Mounting and adjusting device for pouring of solid propellant combustion chamber

A solid propellant, installation and adjustment technology, applied in jet propulsion, rocket engine, transportation and packaging, etc., can solve problems such as increased production and management costs, safety risks, easy to cause fire, etc., to reduce production costs and The effect of managing costs, eliminating safety hazards, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

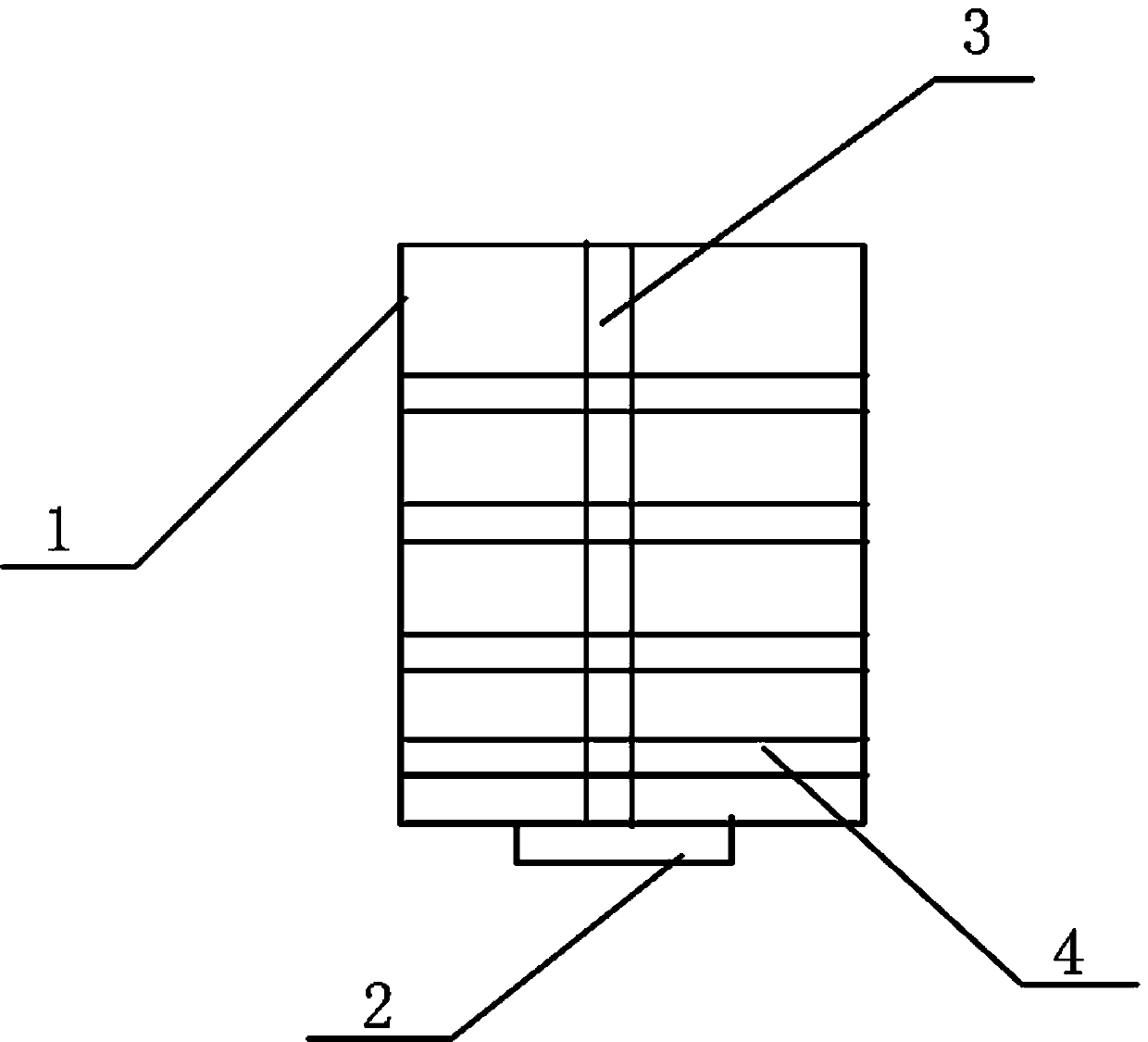

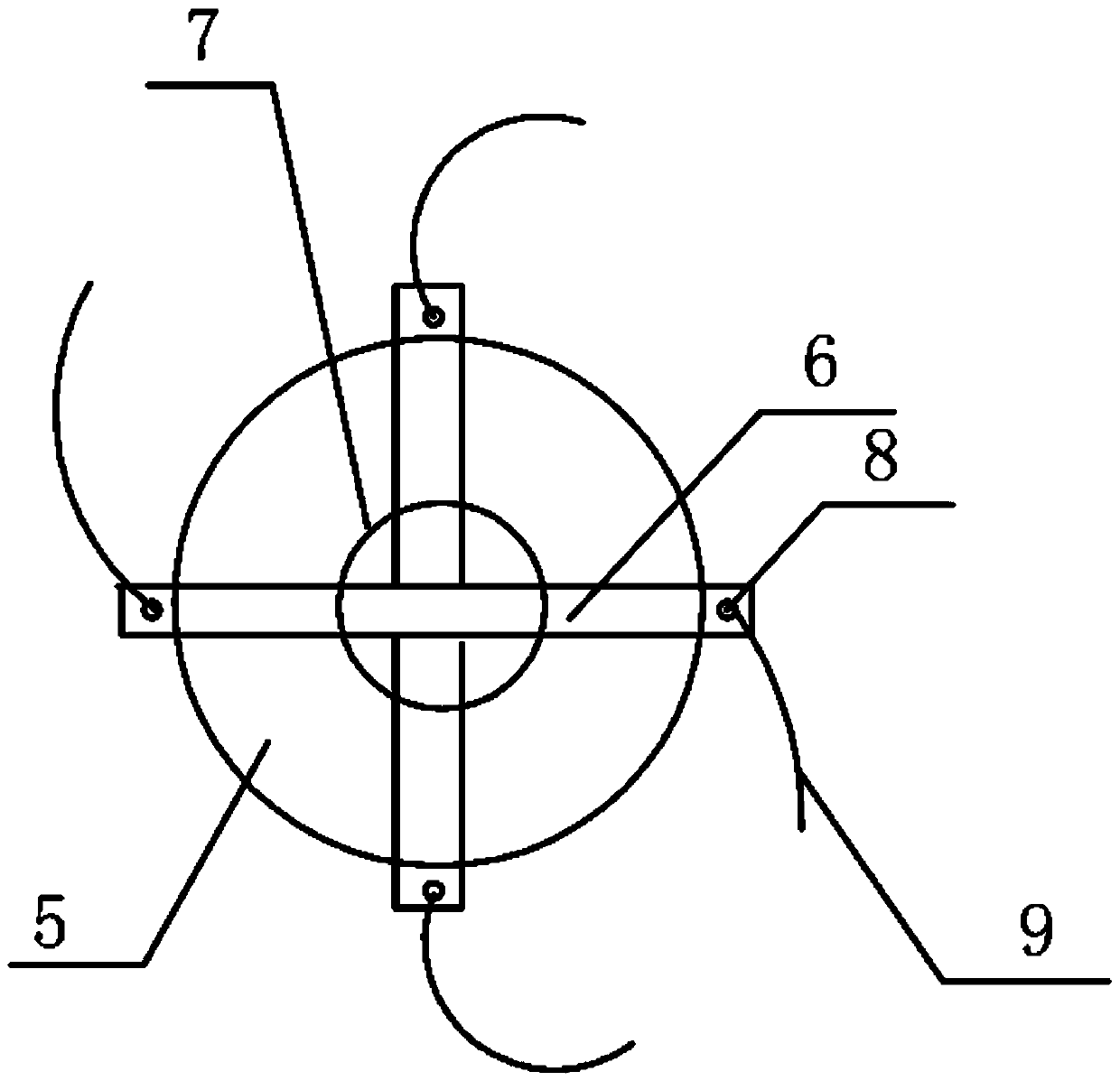

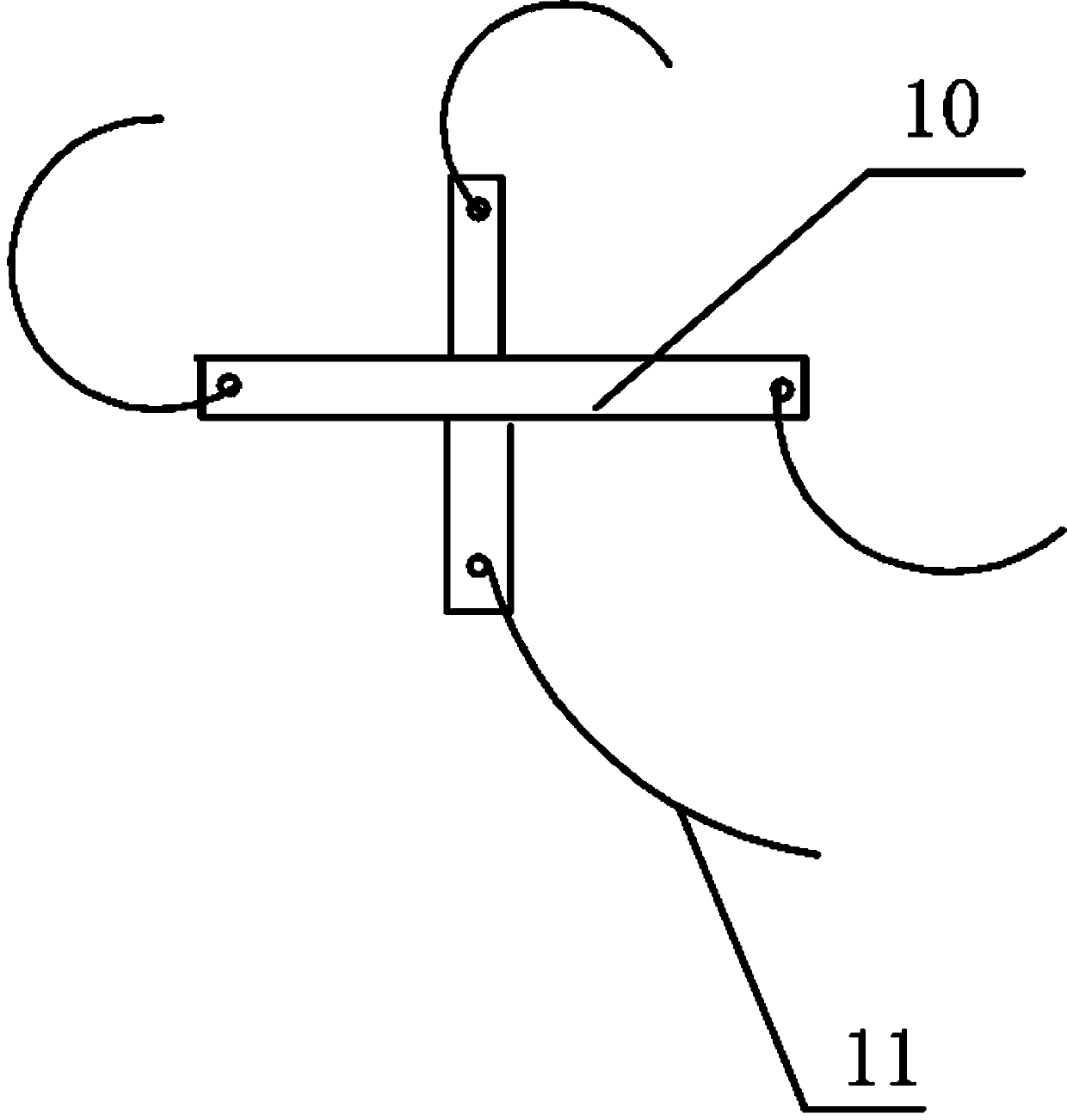

[0024] Such as Figure 1-3 As shown, a pouring installation adjustment device for a solid propellant combustion chamber includes a pouring cylinder 1, which is cylindrical and hollow inside, and a hydraulic lifting platform 2 is installed at the bottom. The side wall of the pouring cylinder 1 is evenly distributed in the axial direction. The guide groove 3 has a plurality of annular grooves 4 distributed in the radial direction, and the guide grooves and the annular grooves are arranged vertically and alternately on the inner side of the side wall; The central part of 6 is equipped with bearing 7.

[0025] Further, the load-bearing beam is a cross load-bearing beam, and there are four guide grooves, and the width of the guide grooves matches the width of the cross load-bearing beam.

[0026] Further, a hole 8 is opened at the end of the load-bearing beam, and a wire rope 9 is connected to the hole, and the wire rope is connected to a lifting device.

[0027] Further, the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com