A rear anti-collision beam assembly suitable for various automobiles

A technology for cross beam assembly and rear collision avoidance, which is applied in vehicle components, vehicle safety arrangements, bumpers, etc., can solve the problems that the stamping depth cannot be widely used, increase the development cost, and affect the drawing rate, so as to reduce the number of tooling and Management cost, easy and reliable installation, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

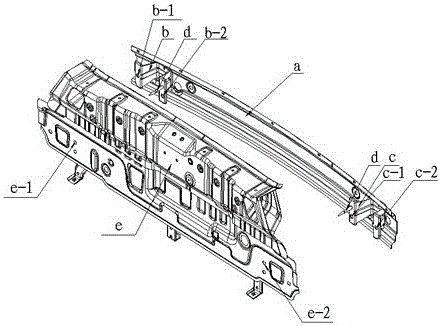

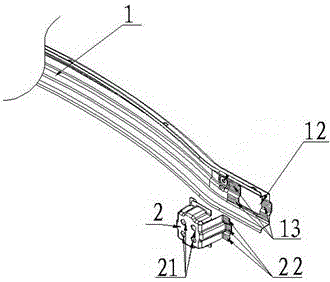

[0026] see figure 2 , image 3 , Figure 4 and Figure 5 , shows a rear anti-collision beam assembly suitable for automobiles, including an exterior panel 1, and mounting brackets 2 respectively connected to the two ends of the exterior panel. Its outstanding substantive features are:

[0027] One end of the profile plate 1 is provided with a process square hole 12, and a first lap surface 13 is provided on the edge close to the process square hole. The structure of the parts is the same and symmetrical to each other;

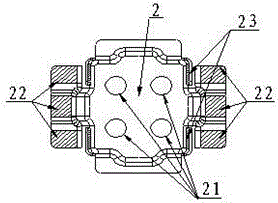

[0028] The mounting bracket 2 is in the shape of an open square box, and the four sides of the mouth are provided with flanging, and are distributed symmetrically with its center, wherein the left and right symmetrical flanging are divided into three second lap joints by two reinforcing ribs respectively. Surface 22, the two sides of the up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com