Patents

Literature

51results about How to "Pouring precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

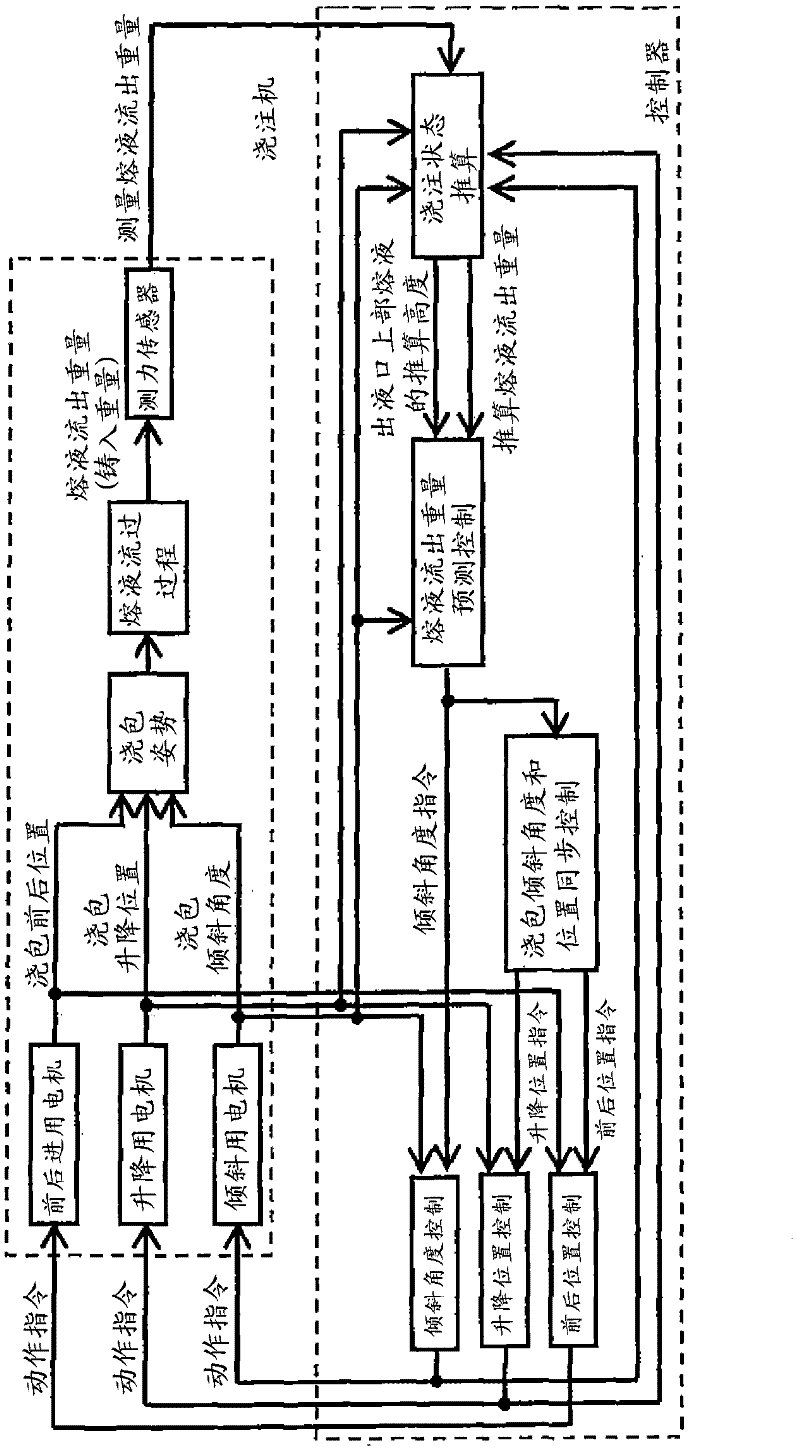

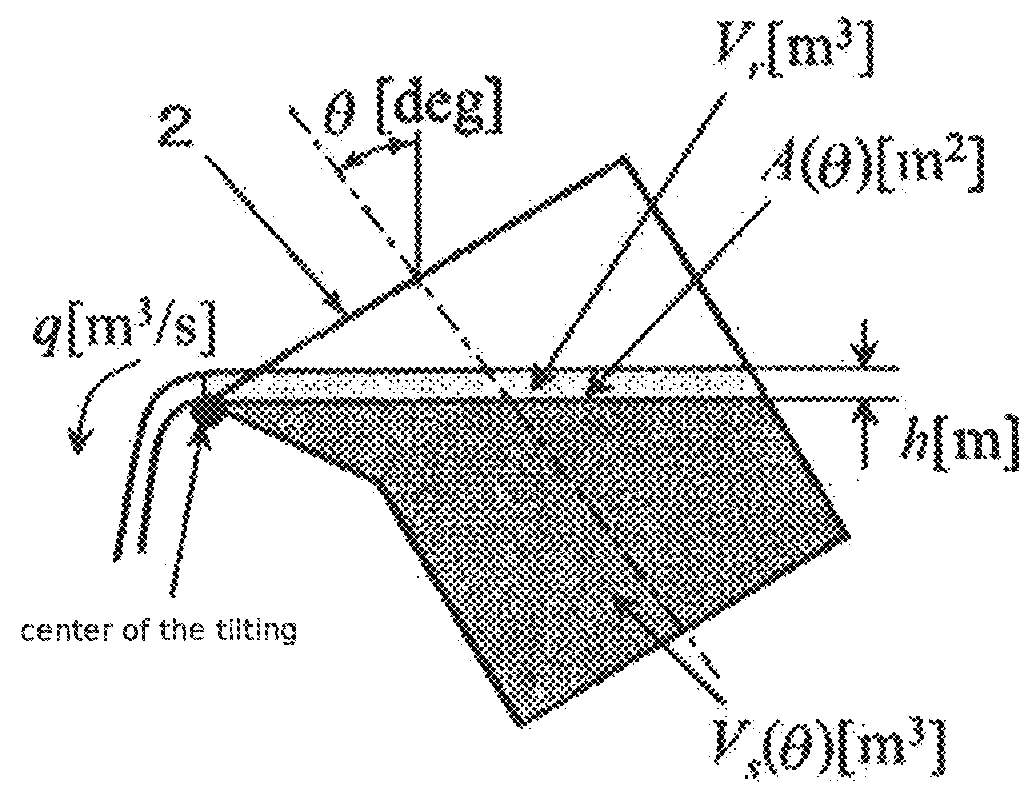

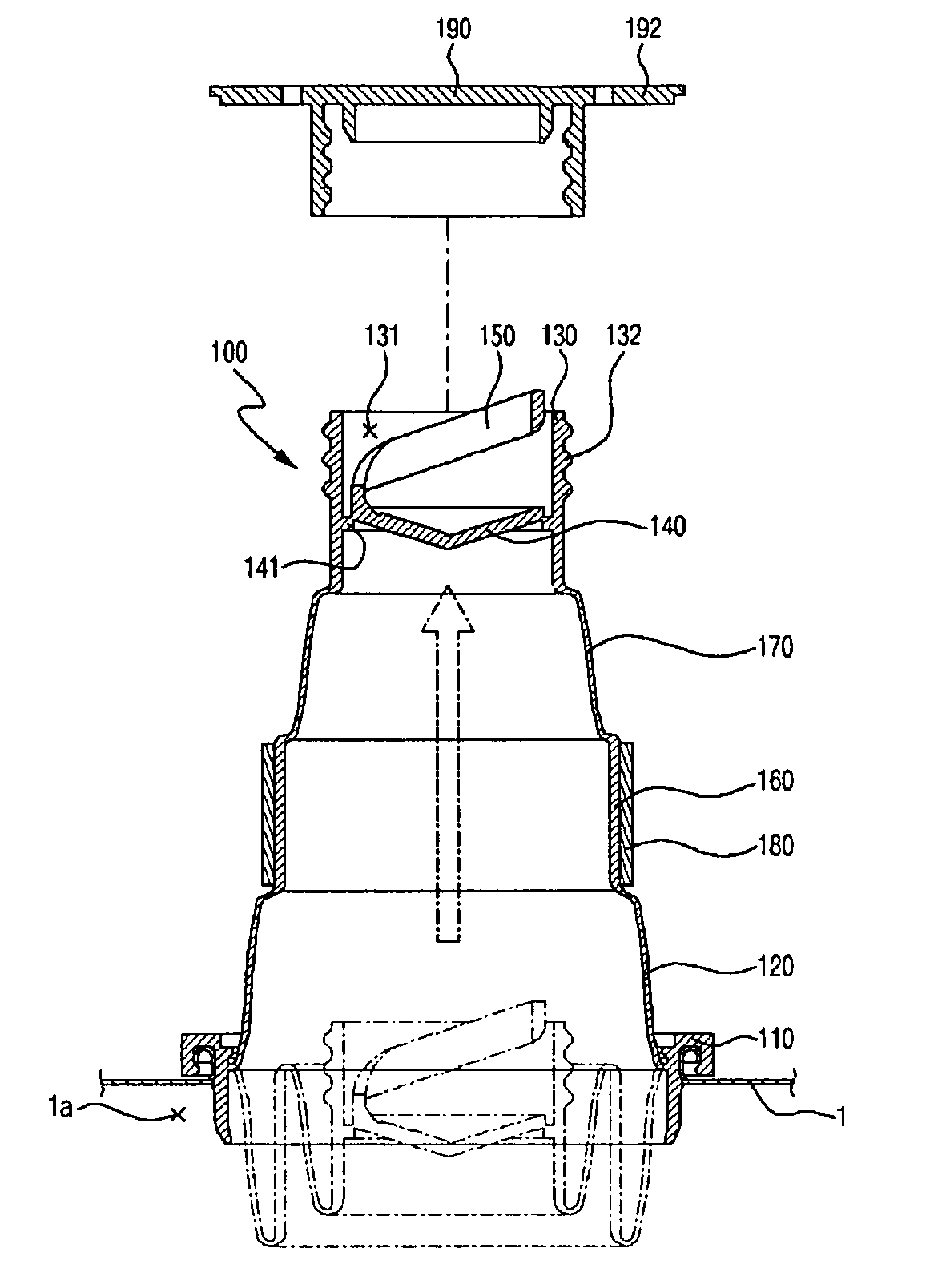

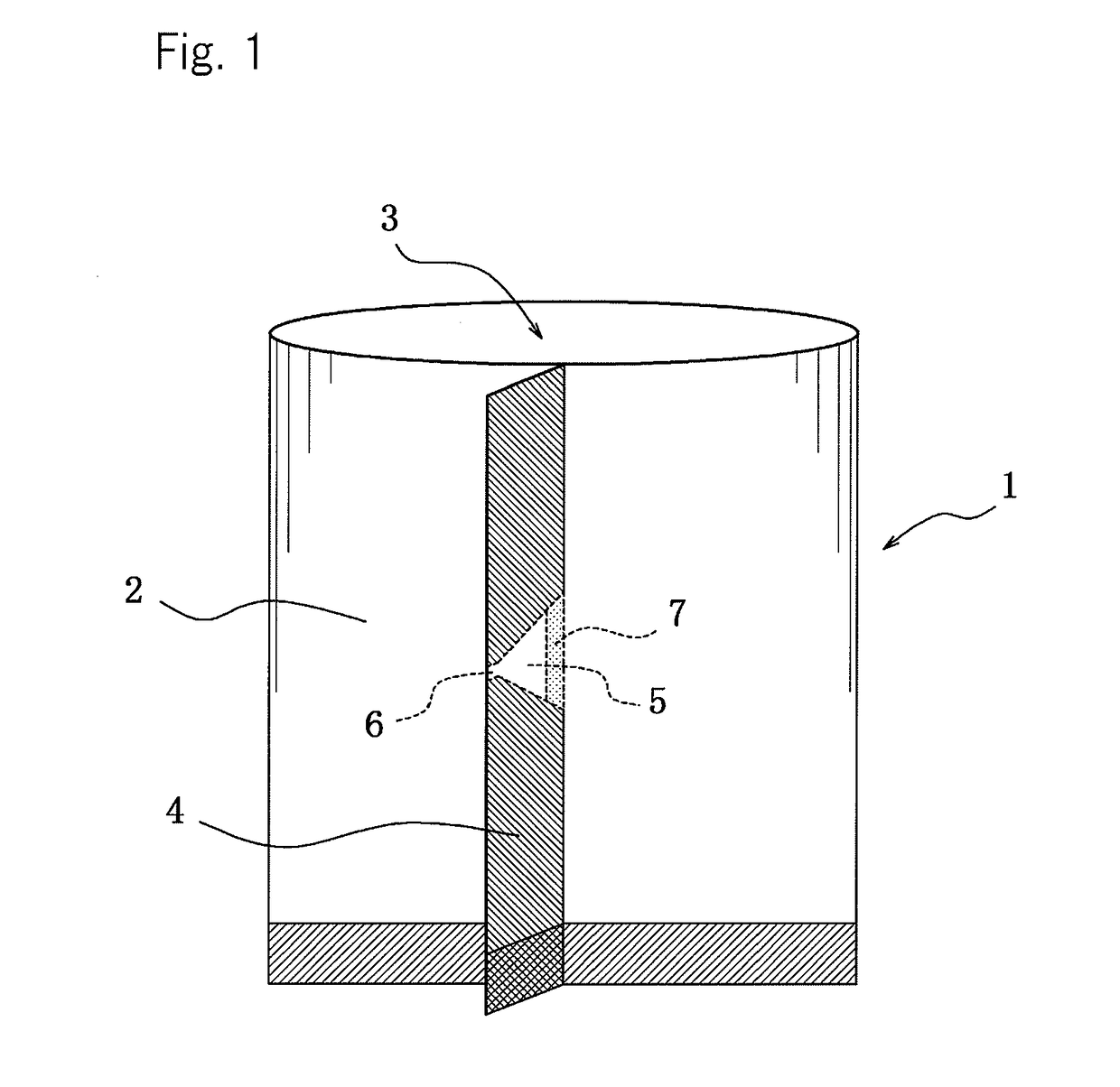

Tilting-type automatic molten metal pouring method, tilting control system, and storage medium having tilting control program stored therein

ActiveCN102448640AAccurate predictionPouring precisionMelt-holding vesselsMolten metal pouring equipmentsKaiman filterMetallurgy

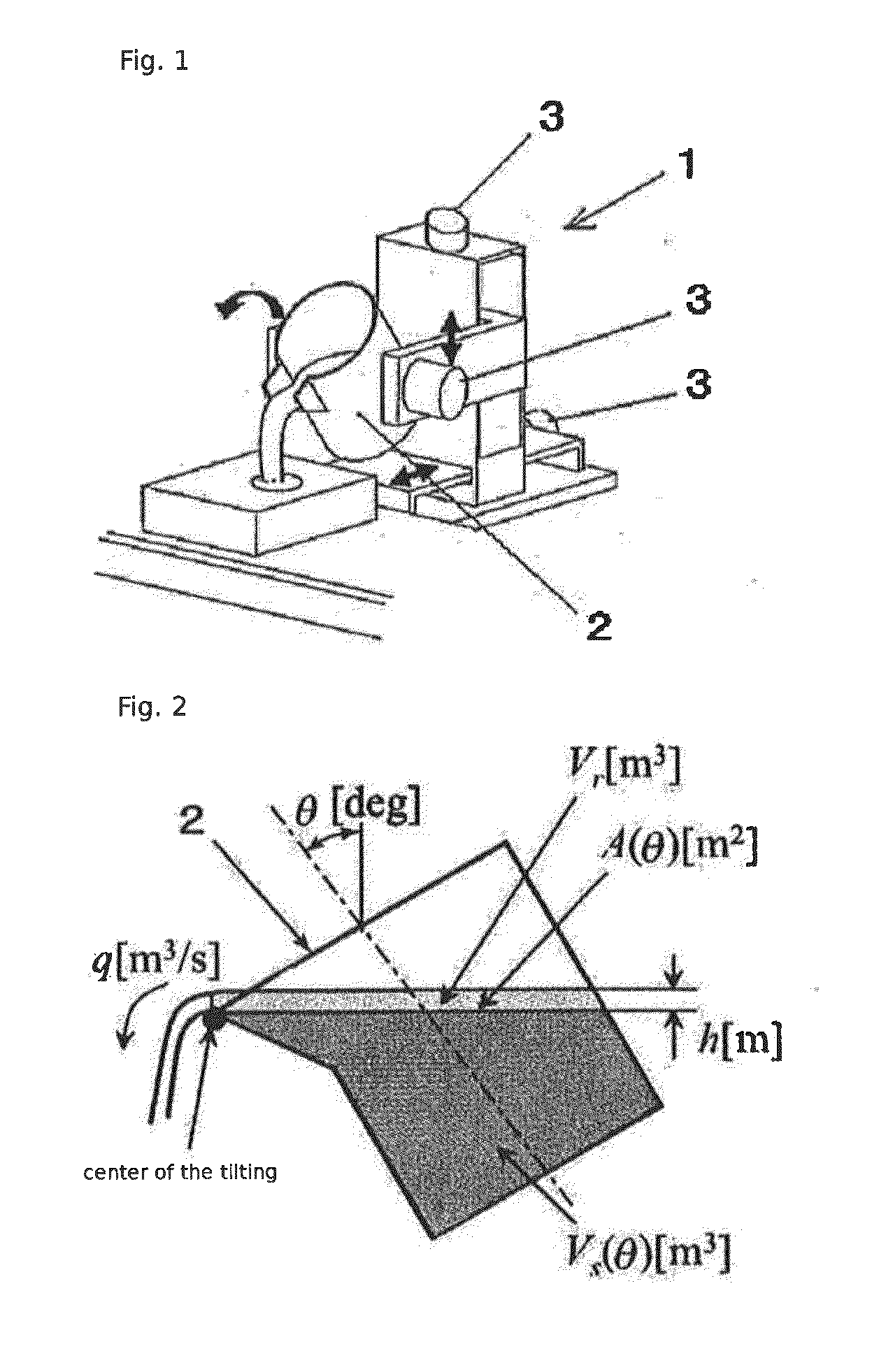

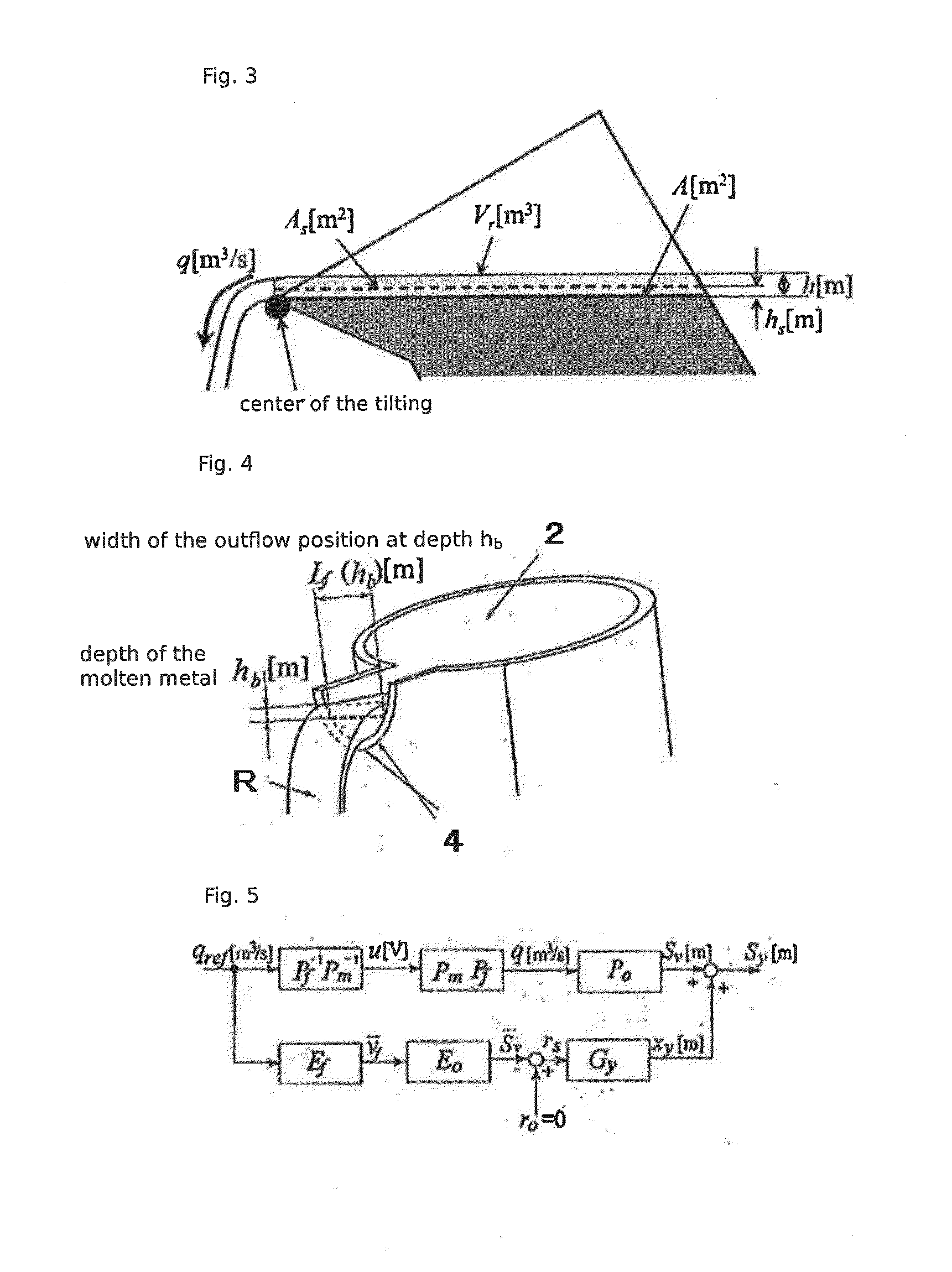

A method of automatically pouring molten metal from a ladle into a mold by tilting the ladle. In the method, the height of molten metal located above a molten metal outlet and the weight of molten metal flowing out of the ladle are estimated using an expanded Kalman filter on the basis of: the weight of the molten metal flowing out of the ladle, said weight being measured using a load cell; the voltage inputted to a servo motor; the angle of tilt of the ladle measured by a rotary encoder; and the position of the ladle in the lifting and lowering direction thereof. The sum of the weight of the molten metal flowing out of the ladle when the ladle is tilted rearward, said weight being estimated from the angle of tilt of the ladle and the height of the molten metal located above the molten metal outlet estimated by the expanded Kalman filter, and the weight of the molten metal flowing out of the ladle estimated by the expanded Kalman filter are estimated as the final weight of outflowing molten metal. The estimated final weight of outflowing molten metal is determined whether or not to be greater than or equal to a specific weight of outflow, and the operation of rearward tilting of the ladle is started on the basis of the result of the determination.

Owner:SINTOKOGIO LTD +1

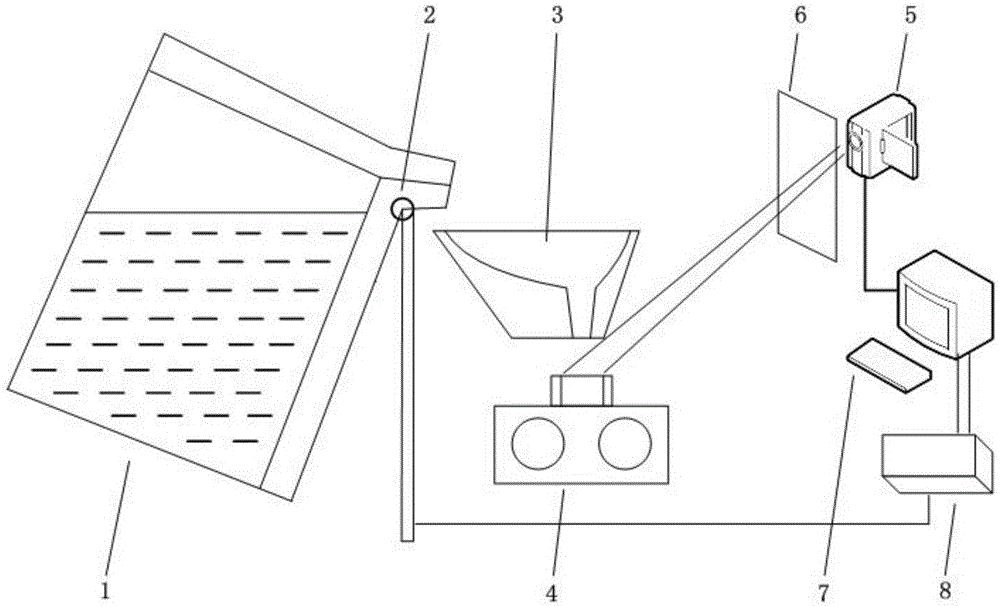

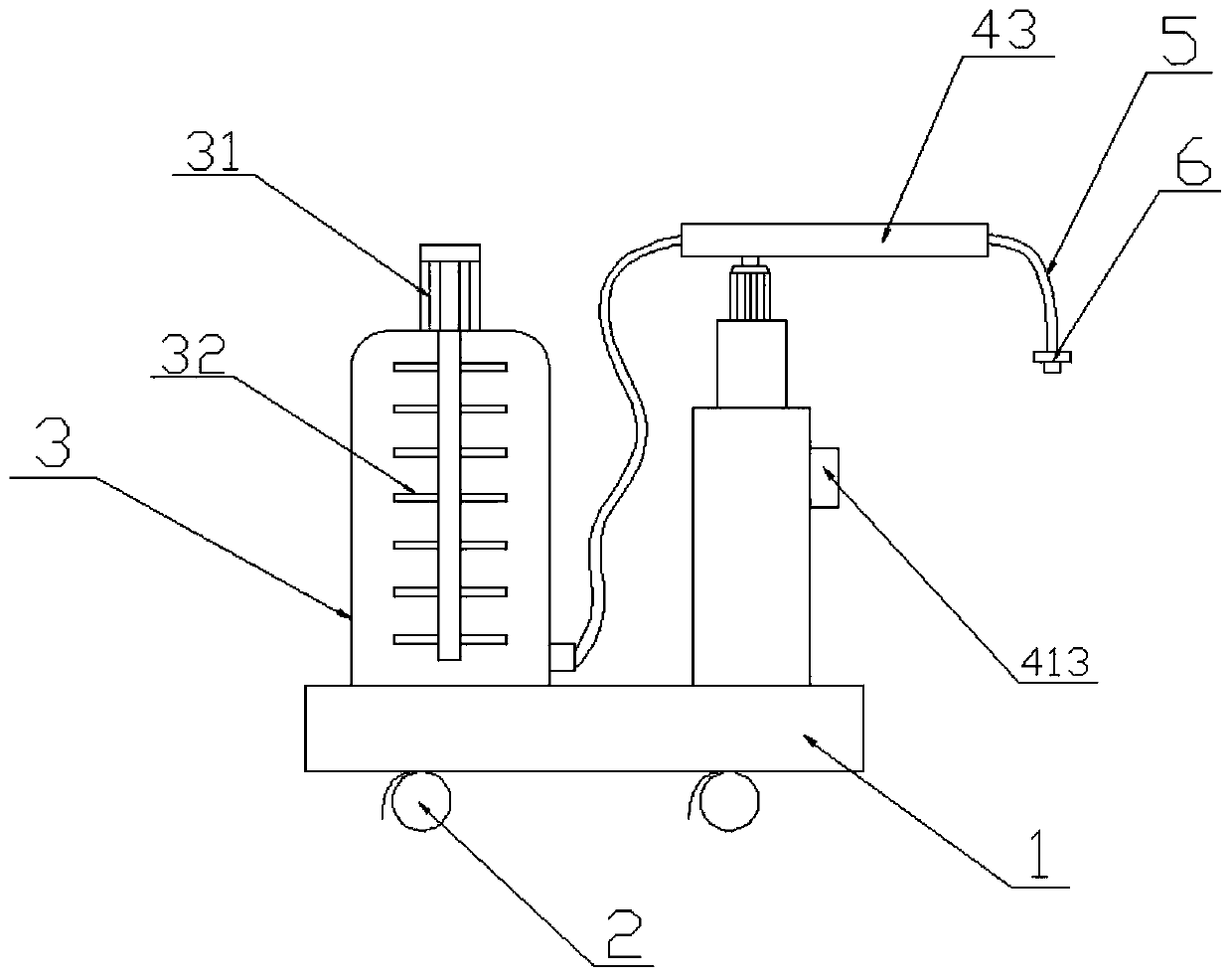

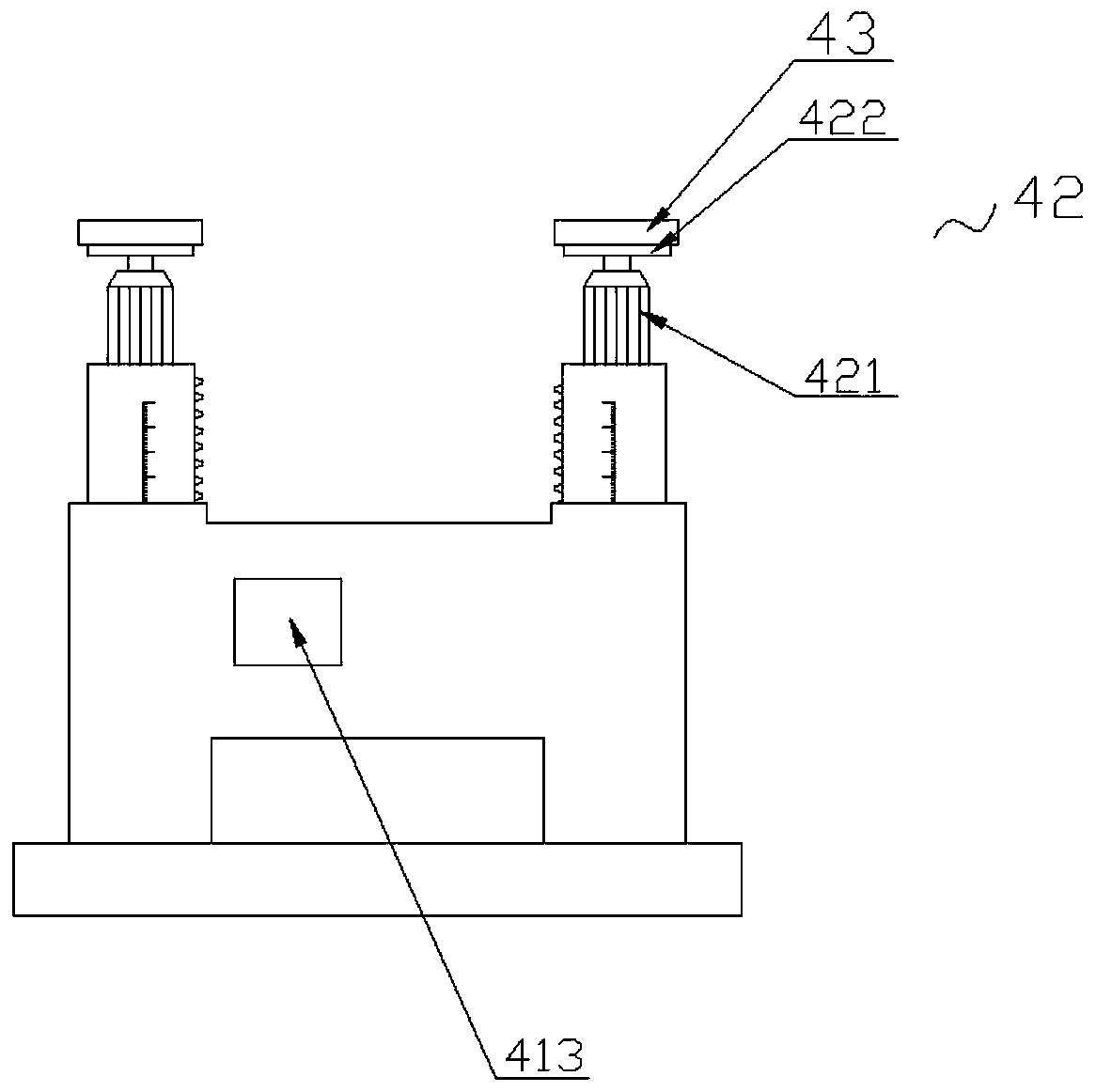

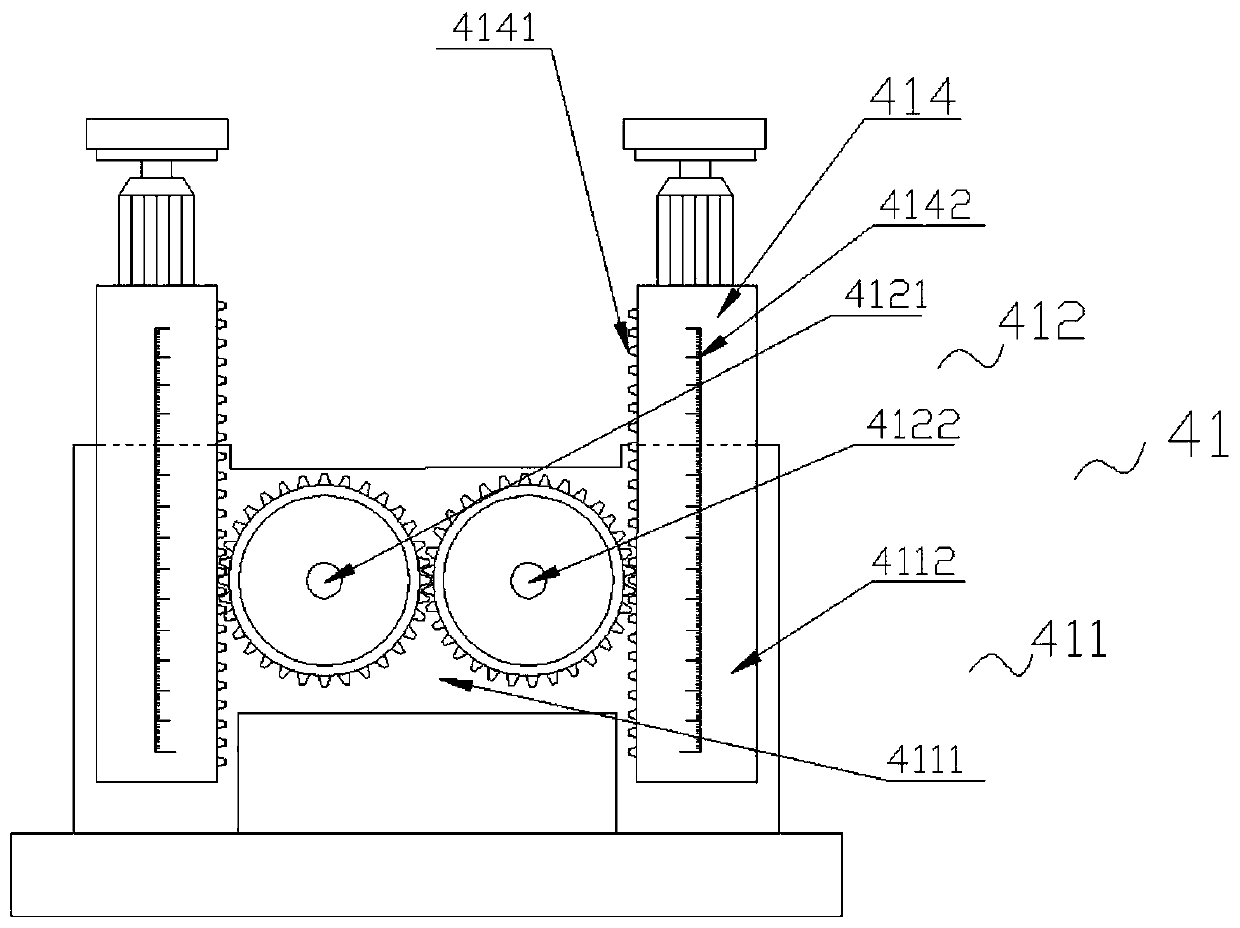

Automatic pouring method and system for heat preserving furnace pouring platform

InactiveCN105478737APouring Precise ControlPrecise control of pouring platform automatic pouringMolten metal pouring equipmentsMetallurgyMolten steel

The present invention relates to the production field of casting technique, in particular to an automatic pouring method and system for a heat preserving furnace pouring platform. By collecting an inclined effluent angle of a heat preserving furnace of the heat preserving furnace pouring platform, a pouring reference datum angle of the heat preserving furnace satisfying the pouring amount is obtained. If the inclined angle of the heat preserving furnace is equal to the pouring reference datum angle, the heat preserving furnace stops inclining. After a predetermined time, a molten steel image from a diversion trench discharge hole to a pouring mold gate is collected, and a molten steel flow velocity value is obtained according to the molten steel image. The extracted molten steel flow velocity value is compared with a corresponding predetermined velocity range. When the molten steel flow velocity value exceeds the corresponding predetermined velocity range, the inclined pouring angle of the heat preserving furnace is adjusted to control the flow velocity of the molten steel within the corresponding predetermined velocity range, so as to solve the problems of the existing technology that the inaccurate control on the pouring angle causes molten steel waste when the heat preserving furnace automatically pours, and the pouring efficiency is low.

Owner:湖南华民控股集团股份有限公司

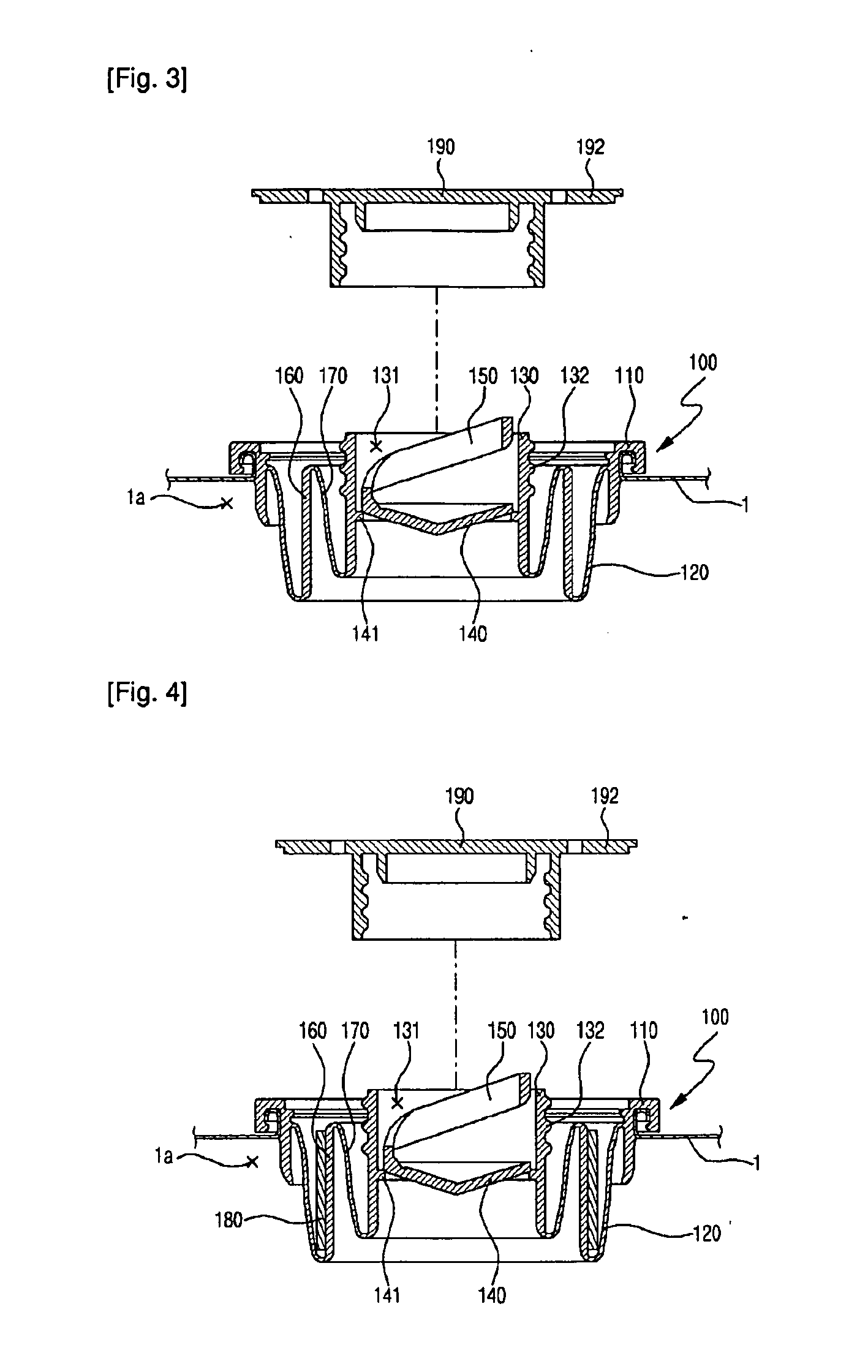

Spout cap having two steps type straw part

This invention discloses a spout cap having a two steps type straw part to easily pour contents in a metal container in the desired place. This invention comprises: a coupling part fixedly coupling with the pouring hole of the metal container, a first straw part extending at a predetermined length on the interior face of said coupling part; a cap coupling part having a pouring outlet through which contents in said metal container flow out, wherein said cap coupling part is selectively positioned in an overlapped disposition or an unfolded disposition with respect to said first straw part; an extension part arranged between said first straw part and said cap coupling part, wherein said extension part is capable of extending the unfolded length when said cap coupling part is unfolded with respect to said first straw part; a second straw part extended from the upper inner face of said extension member at a predetermined length and coupled with the lower end of said cap coupling part; and a can plug coupling with said cap coupling part. In order to retain the outermost diameter and the entire assembly height of the spout cap according to this invention as the same as the prior art spout cap, and to extend the height of the pouring outlet to twice or more as compared with the prior art spout cap, the straw parts by which contents in the container are flowed out are constructed as a two steps type so that contents in the container can be correctly poured into the desired place.

Owner:DAE RYUK CAN

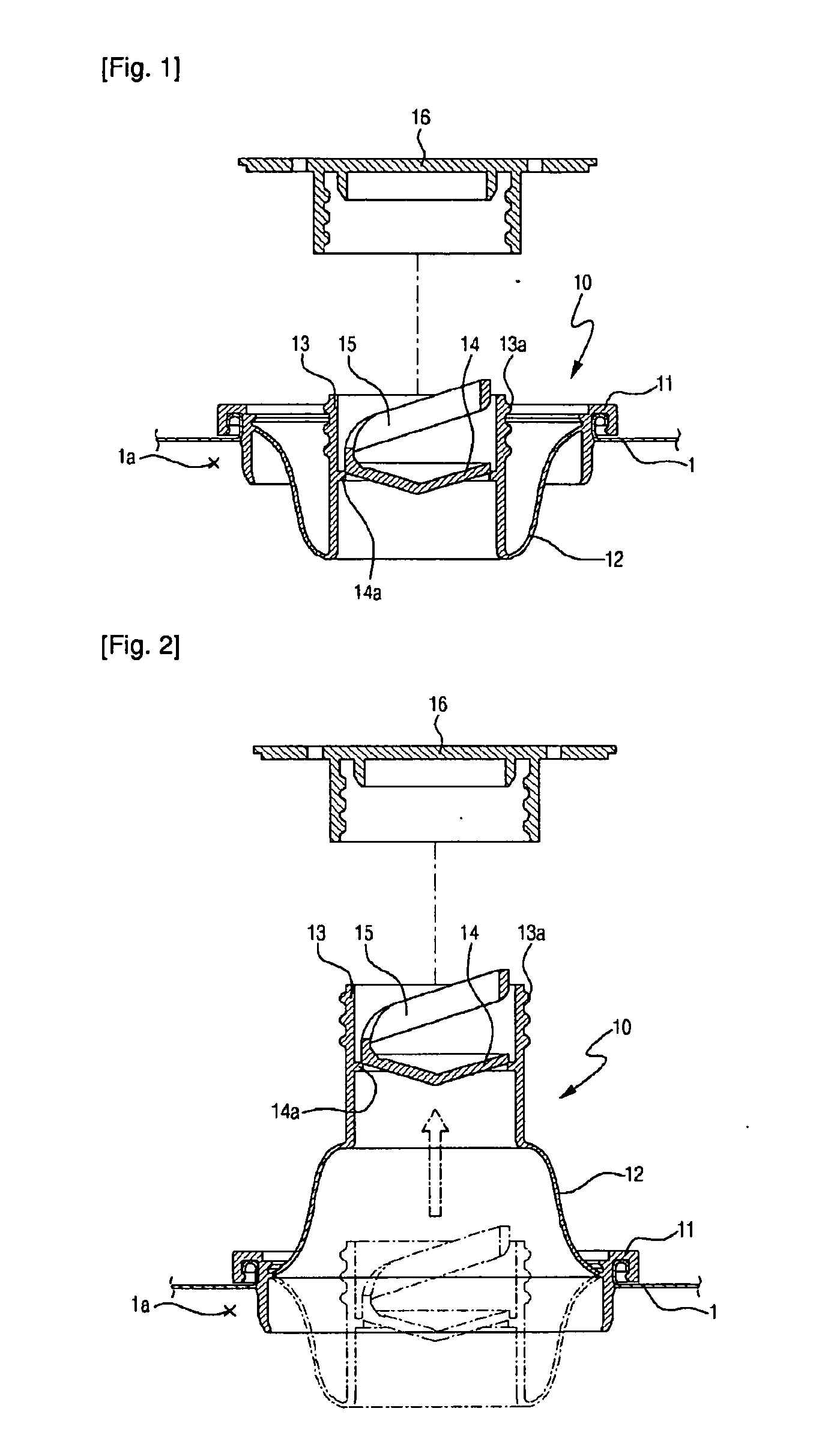

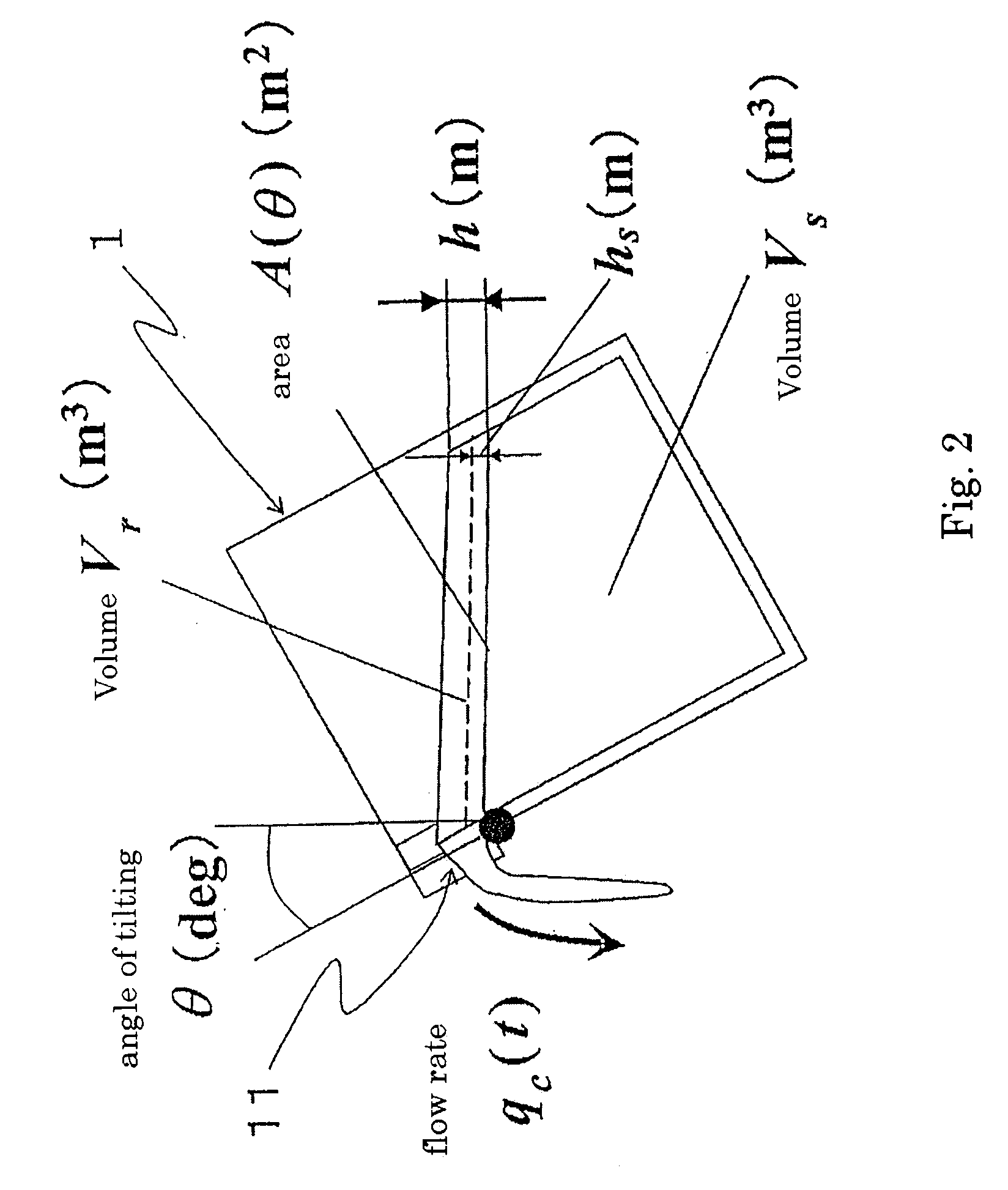

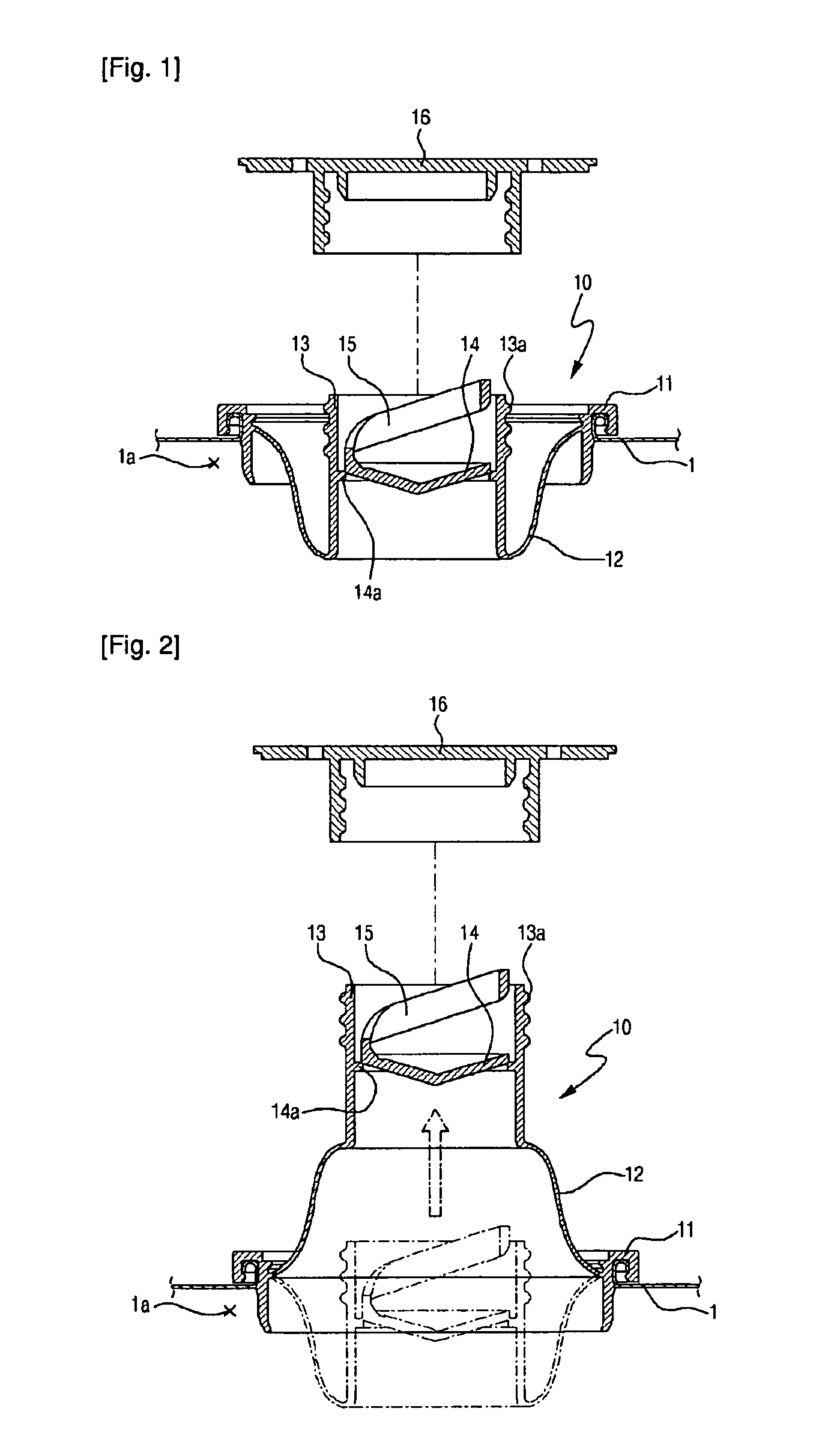

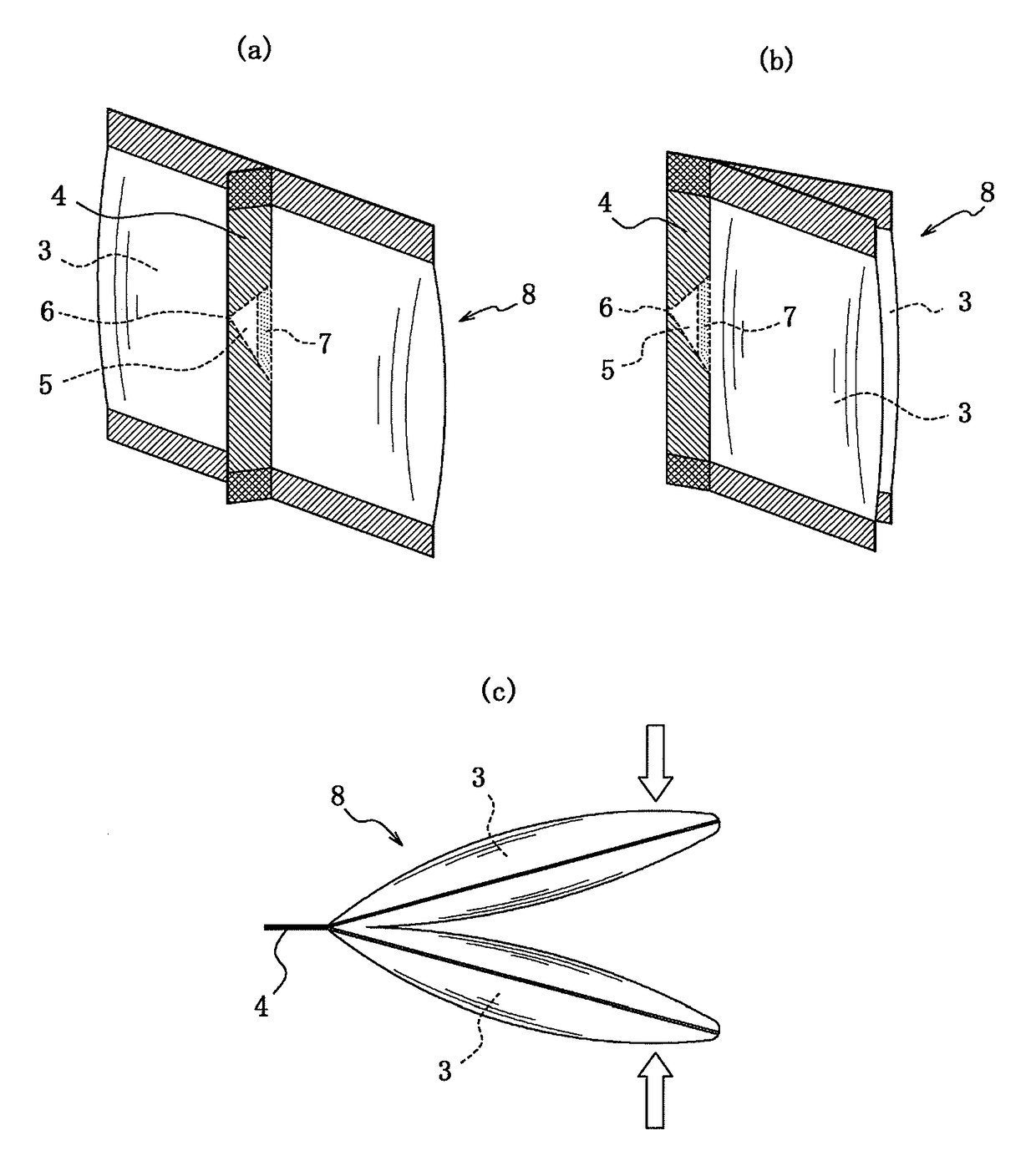

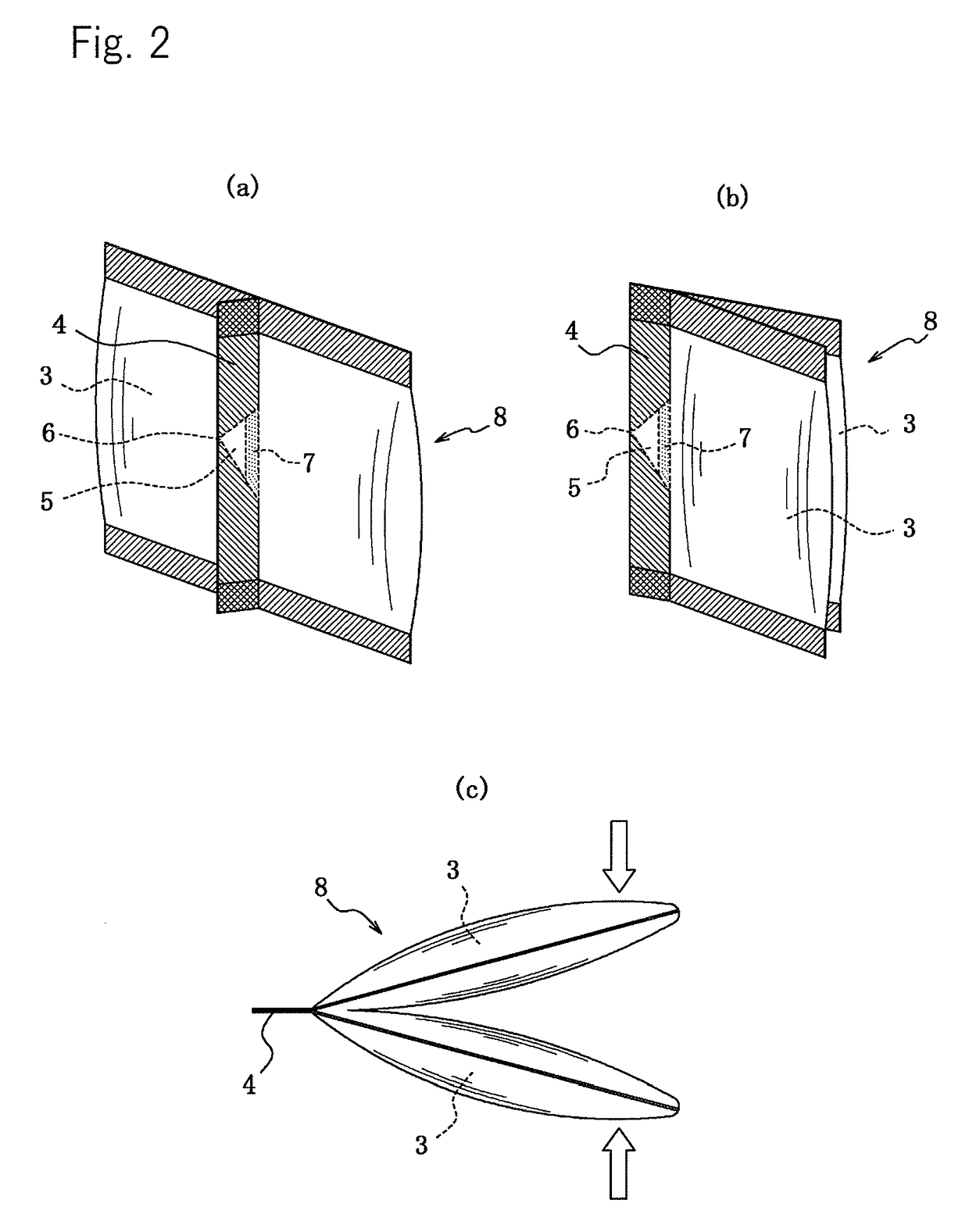

Tilting-type automatic pouring method and storage medium

ActiveUS20100133302A1Keep for a long timeAccurate weighingMelt-holding vesselsMolten metal pouring equipmentsMetallurgyHeight decrease

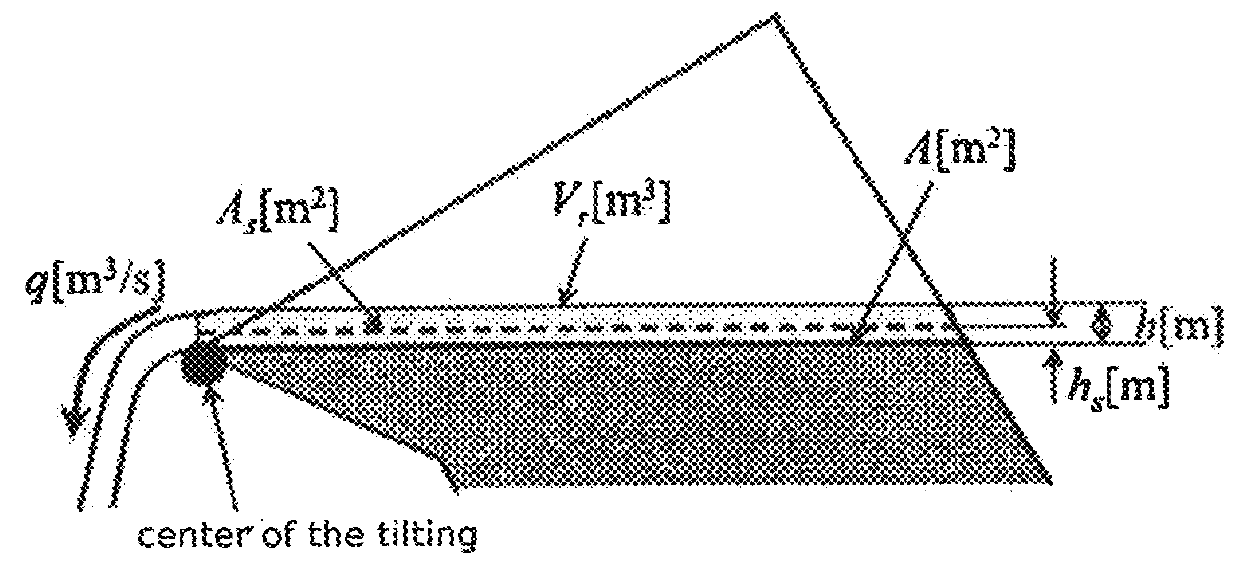

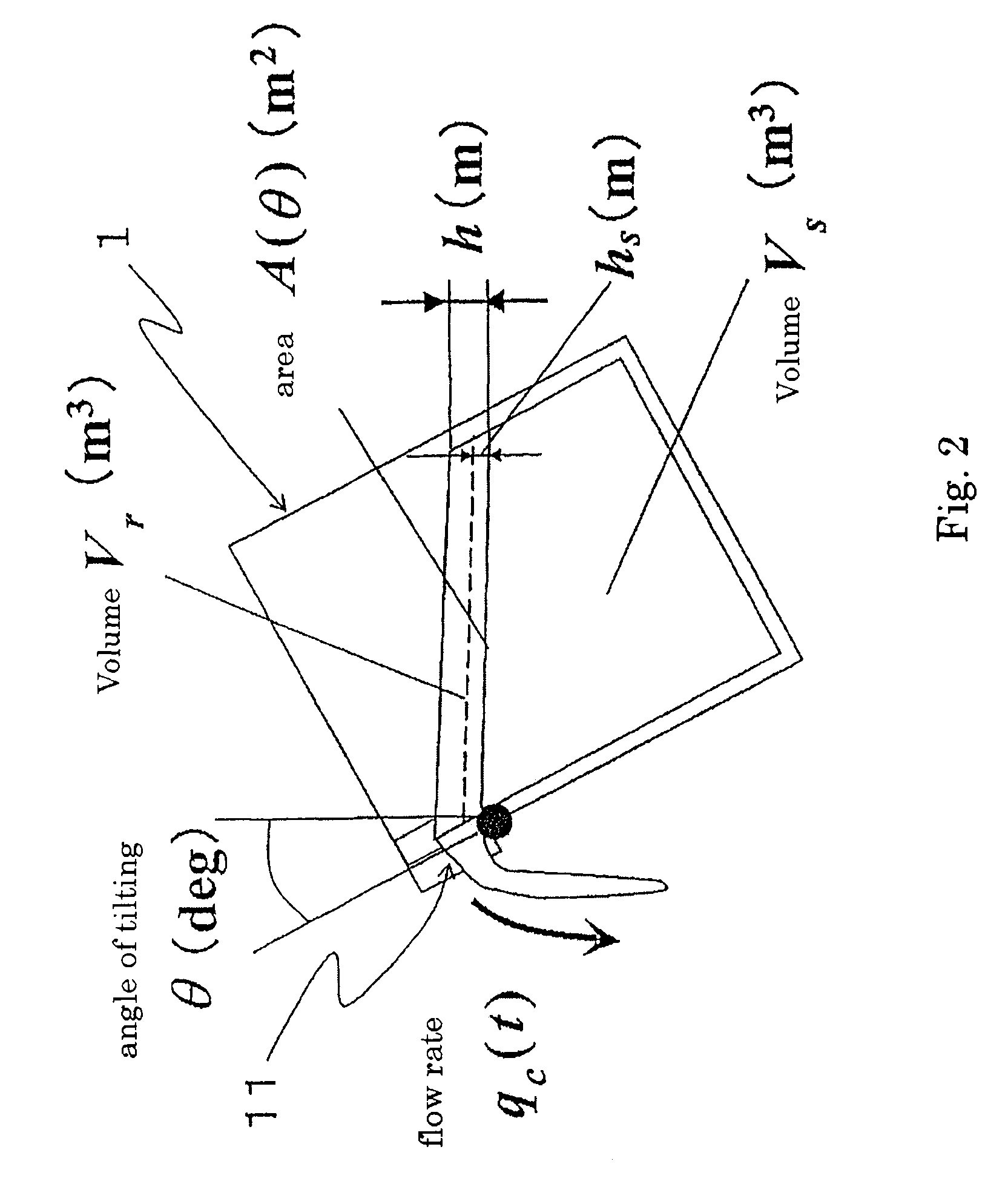

The present invention provides a tilting-type automatic pouring method wherein a very speedy and highly accurate pouring can be realized, which method pours molten metal into a mold by tilting a ladle that holds the molten metal, and the present invention also provides the storage medium for programs used for the method.The tilting-type automatic pouring method of the present invention uses a) the relationship of (1) the height of the molten metal during backward tilting of the ladle, which height is calculated from the height of the molten metal above the outflow position, which height decreases, when the forward tilting of the ladle stops and from the height of the molten metal that is above the outflow position and that decreases after the backward tilting of the ladle starts, and (2) the weight of the molten metal poured from the ladle into the mold, and b) the model expression for the flow of the molten metal, which expression defines the weight of the molten metal that flows from the ladle into the mold.In the tilting-type automatic pouring method of the present invention, the final weight of the molten metal that is poured is estimated by assuming that the final weight of the molten metal that is poured from the forward tilting of the ladle to its backward tilting is equal to the sum of the weight of the molten metal that is poured at the start of the backward tilting and the weight of the molten metal that is poured after the start of the backward tilting.

Owner:SINTOKOGIO LTD +1

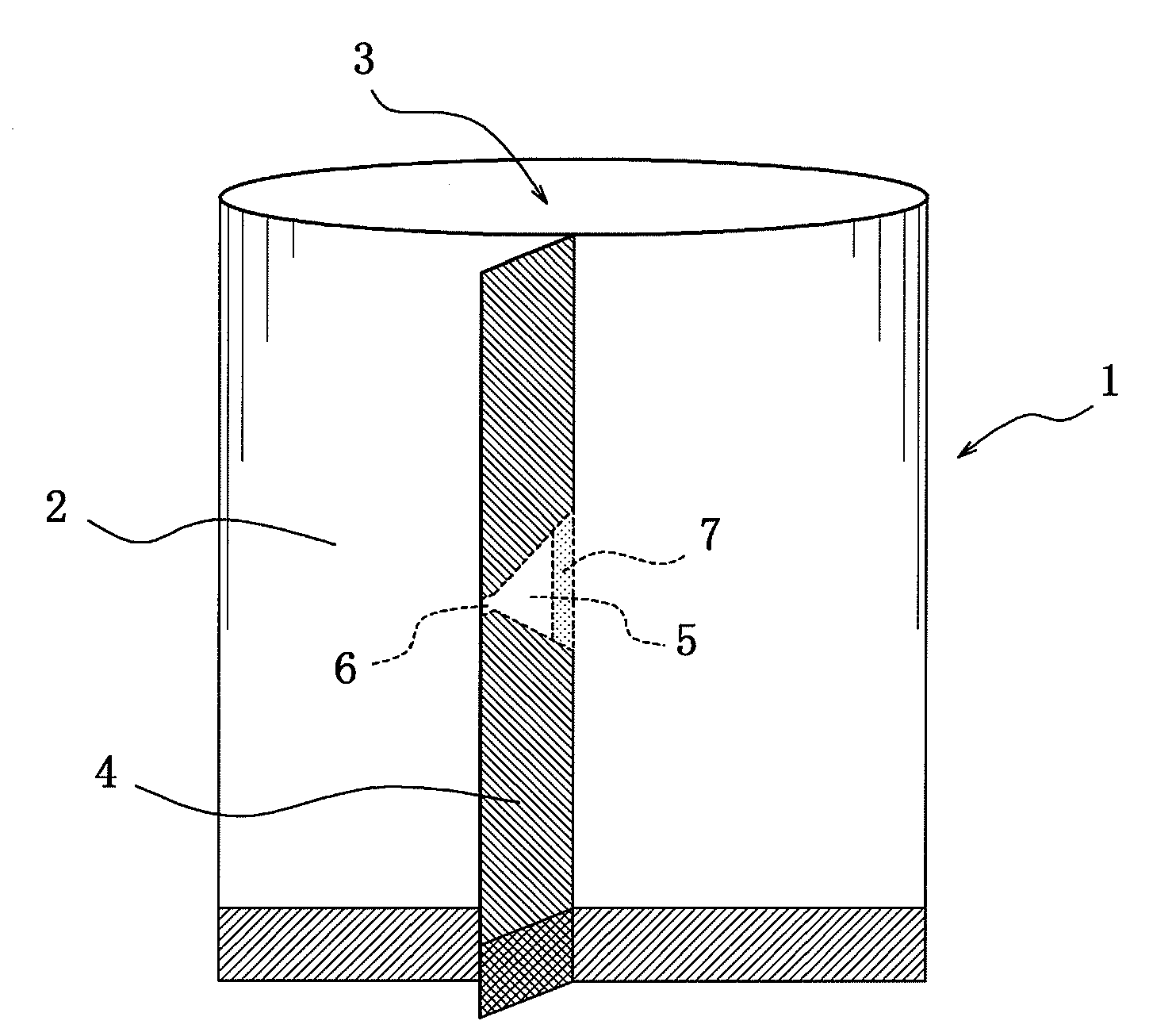

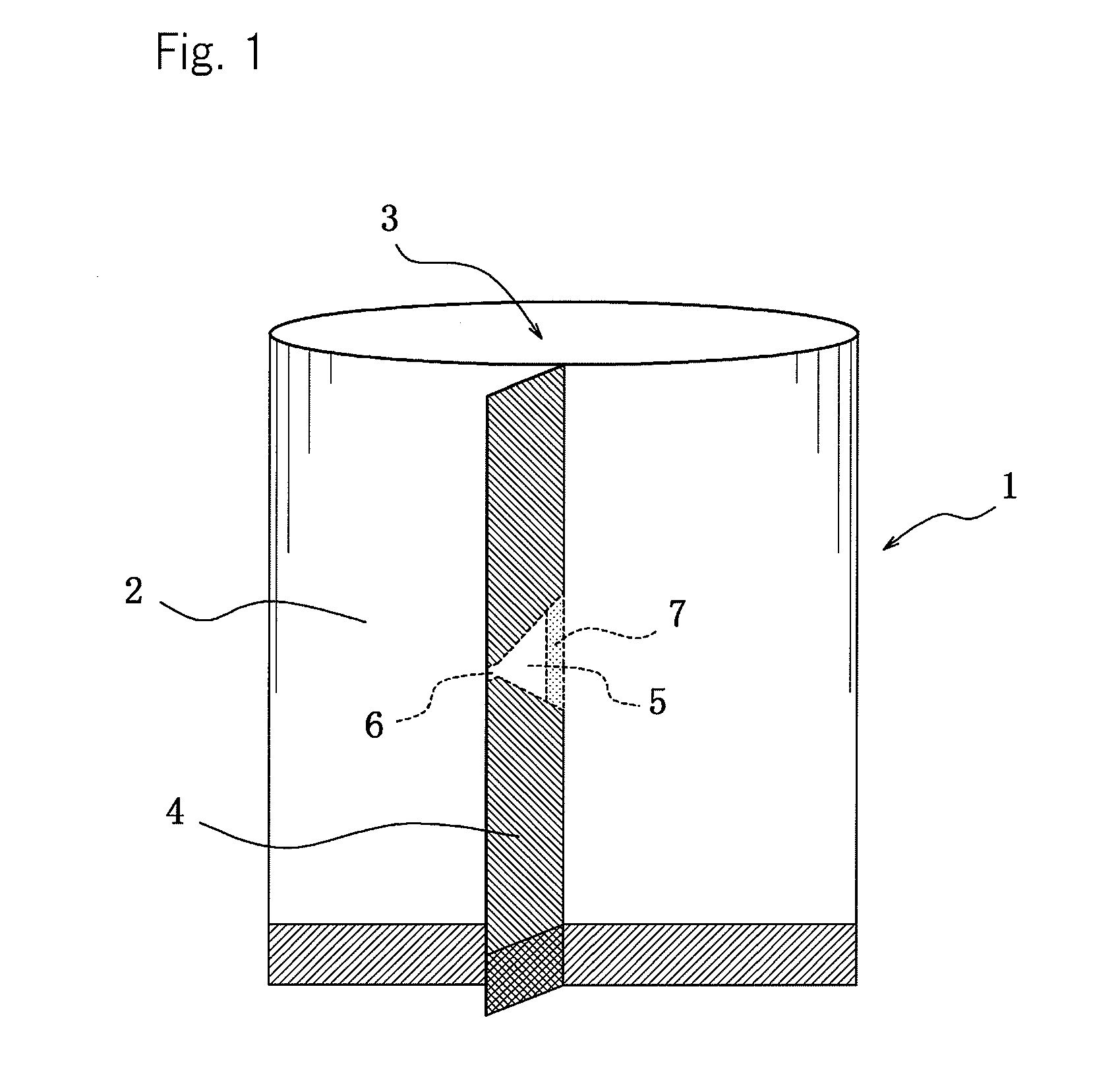

Butt seamed package bag and method for using same

ActiveUS20150016757A1Easy to pourPouring precisionWrappersPower operated devicesButt jointFilling materials

A rectangular, flexible butt-seamed package bag and a method for using the same is provided in which the pouring of a single type of a liquid packing material filled and packed in the filling space for the packed material from the package bag can be easily performed. A butt-seamed package bag formed by joining both side portions of a sealant layer of a laminate film for packing to each other at a butt state and joining bottom portions or top portions thereof to define a filling space for a single packed material, characterized in that a pouring path for the packed material is disposed in a middle part of a butt-seamed joint portion in an extending direction thereof, and at least a part of the pouring path is provided with an easily separable portion having a joint strength relatively lower than that of the butt-seamed joint portion.

Owner:TAISEI LAMICK

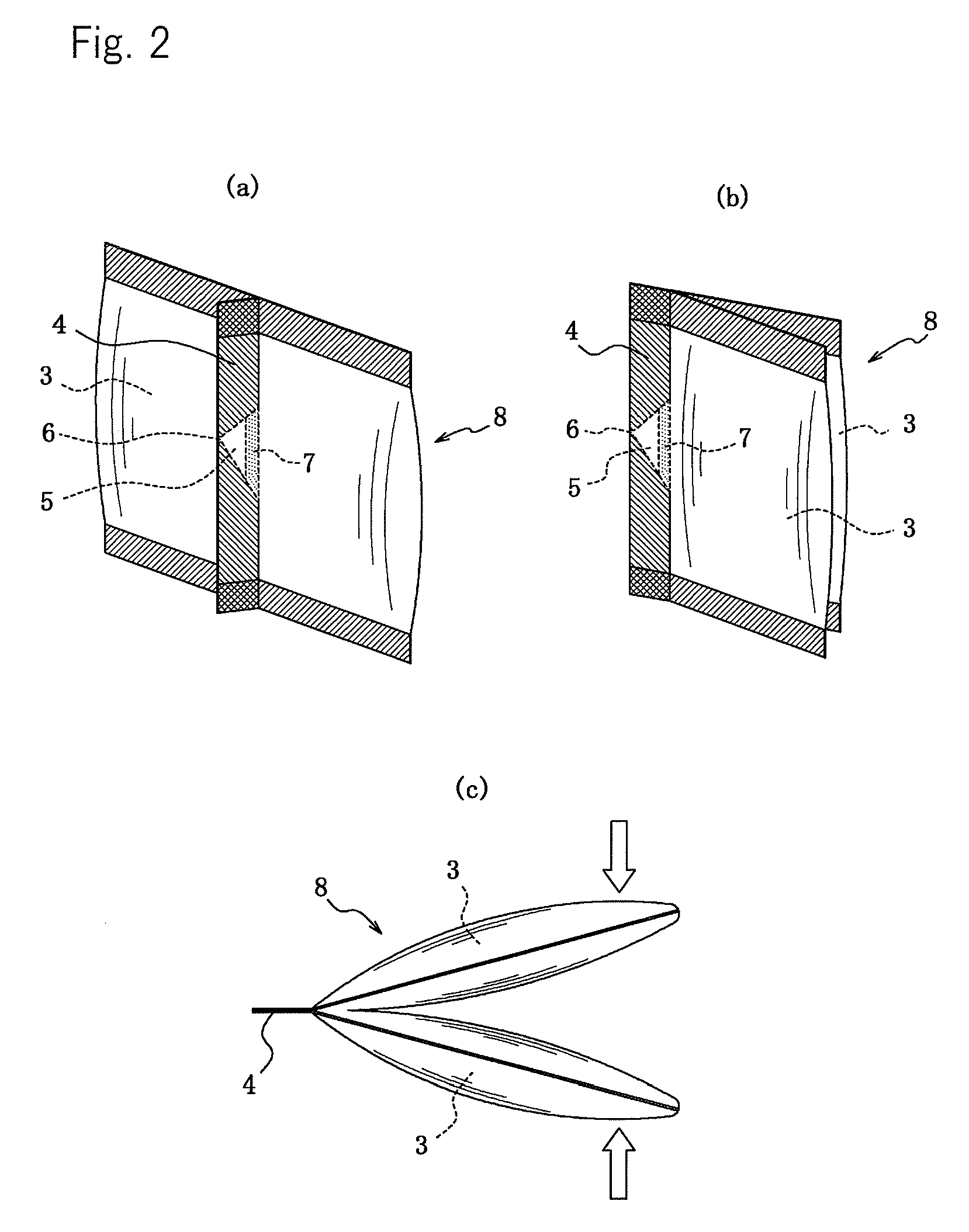

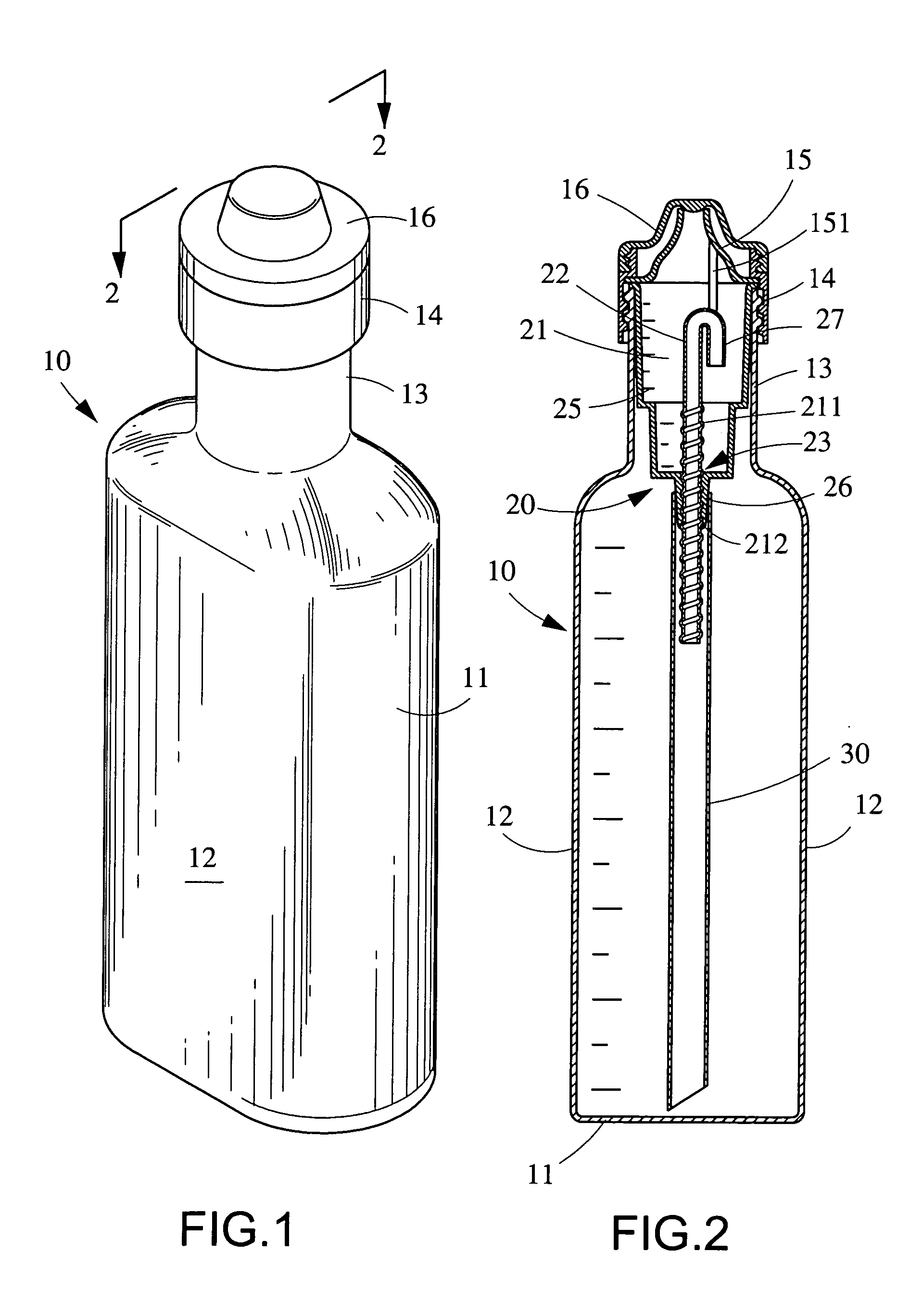

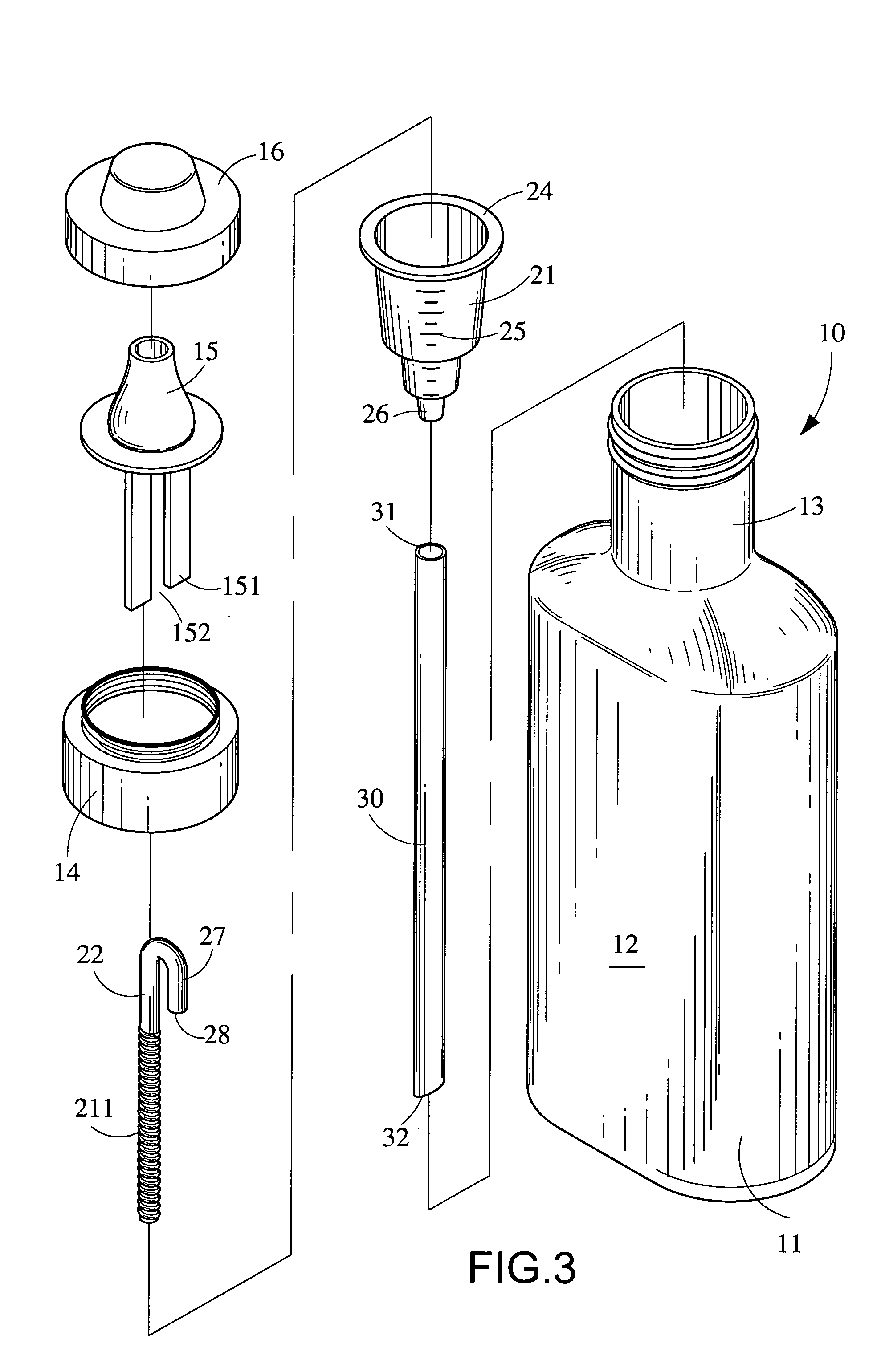

Bottle with constant liquid pouring device

InactiveUS20050067436A1Pouring precisionMovable measuring chambersPortable flexible containersSpray nozzleEngineering

A bottle for dispensing constant liquid is disclosed. Removing a retaining cap from a reservoir and loosening a ring will enable a free rotation of a spout for moving a conduit vertically at a flow regulator as grip means rotates until a top opening of the conduit is flush with a predetermined mark of scale. Fastening the ring and pressing the reservoir will direct liquid to flow upward into a cup through the tube and the conduit until liquid has reached a level higher than the top opening of the conduit. Releasing the pressing will cause liquid above the top opening of the conduit to flow back to the liquid reservoir and store liquid below the top opening of the conduit in the cup. Finally, pressing and turning the reservoir upside down will discharge liquid from the cup.

Owner:PI CHING TIEN

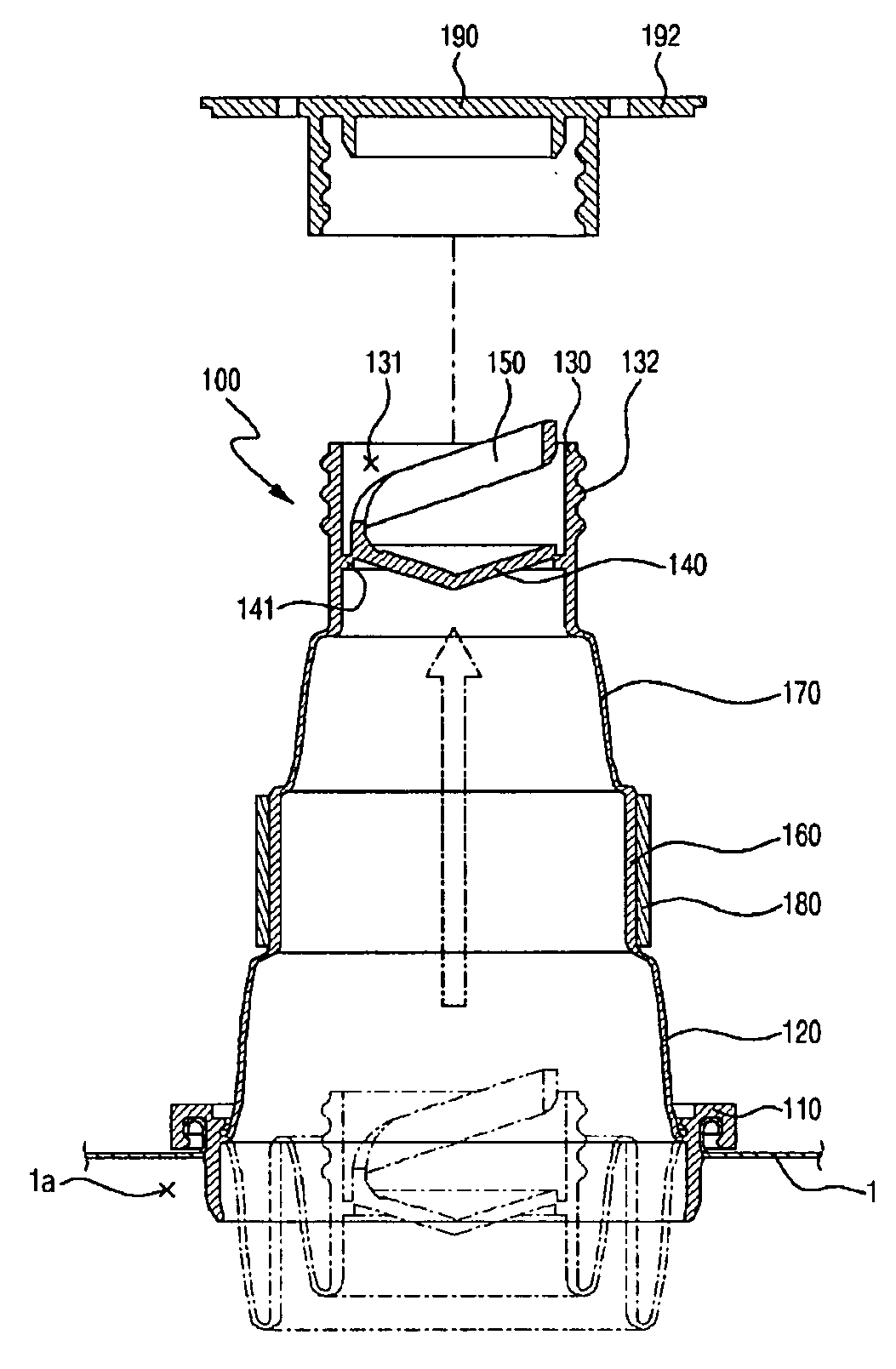

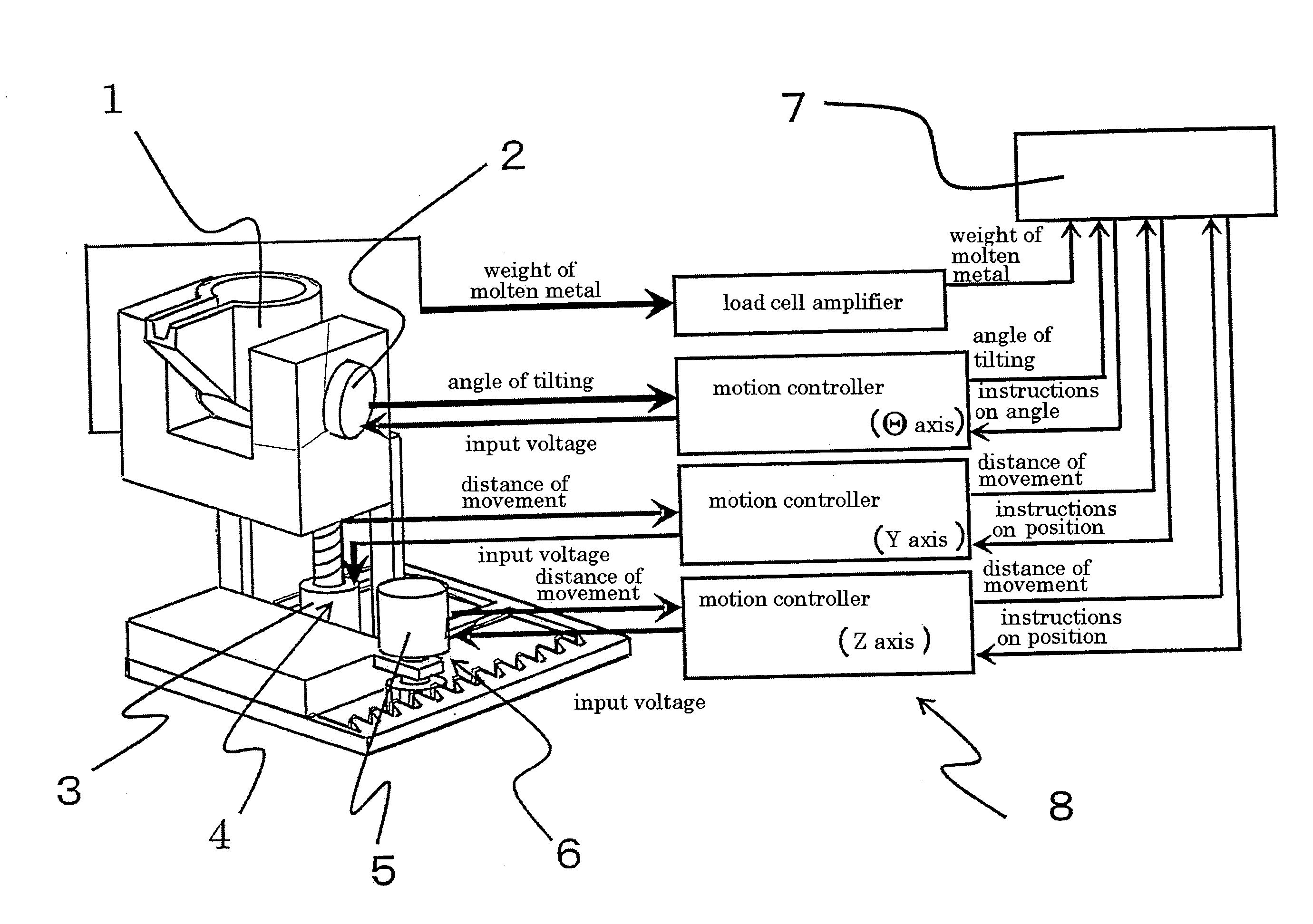

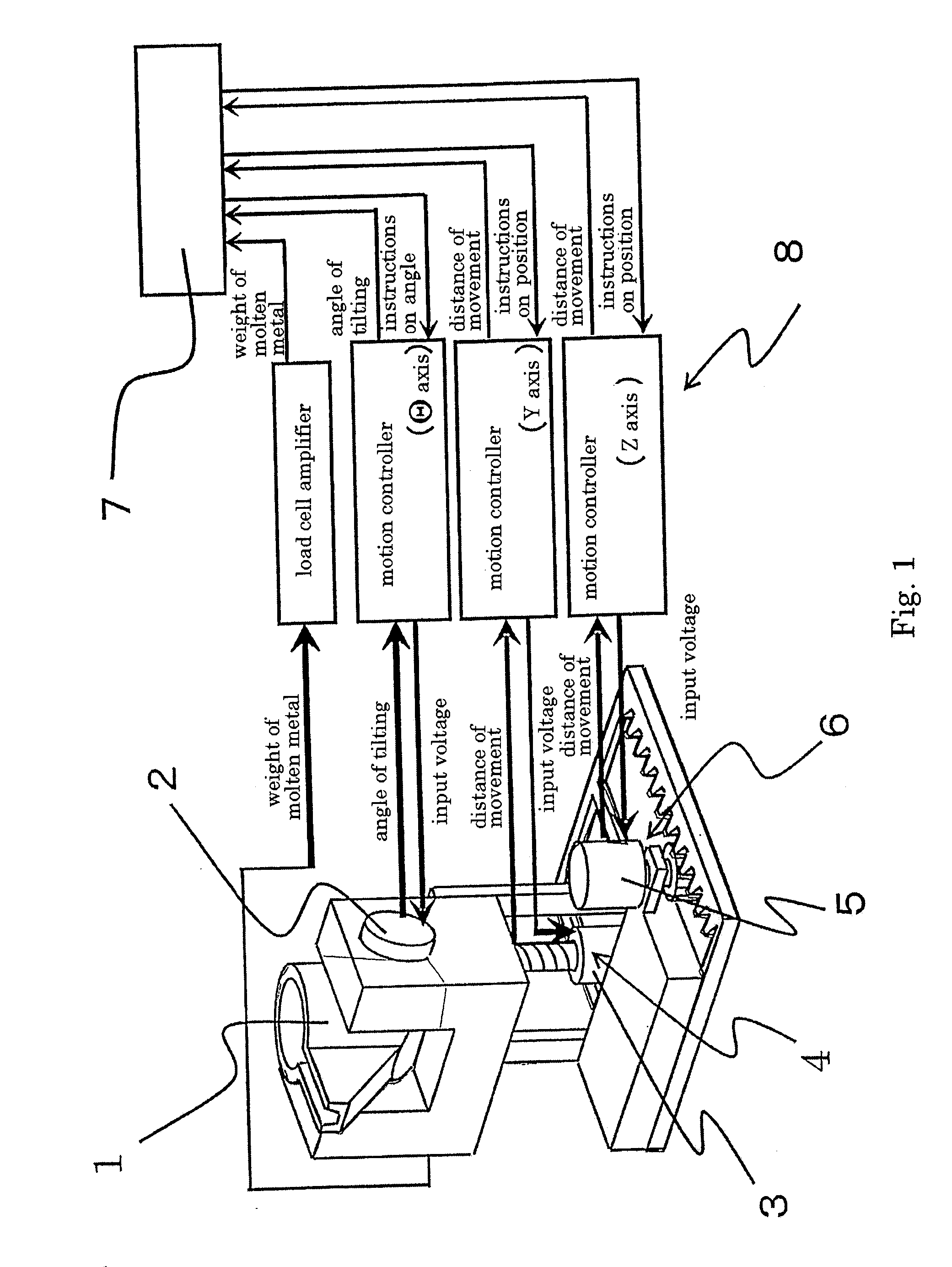

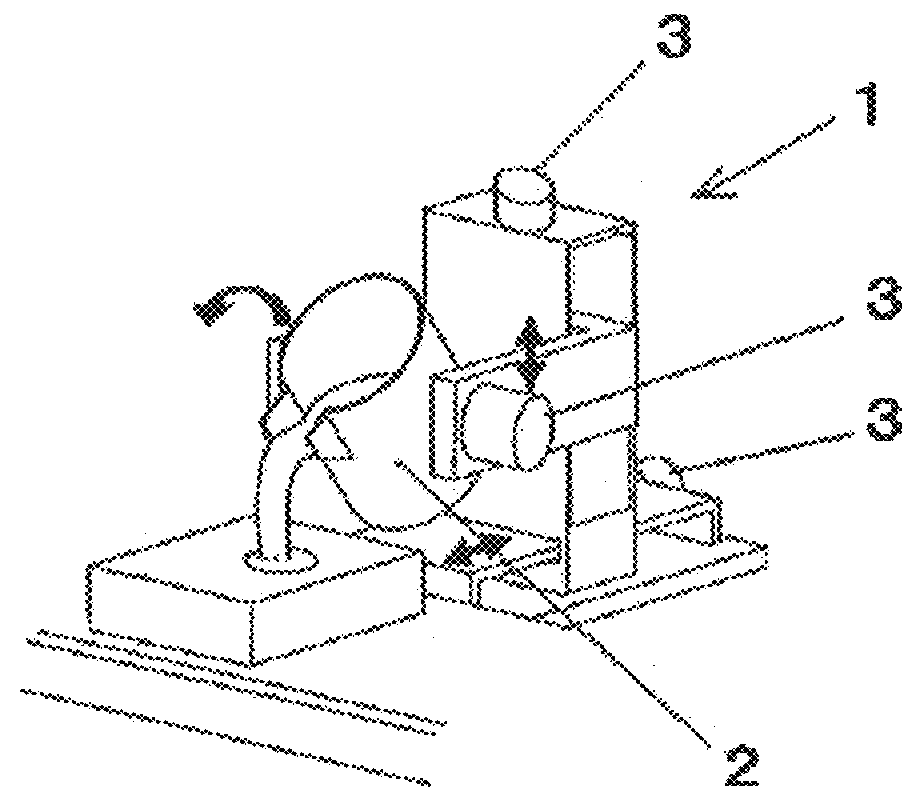

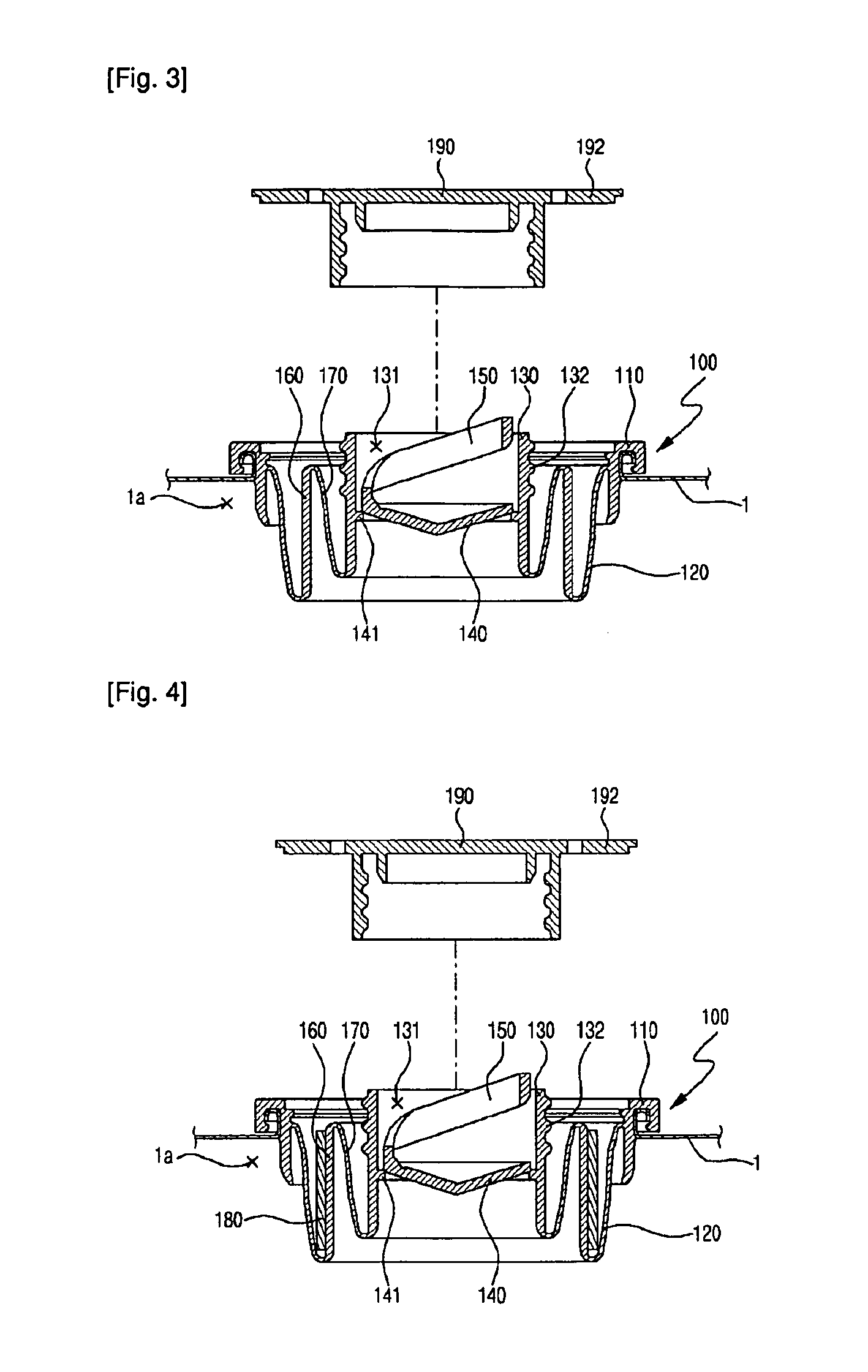

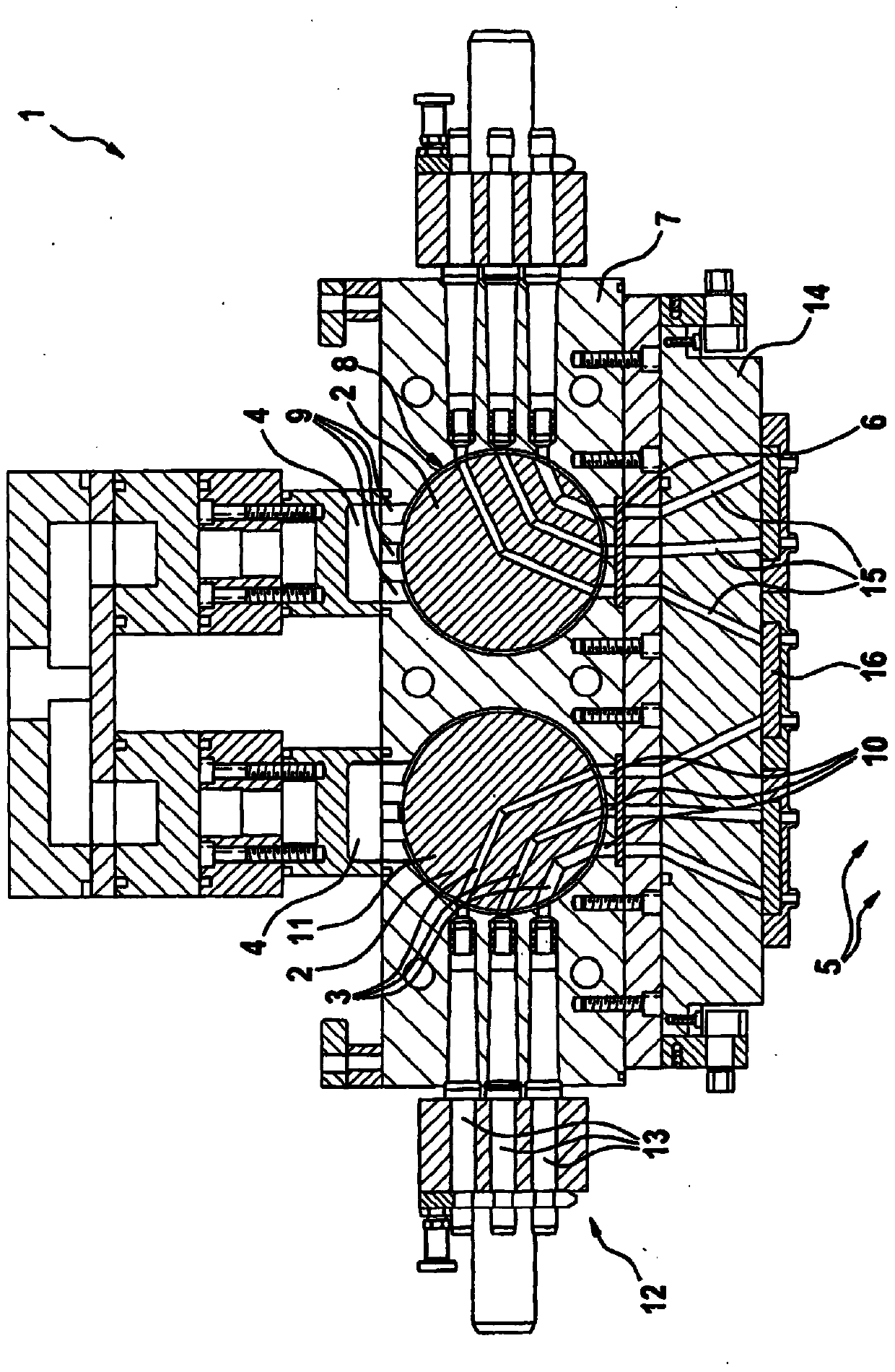

Method for automatically pouring molten metal by tilting a ladle and a medium for recording programs for controlling a tilt of a ladle

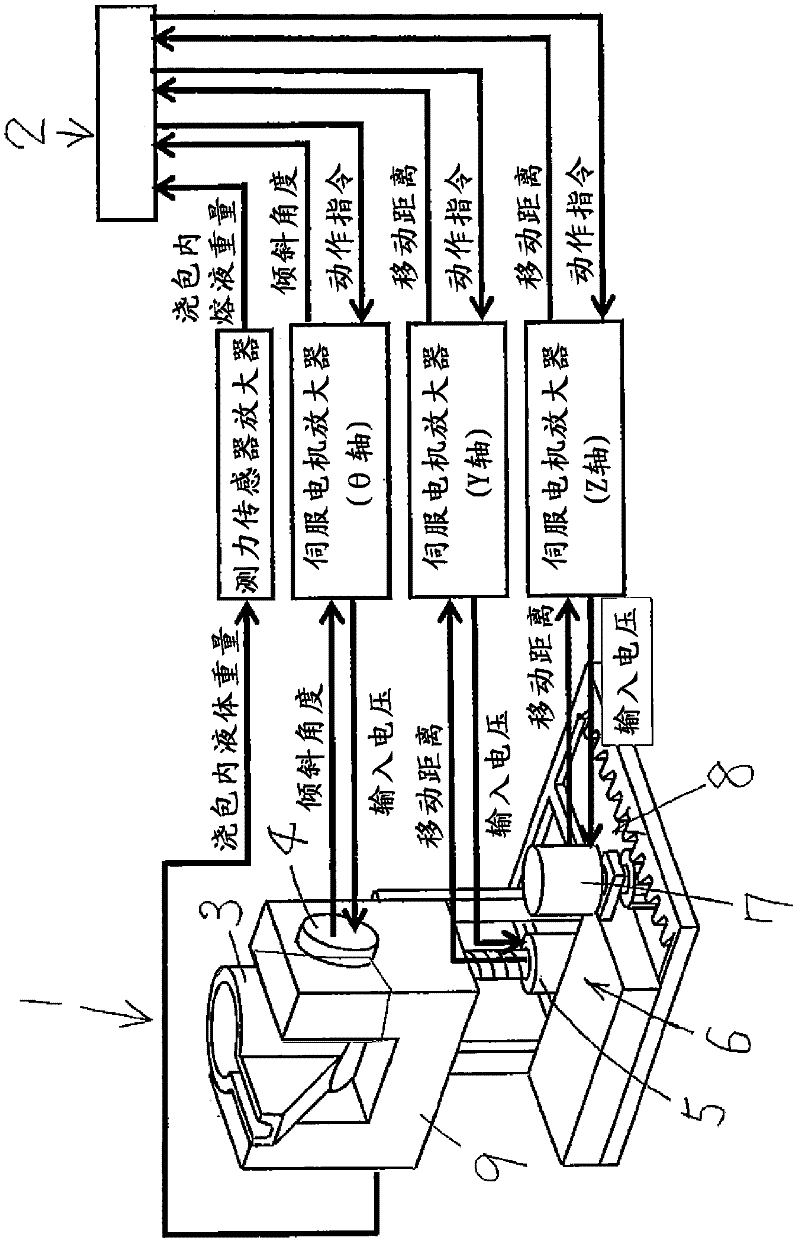

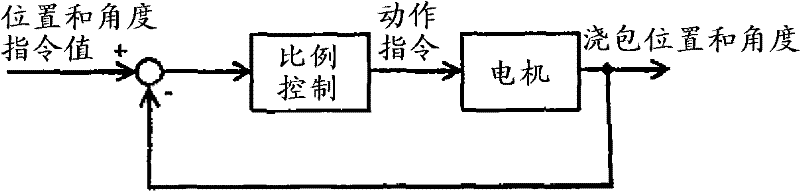

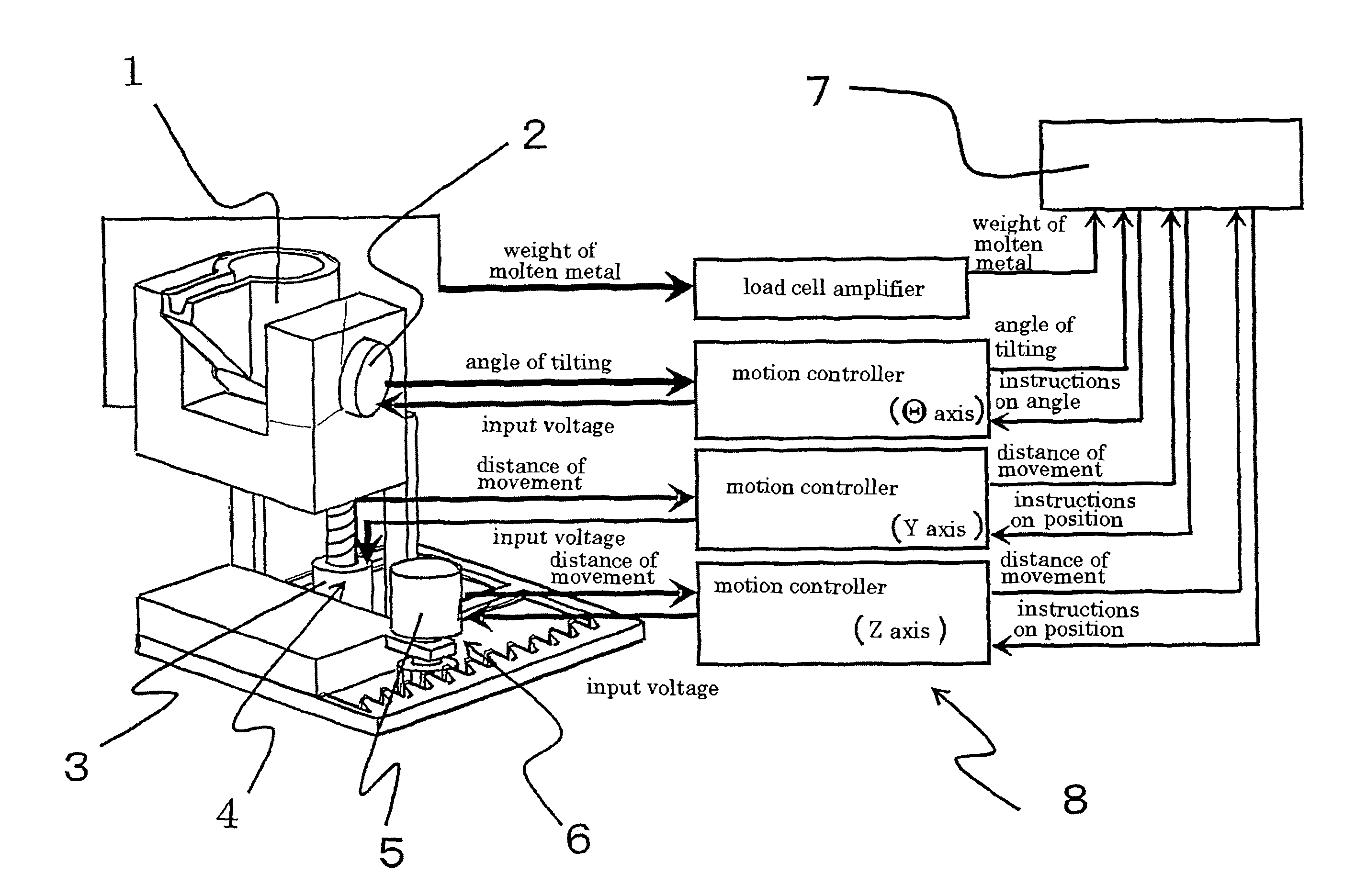

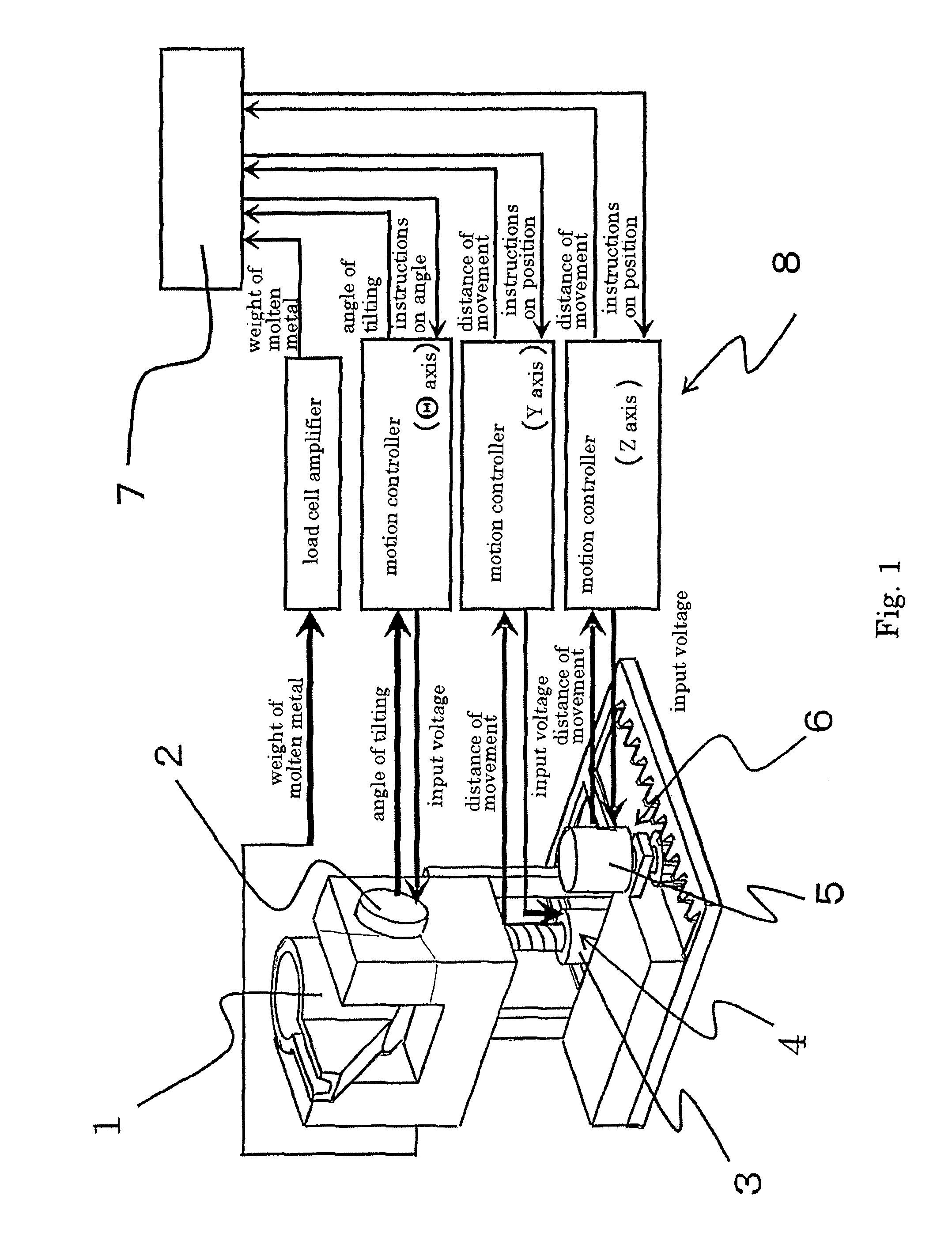

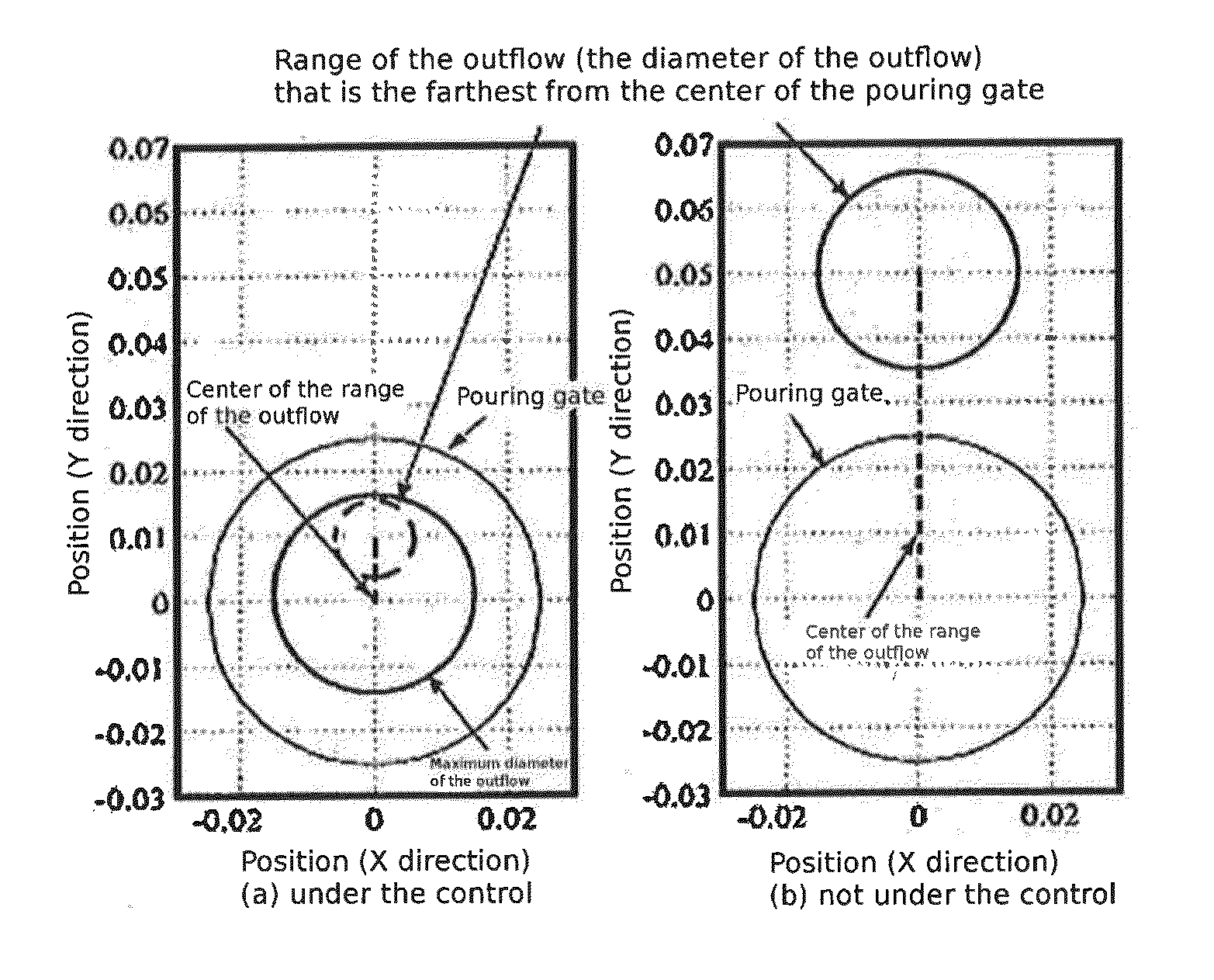

ActiveUS9248498B2Reduce depthPouring precisionMelt-holding vesselsTime indicationMetallurgyMathematical model

A method for controlling the respective input voltages transmitted to a servomotor that tilts the ladle such that the molten metal that flows from the ladle drops accurately into the pouring gate in the mold, a servomotor that moves the ladle back and forth, and a servomotor that moves the ladle up and down, by using a computer. In the method, a mathematical model of the area on which the molten metal that flows from the ladle will drop is produced, and then the inverse problem of the produced mathematical model is solved. In view of the effect of a contracted flow, the position on which molten metal drops is estimated by the estimating device for estimating the pouring rate and the estimating device for estimating the position on which molten metal will drop.

Owner:SINTOKOGIO LTD +1

Tilting-type automatic pouring method and storage medium

ActiveUS8114338B2Precise processDesired weight of the molten metalMelt-holding vesselsMolten metal pouring equipmentsEstimated WeightMetallurgy

A tilting-type automatic pouring method for pouring molten metal from a ladle with an outflow position into a mold. The method includes tilting the ladle forward to pour molten metal into the mold, measuring a weight of poured molten metal, calculating a flow rate of the molten metal flowing out of the ladle based on the measured weight of poured molten metal, estimating a weight of molten metal that will be poured during a backward tilting. The method also includes estimating a total weight of molten metal based on the measured weight of poured molten metal and the estimated weight of molten metal that will be poured during the backward tilting and comparing the estimated total weight of molten metal to a predetermined weight. When the estimated total weight is equal to or larger than the predetermined weight, the backward tilting is started.

Owner:SINTOKOGIO LTD +1

Method and apparatus for controlled transfer of fluid

Owner:VECTION LTD LLC

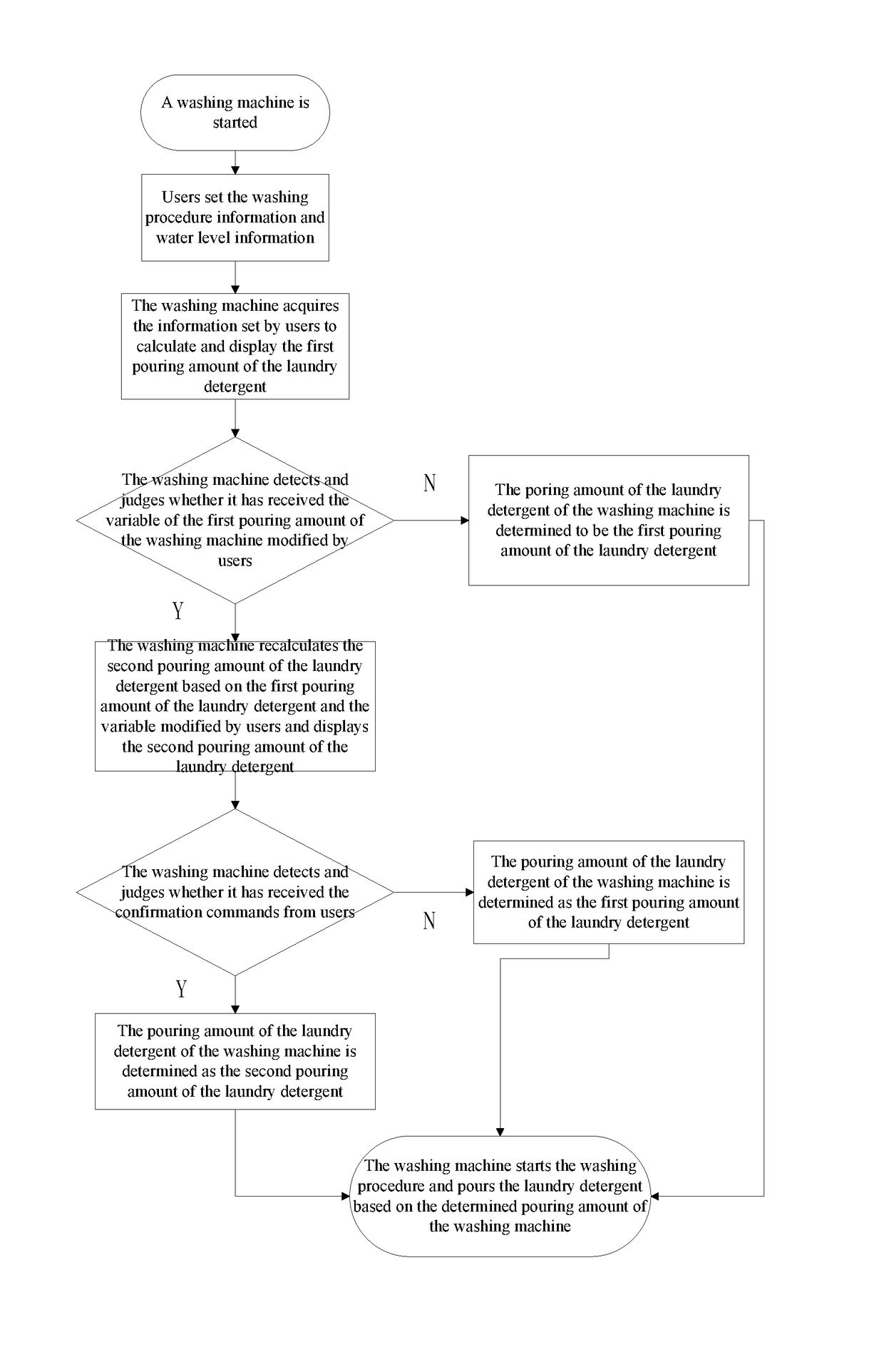

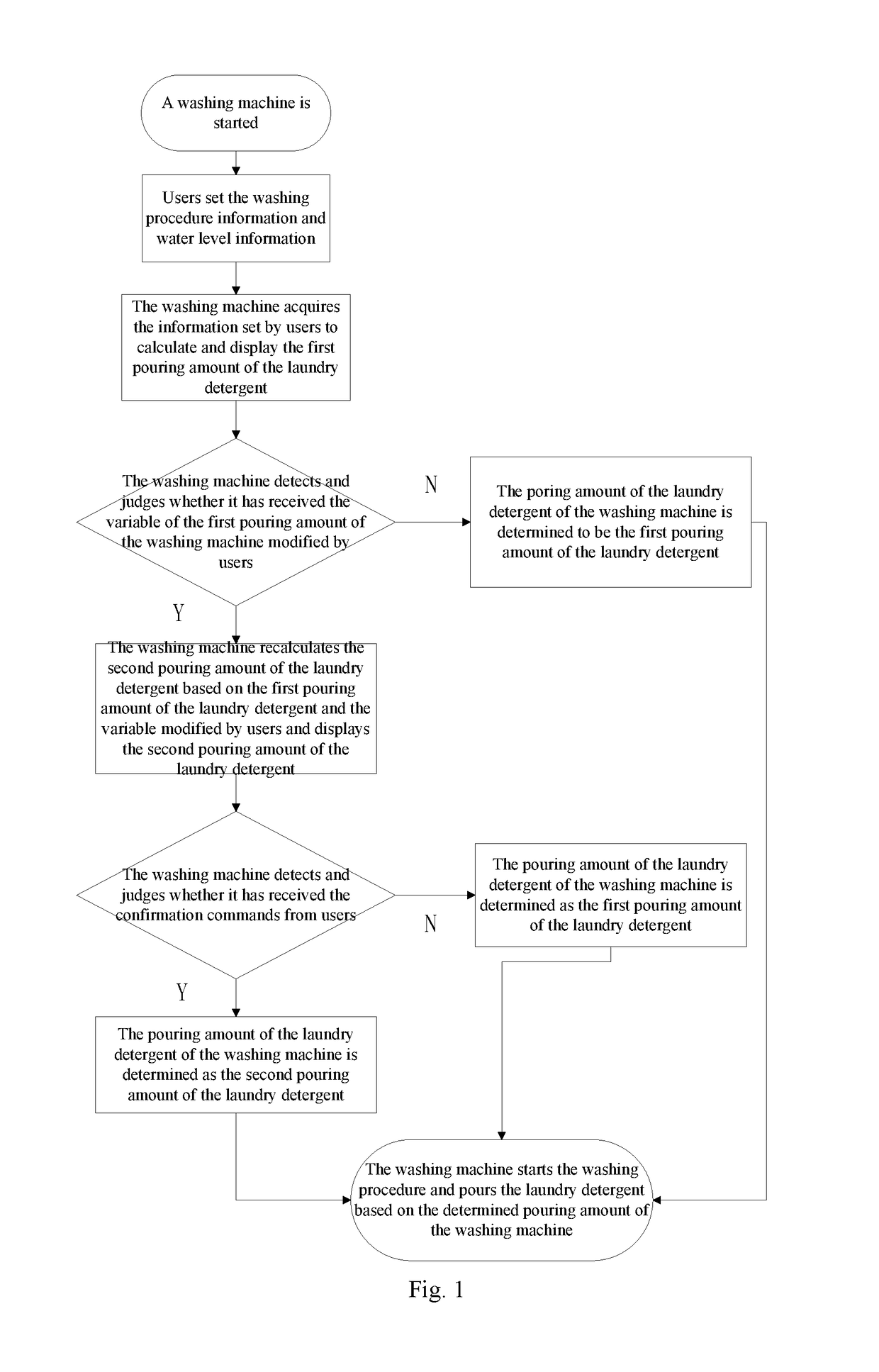

Method for controlling pouring of laundry detergent and washing machine

InactiveUS20180142397A1Pouring precisionFulfil requirementsOther washing machinesControl devices for washing apparatusEngineeringLaundry detergent

A washing machine calculates corresponding first pouring amount of the laundry detergent based on acquired information and displays the first pouring amount of the laundry detergent. The washing machine detects and judges a variable of the first pouring amount of the laundry detergent to form a second pouring amount of the laundry detergent, the washing procedure is started, and the washing machine pours the laundry detergent at a first pouring amount or a second pouring amount of the laundry detergent. The invention further provides a washing machine which includes an automatic pouring device, a computer board and a display screen, wherein the automatic pouring device pours based on the pouring amount of the laundry detergent calculated by the computer board, and the display screen is used for displaying the first pouring amount of the laundry detergent and / or the second pouring amount of the laundry detergent in real time.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

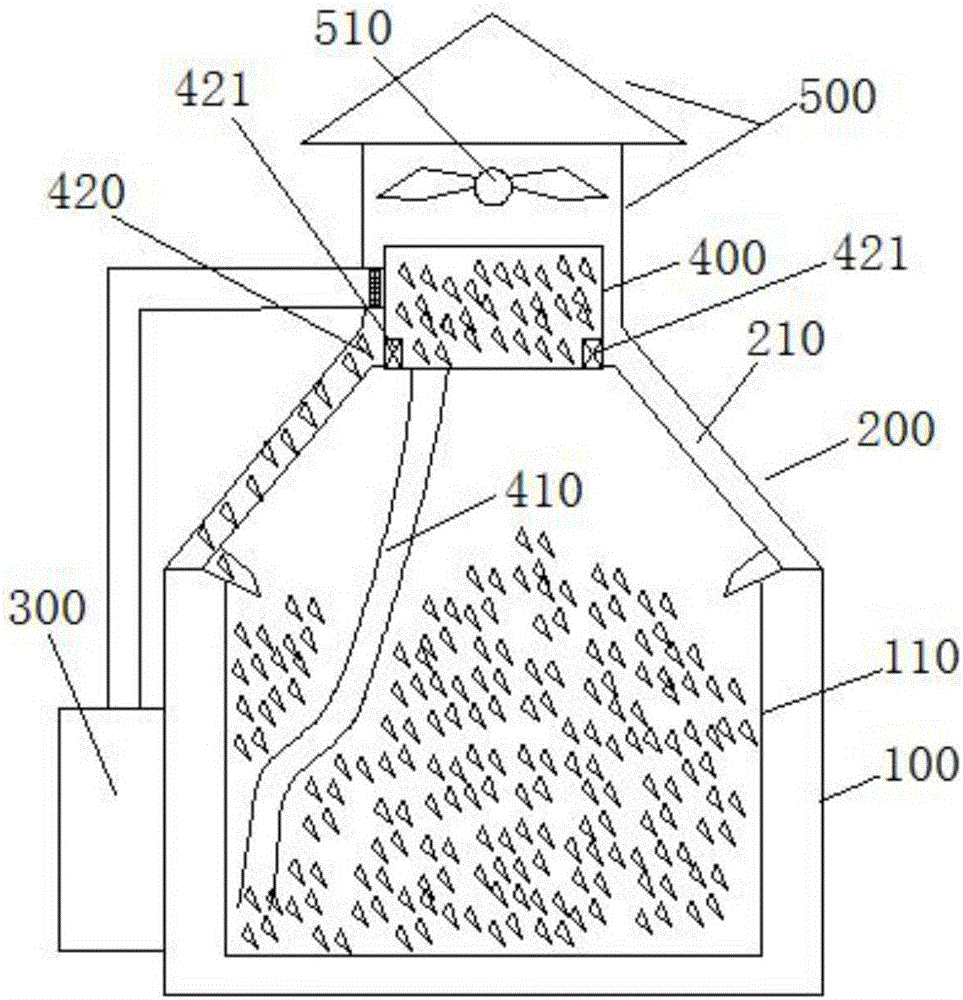

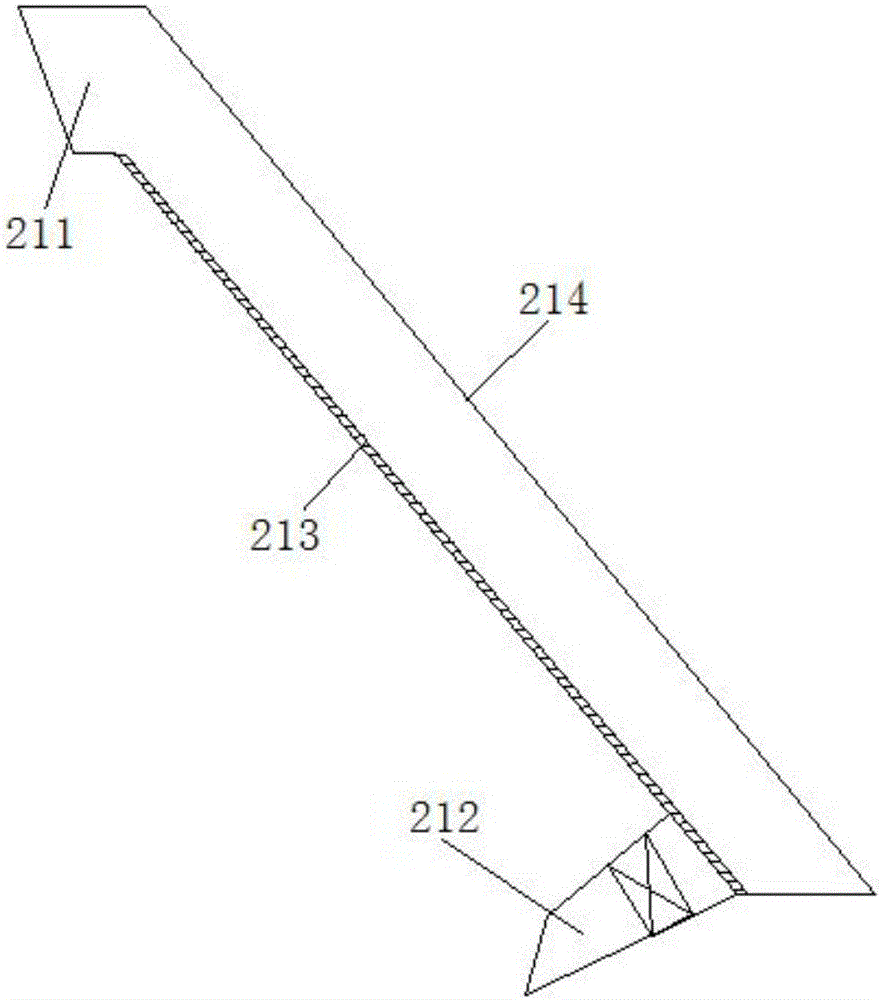

Intelligent grain storage device

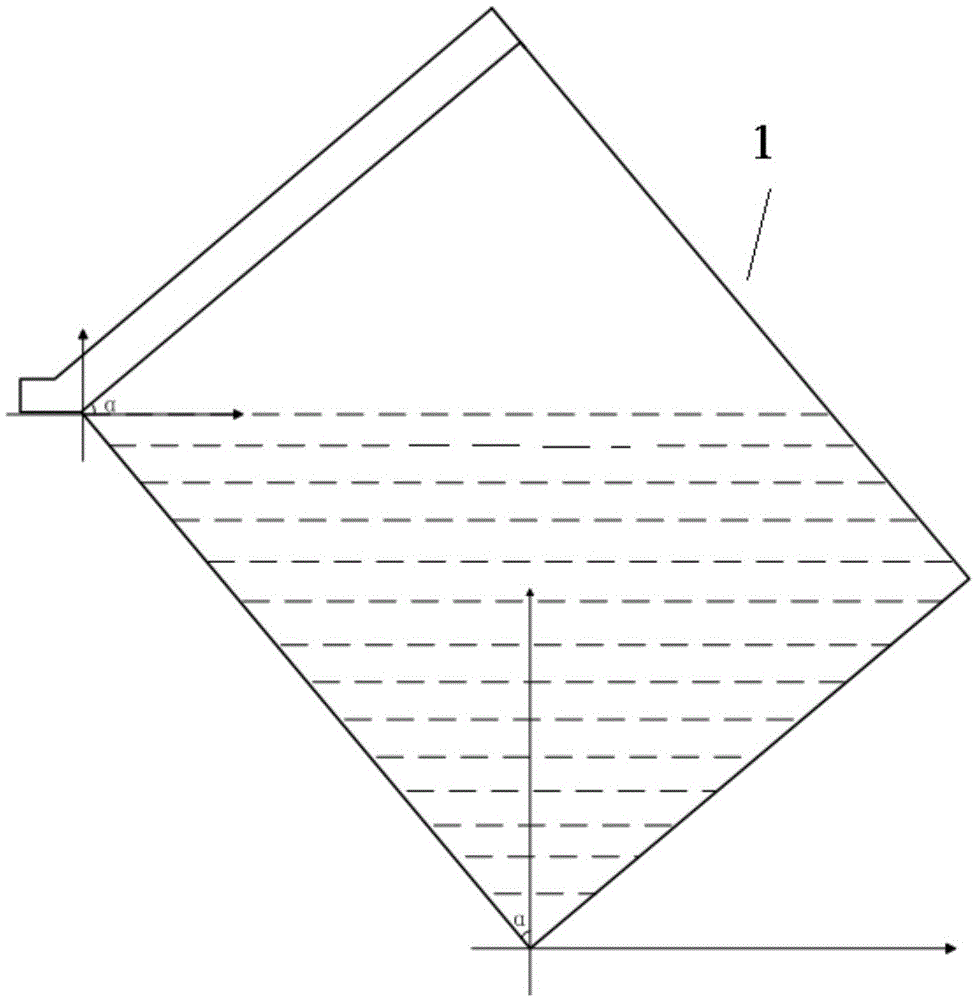

PendingCN106576632ATimely exclusionAchieve the technical effect of chasing light and dryingAgriculture tools and machinesClimate change adaptationEngineeringAir drying

The invention discloses an intelligent grain storage device, having a technical advantage of full-automatic air drying of grains. The structure of the intelligent grain storage device comprises a bin body, a storage bin arranged in the bin body, a bin top, a negative pressure delivery pump, a measuring bin and an exhaust hood, wherein an air-drying bin is arranged at any side wall of the bin top respectively, and consists of a feed port, a discharge port, a light absorbing plate and a transparent cover covering and locked on the light absorbing plate; the discharge port communicated with the storage bin; the measuring bin is arranged in the bin top; the upper end of the measuring bin is connected with the negative pressure delivery pump by virtue of an extraction opening provided with a filter screen; the bottom of the measuring bin is connected with a feed pipe communicating with a storage space of the bin body; a level meter is arranged in the measuring bin and is connected with the negative pressure delivery pump through a controller; the lower end of the measuring bin is provided with a material dividing port connected with the feed port of each air-drying bin respectively, and each material dividing port is provided with a material dividing valve respectively; and a draught fan is arranged in the exhaust hood which is arranged right above the bin top. The intelligent grain storage device disclosed by the invention can achieve intelligent air drying.

Owner:赵亦军

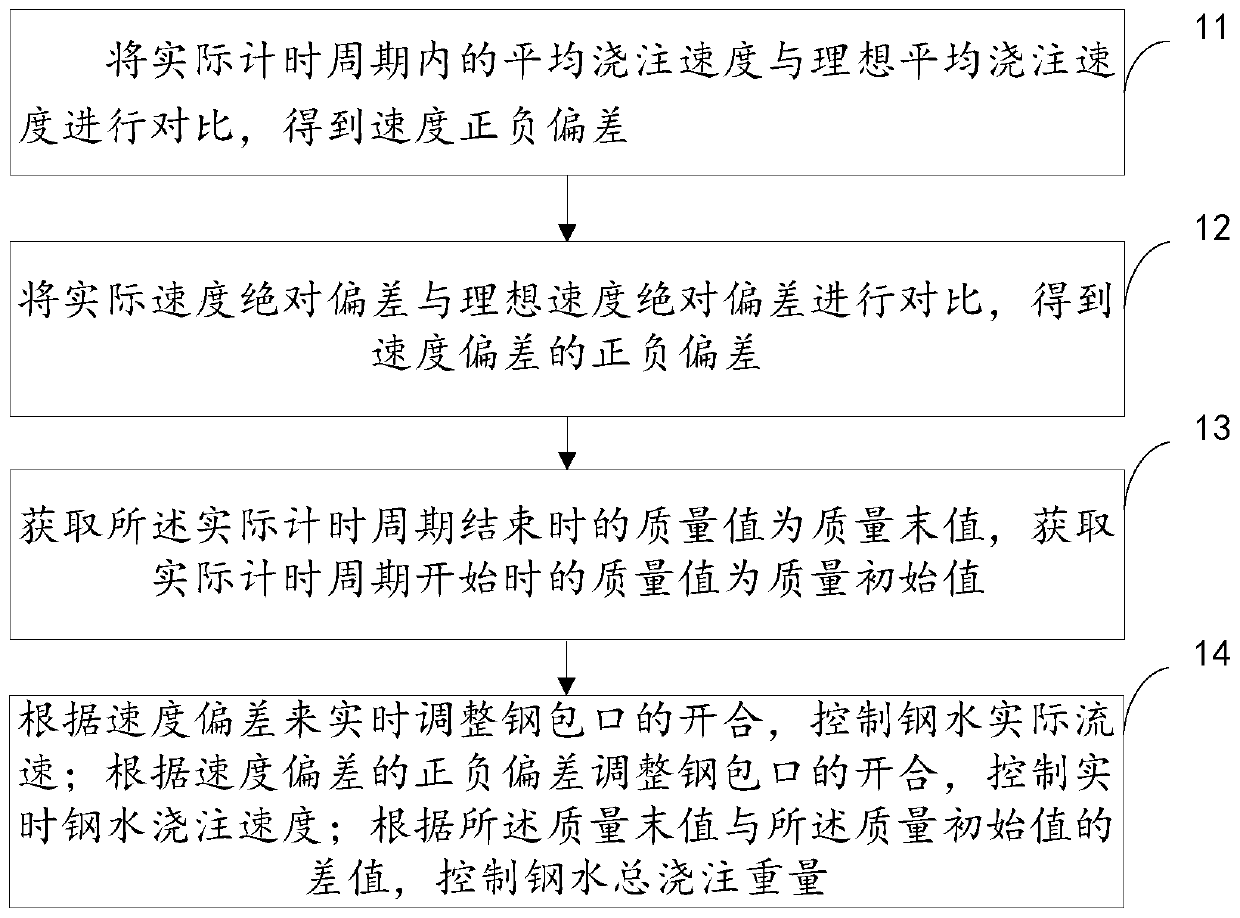

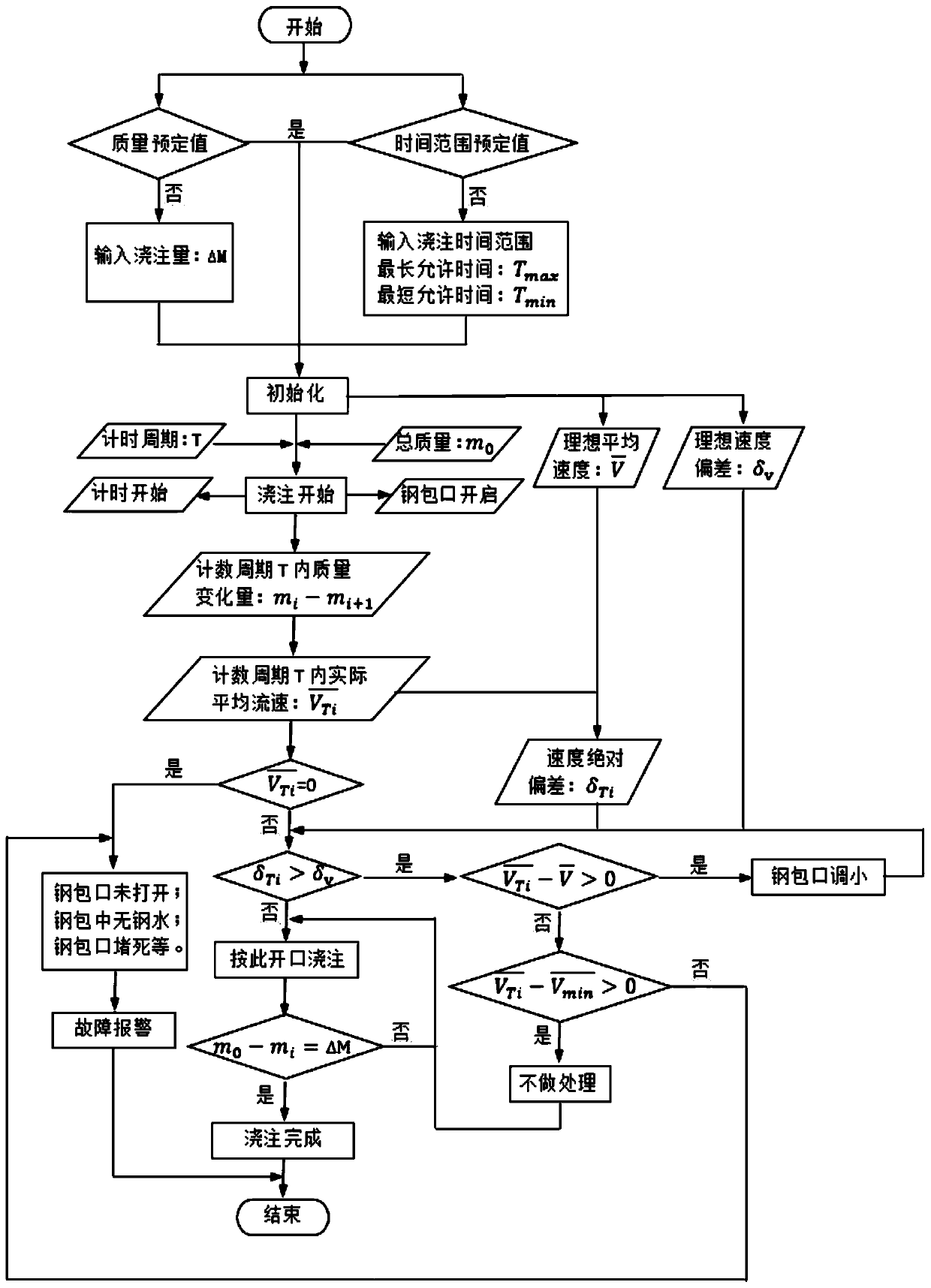

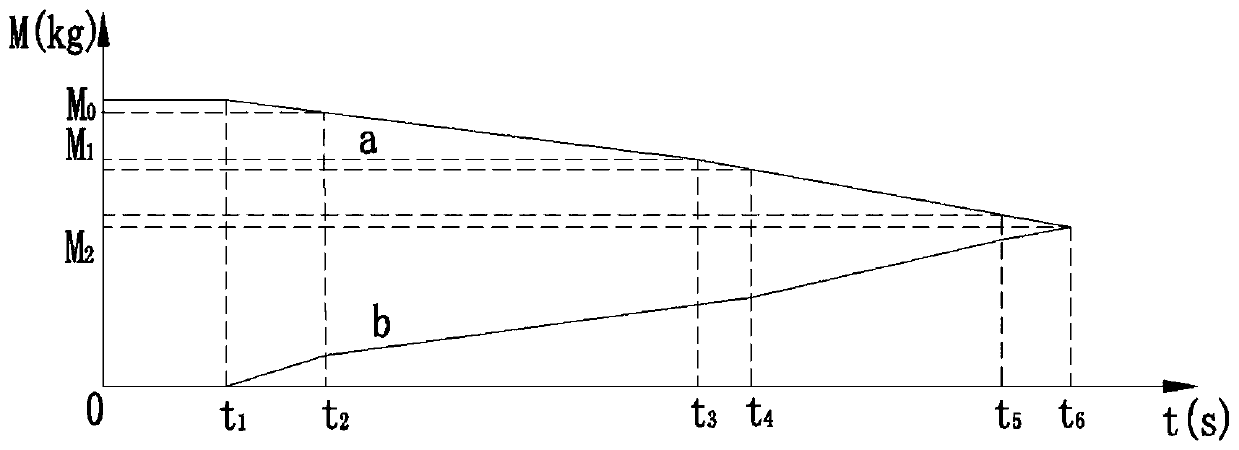

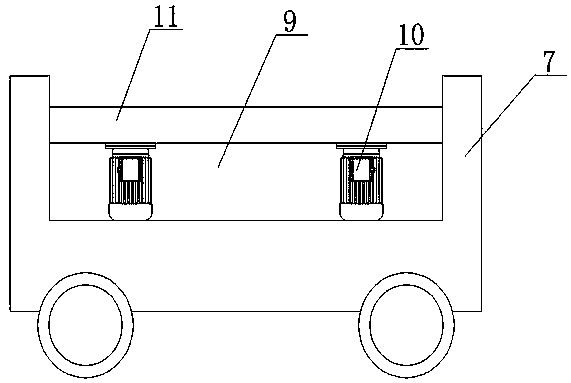

Molten steel pouring control method and pouring truck

PendingCN110328357AControl flow rateControl the total pouring weightMelt-holding vesselsMolten metal pouring equipmentsAbsolute deviationMolten steel

The embodiment of the invention discloses a molten steel pouring control method and a pouring truck. The molten steel pouring control method comprises the following steps: comparing an average pouringspeed in an actual timing period with an ideal average pouring speed to obtain a positive and negative deviation of speed; comparing the absolute deviation of the actual speed with the absolute deviation of the ideal speed to obtain a positive and negative deviation of speed deviation; acquiring a mass value as a an end mass value when the actual timing period is finished to obtain an mass valueas an initial mass value when the actual timing period is started; adjusting opening and closing of a steel ladle port in real time according to the speed deviation to control the actual flow rate ofmolten steel; adjusting opening and closing of the steel ladle port according to deviation of the speed deviation to control the real time molten steel pouring speed; and controlling the total pouringweight of molten steel according to a difference value between the end mass value and the initial mass value.

Owner:HENAN WEITE TRUCK CRANE

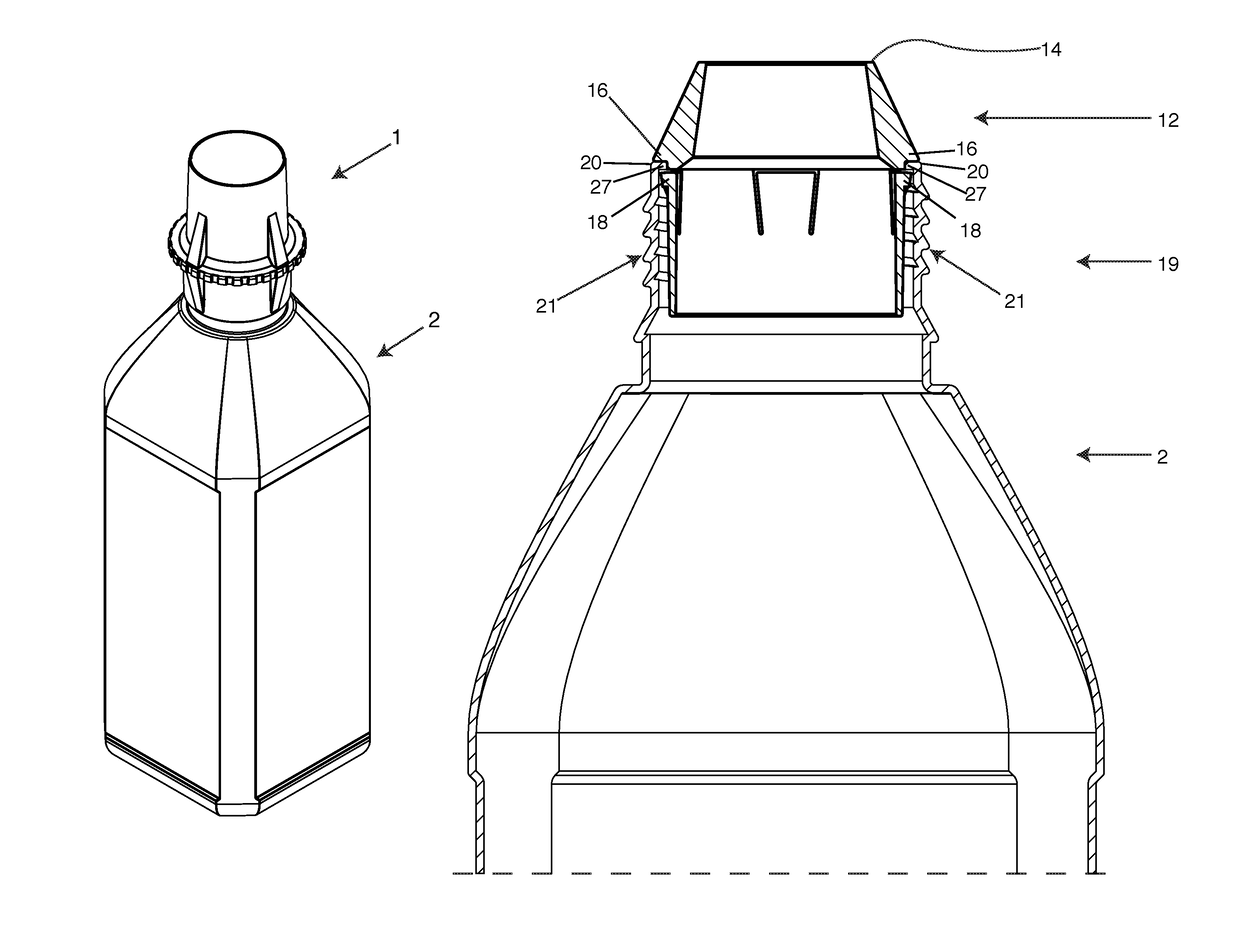

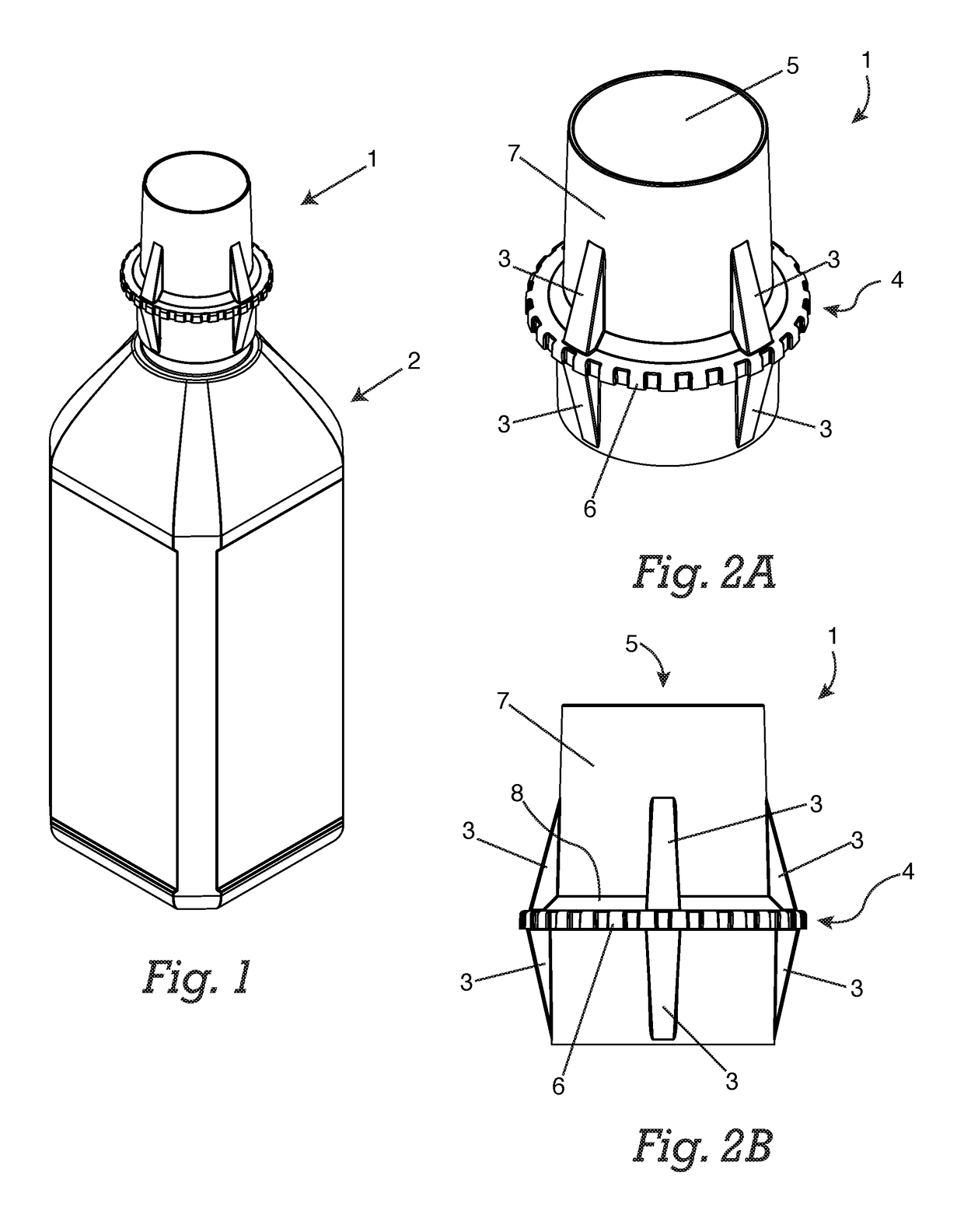

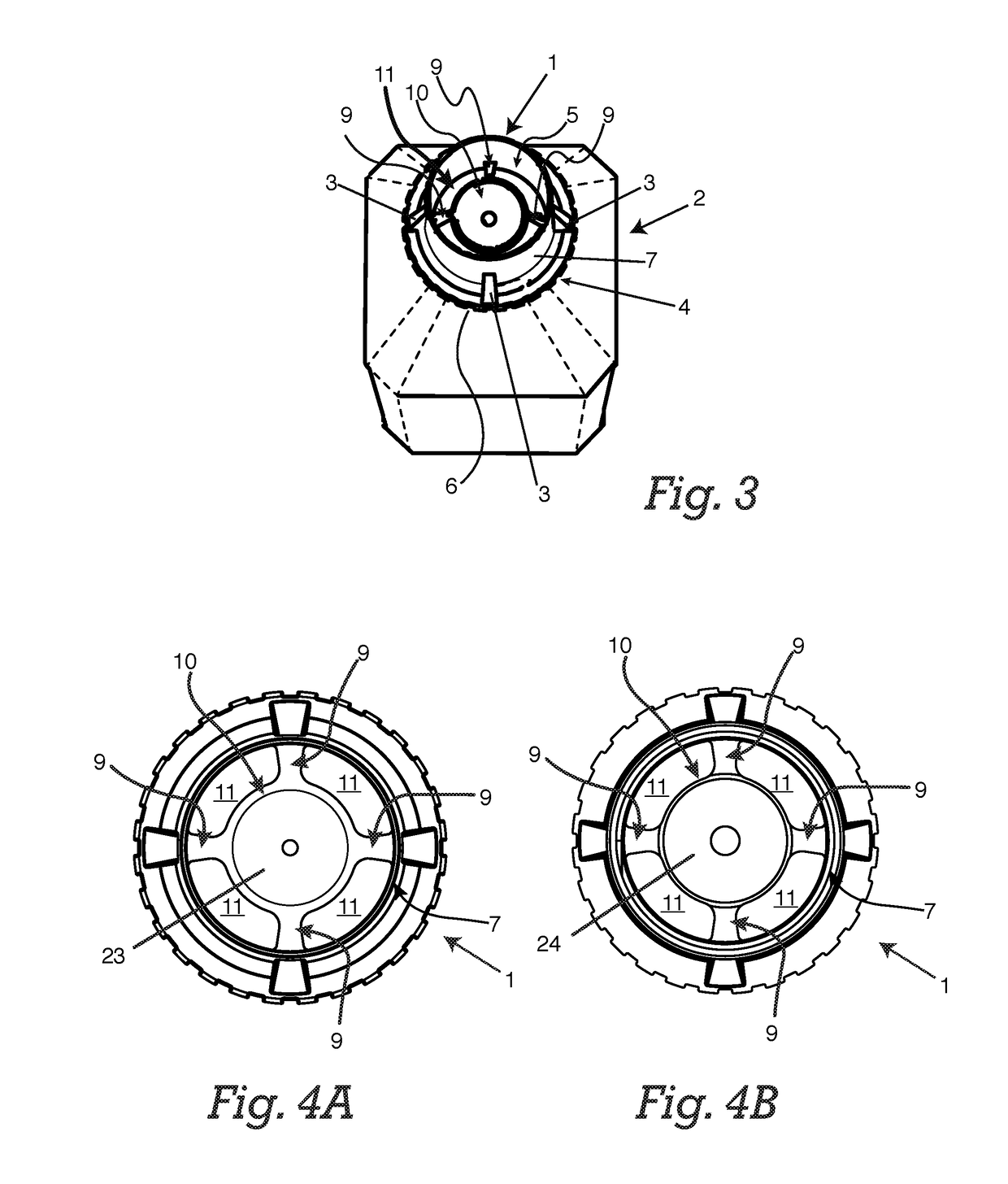

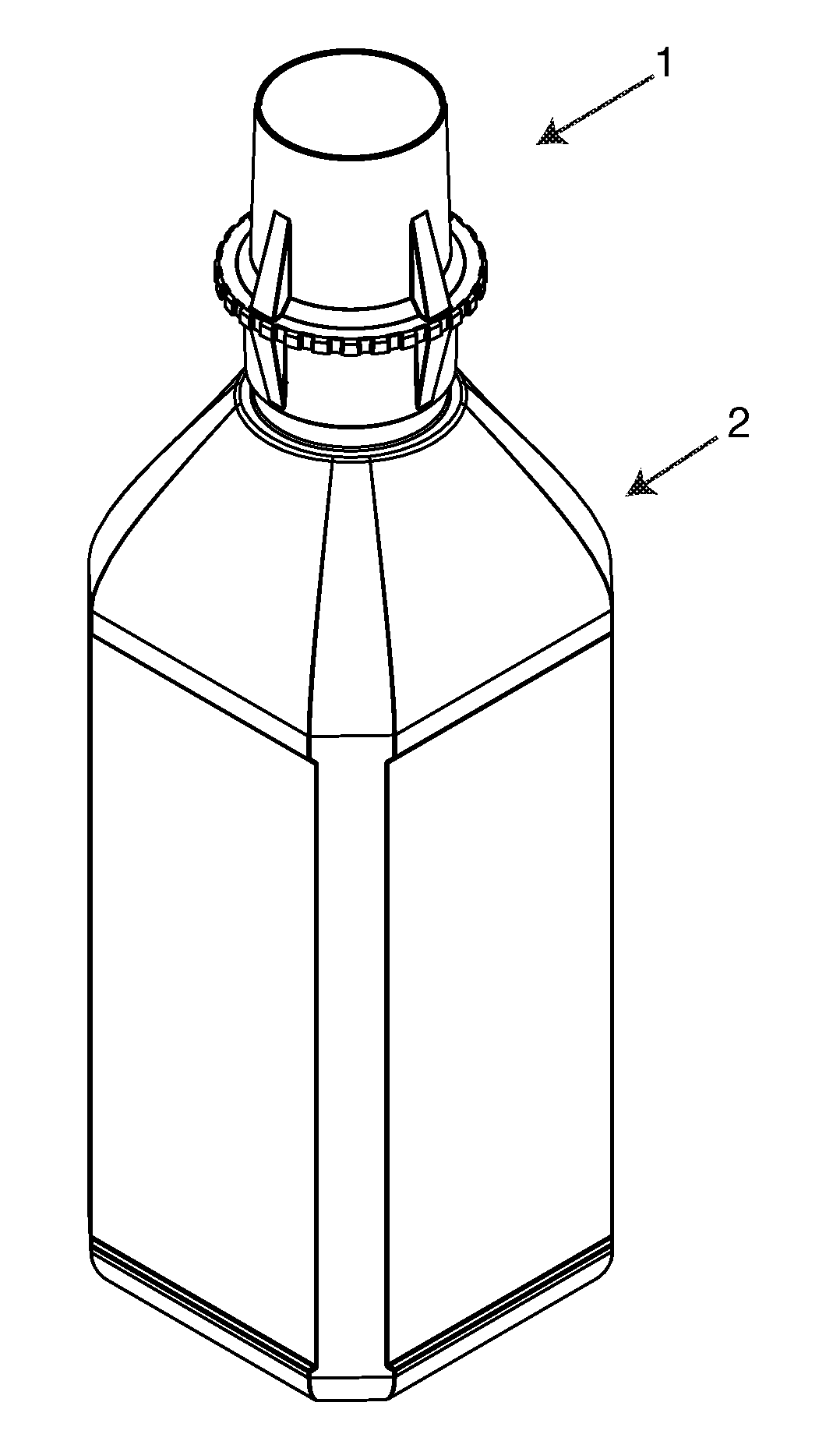

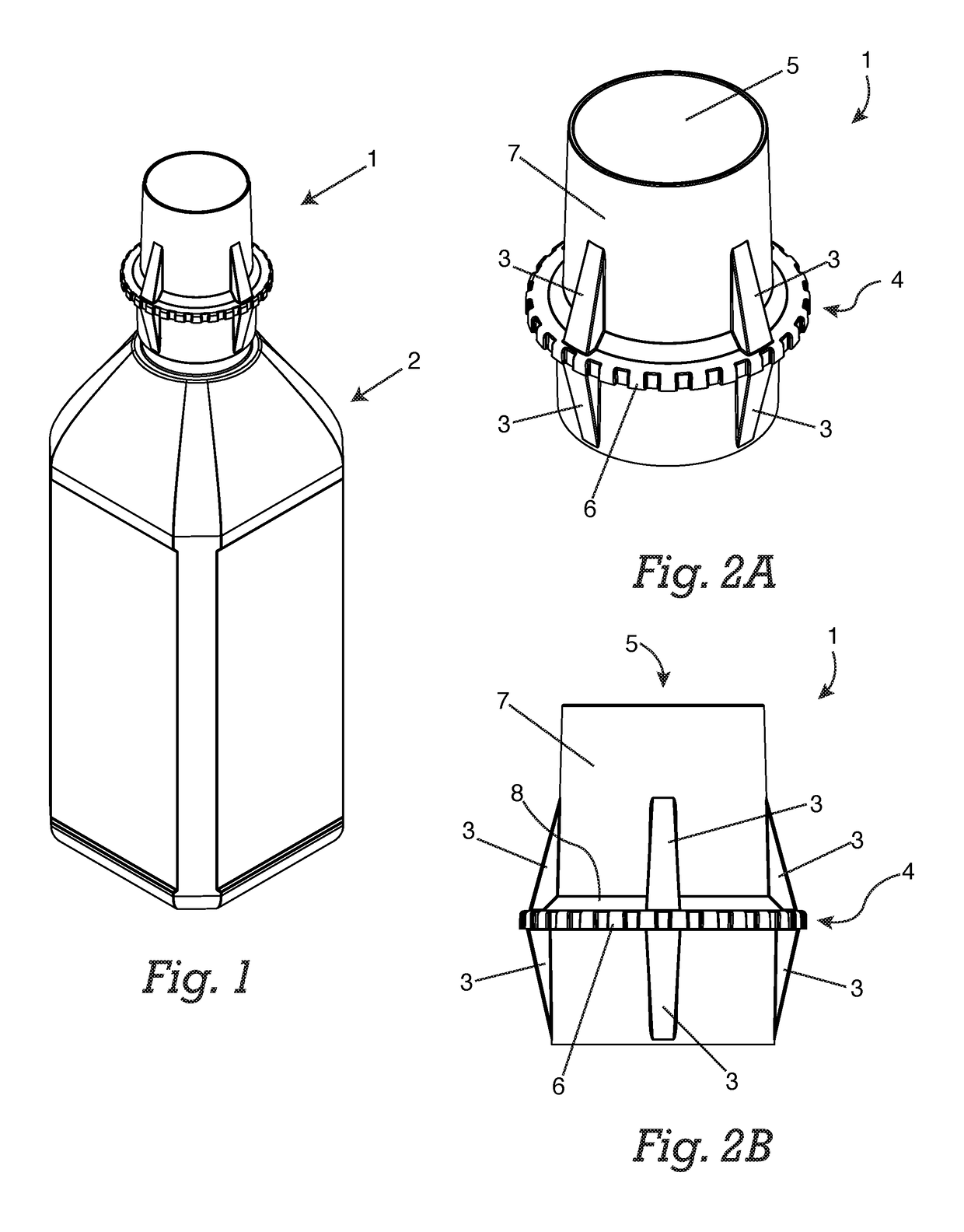

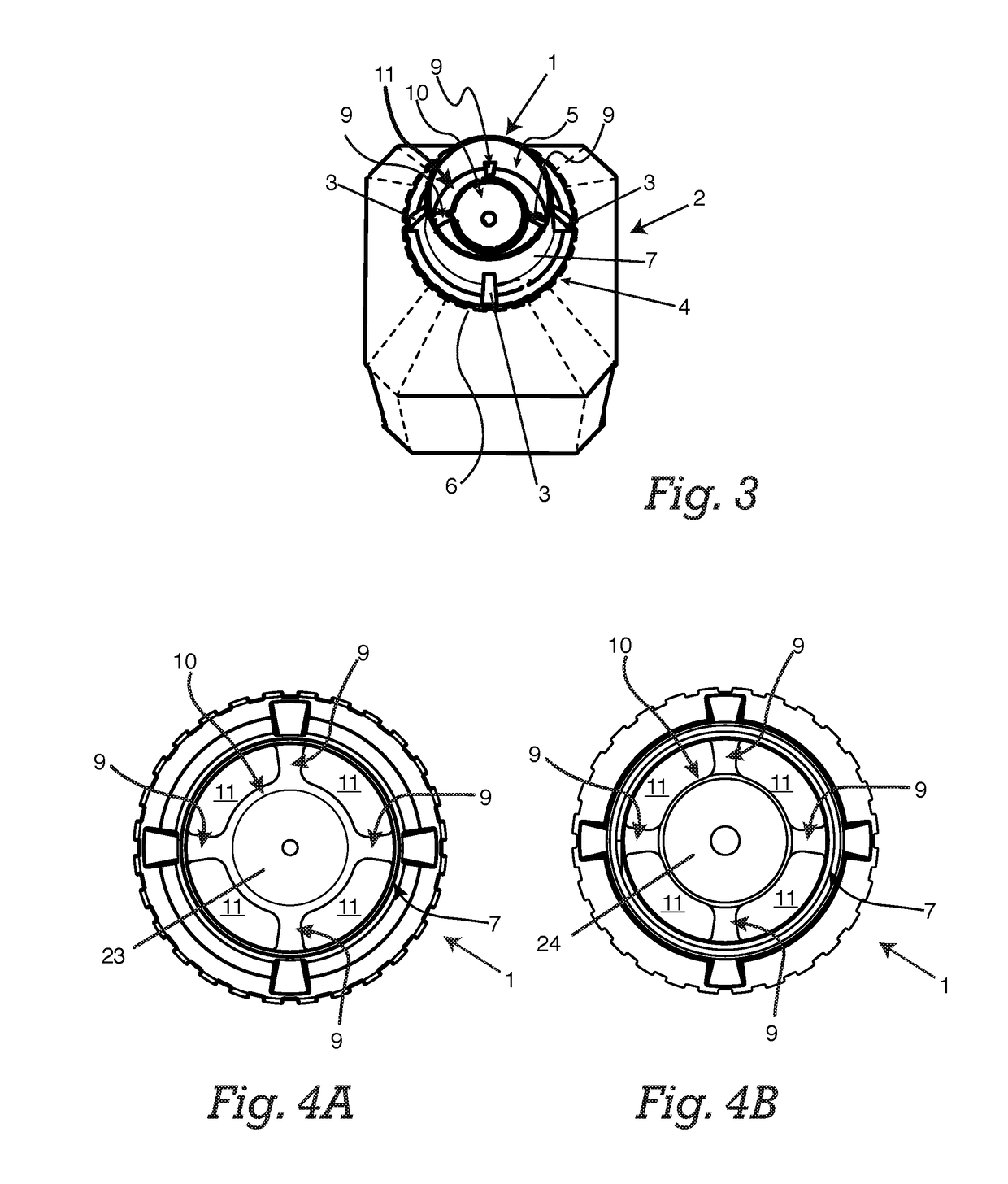

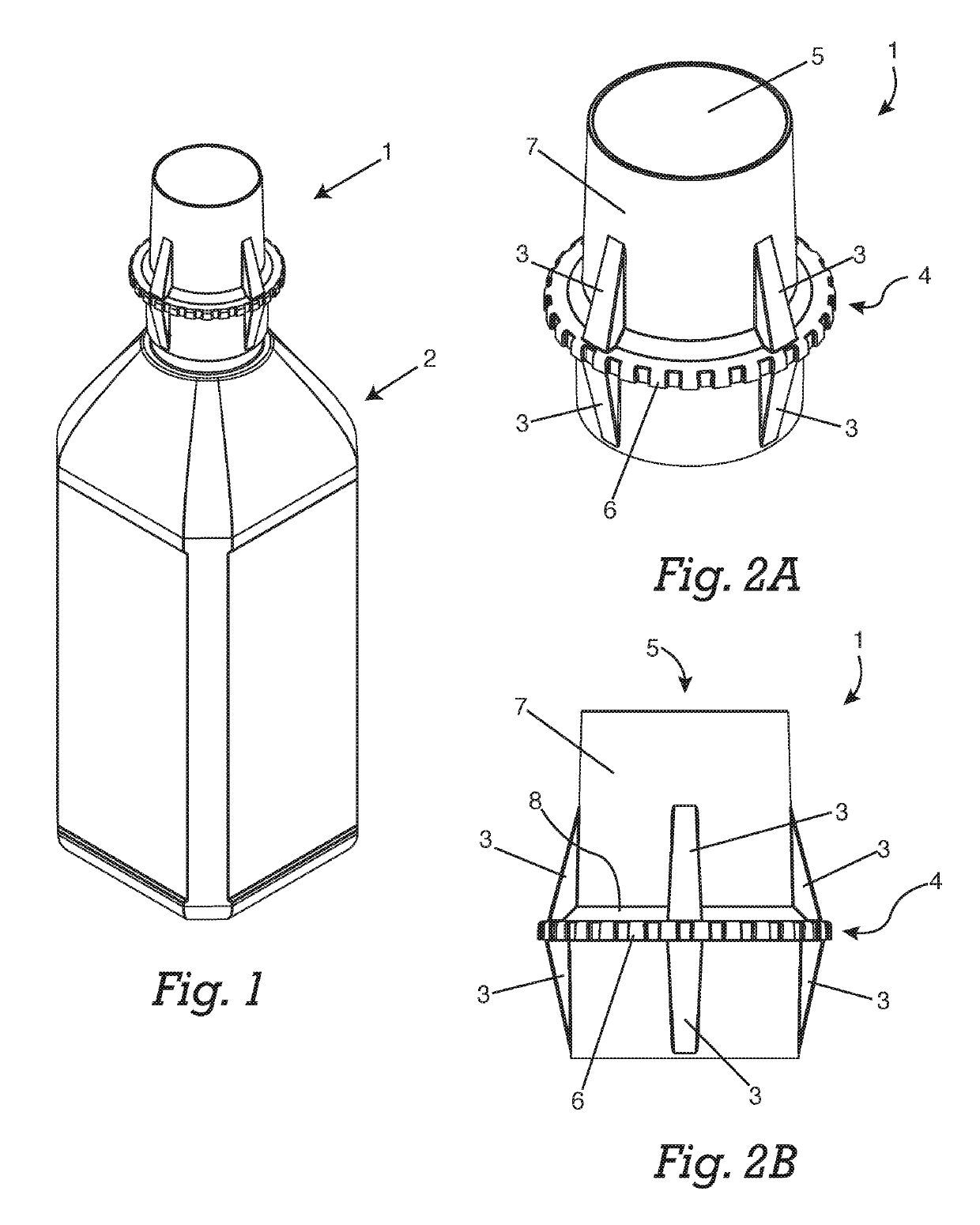

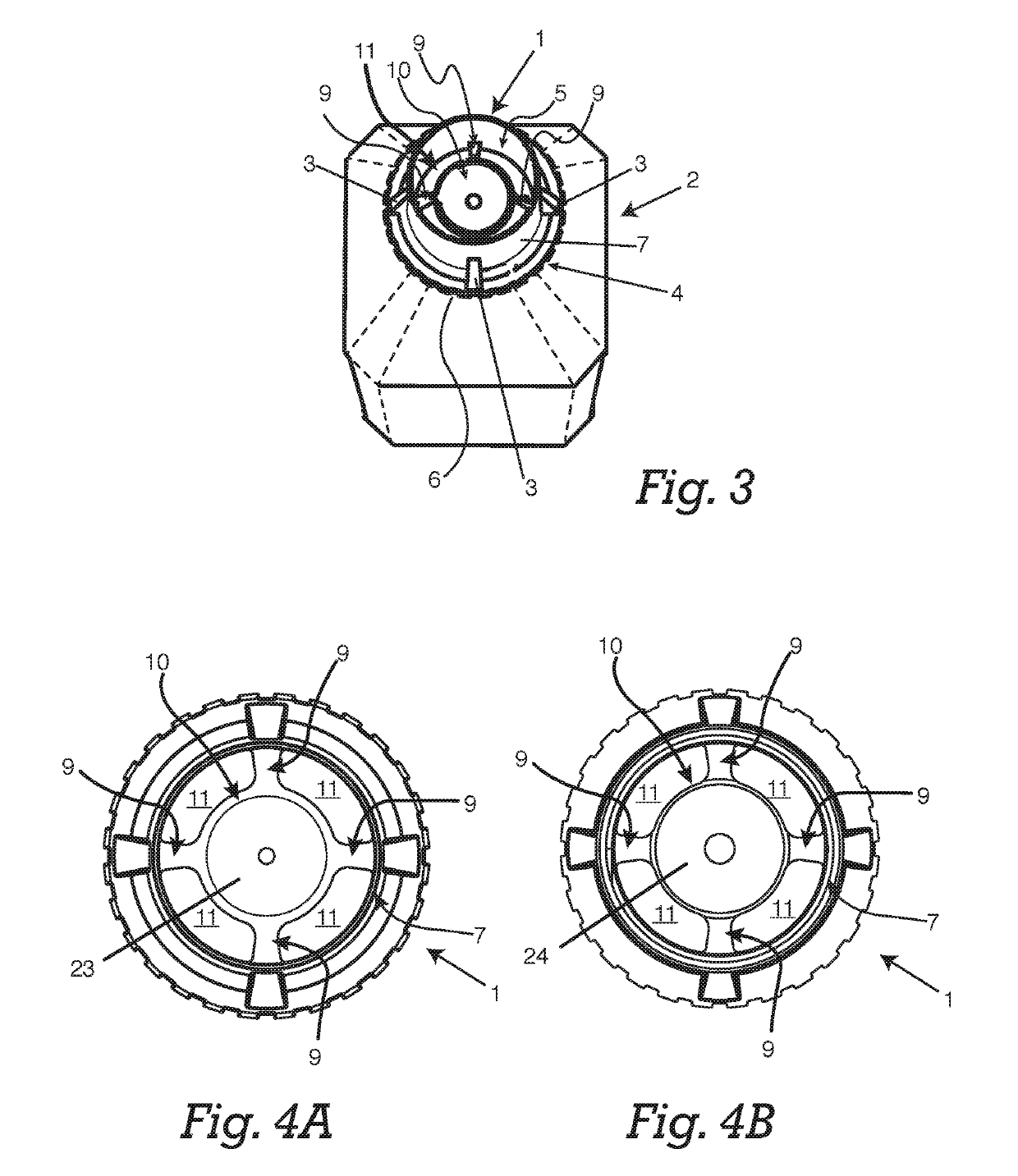

Method and apparatus for controlled transfer of fluid

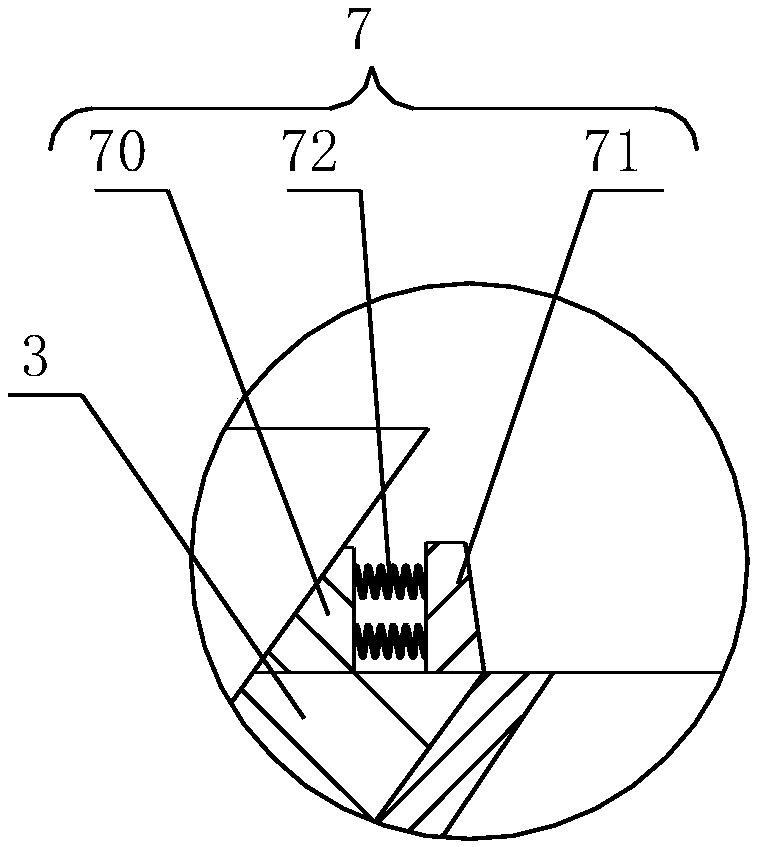

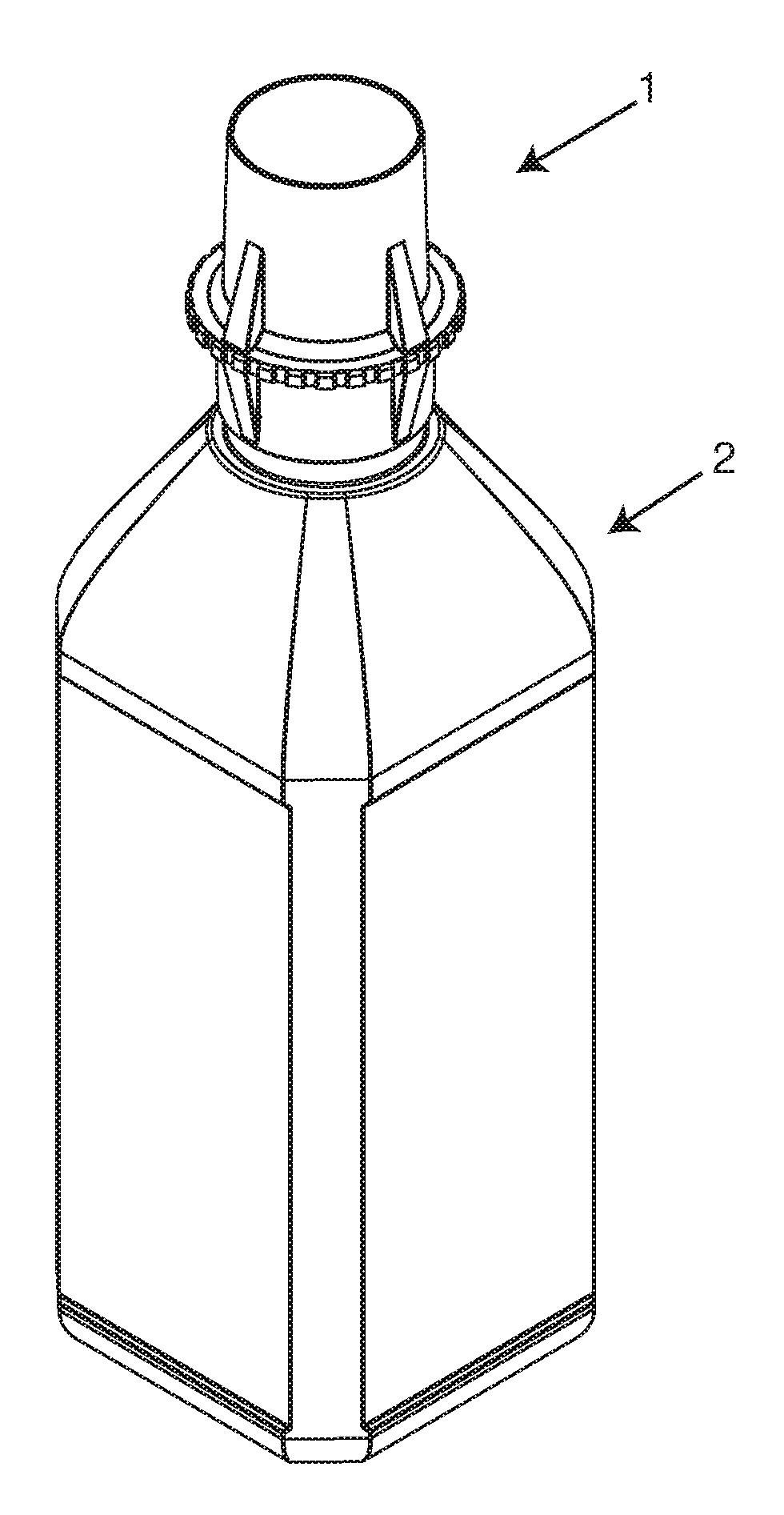

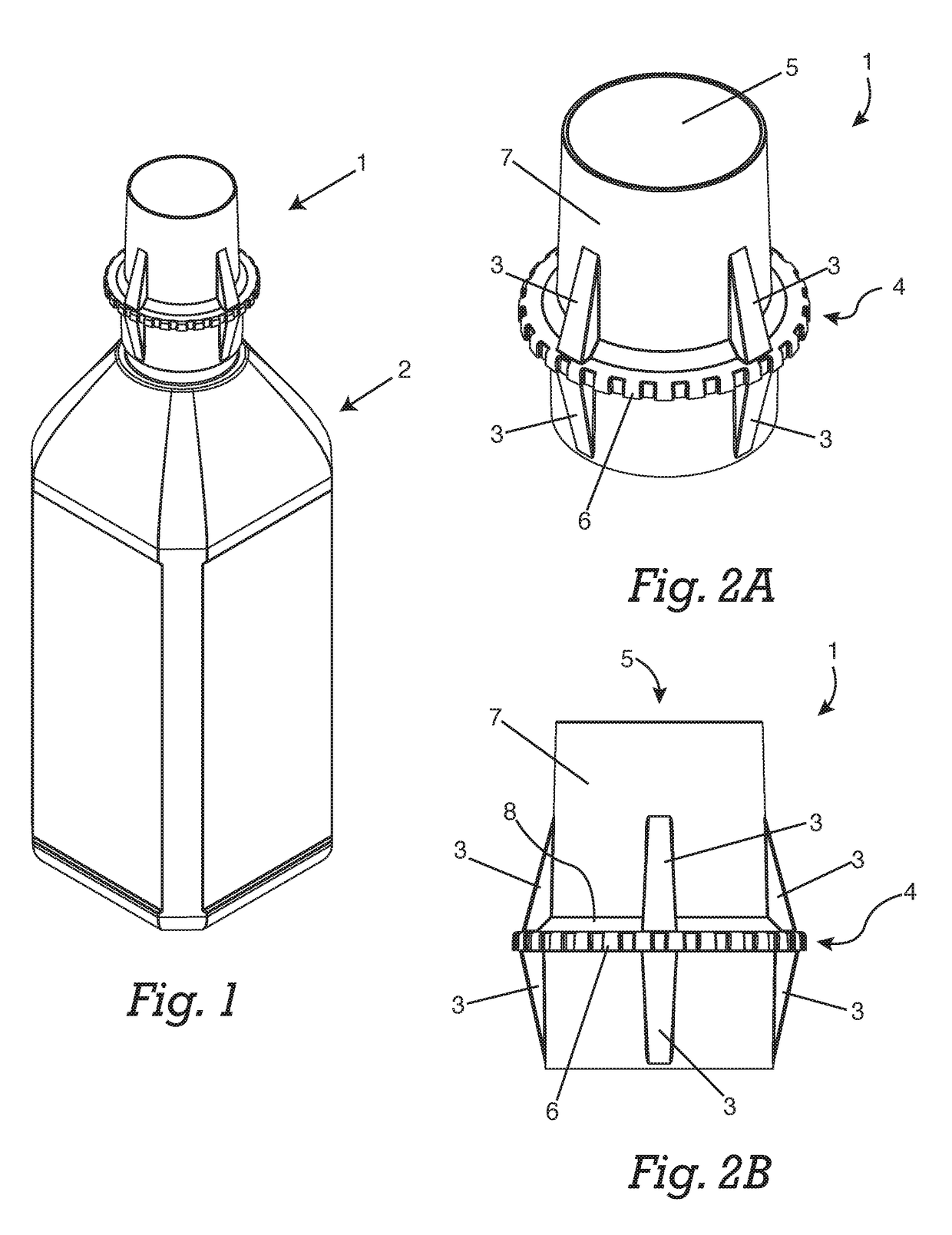

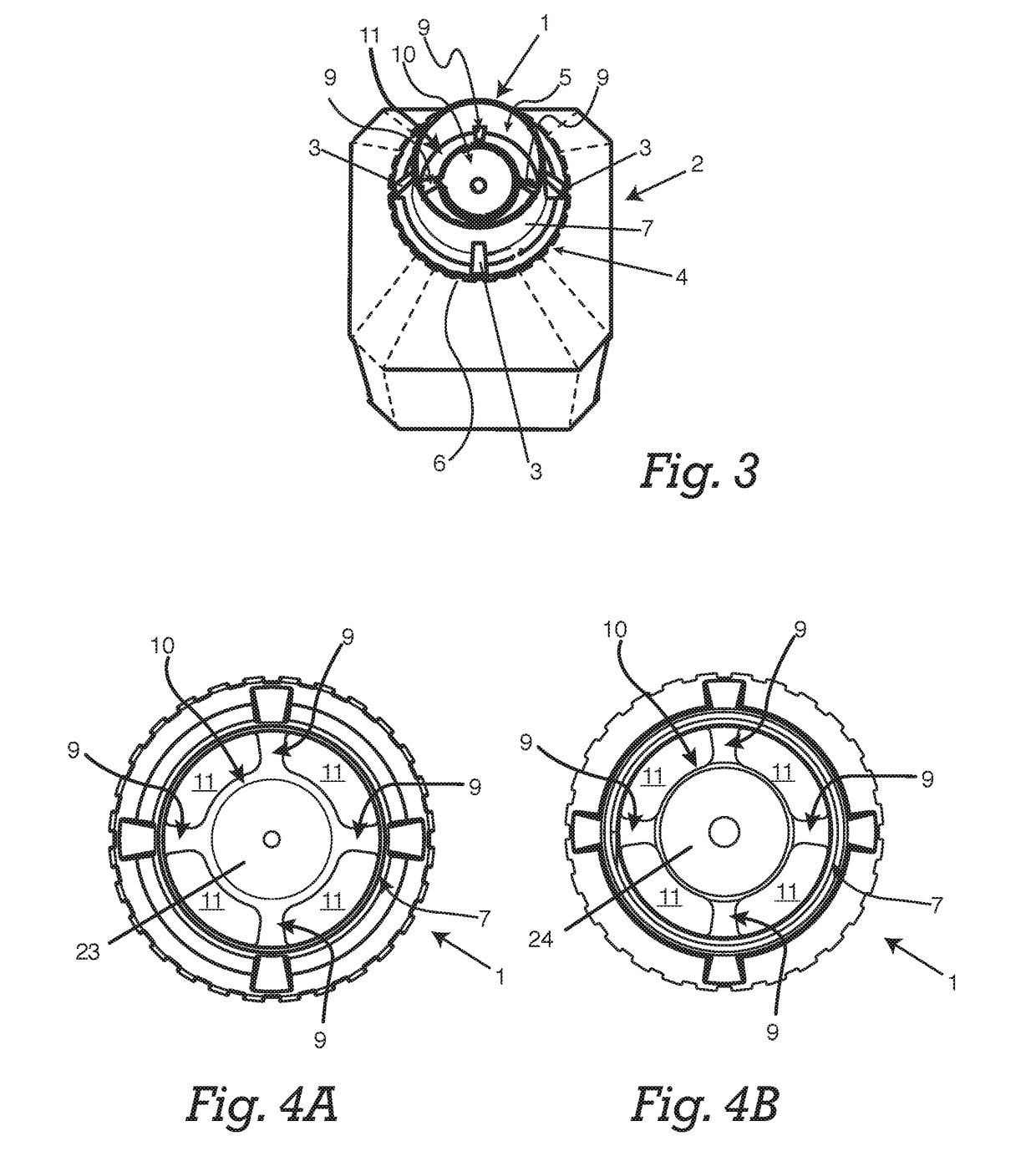

Embodiments of the present disclosure generally relate to caps, closures, seals, and containers, and control of flow of fluids. Certain embodiments can be used with fluids related to machinery, for instance, engine oil, brake fluid, coolant, transmission fluid, and power steering fluid. Certain embodiments of the present disclosure effectively hold and transfer a fluid or a fluid substance, further being able to open, close, and regulate fluid flow. Embodiments include a single piece tubular component that includes a cap interiorly attached to such tubular component with ribs, and a container having a tapered end. In certain embodiments, a nozzle having a tapered end is adapted to attach to a container.

Owner:VECTION LTD LLC

Spout cap having two steps type straw part

InactiveUS8453889B2Pouring precisionClosuresLiquid flow controllersEngineeringMechanical engineering

A spout cap having a two steps type straw part comprises a coupling part fixedly coupling with the pouring hole of the metal container; a first straw part extending at a predetermined length on the interior face of the coupling part; a cap coupling part having a pouring outlet through which contents in the metal container flow out, wherein the cap coupling part is selectively positioned in an overlapped disposition or an unfolded disposition with respect to the first straw part; an extension part between the first straw part and the cap coupling part, wherein the extension part is capable of extending the unfolded length when the cap coupling part is unfolded with respect to the first straw part; a second straw part extended from the upper inner face of the extension member at a predetermined length and coupled with the lower end of the cap coupling part.

Owner:CONTINENTAL CAN CO INC

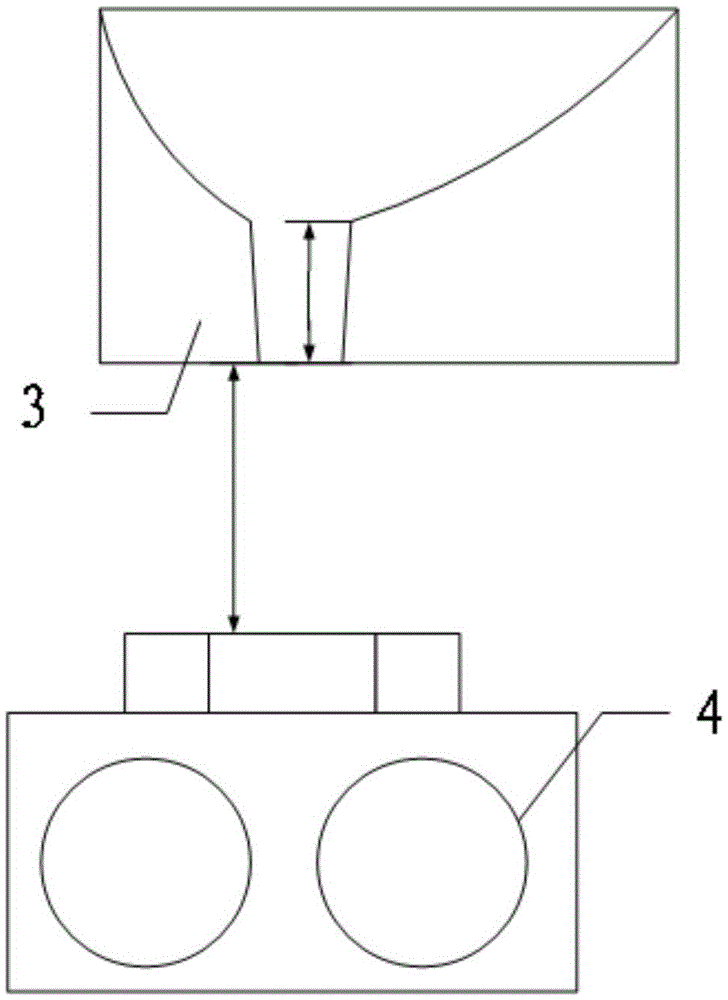

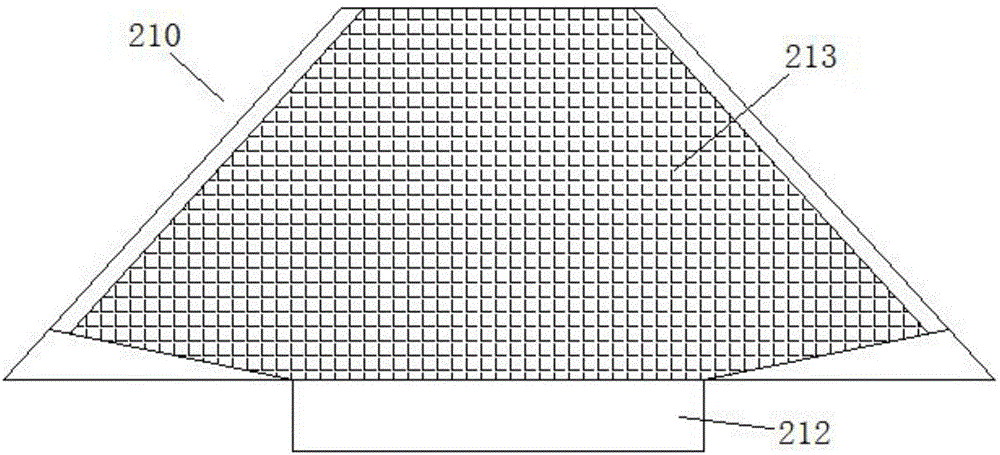

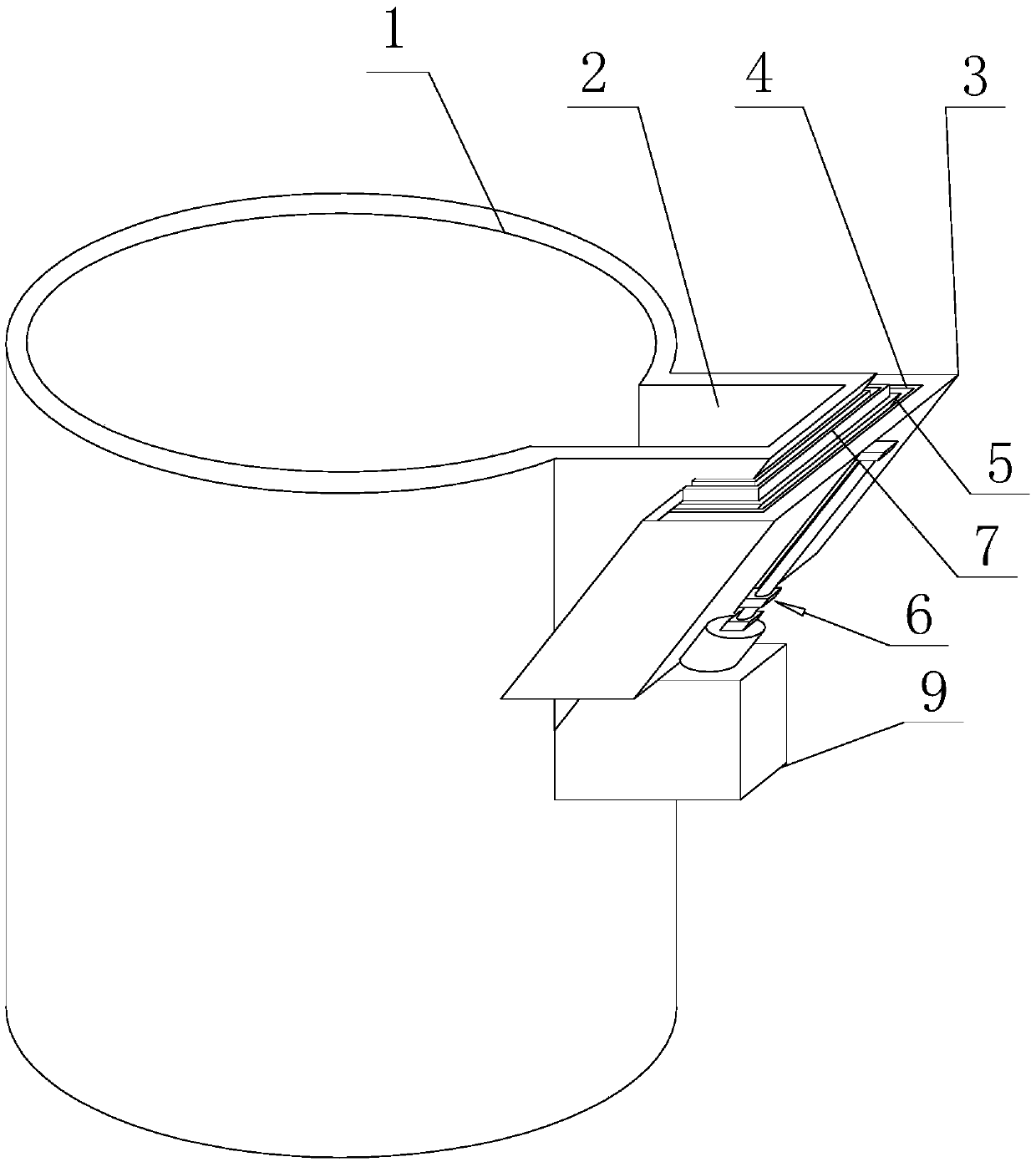

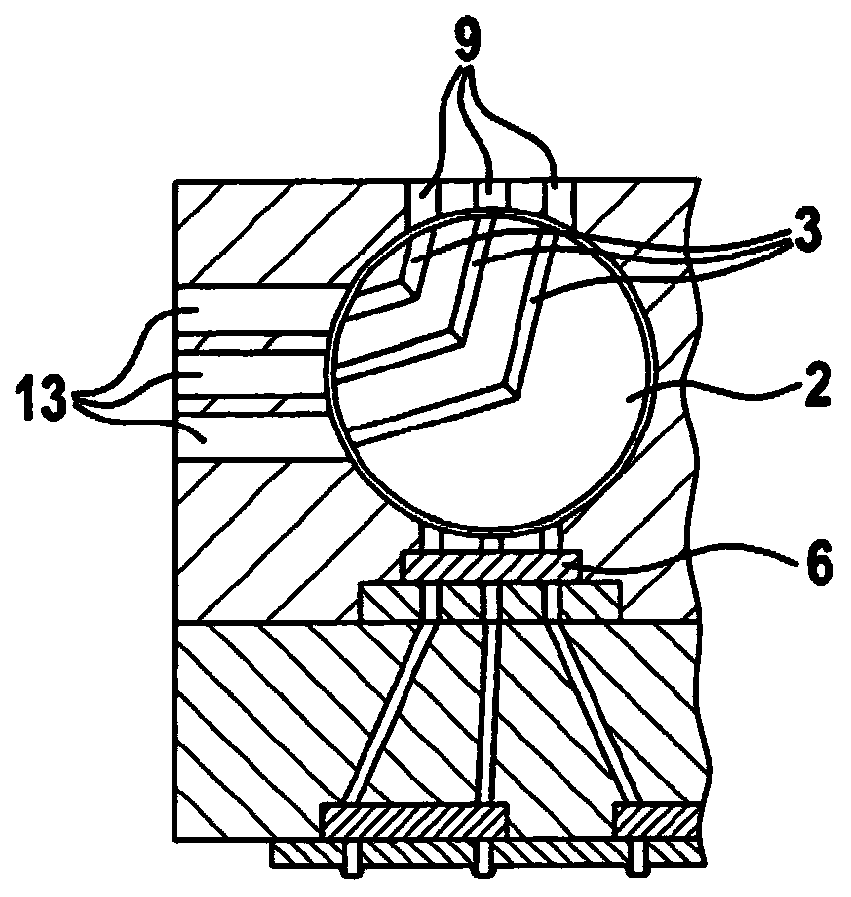

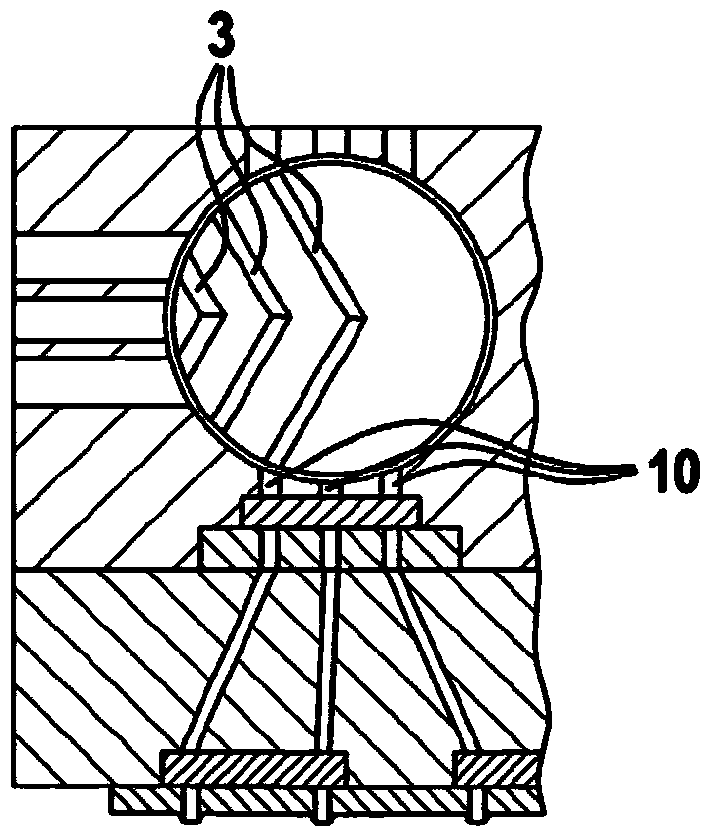

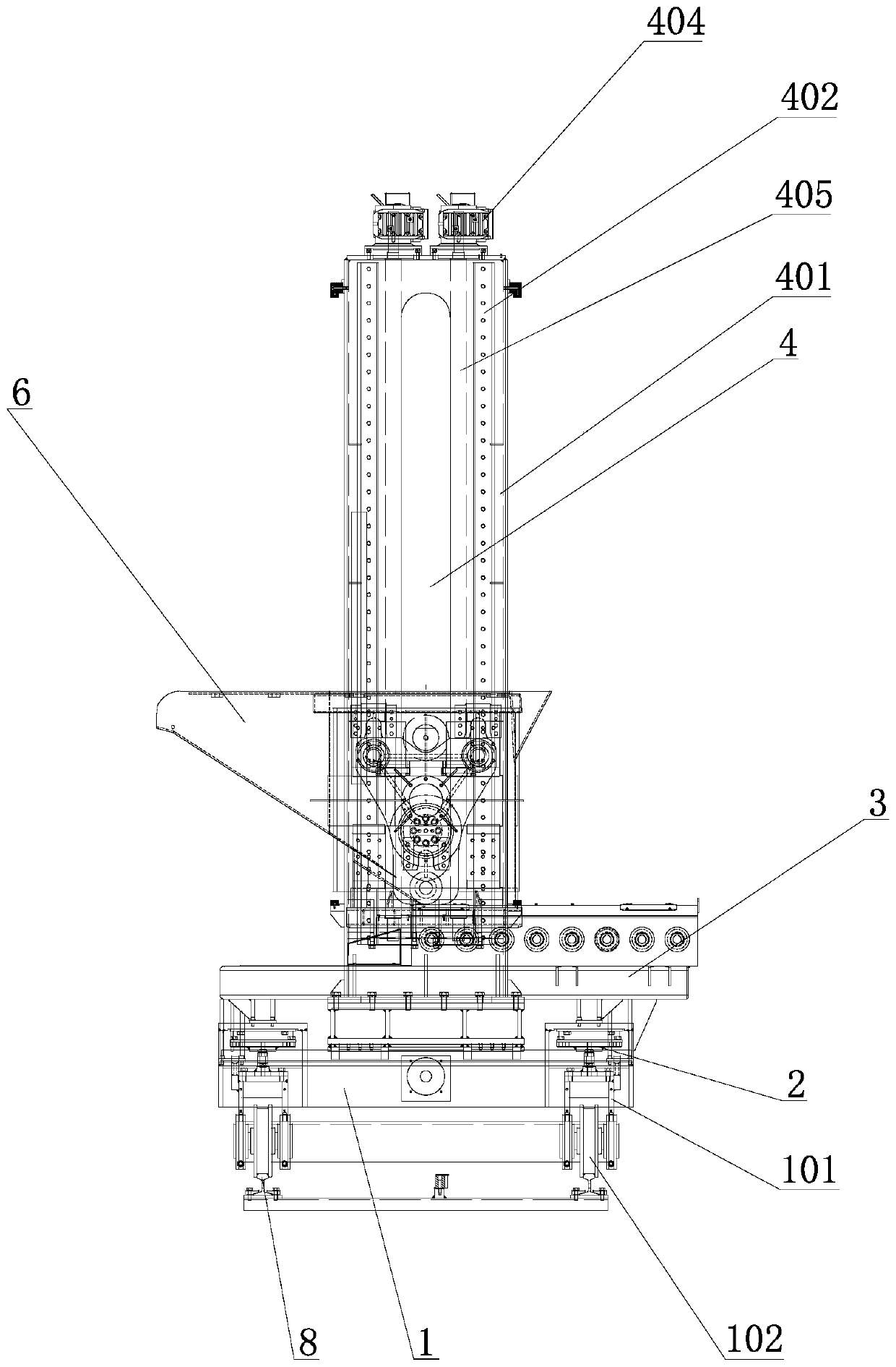

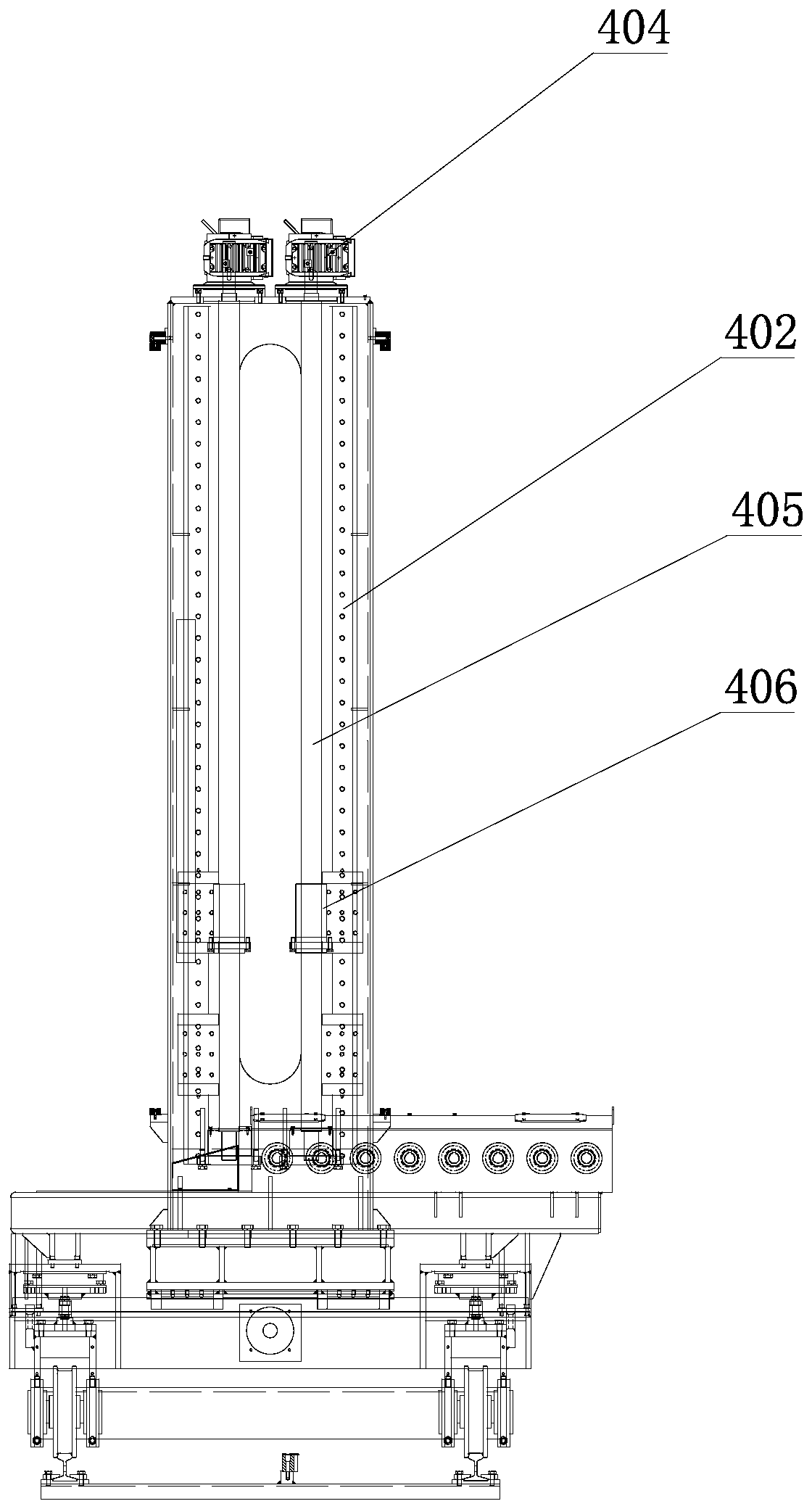

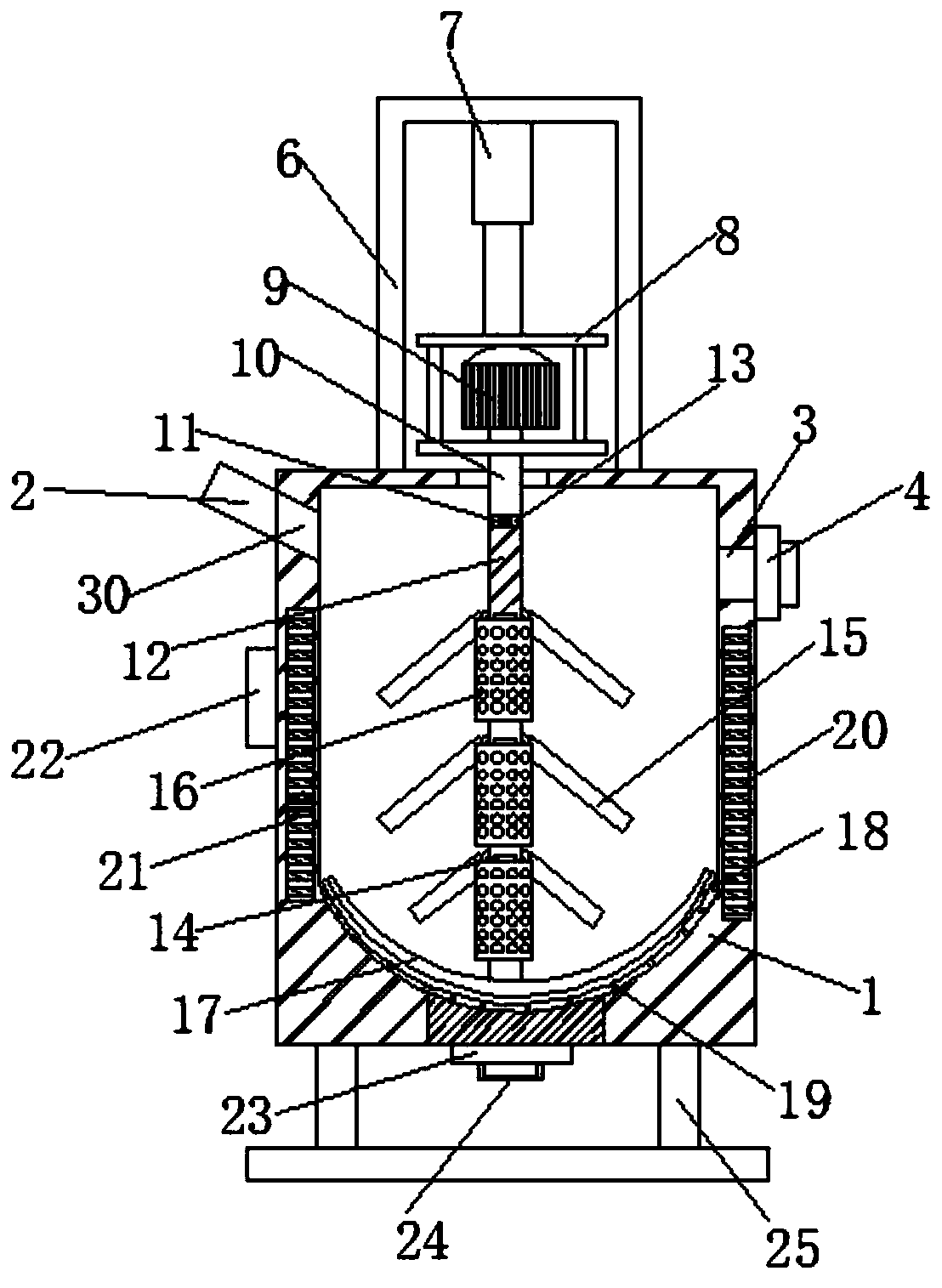

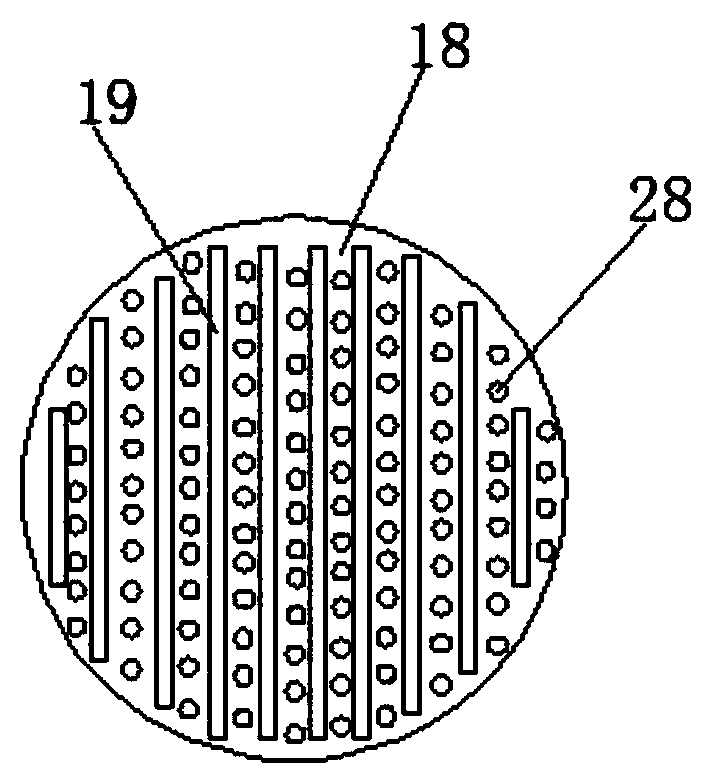

Ladle pouring device

ActiveCN109530668AEnsure consistencyPouring precisionMelt-holding vesselsMolten metal conveying equipmentsLiquid stateLiquid metal

The invention discloses a ladle pouring device. The ladle pouring device comprises a ladle pouring body, wherein the ladle pouring body is provided with a ladle pouring opening; a guide part is arranged on an outer wall of the ladle pouring opening; the guide part is in sliding connection with a flow guide plate; the surface, close to the ladle pouring opening, of the flow guide plate is parallelto the inner surface of the ladle pouring opening; the flow guide plate is connected with the guide part through a sliding mechanism; and the sliding mechanism drives the flow guide plate to move up and down relative to the ladle pouring opening. According to the ladle pouring device disclosed by the invention, liquid-state metal of the ladle pouring opening is drained through the flow guide plate; and the sliding mechanism drives the flow guide plate to move relative to the ladle pouring opening and the horizontal position of pouring the liquid-state metal, which flows out from the flow guideplate, into a mold is adjusted.

Owner:广德亚太汽车智能制动系统有限公司

Method and apparatus for controlled transfer of fluid

Embodiments of the present disclosure generally relate to caps, closures, seals, and containers, and control of flow of fluids. Certain embodiments can be used with fluids related to machinery, for instance, engine oil, brake fluid, coolant, transmission fluid, and power steering fluid. Certain embodiments of the present disclosure effectively hold and transfer a fluid or a fluid substance, further being able to open, close, and regulate fluid flow. Embodiments include a single piece tubular component that includes a cap interiorly attached to such tubular component with ribs, and a container having a tapered end. In certain embodiments, a nozzle collar having a tapered end is adapted to attach to a container.

Owner:VECTION LTD

Workpiece overturning device of net belt shot blasting machine

PendingCN107600990APouring precisionDump cleanAbrasive blasting machinesConveyor partsPulp and paper industryBlasting machine

The invention provides a workpiece overturning device of a net belt shot blasting machine. The device comprises a main chamber net belt positioned in a shot blasting machine chamber body, an overturning roller positioned in an outlet of the shot blasting machine chamber body, an arc guide plate and a conveying net belt; the main chamber net belt is in transmission connection with the overturning roller; the main chamber net belt is turned on the overturning roller; the arc guide plate coats the net belt in transmission connection with the overturning roller; a gap between the arc guide plate and the main chamber net belt can contain workpieces to pass through; the overturning roller and the arc guide plate are arranged in a concentric circle manner; and the conveying net belt is arranged below the overturning roller. In the falling process, shots in the workpieces can be poured totally, then, fall onto the overturned conveying net belt, and are conveyed to a next procedure. The workpieces without the shots can be directly fed in the next procedure without stopping operation, and the shots in the workpieces are manually cleaned, so that the working efficiency is better.

Owner:YANCHENG FENGTE CASTING MACHINERY

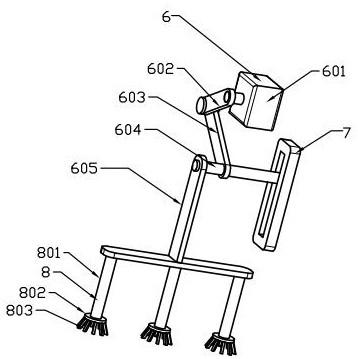

Small automatic wall building machine

InactiveCN108979177ARealize transportationMeet horizontalBuilding material handlingBrickElectric machinery

The invention relates to a small automatic wall building machine comprising a rack, a traveling mechanism, a conveying mechanism, a clamping mechanism, a moving mechanism, an injection mechanism and alifting mechanism. The traveling mechanism is formed by a traveling motor and two parallel crawler belts. The conveying mechanism includes a conveyor belt, a transmission motor and a belt shaft. Themoving mechanism includes a moving motor, a first horizontal lead screw and two first horizontal polished rods arranged in parallel. The clamping mechanism includes a top base, a fixed clamping plate,a movable clamping plate, and a clamping motor, a lifting motor and a steering motor. According to the small automatic wall building machine, the cement slurry can be poured accurately and bricks canbe conveyed, clamped, moved and stacked automatically, so that the labor level of the worker is reduced substantially, the risk factor of the manual building is reduced, and the work efficiency is improved greatly. Moreover, the wall is built by using the machine, so that the project quality becomes uniform and the engineering quality of the built wall is improved.

Owner:BINZHOU UNIV

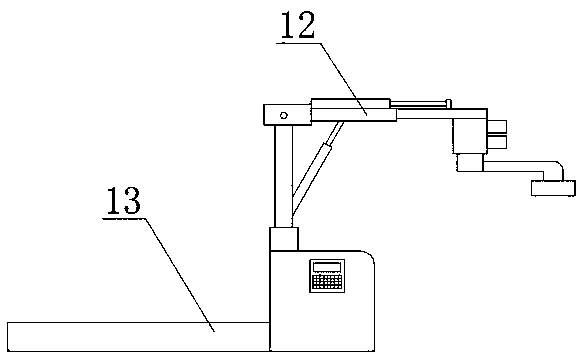

Polyurethane casting machine

The invention discloses a polyurethane casting machine. The polyurethane casting machine comprises a base, locking universal wheels are arranged at the bottom of the base, and a plurality of polyurethane storage tank bodies, a plurality of lifting rotating units corresponding to the polyurethane storage tank bodies and a control cabinet connected with the lifting rotating units are sequentially and fixedly installed on the upper surface of the base from left to right; and each lifting rotating unit comprises a lifting mechanism, a steering mechanism and a transverse frame connected with the steering mechanism. The lifting rotating units are arranged on the base, the dual functions of synchronous rising and rotating of a pouring head are achieved, the cost performance is improved, the rising distance of a lifting column can be accurately adjusted, the lifting of the lifting column can drive the transverse frame and a material conveying pipe to rise and fall, the proper height is adjusted for pouring use, the requirement for accurate pouring is met, and various different pouring areas can be met.

Owner:ZHENJIANG SINOWA POLYURETHANE EQUIP

Device and a method for distributing flowable or pourable substances, in particular air chocolate

Owner:BUEHLER AG

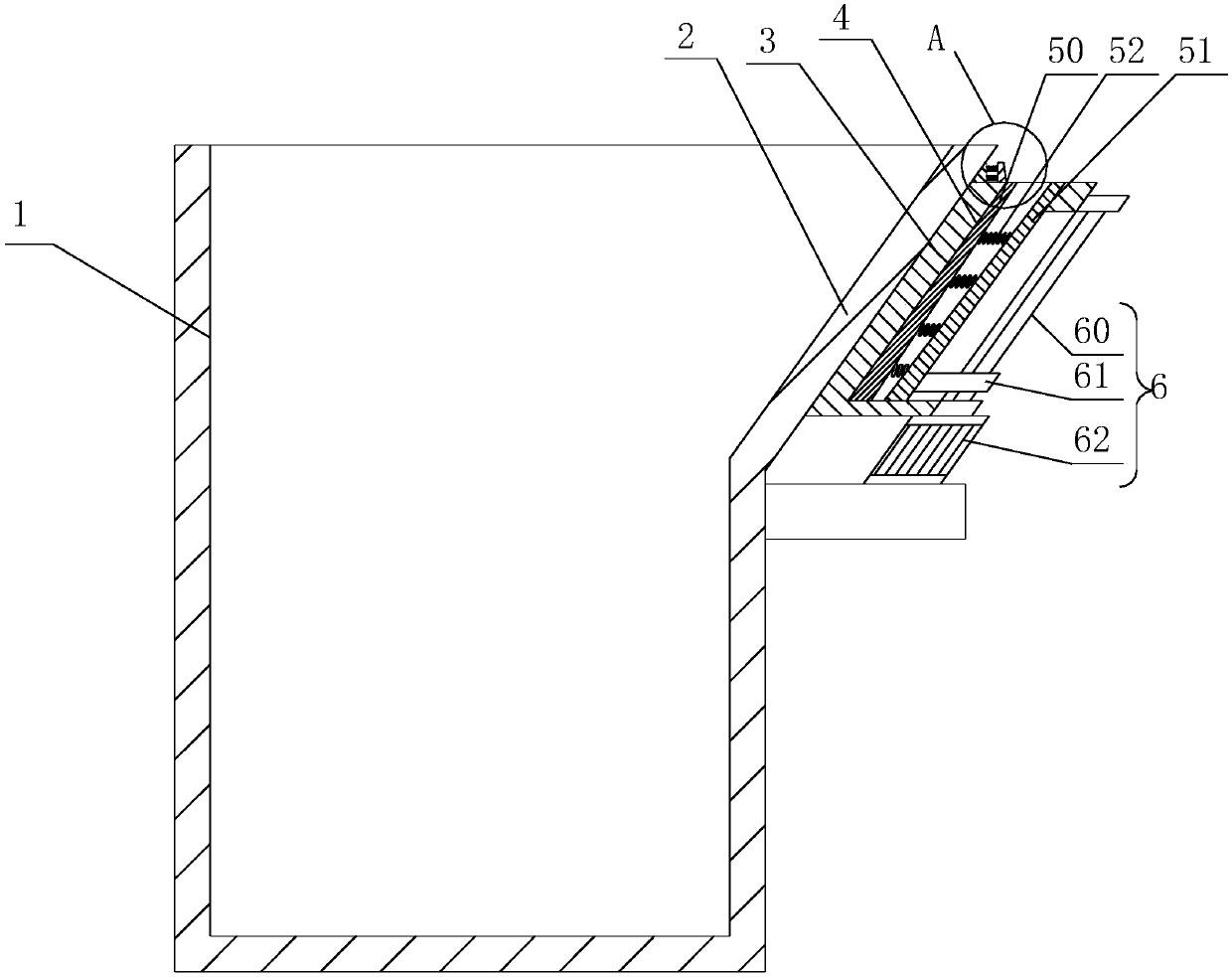

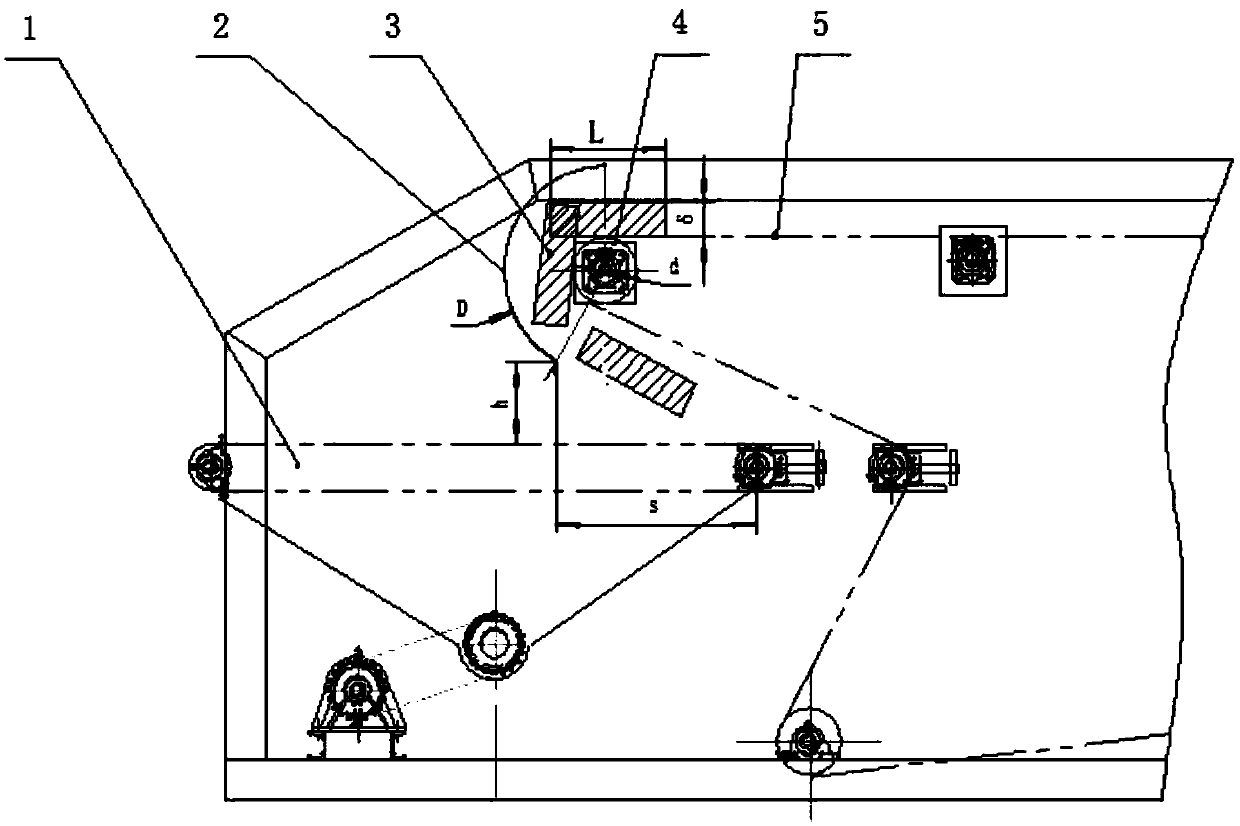

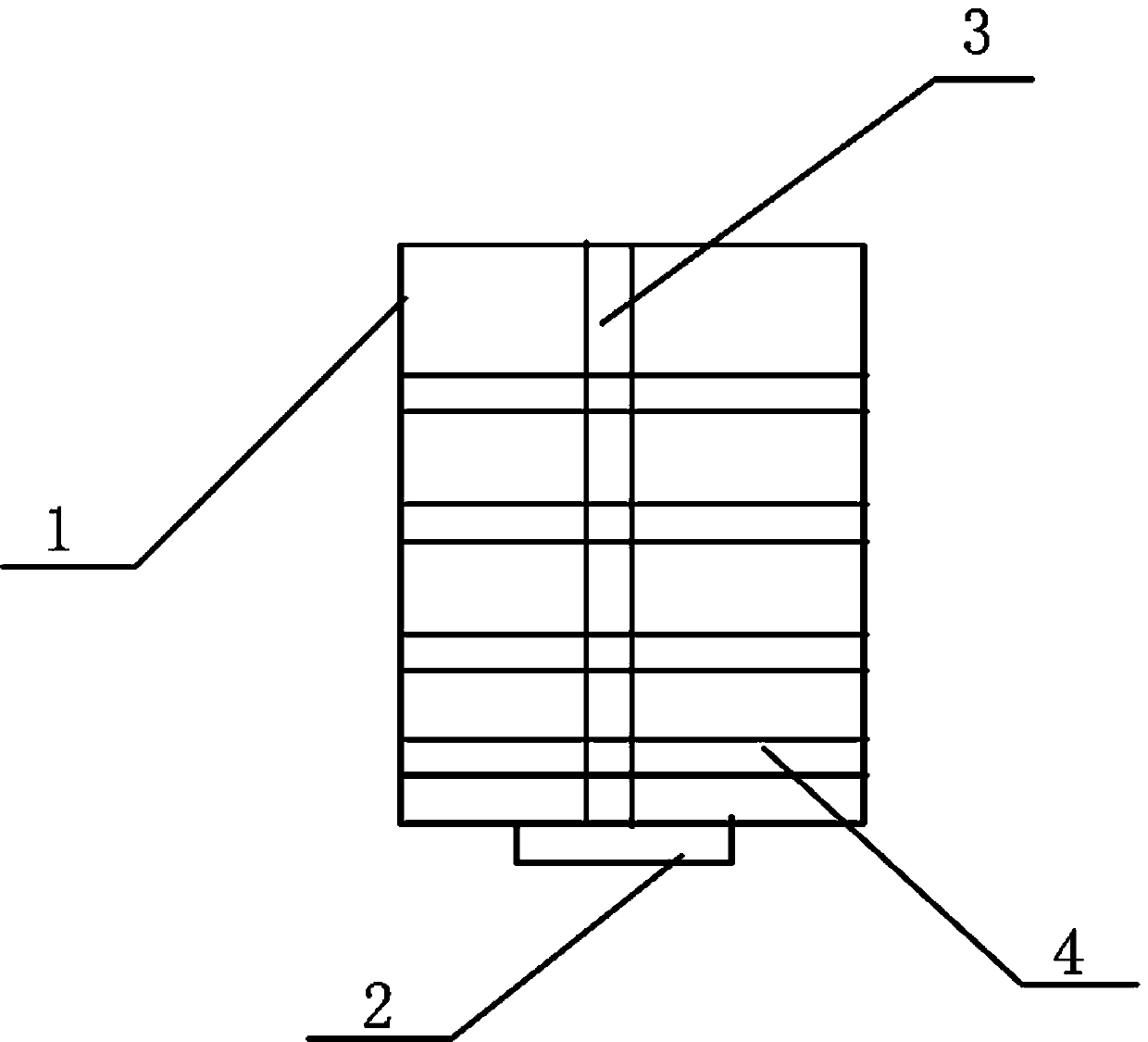

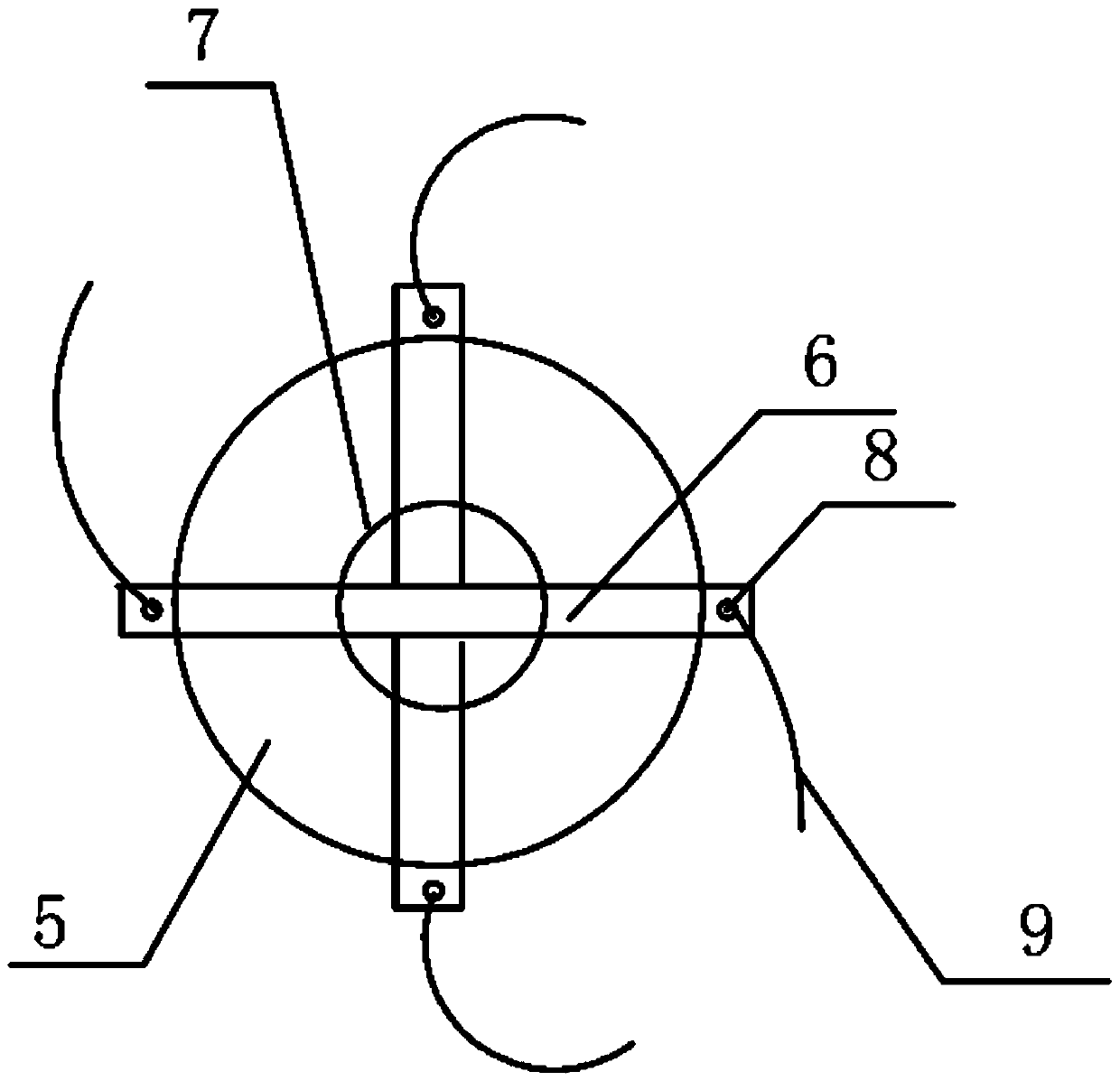

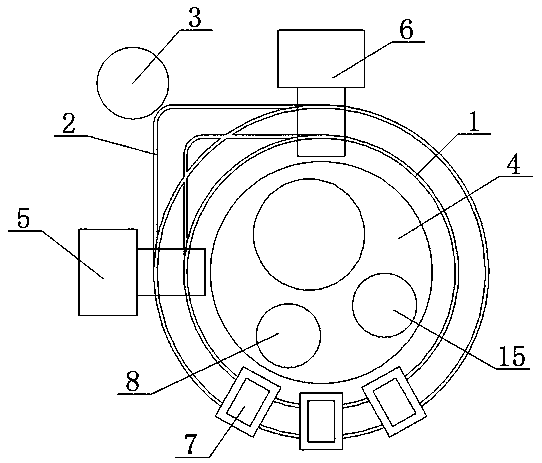

Mounting and adjusting device for pouring of solid propellant combustion chamber

ActiveCN107687377AGuaranteed stabilityAccurate entryRocket engine plantsLoad-engaging elementsCombustion chamberEngineering

The invention discloses a mounting and adjusting device for pouring of a solid propellant combustion chamber. The mounting and adjusting device comprises a pouring cylinder which is cylindrical and isprovided with the hollow interior, and the bottom of the pouring cylinder is provided with a hydraulic lifting platform. A plurality of guiding grooves are uniformly distributed in the side wall of the pouring cylinder in the axial direction, a plurality of annular grooves are distributed in the side wall of the pouring cylinder in the radical direction, and the guiding grooves and the annular grooves are vertically formed in the inner side of the side wall in a staggered mode. The mounting and adjusting device further comprises a bearing disc, the bottom of the bearing disc is connected witha bearing beam, and the center of the bearing beam is provided with a bearing. The mounting and adjusting device is reasonable in structure, reliable in work and easy to operate, various potential safety hazards are completely eliminated, the number of tools is decreased, and the production cost and management cost of enterprises are greatly reduced.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

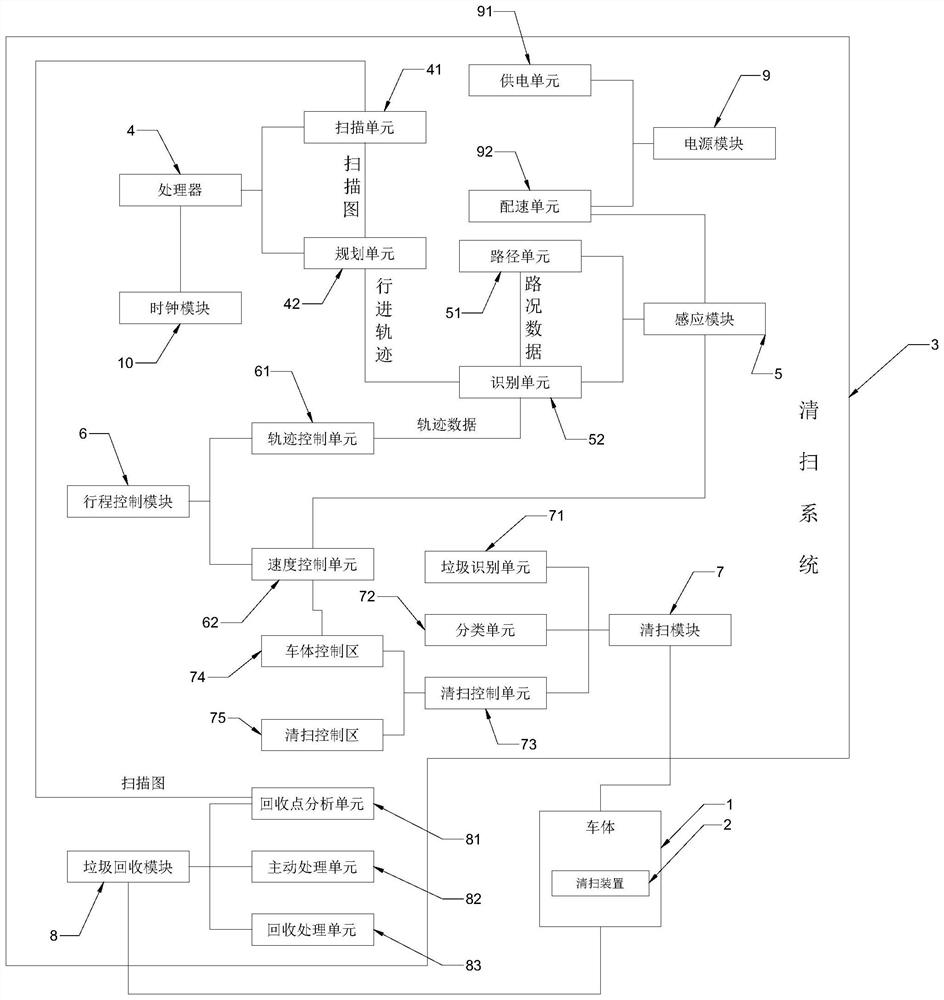

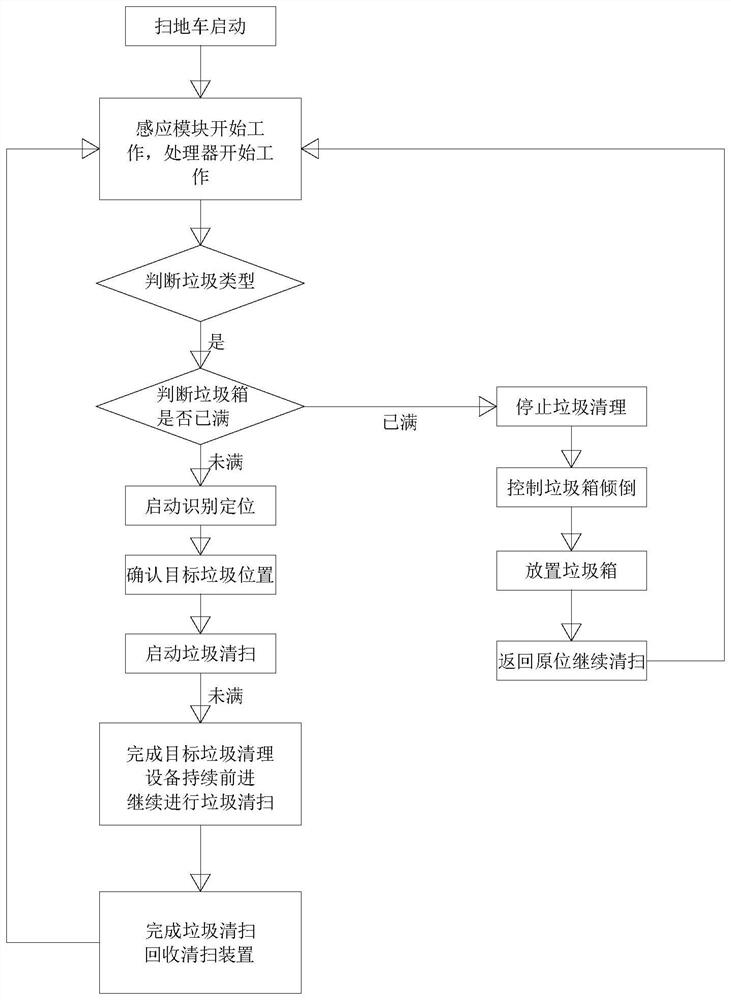

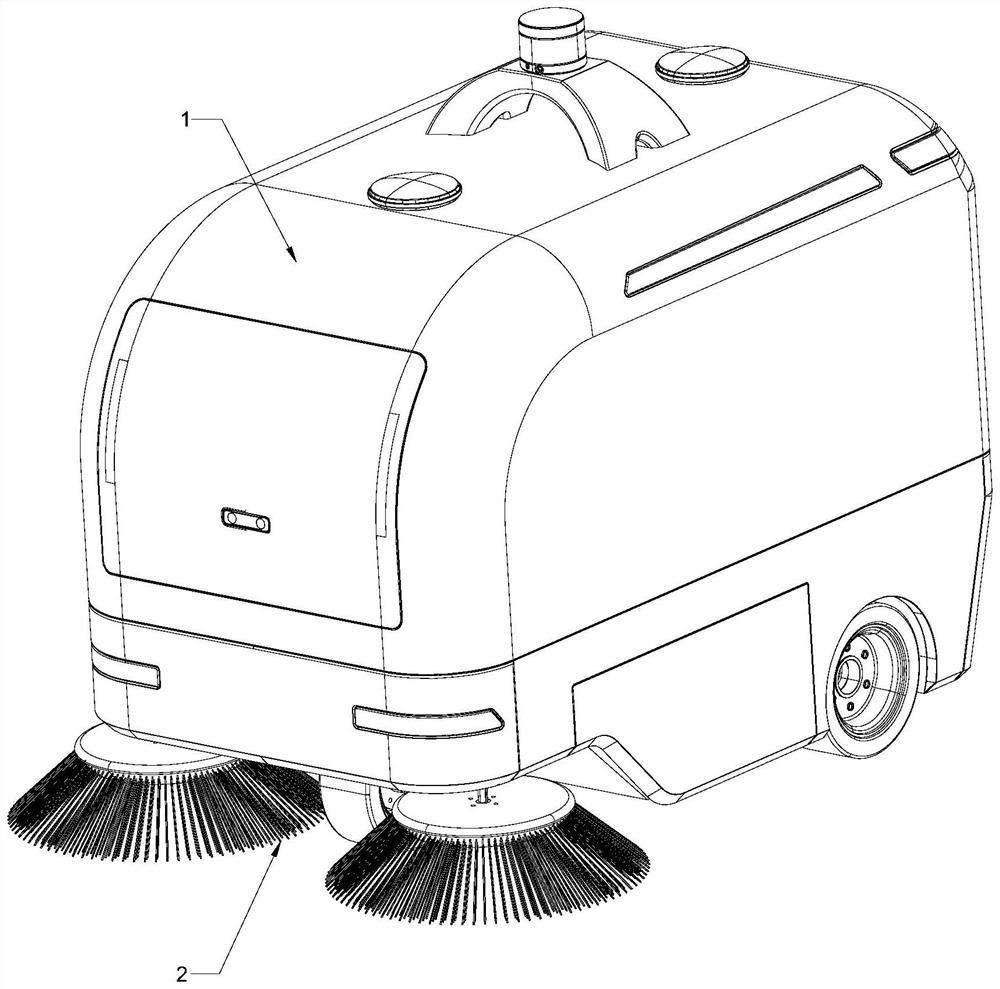

Novel sweeper equipment

PendingCN114411601APouring precisionPrecise deliveryScene recognitionRoad cleaningGarbage collectionReliability engineering

According to the technical scheme, the novel sweeper equipment is characterized in that the novel sweeper equipment comprises a sweeper body and a garbage can arranged in the sweeper body, and a sweeping device is further arranged on the sweeper body and used for sweeping garbage and throwing the garbage into the garbage can; the cleaning system comprises a processor, a sensing module, a stroke control module, a sweeping module and a garbage recycling module; the processor is used for obtaining a peripheral scanning image of the vehicle body and planning an advancing track according to the scanning image, the sensing module is used for detecting the vehicle body in real time, controlling the vehicle body to move along the advancing track and controlling the vehicle body to start detection and sweeping, the stroke control module is used for keeping the vehicle to run on the advancing track, and the sweeping module is used for controlling garbage sweeping. The garbage recycling module is used for controlling garbage in the garbage can to be recycled and dumped. The novel sweeper equipment has the effects of accurately sweeping garbage and improving the sweeping efficiency.

Owner:英博超算(南京)科技有限公司

Butt seamed package bag and method for using same

A rectangular, flexible butt-seamed package bag and a method for using the same is provided in which the pouring of a single type of a liquid packing material filled and packed in the filling space for the packed material from the package bag can be easily performed. A butt-seamed package bag formed by joining both side portions of a sealant layer of a laminate film for packing to each other at a butt state and joining bottom portions or top portions thereof to define a filling space for a single packed material, characterized in that a pouring path for the packed material is disposed in a middle part of a butt-seamed joint portion in an extending direction thereof, and at least a part of the pouring path is provided with an easily separable portion having a joint strength relatively lower than that of the butt-seamed joint portion.

Owner:TAISEI LAMICK

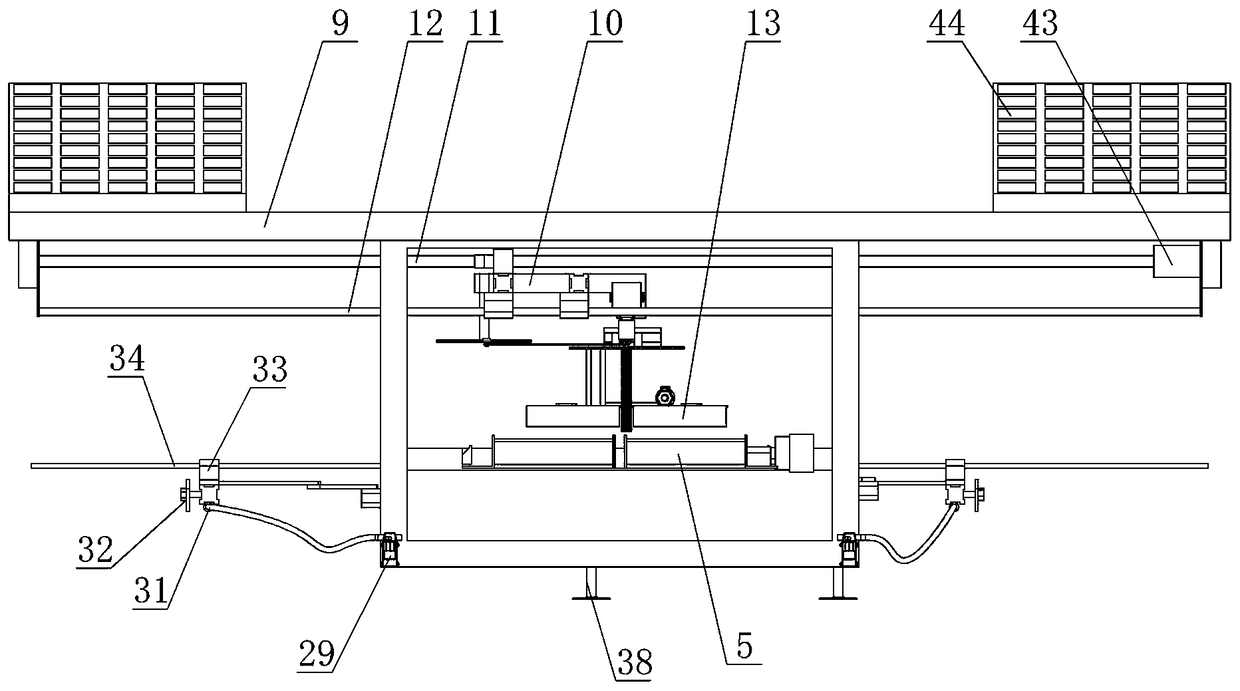

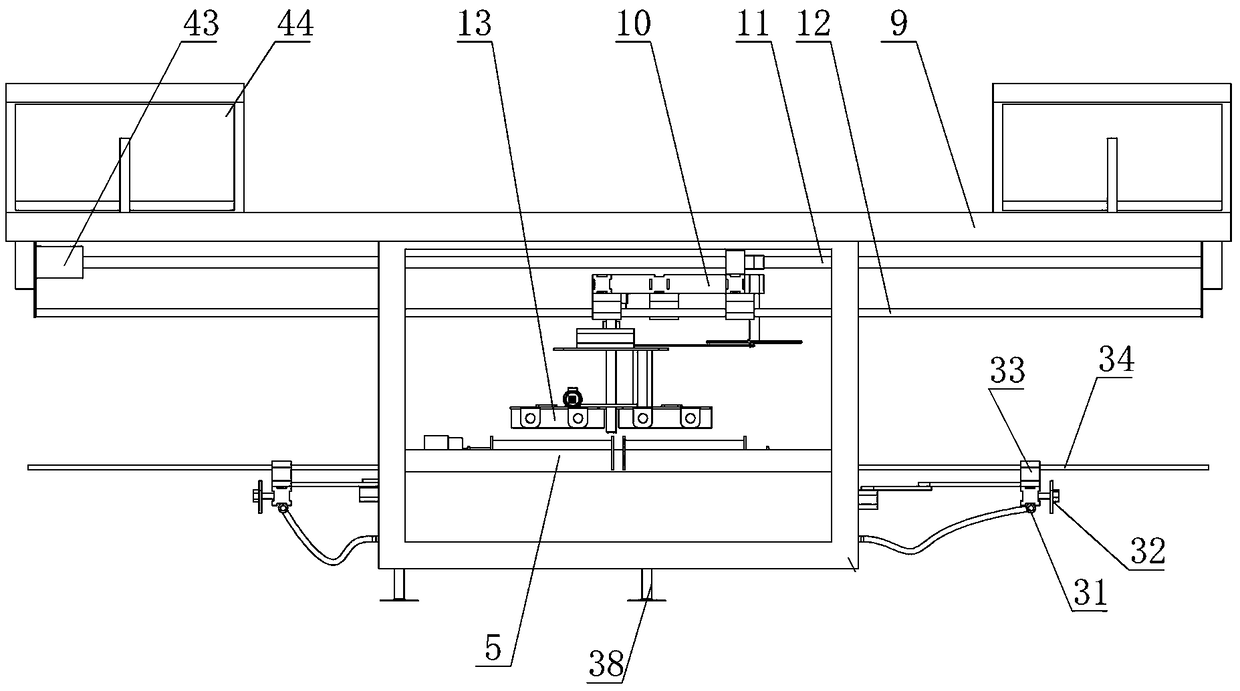

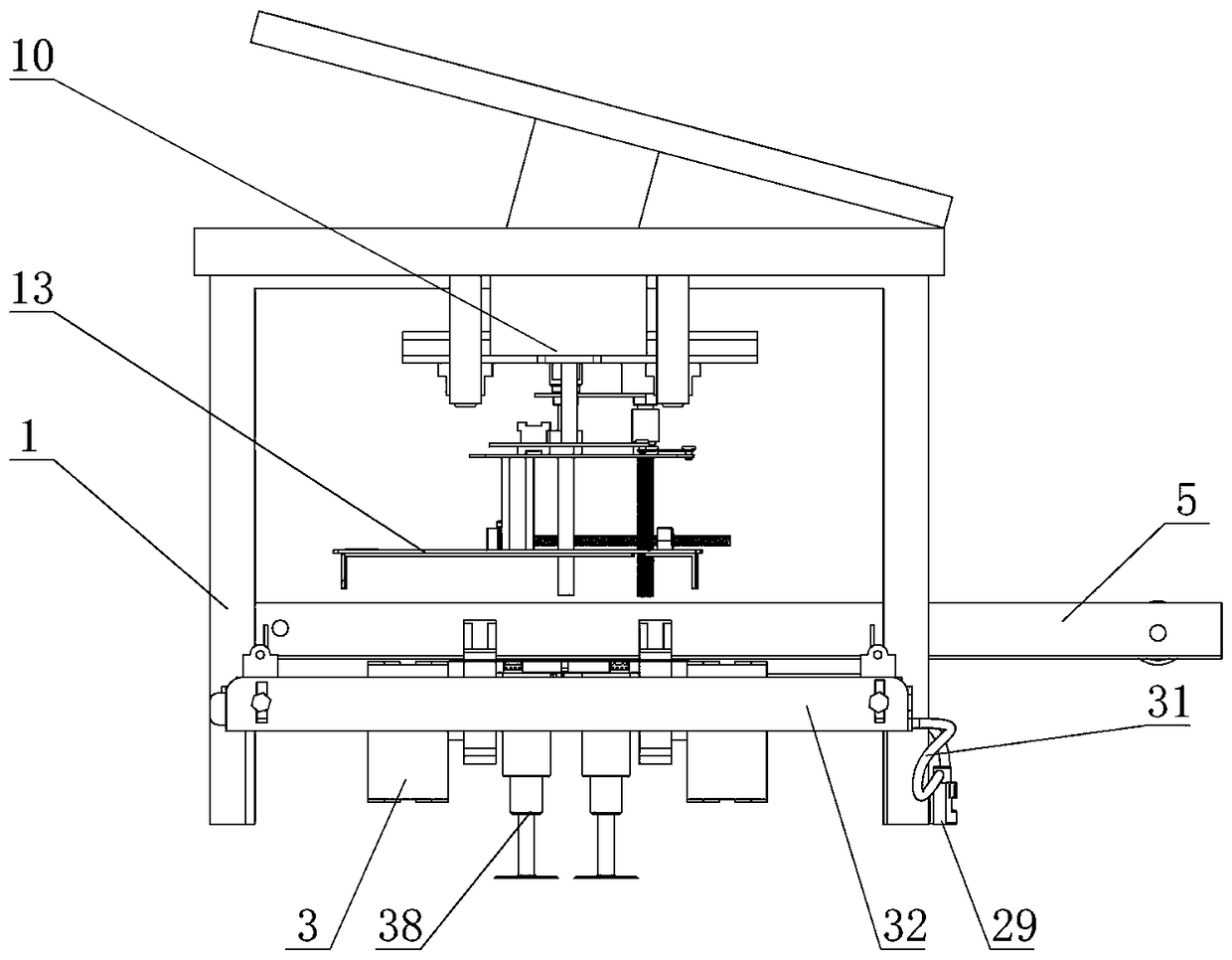

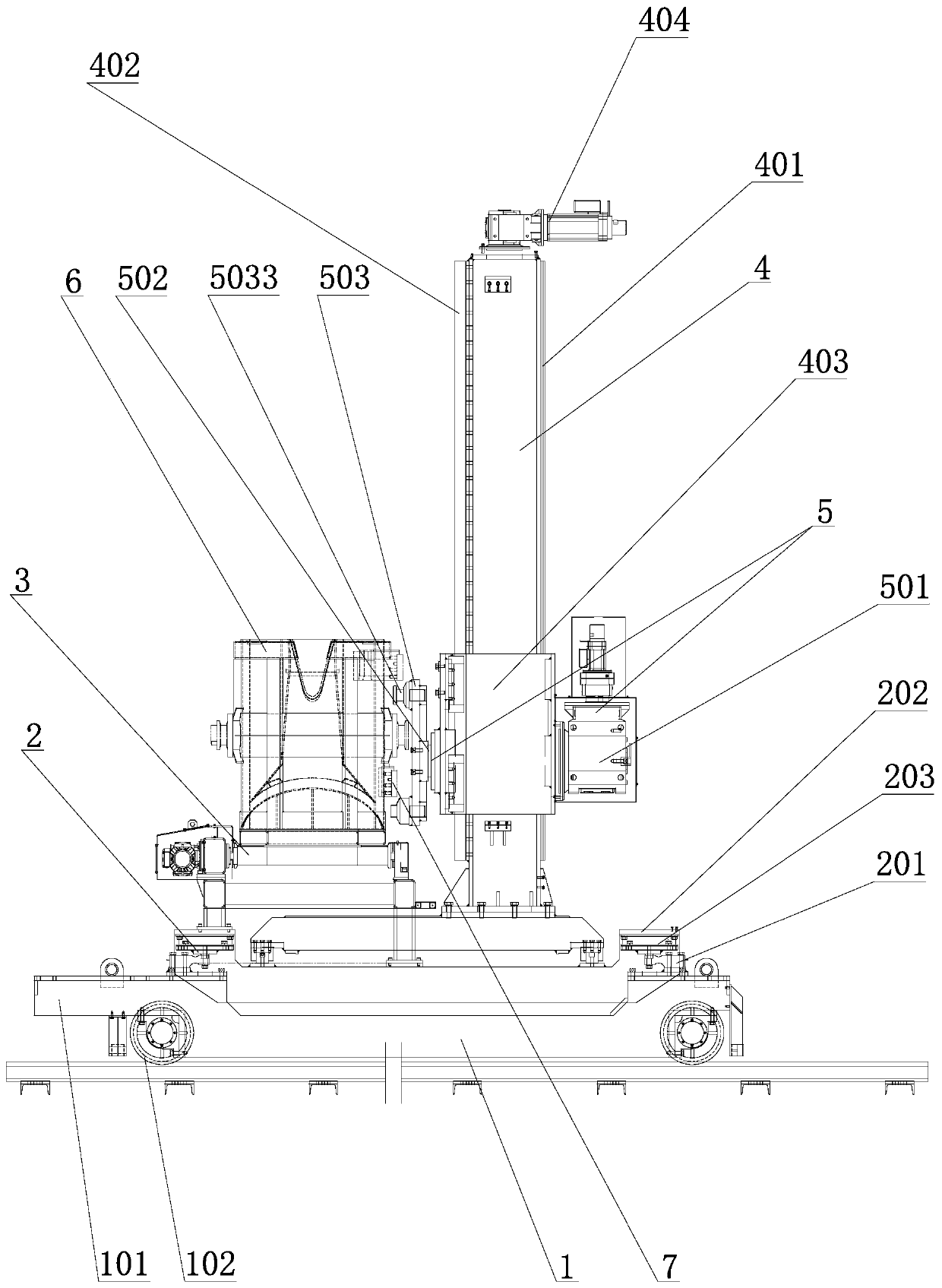

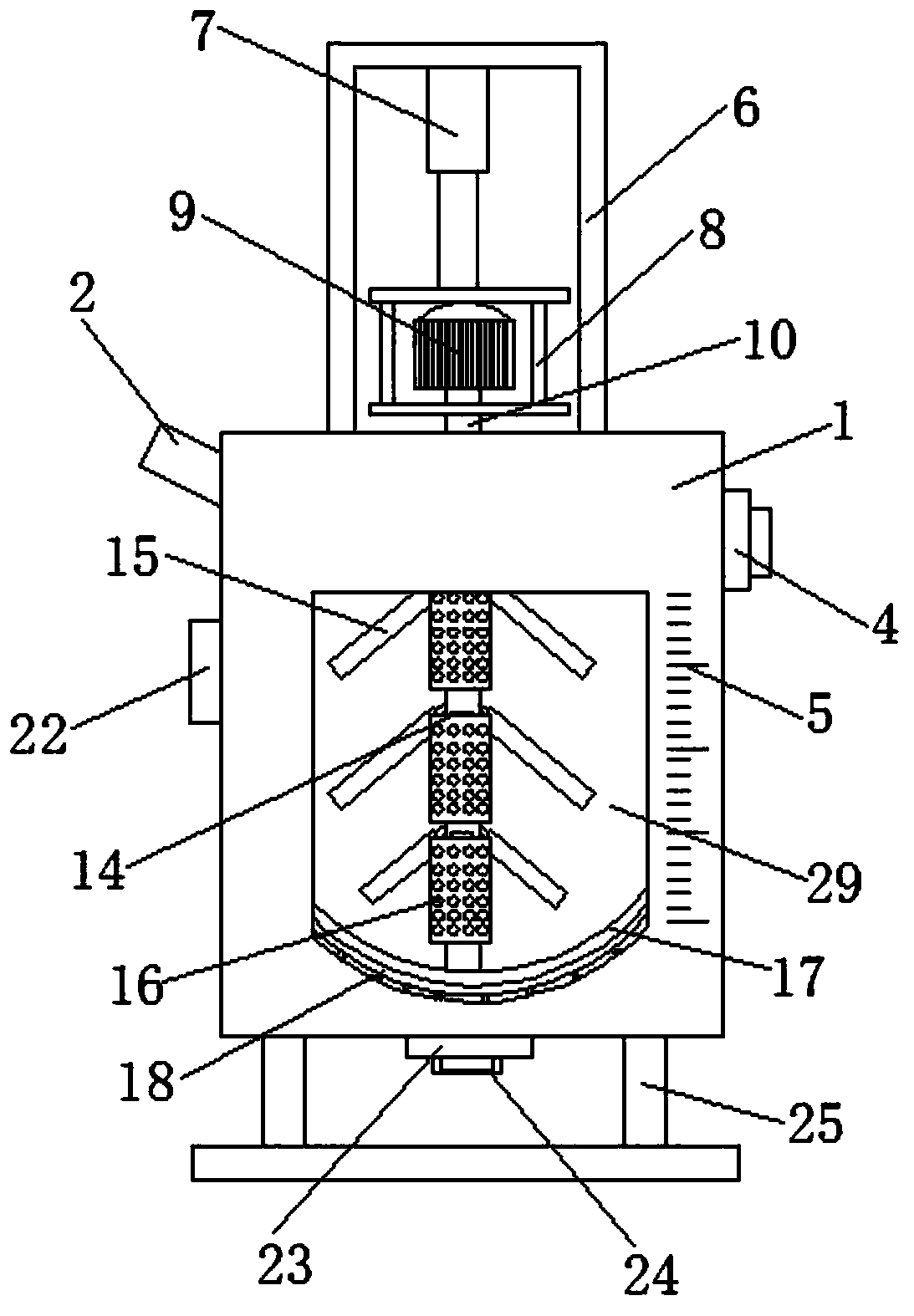

Intelligent casting machine

PendingCN111318678AFulfil requirementsReal-time detection of weightMelt-holding vesselsMolten metal supplying equipmentsControl engineeringProcess engineering

The invention relates to an intelligent casting machine. The intelligent casting machine comprises a walking mechanism, a weighing mechanism, a receiving translation mechanism, a lifting mechanism anda tilting mechanism, wherein the walking mechanism comprises a machine frame, wheels are arranged at the four corners of the machine frame correspondingly, and a walking driver is arranged on the machine frame; the weighing mechanism comprises a weighing sensor, wherein a bearing plate is arranged on the weighing sensor; the receiving translation mechanism comprises a translation support arrangedon the bearing plate, multiple transmission rollers are arranged on the translation support, and a translation driver is arranged on the translation support; the lifting mechanism comprises a liftingstand column, a lifting frame is movably arranged on a lifting guide rail, a lifting servo motor is arranged at the top of the lifting stand column and connected with the lifting frame through a lifting lead screw; and the tilting mechanism comprises a tilting servo motor, wherein the tilting servo motor is connected with a casting ladle grabber through a tilting shaft. The intelligent casting machine has the advantages of being good in heavy-load capacity, high in safety and capable of achieving stable operation of a whole machine, and therefore the pouring quality and the pouring efficiencyare remarkably improved.

Owner:山东杰创机械有限公司

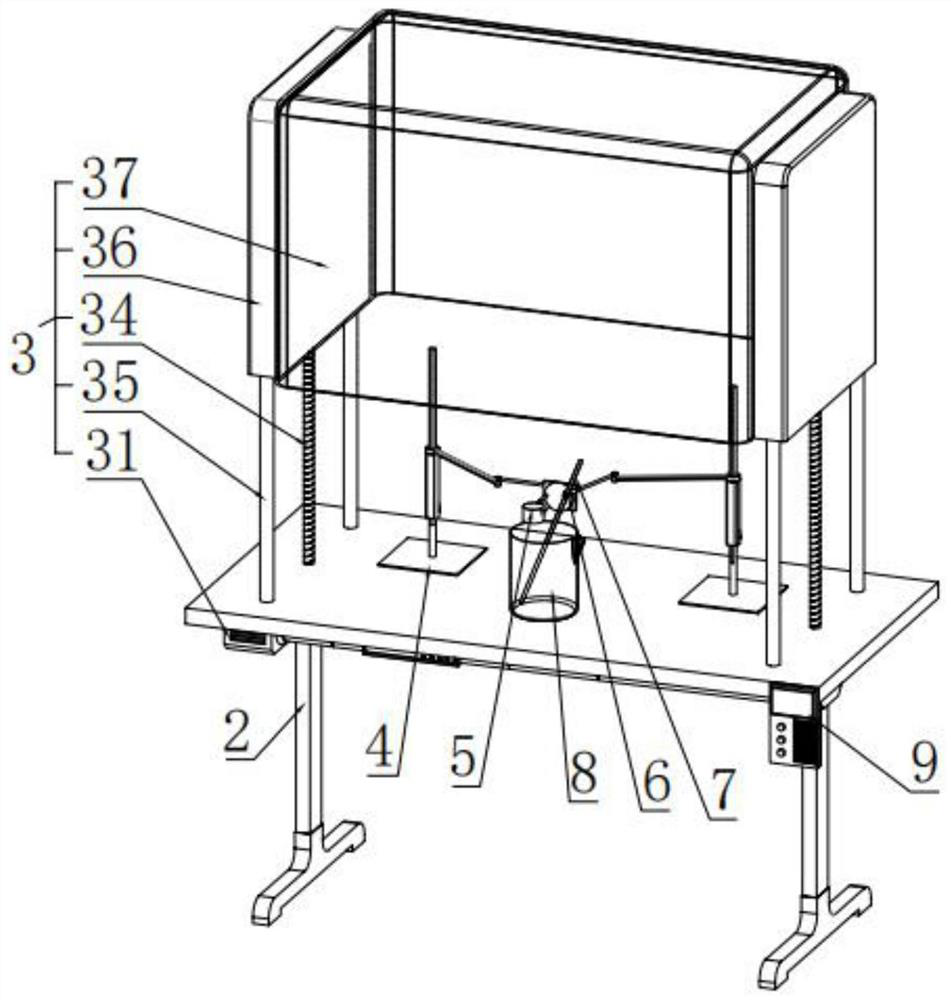

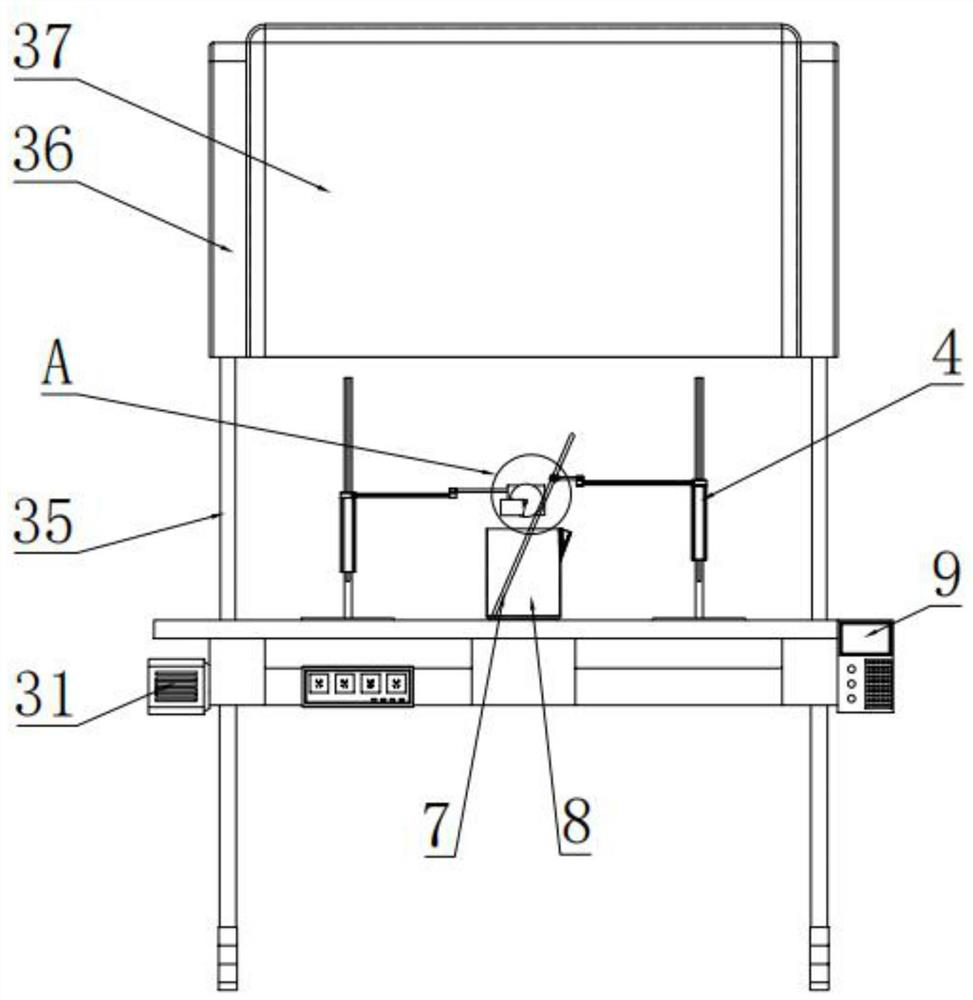

Safety protection device for chemical experiment

PendingCN113117764AEasy to operateImprove securityAnalysis material containersDirt cleaningBeakerEngineering

The invention discloses a safety protection device for a chemical experiment. The safety protection device comprises an experiment table; a protective cover lifting mechanism which is mounted at the top of the experiment table; two adjustable support assemblies which are installed at the left end and the right end of the rear side of the top end of the experiment table respectively; an automatic dumping mechanism which is fixedly mounted at the top of the adjustable support assembly on the left side; a glass rod clamp which is fixedly mounted at the top of the adjustable support assembly on the right side; and a beaker which is placed in the middle of the top end of the experiment table. According to the safety protection device for the chemical experiment, the protective cover can be controlled to move up and down, so that opening and closing of the protective cover are achieved, operation is easy, test agents splashed in the experiment process can be blocked, safety is extremely high, the test agents can be automatically poured, meanwhile, the positions and the angles of the small beaker and the glass rod can be quickly adjusted, so that the experimental reagent in the small beaker can be accurately poured on the outer wall of the glass rod.

Owner:ZIBO VOCATIONAL INST

Method and apparatus for controlled transfer of fluid

Embodiments of the present disclosure generally relate to caps, closures, seals, and containers, and control of flow of fluids. Certain embodiments can be used with fluids related to machinery, for instance, engine oil, brake fluid, coolant, transmission fluid, and power steering fluid. Certain embodiments of the present disclosure effectively hold and transfer a fluid or a fluid substance, further being able to open, close, and regulate fluid flow. Embodiments include a single piece tubular component that includes a cap interiorly attached to such tubular component with ribs, and a container having a tapered end. In certain embodiments, a nozzle collar having a tapered end is adapted to attach to a container.

Owner:VECTION LTD

Method for automatically pouring molten metal by tilting a ladle and a medium for recording programs for controlling a tilt of a ladle

ActiveUS20130041493A1Reduce depthPouring precisionMelt-holding vesselsMolten metal pouring equipmentsMetallurgyMathematical model

The purpose of the present invention is to provide a method for accurately dropping molten metal that flows from a ladle into a pouring gate in a mold. The present invention includes a method for controlling the respective input voltages transmitted to a servomotor that tilts the ladle such that the molten metal that flows from the ladle drops accurately into the pouring gate in the mold, a servomotor that moves the ladle back and forth, and a servomotor that moves the ladle up and down, by using a computer. In the method, a mathematical model of the area on which the molten metal that flows from the ladle will drop is produced, and then the inverse problem of the produced mathematical model is solved. In view of the effect of a contracted flow, the position on which molten metal drops is estimated by the estimating device for estimating the pouring rate and the estimating device for estimating the position on which molten metal will drop. Then the estimated position is calculated by a computer. Thereby the respective input voltages transmitted to the servomotor that tilts the ladle, the servomotor that moves the ladle back and forth, and the servomotor that moves the ladle up and down, are obtained. Then the three respective servomotors are controlled based on the obtained input voltages.

Owner:SINTOKOGIO LTD +1

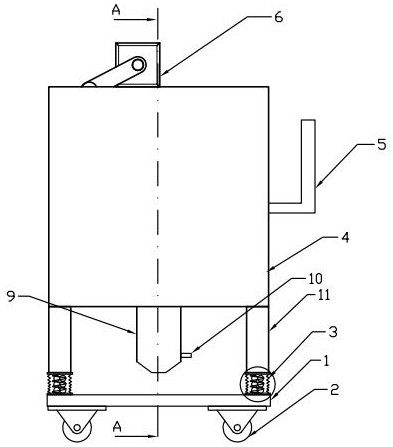

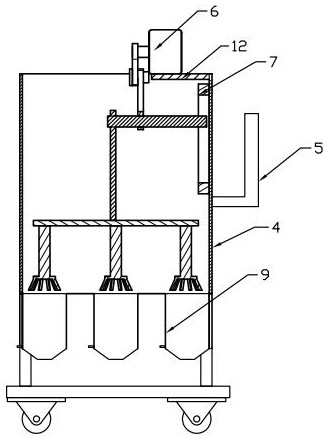

Uniform stirring device for cattle and sheep breeding feed

InactiveCN110548434AEasy to observePouring precisionFeeding-stuffRotary stirring mixersHeifer calfCoupling

The invention relates to the technical field of cattle and sheep breeding, in particular to a uniform stirring device for cattle and sheep breeding feed. The stirring device comprises a shell, a feeding inlet is formed in the surface of one side of the upper part of the shell, a water inlet is formed in the surface of the other side of the upper part of the shell, a U-shaped frame is welded to theupper part of the shell, a telescopic air cylinder is welded to the lower part of the U-shaped frame, a fixing frame is welded to the other end of the telescopic air cylinder, a motor is installed onthe upper part of the fixed frame, the input end of the motor is connected with an external power supply, the output end of the motor is connected with a rotating shaft through a coupling, the otherend of the rotating shaft penetrates through the shell and is welded to a clamping mechanism, the other end of the clamping mechanism is connected with a fixing rod in a clamped mode, the upper part of the fixing rod is provided with a clamping groove, the surface of the fixing rod is cyclically welded to a plurality of fixing blocks, the other ends of the fixing blocks are welded to a plurality of mixing blades correspondingly, a plurality of first through holes are formed in the upper surfaces of the mixing blades correspondingly, and the other end of the fixing rod is welded to an auxiliarymixing mechanism. The stirring device can evenly stir the feed.

Owner:奉节县斌旗牲畜饲养有限公司

An anti-leakage device for bridge construction

ActiveCN110485307BEasy squeezeAvoid squeezingBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses an anti-leakage device for bridge construction, which comprises a base, a feeding box is installed above the base, and a plurality of supporting legs are installed at the bottom of the feeding box, and the supporting legs are connected by a shock absorbing device and The base is connected, the top right end of the feed box is equipped with a support, the support is connected with the push mechanism, three pushers are installed at the bottom of the push mechanism, and three discharge ports are installed at the bottom of the feed box , a piston is installed in the three feeding ports. The invention is not easy to be blocked, has precise pouring and is convenient to move.

Owner:李双 +2

Production line of concrete prefabricated part and production process thereof

ActiveCN111203974AIncrease productivitySmall footprintCeramic shaping plantsAuxillary shaping apparatusProduction lineStructural engineering

The invention provides a production line of a concrete prefabricated part and a production process thereof. The production line comprises an annular track, an outward track, a die unloading mechanism,a central circular truncated cone, a die placement mechanism, several electric railcars, a die cover placement mechanism and a computer; two ends of the outward track are connected with the annular track, the die unloading mechanism is arranged on one side of the outward track, the die placement mechanism and the die cover placement mechanism are arranged on the outer edge side of the annular track correspondingly, each of the die placement mechanism and the die cover placement mechanism comprises a grabbing mechanical arm and a placing plate, the electric railcars are mounted on the annulartrack, the central circular truncated cone is arranged at the central position of the annular track, and a pouring mechanism and a leveling mechanism are mounted on the central circular truncated cone. The production line of the concrete prefabricated part and the production process thereof are reasonable in design, and the production efficiency of the concrete prefabricated part can be effectively improved.

Owner:福建莲春环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com