Permanent magnet generator with stator inclined grooves and inclined groove realization method of permanent magnet generator

A technique for permanent magnet generators and implementation methods, applied in the manufacture of stator/rotor bodies, magnetic circuit static components, magnetic circuit shape/style/structure, etc., can solve problems such as difficult process implementation, reduce cogging torque, etc., and achieve The effect of less tooling, reduced cogging torque, and reduced harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

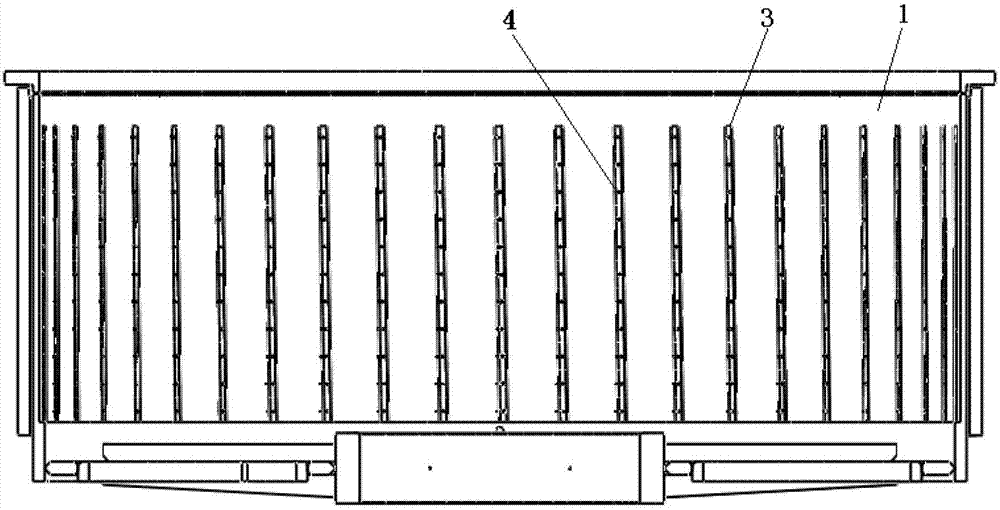

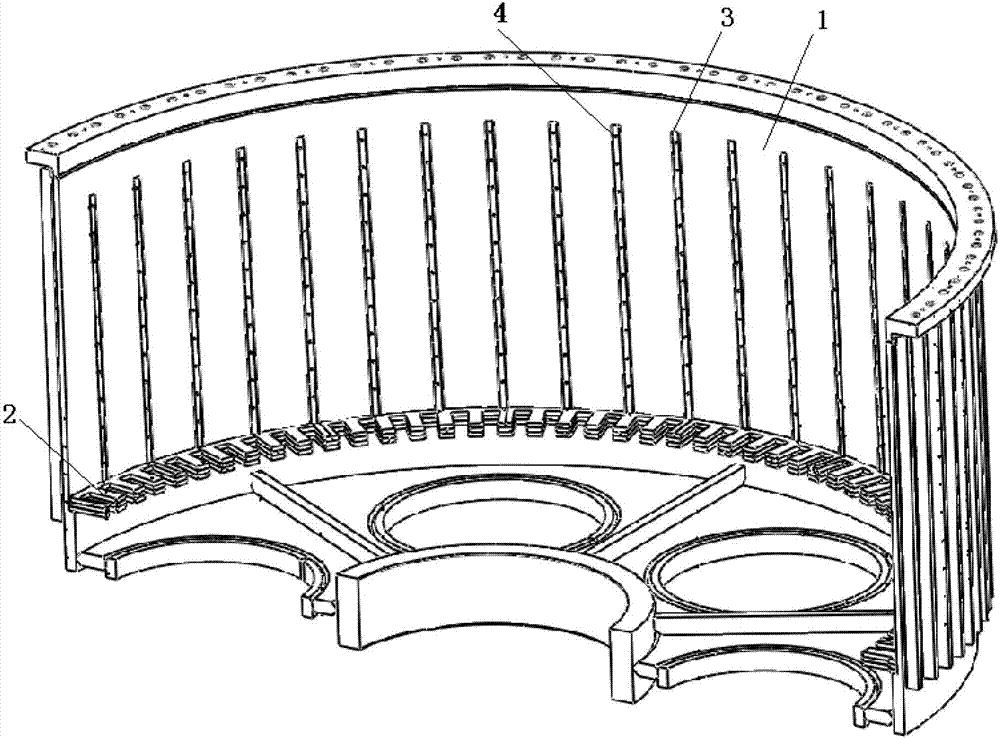

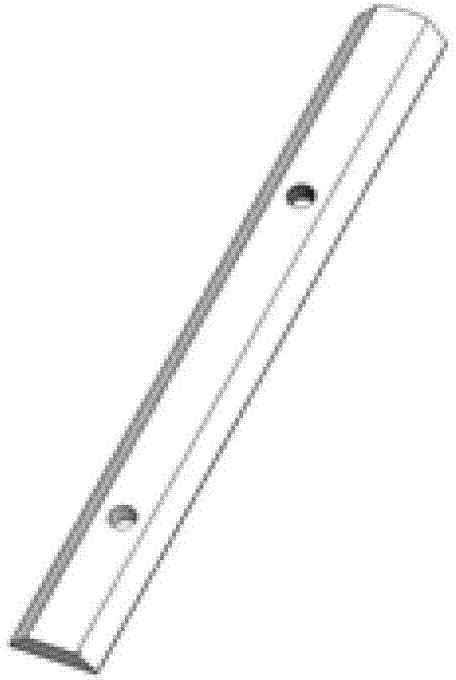

[0020] Such as figure 1 , 2 , 3, and 4, a permanent magnet generator with a stator chute of the present invention, taking a large permanent magnet direct drive wind power generator as an example, includes a generator stator, and the stator includes a stator housing 1 and a stator iron The core punching piece 2, the stator also includes a plurality of raised strips 3, the raised strips 3 are installed on the inner wall of the stator housing 1 according to a certain inclination, and the back of the yoke of the stator core punching piece 2 is provided with a The card slot 21 where the protruding bar 3 engages, the stator core punching sheet 2 is stacked and engaged on the protruding bar 3 through the card slot 21, and the card slot 21 is stacked and the slot of the stator chute The inclination is consistent with the installation inclination of the raised strip 3. The protruding strips 3 can be fixedly installed in the stator housing 1 by screws 4 , and the number of the screws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com