A method for integral co-curing molding of UAV wings

A curing molding and unmanned aerial vehicle technology, applied in aircraft assembly, weight reduction, etc., can solve the problems of high technical requirements for operators, long preparation time, and unstable overall quality, so as to achieve obvious advantages, avoid inspection workload, The effect of avoiding hole sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

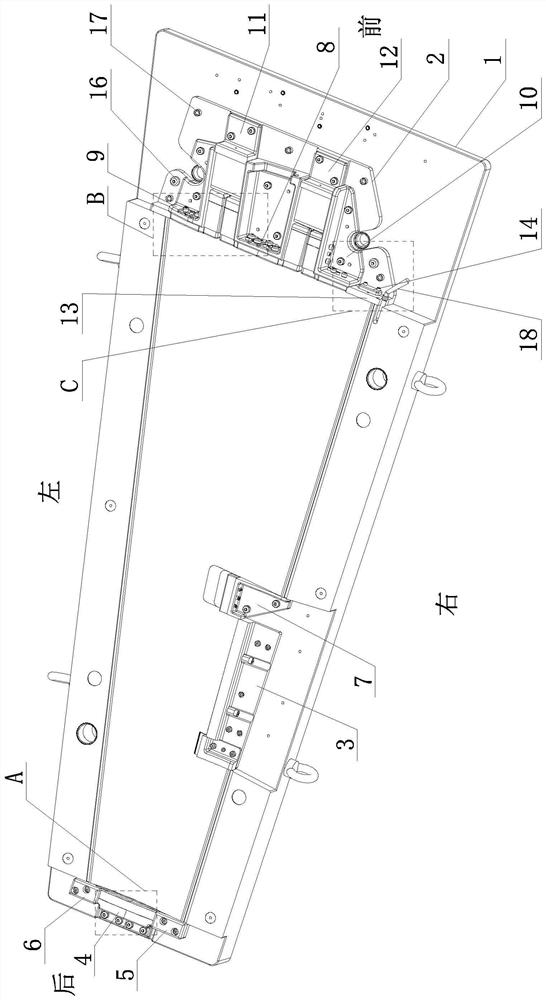

[0049] Specific implementation one: as Figure 1-Figure 4 , Figure 16-Figure 18 As shown, this embodiment discloses a method for integral co-curing molding of a UAV wing, the method comprising the following steps:

[0050] Step 1: Assemble the wing frame 15;

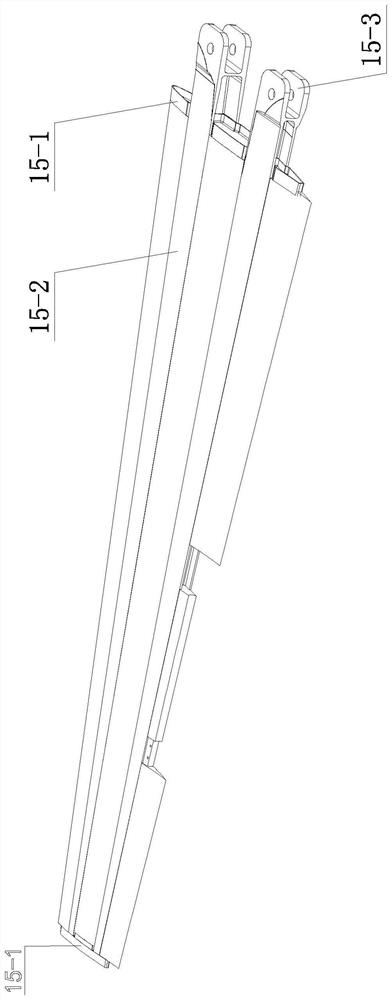

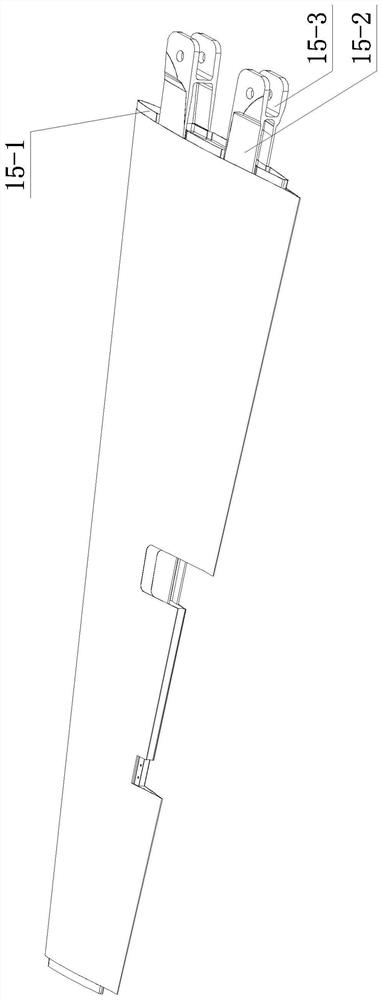

[0051] Two beams 15-2 are pre-laid with front and rear beam forming molds (for the prior art), and the pre-laid two beams 15-2 are arranged in parallel, and four rib boxes 15-1 are pre-laid with foam. Three of the rib boxes 15-1 laid on the foam are arranged close to the front ends of the two beams 15-2, and the three rib boxes 15-1 are all connected with the fork ears 15-3 provided at the front ends of the two beams 15-2. They are arranged in parallel, and the three rib boxes 15-1 and the two beams 15-2 are arranged alternately in turn. -1 is respectively fixedly connected with a corresponding beam 15-2, and the remaining rib box 15-1 laid on the foam is placed against the rear ends of the two beams 15-2 to form a w...

specific Embodiment approach 2

[0064] Embodiment 2: This embodiment is a further description of Embodiment 1. In step 3, the cleanliness of the air in the purification room is that the content of dust particles with a diameter greater than 10 μm is not greater than 10 / L.

specific Embodiment approach 3

[0065] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. In step 4, when the ambient temperature and humidity conditions meet the requirements, the temperature is 18-22°C, and the humidity is less than 25-30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com