Rectifying blade body end face position measuring device and method

A technology of rectifying blade and measuring device, applied in measuring device, mechanical measuring device, using mechanical device and other directions, can solve problems such as batch out of tolerance, and achieve the effect of simple structure, simple operation and improved inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

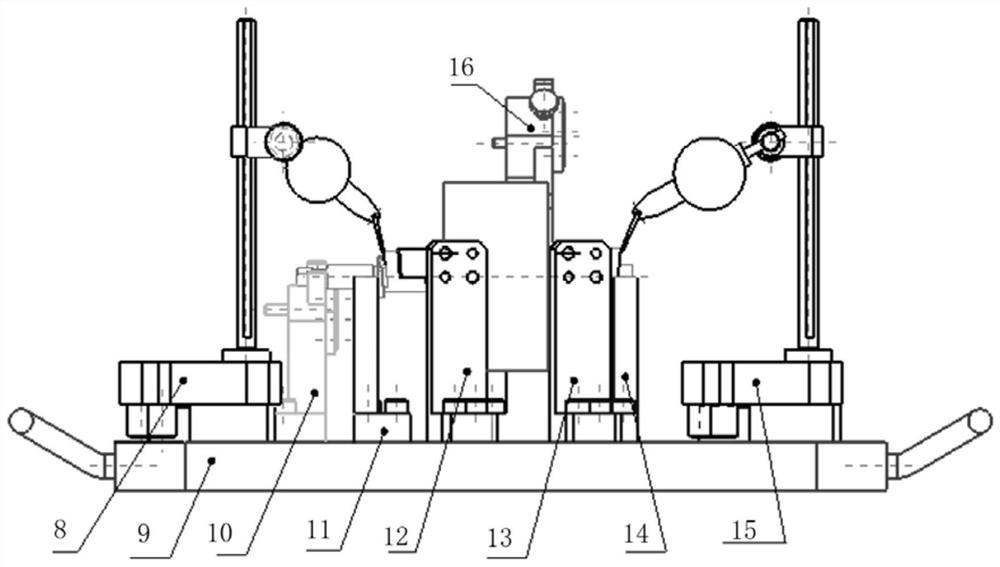

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

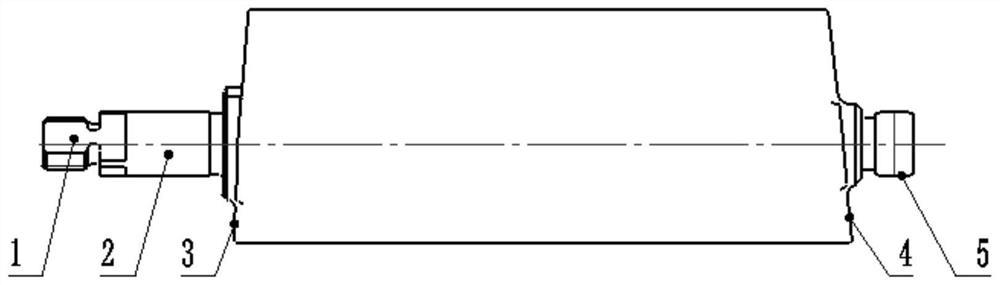

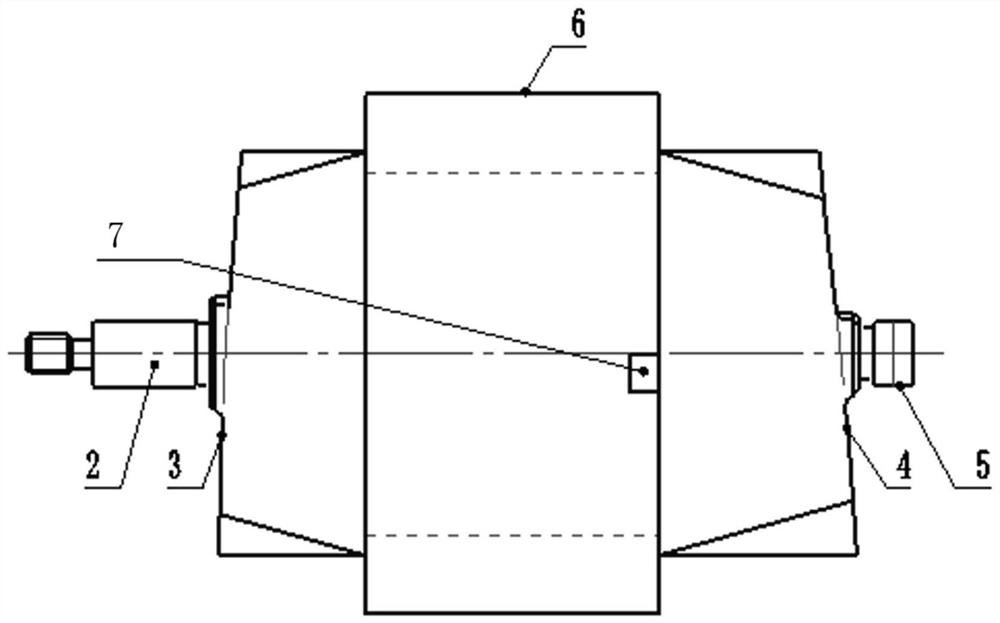

[0034] see Figure 1 to Figure 10 , a device for measuring the position of the airfoil end surface of a rectifying blade, comprising a first positioning V-shaped block 11 and a second positioning V-shaped block 14 for positioning the upper journal 2 and the lower journal 5 of the rectifying blade respectively, said The first positioning V-shaped block 11 and the second positioning V-shaped block 14 are used to limit the deviation of the rectifying blades in the X, Y, and Z directions and the twisting around the Y and Z directions, and also include a device for limiting the twisting of the rectifying blades around the X direction. Positioning means.

[0035] When the side of the upper journal 2 of the rectifier blade is provided with a mounting flat 1, the positioning device adopts the upper journal positioning device arranged between the first positioning V-shaped bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com