Marine gas hydrate electronic-spraying pump composite exploitation method and apparatus

A hydrate and natural gas technology, which is applied in the mining of minerals, earthwork drilling, special mining, etc., can solve the problems of low equipment reliability, small heating area and high cost, and achieves stable working conditions without sand burial and hydrate blockage. , the effect of simple production structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

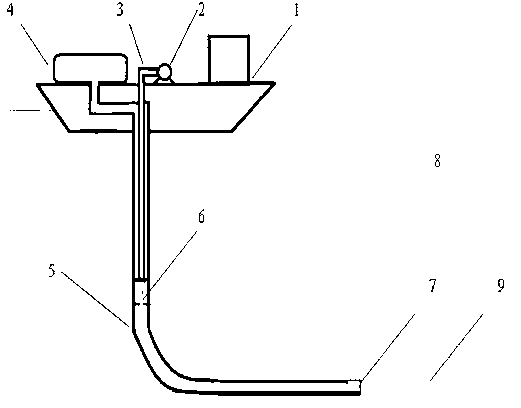

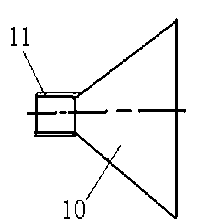

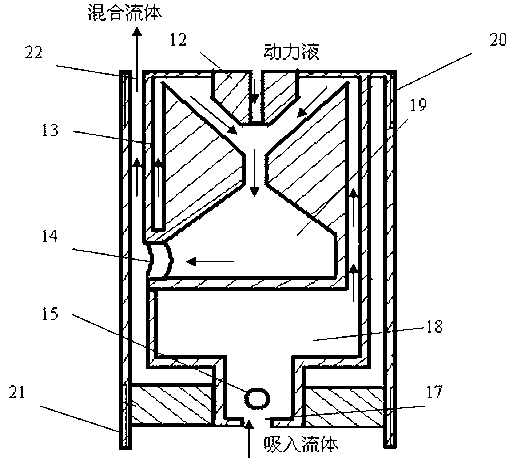

[0015] see figure 1 The sea surface gas production platform or ship 1 is on the sea surface of seawater 8, and an electric centrifugal pump 2 and a multiphase separation and storage system 4 for natural gas are installed on the sea surface gas production platform or ship 1 . The multi-phase separation and storage system 4 is connected to the subsea natural gas hydrate and sediment mixed layer 9 under the seawater 8 through the gas production pipeline 5, and the jet pump 6 is connected in series on the gas production pipeline 5, the jet pump 6 is located under the sea surface, and the jet pump 6 Become a part of the gas production pipeline 5, and divide the gas production pipeline 5 into upper and lower sections. The electric centrifugal pump 2 is connected to the jet pump 6 through the power fluid pipeline 3 , and the power fluid pipeline 3 is hollowly sleeved in the gas production pipeline 5 . The electric centrifugal pump 2 is connected to the upper end of the power fluid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com