Power outlet for cordless electric appliance

A technology for cordless electrical appliances and power sockets, applied in circuits, electrical components, parts of connecting devices, etc., can solve problems such as difficulty in use, waste of electricity, and affect the convenience of use, etc. Effects of electric shock hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

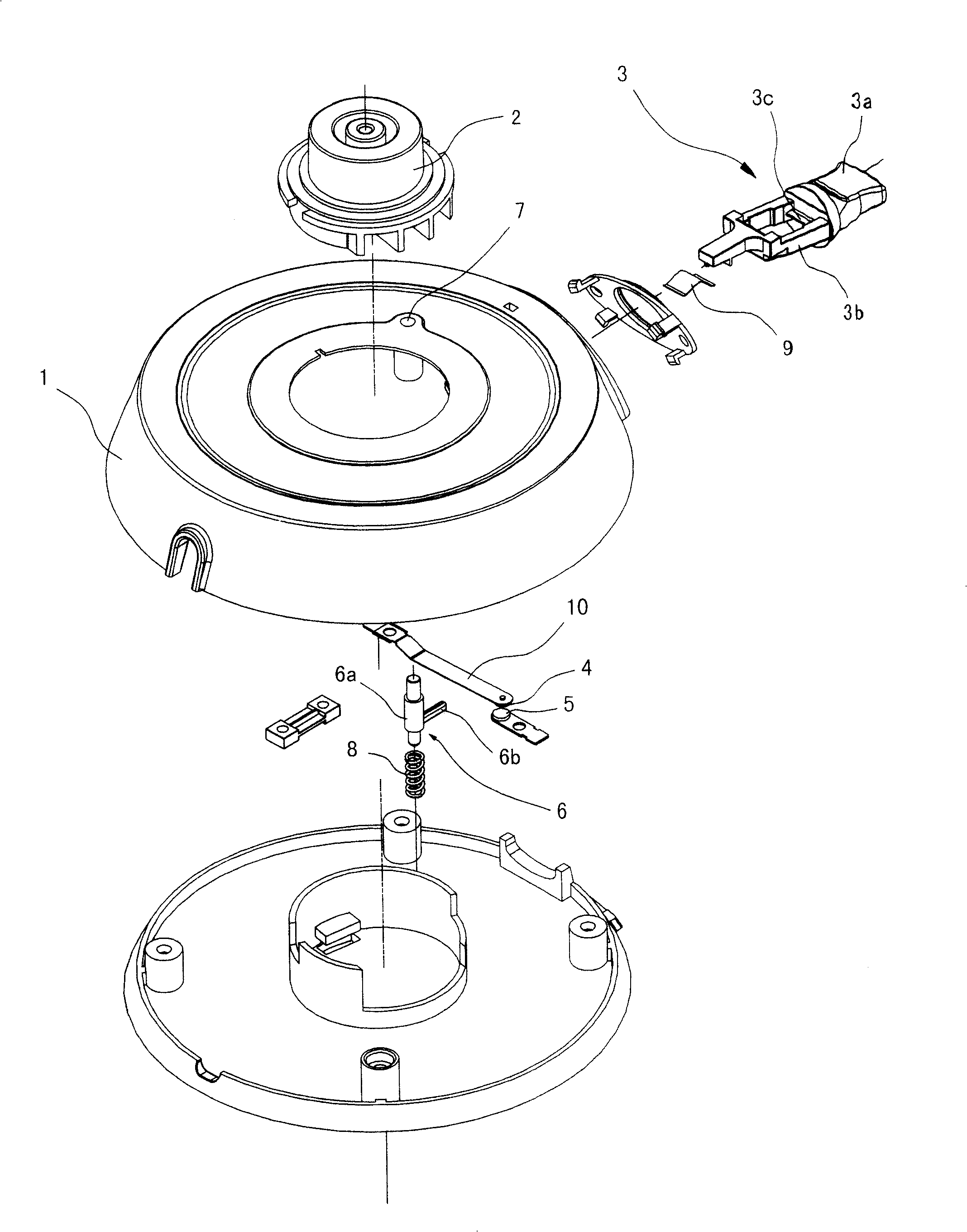

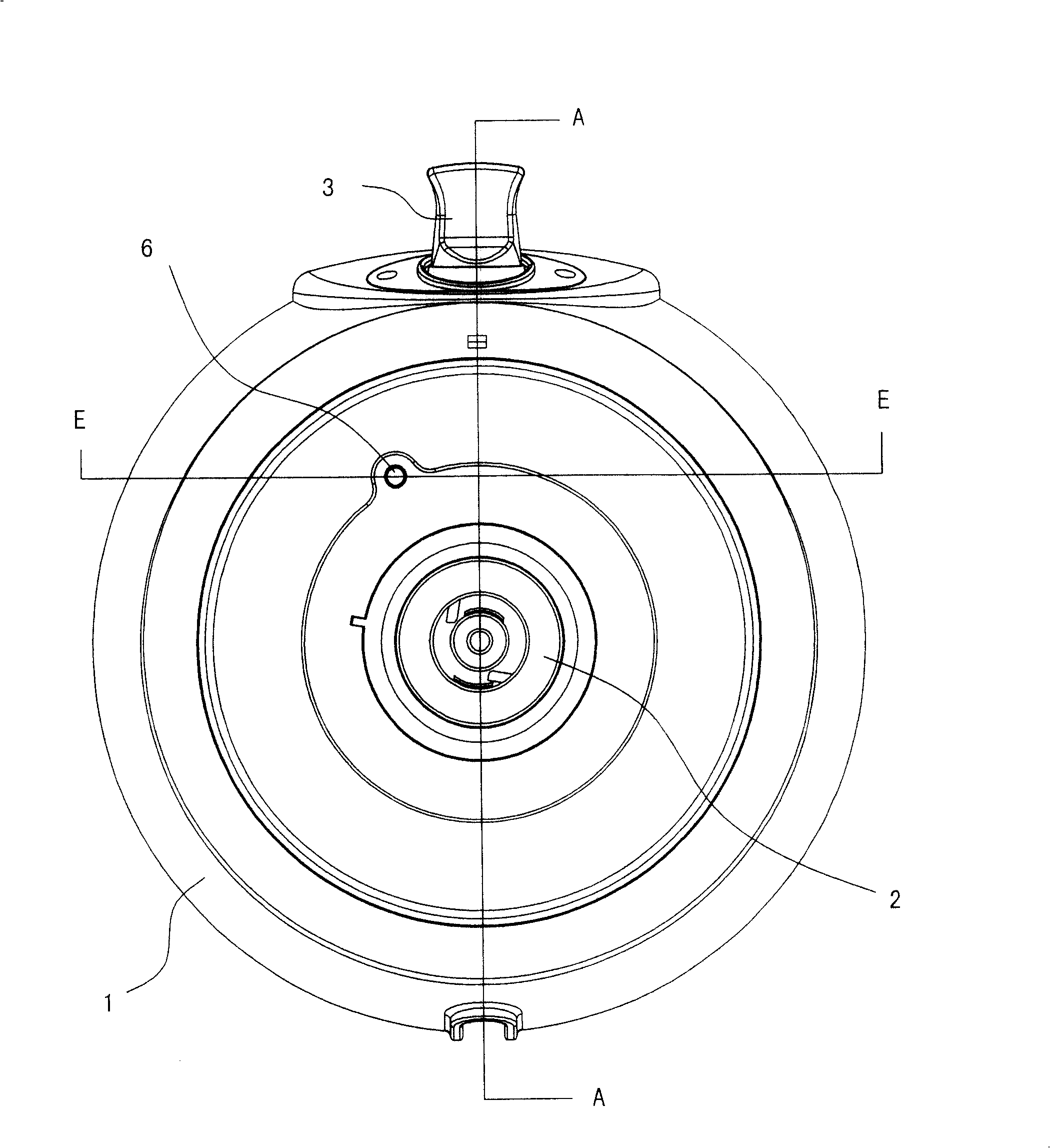

[0031] Such as Figure 1 to Figure 8 As shown, this embodiment is used for the power base of cordless electrical appliances, which has a base body 1, on which a socket body 2 and a manual switch 3 are arranged, and a pair of moving contacts that cooperate with each other are arranged on the live line in the base body 1 4 and the static contact 5 and the corresponding contact opening and closing control mechanism, the contact opening and closing control mechanism includes a control rod 6 and the manual switch 3, the control rod 6 is in the shape of thin middle and thick at both ends, and the seat body 1 The upper end surface is provided with a through hole 7 that can accommodate the upper end of the control rod 6, and the contact opening and closing control mechanism also includes an elastic mechanism that is arranged in the seat body 1 so that the control rod 6 always has a tendency to extend upwards.

[0032] The elastic mechanism includes a coil spring 8, the upper part of t...

Embodiment 2

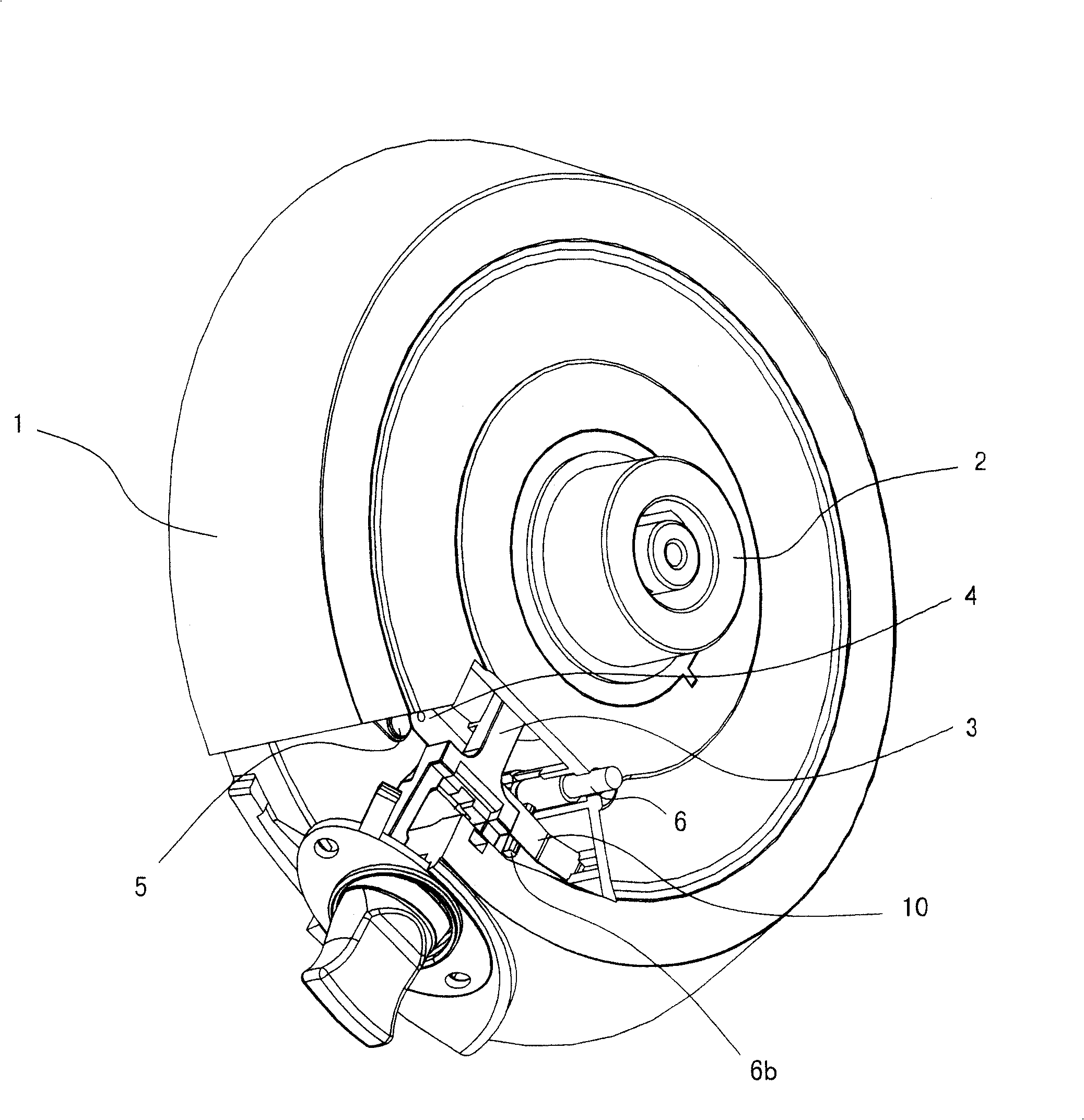

[0036] Such as Figure 9 As shown, and with reference to the drawings in the first embodiment, this embodiment is used for a power base of a cordless electrical appliance. Compared with the first embodiment, the only difference is that the contact opening and closing control mechanism is different.

[0037] The contact opening and closing control mechanism in this embodiment includes a control rod 6 and the manual switch 3. The control rod 6 has a thin shape at both ends and a thick middle. The protruding through hole 7, the contact opening and closing control mechanism also includes an elastic mechanism arranged in the seat body 1 to make the control rod 6 always have a tendency to protrude upward. The movable contact 4 is arranged on the free end of an elastic sheet 10, and the elastic sheet 10 makes the movable contact 4 have a tendency to move upward all the time; the control rod 6 of the contact opening and closing control mechanism is fixed A horizontally arranged shift...

Embodiment 3

[0039] Such as Figure 10 As shown, and with reference to the drawings in the first embodiment, this embodiment is used for a power base of a cordless electrical appliance. Compared with the first embodiment, the only difference is that the contact opening and closing control mechanism is different.

[0040] The contact opening and closing control mechanism in this embodiment includes a control rod 6 and the manual switch 3. The control rod 6 has a thin shape at both ends and a thick middle. The protruding through hole 7, the contact opening and closing control mechanism also includes an elastic mechanism arranged in the seat body 1 to make the control rod 6 always have a tendency to protrude upward. The movable contact 4 is arranged on the free end of an elastic sheet 10, and the elastic sheet 10 makes the movable contact 4 always have a tendency to move downward; Fixedly connected with a horizontally arranged driving rod 6b; the front end of the manual switch 3 and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com