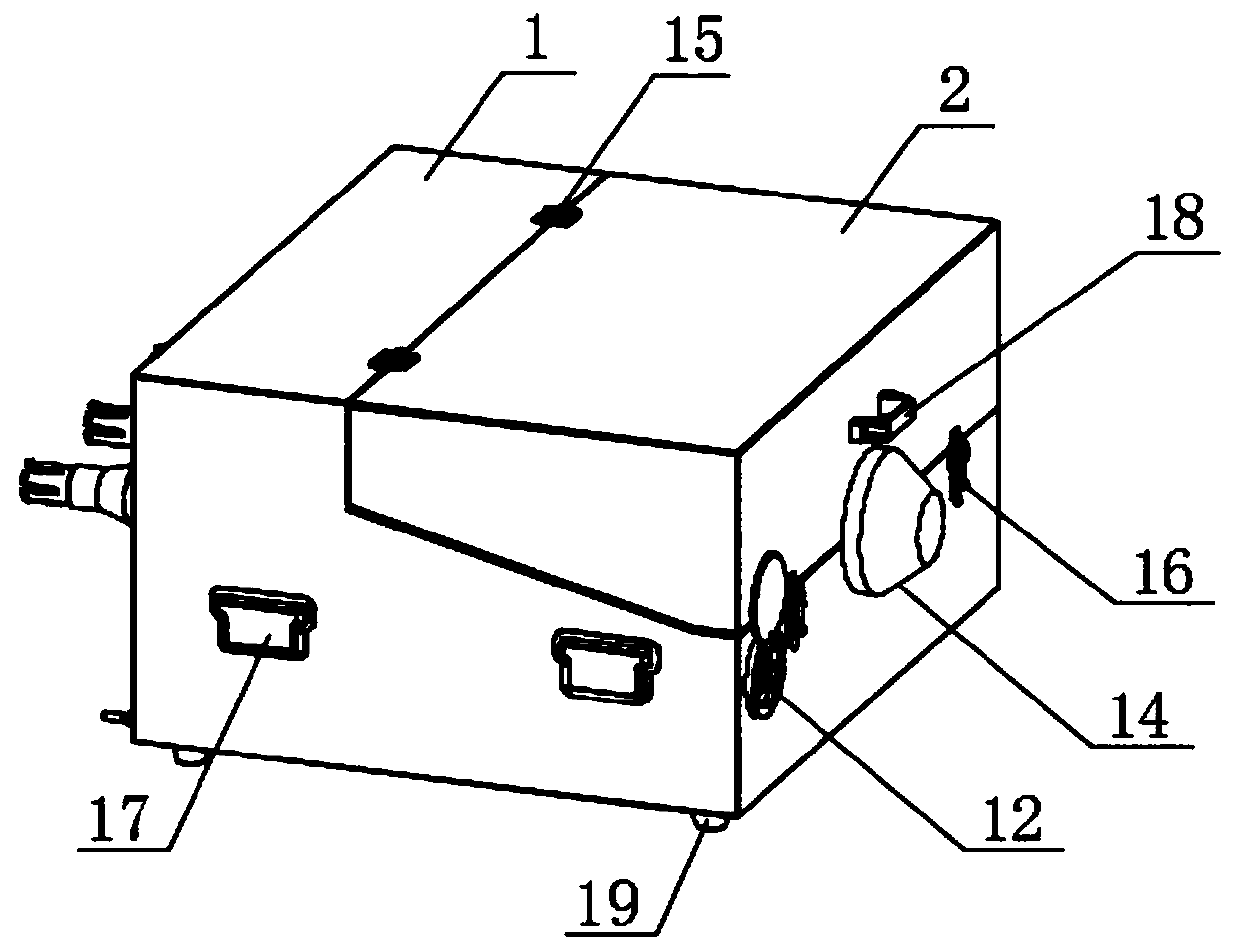

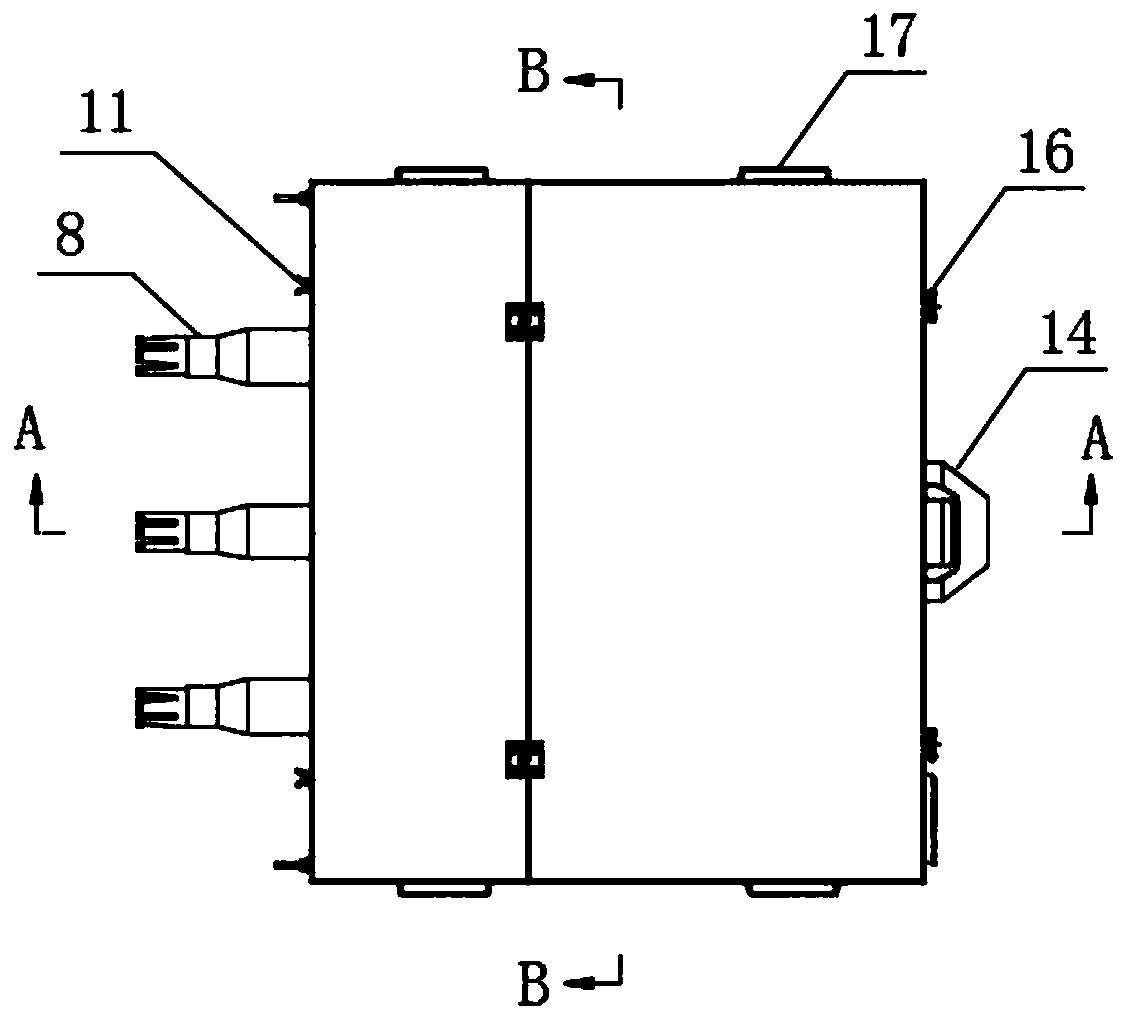

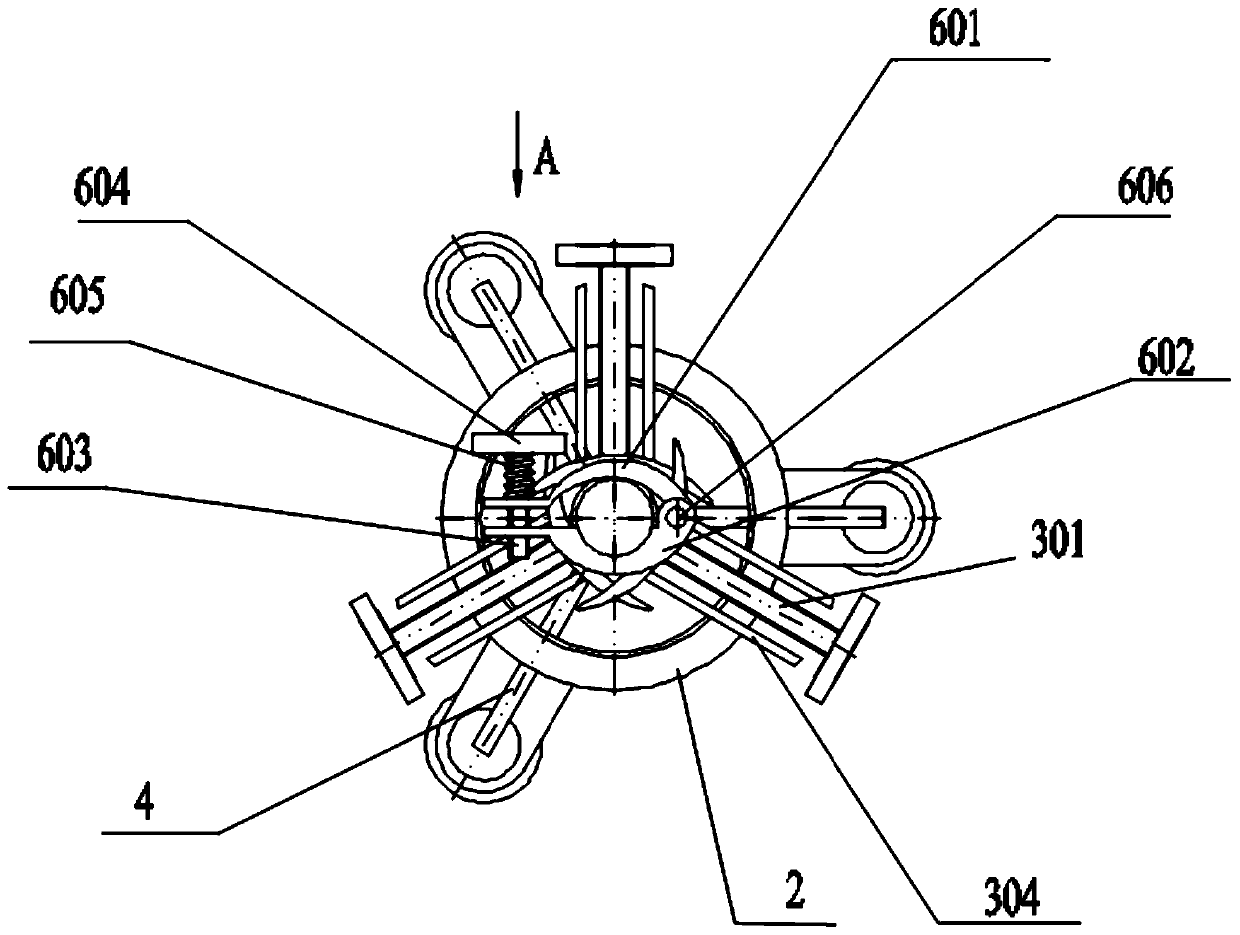

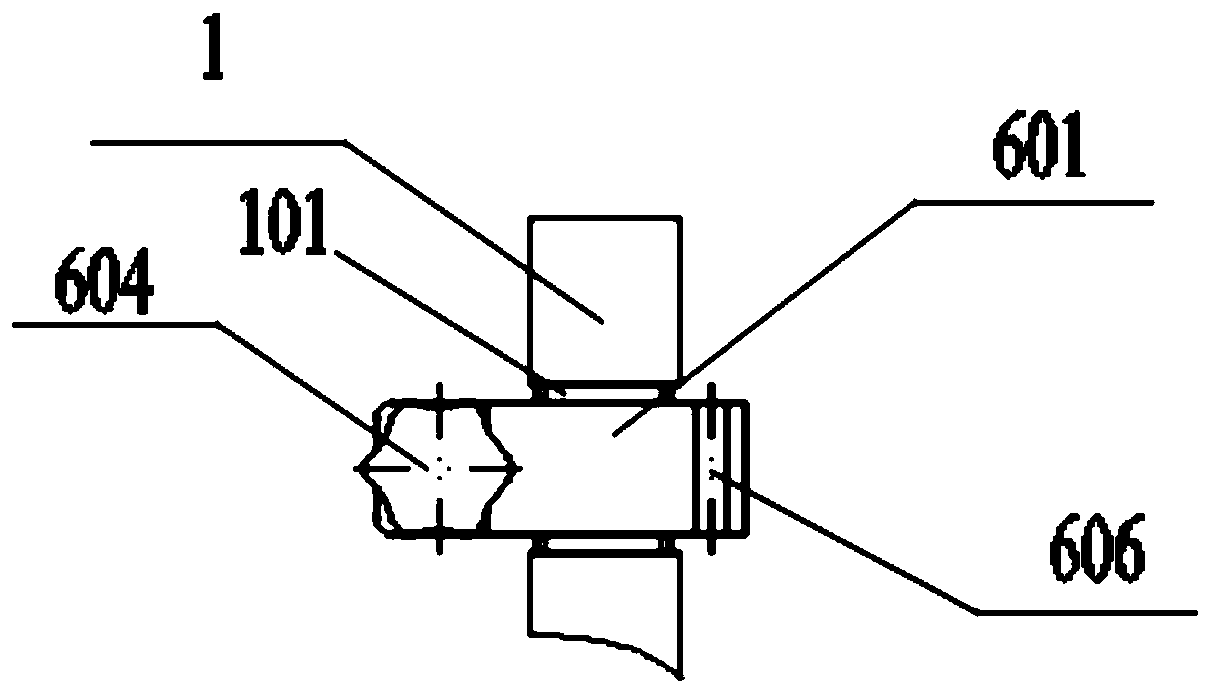

Tool for overall assembling welding of engine outer ring assembly

ActiveCN113894459AReduce the number of toolsReduce processing costsWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld seam

A tool for overall assembling welding of an engine outer ring assembly comprises a base plate, a positioning ring, a pressing plate, a main expansion block, an auxiliary expansion block, a pressing cover, a screw rod, a guide plate, a spring, a rubber mat, a locking nut, an end cover nut, a shoulder nut, a guide column, a cone, a pipe connecting nozzle, an air guide pipe and an air nozzle. By means of the tool, two circular welding seams of the engine outer ring assembly and three groups of mounting seat welding seams can be integrated in one device for limiting machining, so that the number of tools required in the machining process is greatly reduced, and the machining cost is greatly reduced; meanwhile, one-time clamping machining is achieved, error accumulation caused by repeated clamping is avoided, clamping positioning is accurate, rapid and stable, dismounting is convenient and rapid, meanwhile, the error prevention effect is achieved, the conditions of wrong mounting, neglected mounting and the like are avoided, and the machining efficiency is greatly improved; and in addition, the device can achieve manual welding and automatic welding expansion, and meanwhile the multi-application requirements of products are met.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

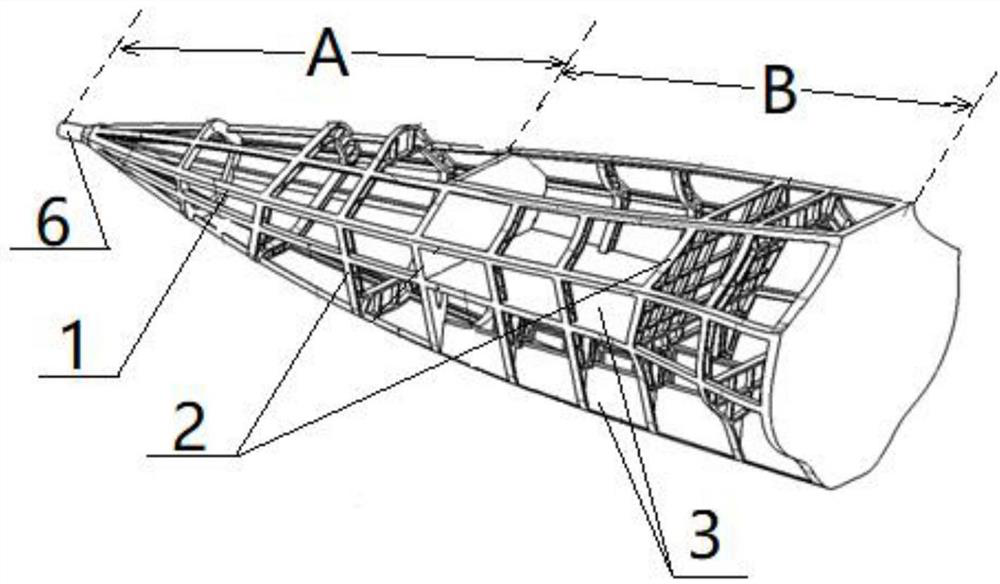

An aircraft front fuselage integral frame structure

ActiveCN109131825BReduce the number of toolsReduce structural weightFuselage framesStructural engineeringMechanical engineering

The application belongs to the field of aircraft structure design, and in particular relates to an integral frame structure of an aircraft front fuselage. To solve the negative impact of the traditional aircraft front fuselage structure, multiple longitudinal girders, transverse reinforcement frames, and longitudinal plates of the overall frame structure of the aircraft front fuselage in the present application are integrally formed, and the surface of the longitudinal girder facing the outside of the aircraft Conformal with the surface of the transverse reinforcement frame facing the outside of the aircraft, the surface of the longitudinal plate and the surface of the longitudinal girder facing the outside of the aircraft, the surface of the longitudinal plate and the surface of the transverse reinforcement frame facing the outside of the aircraft are in the same shape; Significantly reduce structural weight, reduce fatigue weak links, reduce the number of structural parts, standard parts, and tooling, and shorten the manufacturing cycle.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

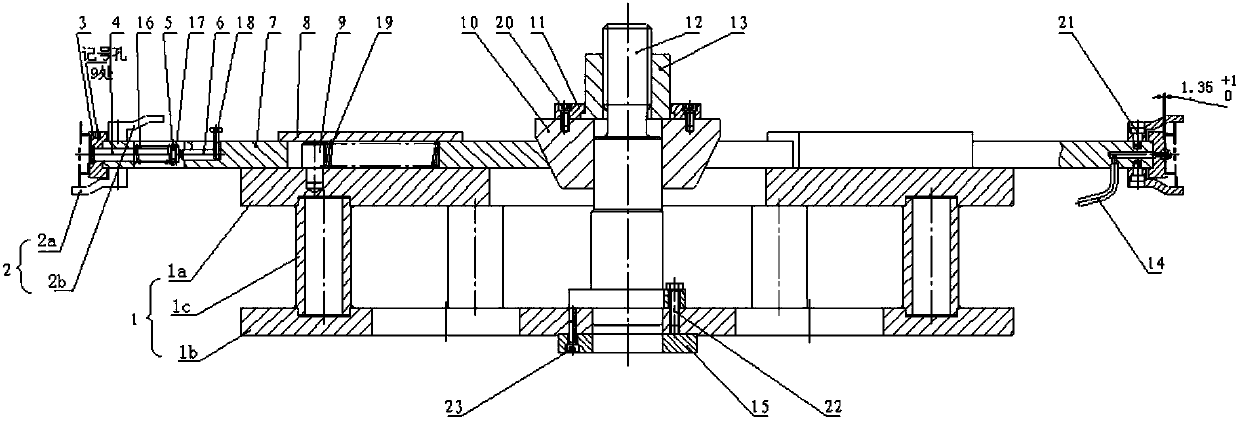

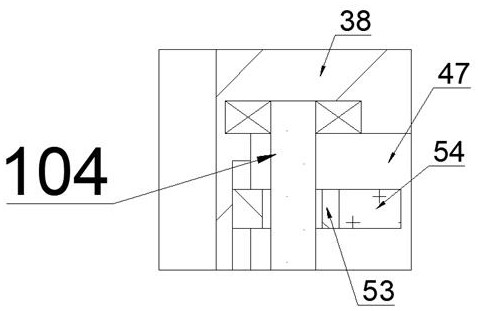

A two-way positioning thin-walled welding fixture

ActiveCN106425256BPrevent oxidationEliminate positioning gapsWelding/cutting auxillary devicesAuxillary welding devicesSplit pinWeld seam

The invention discloses a bidirectional location thin-walled workpiece welding clamp. The bidirectional location thin-walled workpiece welding clamp comprises a body base, a clamping plate, overturnable locating blocks, small shafts, gaskets, push pins, expansion blocks, guide plates, stop pins, a conical body, a cover plate, a mandrel, a nut, a ventilation pipe, a locating plug, springs I, split pins, bolts I, springs II, screws I, screws II, bolts II and screws III. By means of the bidirectional location thin-walled workpiece welding clamp, location clearance can be effectively eliminated, welding deformation can be resisted, and a welding seam zone is prevented from metal oxidation; and due to the fact that a locating face can be overturned, a support ring can be welded to a tool, and the number of tools and tool replacement time are reduced. When the bidirectional location thin-walled workpiece welding clamp is used practically, the problems that welding deformation of the support ring is large, and dimensions and angles are out of tolerance are solved; tool cost is saved; labor intensity is lowered; the qualification rate of products is increased; and production efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Quick joint transfer box with current display

ActiveCN110311335AAvoid direct contactReduce the number of toolsMultiple conductors connectorMaterial resourcesFlange

The invention discloses a quick joint transfer box with current display. The box includes a casing and a cover, wherein one end of the cover is hinged with a top surface of the casing through a hinge,the other end is in locking connection with a front surface of the casing through a buckle, a bottom surface in the casing is provided with multiple guide rails, each guide rail is in sliding connection with a sliding seat, each sliding seat is provided with an adapter support, each adapter support is provided with a first through hole, each first through hole is internally provided with a flangedisc and an adapter sleeve which penetrates through the flange disc and is in fixed connection with the flange disc, a tail end of each adapter sleeve is sleeved with a clamping head, each clamping head is internally plugged with a wire middle end sleeve, and the wire middle end sleeve extends from a back surface of the casing to an outer part of the casing. The box is advantaged in that an operator is prevented from directly contacting a cable joint, more safety is achieved, the quantity of tools for live-line operation is further reduced, operation loads are alleviated, and manpower and material resources are saved.

Owner:云南电网有限责任公司丽江供电局 +1

A rear anti-collision beam assembly suitable for various automobiles

The invention relates to a rear anti-collision beam assembly suitable for multiple automobiles. The rear anti-collision beam assembly comprises an exterior board and installation supports. A square auxiliary hole is formed in one end of the exterior board, a first lap joint surface is arranged close to the edge of the square auxiliary hole, and the structure of the other end of the exterior board is the same as that of one end of the exterior board. Each installation support is of an open square box shape, and folded edges are arranged on the four sides of each opening portion and distributed symmetrical about the center of the opening portion, wherein the two laterally-symmetrical folded edges are spaced into three second lap joint surfaces through two reinforcing ribs, the two sides of the two vertically-symmetrical folded edges are provided with small planes connected with the left side wall and the right side wall of the square box shape, multiple installation holes are formed in the bottom of the square box shape, and the installation supports are correspondingly connected with the first lap joint surface at the edge of the square auxiliary hole in the exterior board. The left installation support and the right installation support can be interchanged and used, the positions of the installation supports can be adjusted, the installation supports are matched with different automobile types by changing the distance between installation points, and universality is high.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

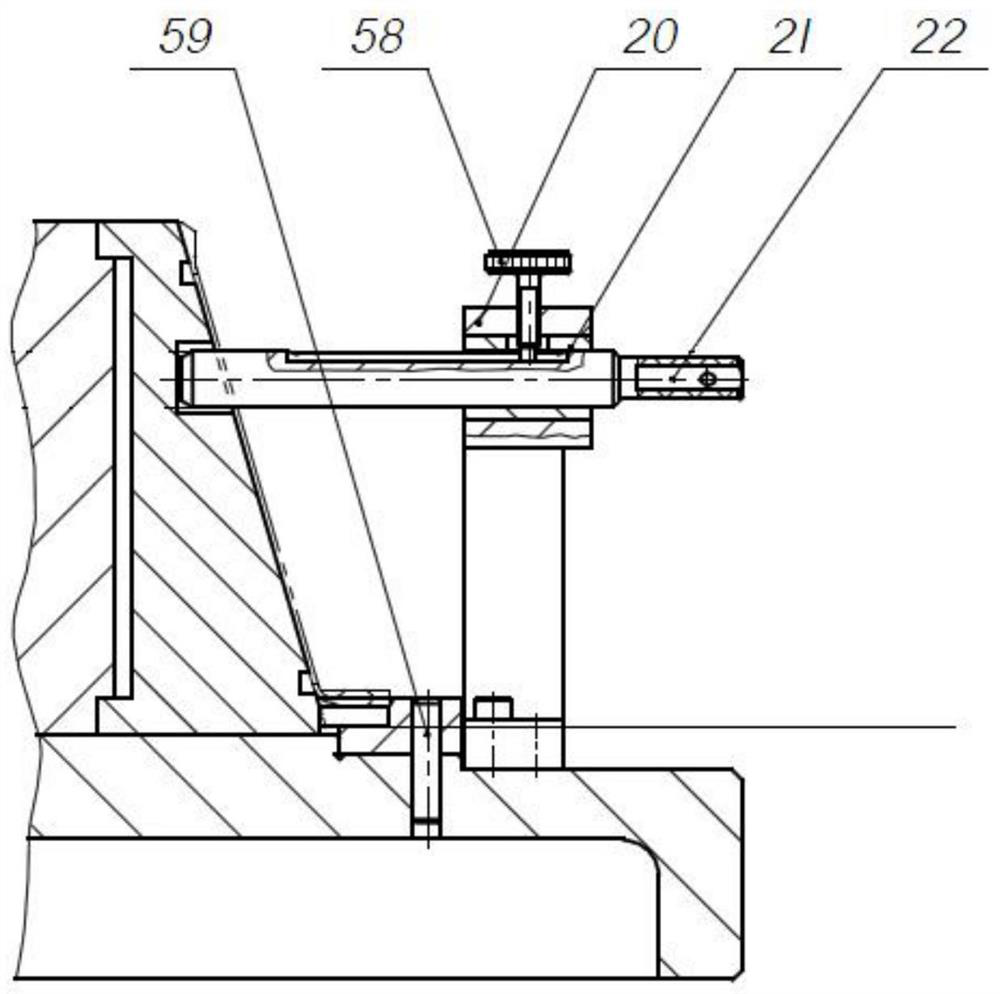

Rectifying blade body end face position measuring device and method

InactiveCN112179238AAvoid the impact of measurement accuracyImprove detection efficiencyMechanical clearance measurementsStructural engineeringMechanical engineering

Owner:AECC AVIATION POWER CO LTD

Fixing device for detection lever of engine borescope

ActiveCN110530405AImprove accuracyReduce labor costsMeasurement apparatus componentsAero engineEconomic benefits

The invention discloses a fixing device for a detection lever of an engine borescope, thereby effectively solveing problems existing in existing aero-engine borescope detection. The fixing device hasadvantages of small tool number and simple structure; and the labor cost in the detection process can be effective saved and the detection efficiency can be improved. A first threaded sleeve and a second threaded sleeve rotate to clamp each other; a first clamping plate and a second clamping plate clamp a detection lever; and three groups of jacking locks adjust the position of the detection leverslightly. While the fixation of the detection lever is ensured, the operation difficulty is reduced. With the clamp, the engine detection efficiency can be improved, the labor cost in the detection process can be lowered, and the economic benefit can be increased.

Owner:AECC AVIATION POWER CO LTD

A soft peeling device for rough jadeite

InactiveCN111331480BReduce the number of toolsReduce labor costsGrinding drivesBelt grinding machinesEmeraldEngineering

A soft jadeite rough peeling device disclosed in the present invention comprises a machine base, and a rough stone clamping device is arranged on the machine base, and the rough stone clamping device is used to clamp and fix the jadeite rough stone, and the rough stone clamps The device can turn over the rough jadeite, so that all four sides of the rough jadeite can be processed, reducing the number of tooling required for peeling and processing the rough jadeite. The rough stone clamping device is equipped with a support plate device, and the support plate The device is used to provide the supporting force required for the peeling processing of the rough jadeite. The base is provided with a peeling lifting device located on the upper side of the rough stone clamping device. The peeling lifting device is provided with a flexible peeling device. device, the flexible peeling device can automatically adapt to the shape of the rough jadeite and grind the rough jadeite. The invention can automatically perform flexible peeling on the rough jadeite, with high processing efficiency and reduced labor costs.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

Small-bending-radius aviation conduit bend forming die and forming method thereof

The invention relates to a small-bending-radius aviation conduit bend forming die and a forming method thereof. The small-bending-radius aviation conduit bend forming die comprises an upper die and a lower die, wherein a cavity formed after the upper die and the lower die are buckled is in a bent conduit shape, the two ends of the cavity are respectively provided with a limiting table, the limiting tables are provided with guide sleeve coaxial with the two ends of the cavity, a flexible central spindle is arranged in one guide sleeve and is connected with a low pressure piston through a connecting rod, a gasket is arranged in the other guide sleeve, the outer end face of the gasket is matched with a high pressure piston, and the low pressure piston and the high pressure piston are respectively in coaxial sliding fit with the corresponding guide sleeves. The forming die and the method thereof solve the processing difficult problem about forming of a small-bending-radius aviation conduit and realize the forming of the aviation conduit in a stable state, the phenomena of cracking, wrinkling and necking do not easily occur during forming, and a high-quality stable and efficient shaping processing method of small-bending-radius aviation conduit parts is realized.

Owner:SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com