Rope wheel type glass lifter with modularized structural design and design method for rope wheel type glass lifter

A glass lifter and structural design technology, applied in the direction of building structure, power control mechanism, wing leaf control mechanism, etc., can solve the complex product structure and parts, low design efficiency, increase mold material process and management costs, etc. problems, to achieve the effect of reducing the number of tooling, simplifying the changeable production process, and shortening the product design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

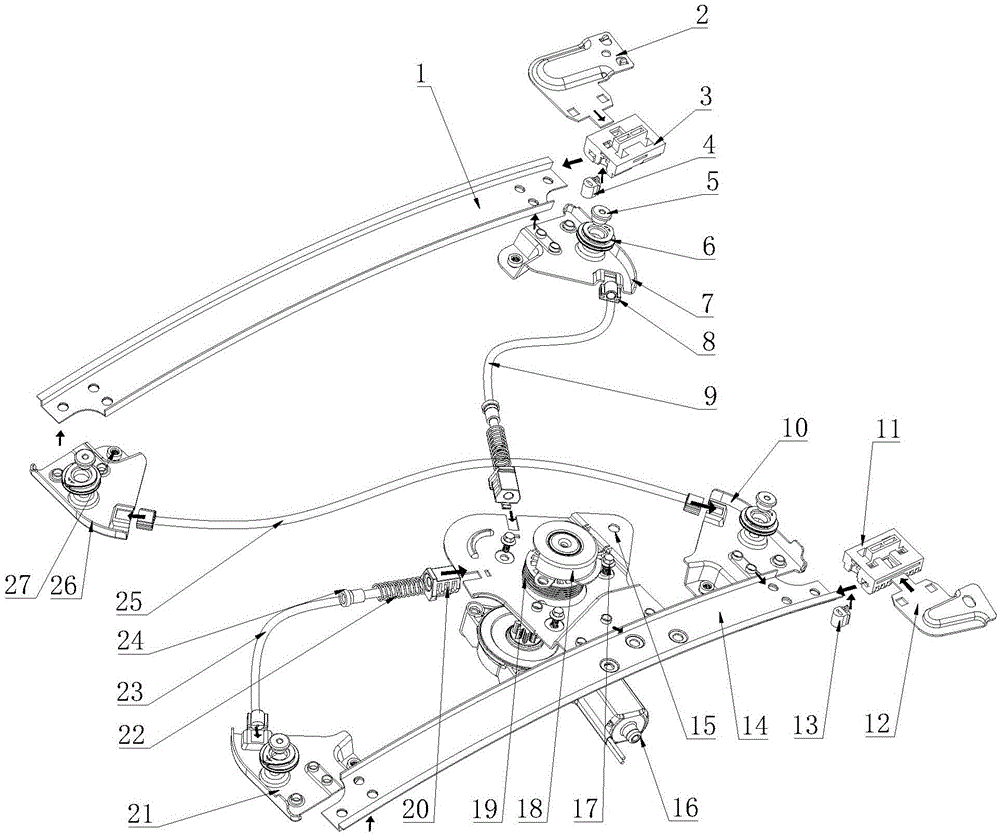

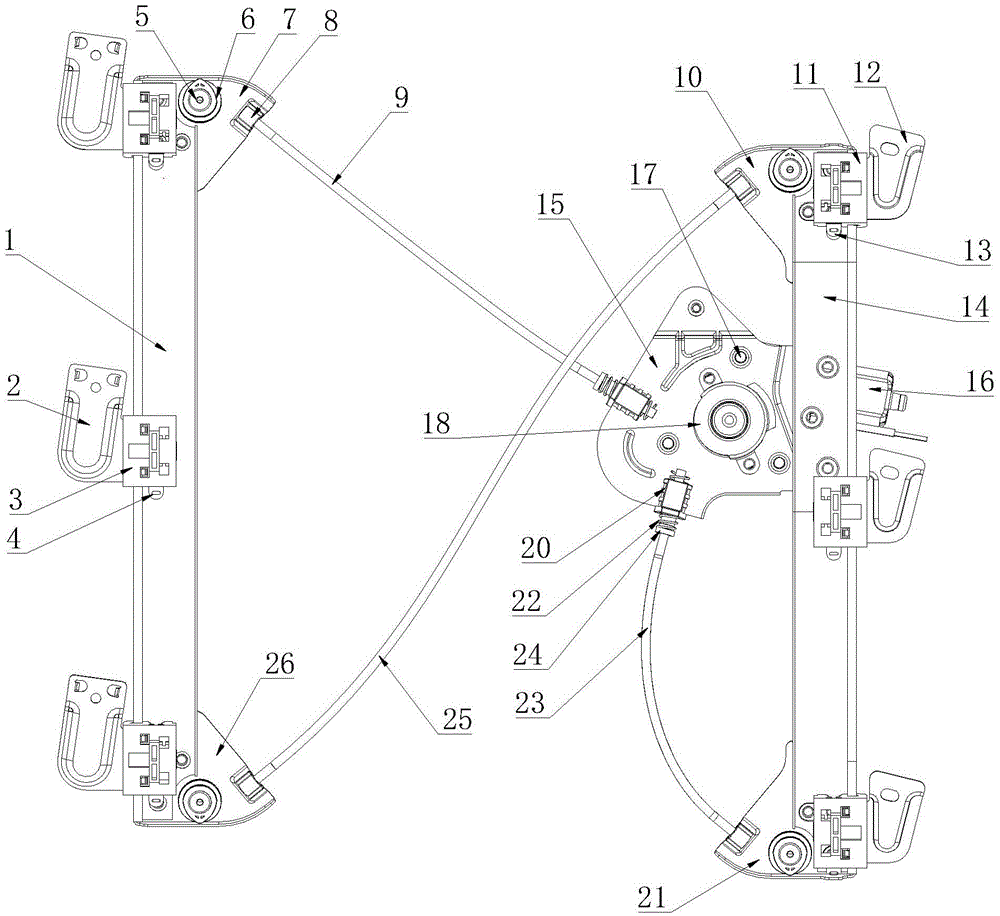

[0034] see Figure 1-2 , a sheave-type glass regulator with a modular structure design, including a first rolling guide rail 1, a first guide rail drive assembly, a first guide rail upper bracket 7, an upper pressure tube assembly 9, a second guide rail upper bracket 10, The second guide rail drive assembly, the second rolling guide rail 14, the motor 16, the reel 19, the second guide rail lower bracket 21, the lower pressure tube assembly 23, the middle pressure tube assembly 25 and the first guide rail lower bracket 26; The first guide rail drive assembly is slidably installed on the first rolling guide rail 1. The first guide rail drive assembly includes the first slider bottom plate 2 and the first slider 3. The first slider 3 is slidably installed on the first rolling guide rail. 1, the first slider bottom plate 2 is fixed on the first slider 3, and the first slider bottom plate 2 is used to be fixedly connected to the automobile glass, so that when the first slider 3 sli...

Embodiment 2

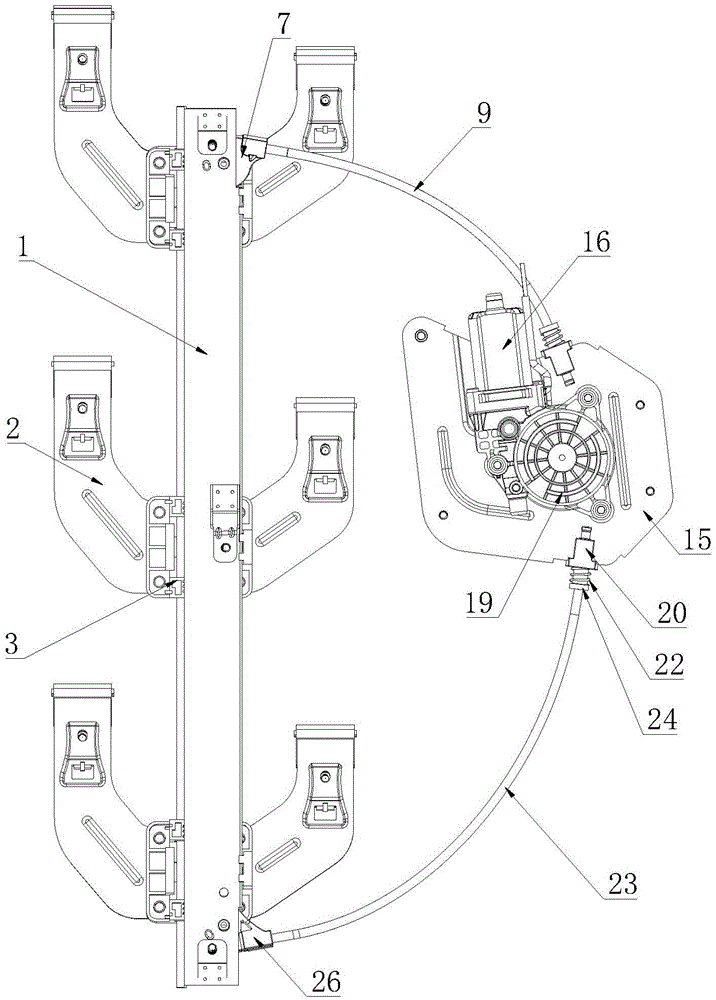

[0057] see image 3 , a sheave-type glass lifter designed for a single guide rail modular structure, the design method is the same as that of Embodiment 1.

[0058] The significance of the present invention lies in that all sheave-type electric window regulators can be realized by combining standard modules. That is to say, on the premise that all products work on the same principle, the product structure design is completed through the combination of standard modules, which avoids the arbitrariness of component structure design due to different models, thus forming a standard design specification, more than 80% Parts are universal in nature. Since more than 80% of the parts in product design and production are mature modules that have been tested in practice, it completely avoids the high cost and quality risks caused by the changeable product structure and style caused by the variety of parts in the past due to different models and complex and changeable production processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com