Intelligent grain storage device

An intelligent, storage bin technology, applied in fruit hanging devices, lighting and heating equipment, applications, etc., can solve problems such as lack of temperature and humidity management, high labor intensity, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

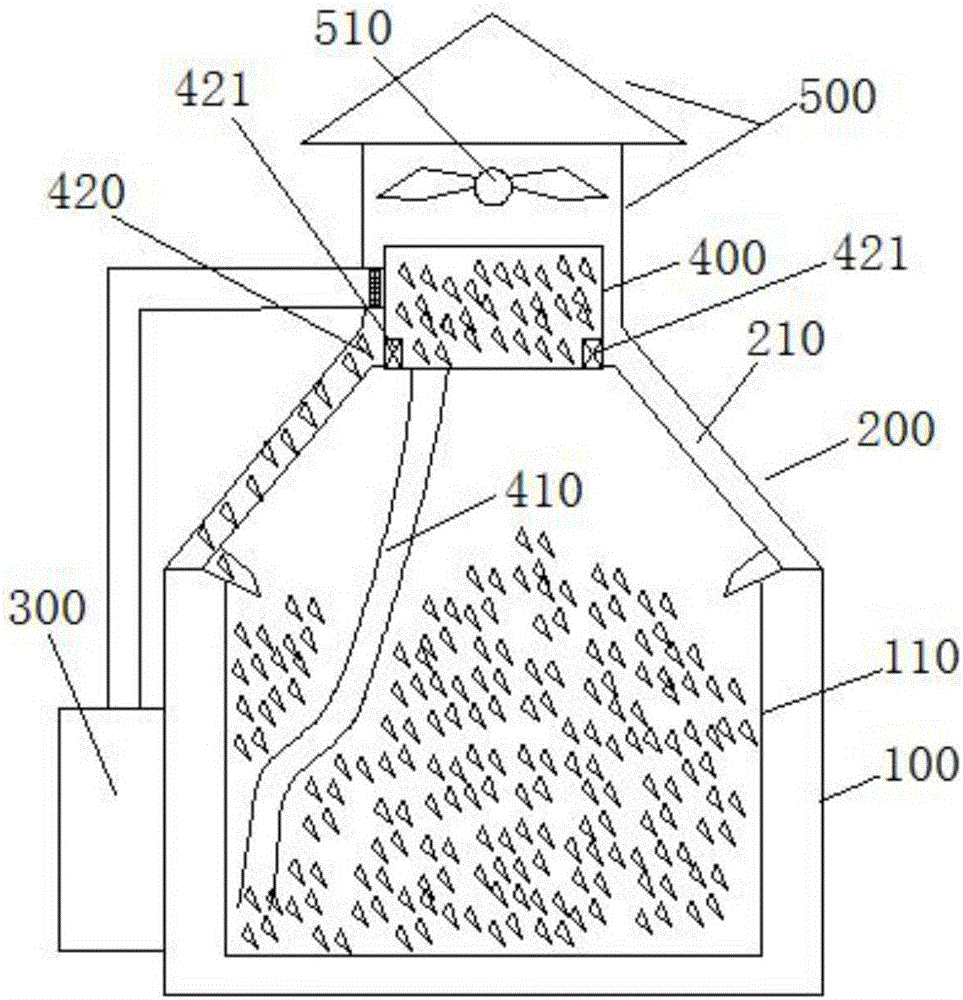

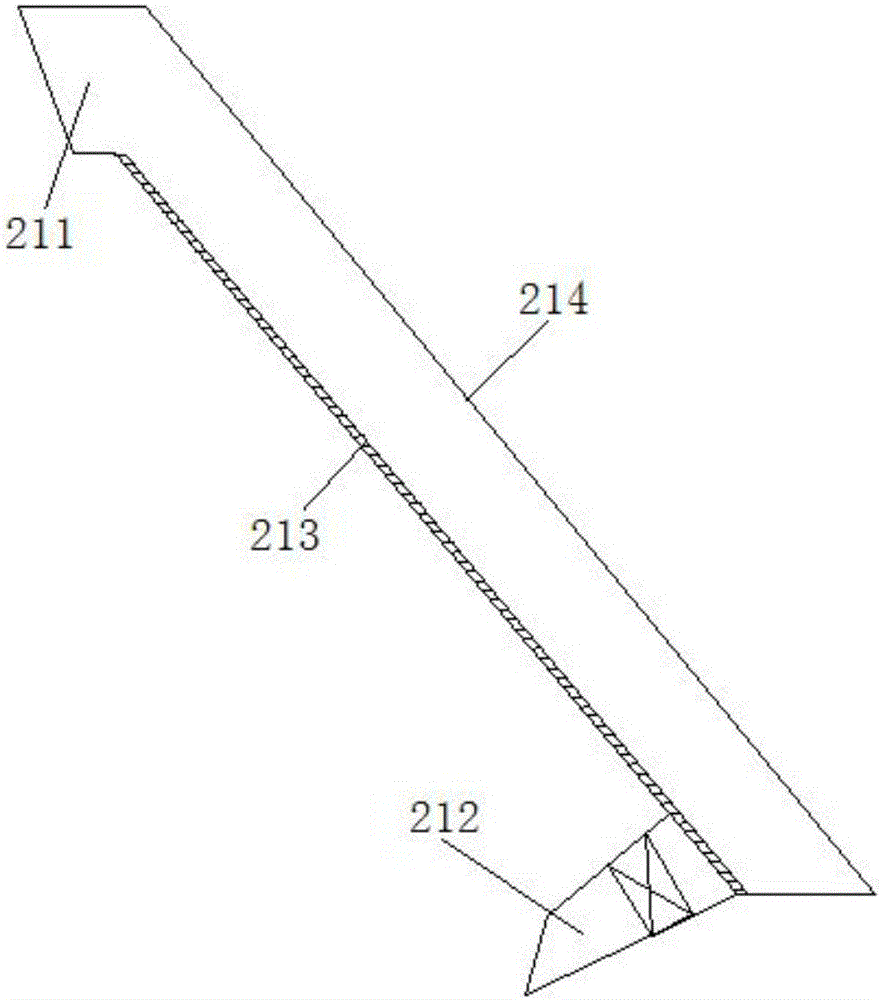

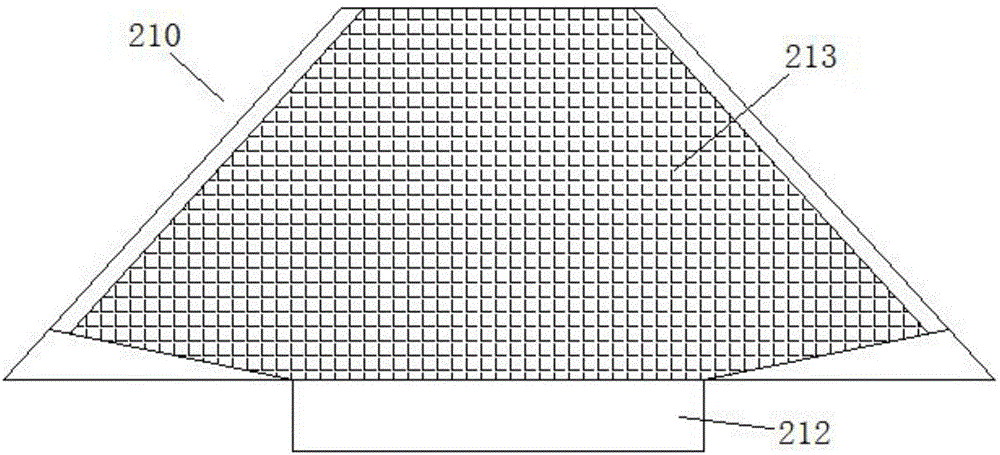

[0045] figure 1 As shown, the present invention provides an intelligent grain storage device, including a bin body 100, a storage bin 110 is arranged in the bin body 100, and a bin roof 200, a negative pressure delivery pump 300, a metering bin 400 and an exhaust hood 500; the cover of the warehouse roof 200 is buckled on the warehouse body 100 and is sealed and connected with the warehouse body 100; the warehouse roof 200 is in the shape of a positive prism; any side wall of the warehouse roof 200 is respectively provided with drying bin 210; figure 2 and image 3 As shown, the drying bin 210 is composed of an inlet port 211, an outlet port 212, a light-absorbing plate 213, and a transparent cover 214 buckled on the light-absorbing plate 213. An interlayer for drying grain; the discharge port 212 communicates with the storage bin 110; the metering bin 500 is arranged in the bin roof 200 and is tightly connected with the bin roof 200; the metering bin The upper end of the ...

Embodiment 2

[0057] Figure 8 As shown, in this embodiment, on the basis of Embodiment 1, each of the drying bins 210 is provided with a light intensity sensor 217, a distribution valve controller 218 and / or a temperature sensor 219; the light intensity sensor 217 passes The material distribution valve controller 218 is connected to the corresponding material distribution valve 421 ; the temperature sensor 219 is connected to the material distribution valve 421 through the material distribution valve controller 218 .

[0058] It should be noted that in this embodiment, the structures of the light intensity sensor 217, the material dispensing valve controller 218 and the temperature sensor 219 are prior art, so their detailed structures and models will not be further illustrated and described here. The present invention can automatically identify the position of the current strongest light by setting a light intensity sensor on the drying bin, and then achieve the technical effect of contro...

Embodiment 3

[0062] Such as Figure 9 As shown, in this embodiment, on the basis of Embodiment 1, the lower end of the drying bin 210 is hinged to the lower end of the bin roof 200; a drying bin inclination adjustment device 220 is also arranged in the bin roof; the drying bin The inclination adjustment device includes: a fixed bracket 221 and an electric push rod 222 hinged on the fixed bracket; the execution end of the electric push rod 222 is hinged to the upper end of the drying bin 210 . The present invention is provided with an inclination adjusting device for the drying bin, which helps to achieve the technical effect of removing snow, dust or poultry feces deposited on the drying bin to a certain extent by changing the inclination angle of the drying bin.

[0063] Preferably, in a preferred technical solution of this embodiment, the upper end of the warehouse roof is provided with a high-pressure air nozzle and / or a high-pressure water nozzle; the high-pressure air nozzle is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com