Time-grating linear displacement sensor

A linear displacement and sensor technology, applied in instruments, measuring devices, electrical devices, etc., can solve the problems of complex sensor structure, low precision, and complicated excitation coil windings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

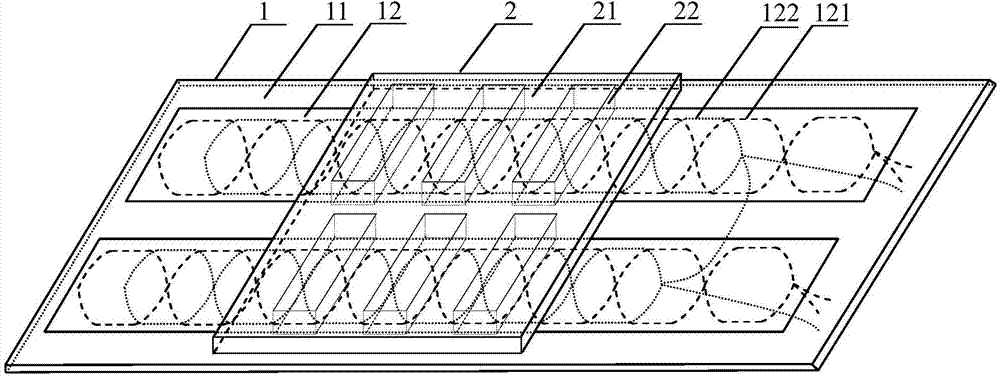

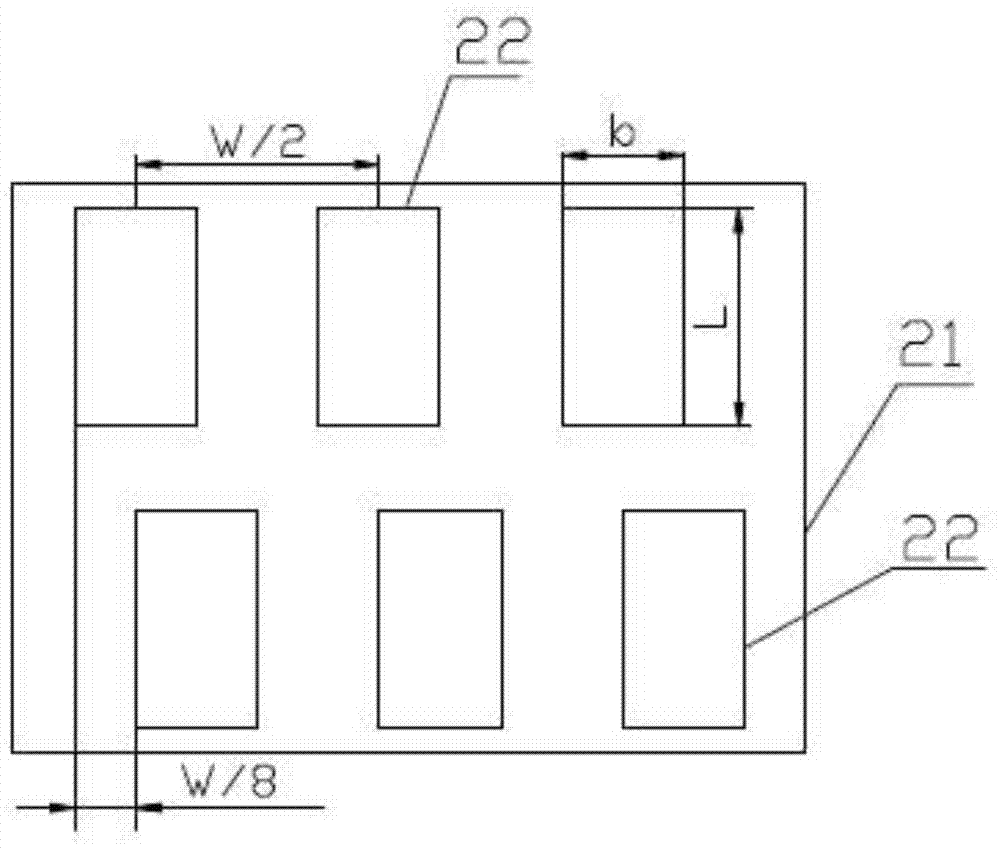

[0027] Embodiment 1: as Figure 1 to Figure 4 The time grating linear displacement sensor shown includes fixed scale 1 and moving scale 2.

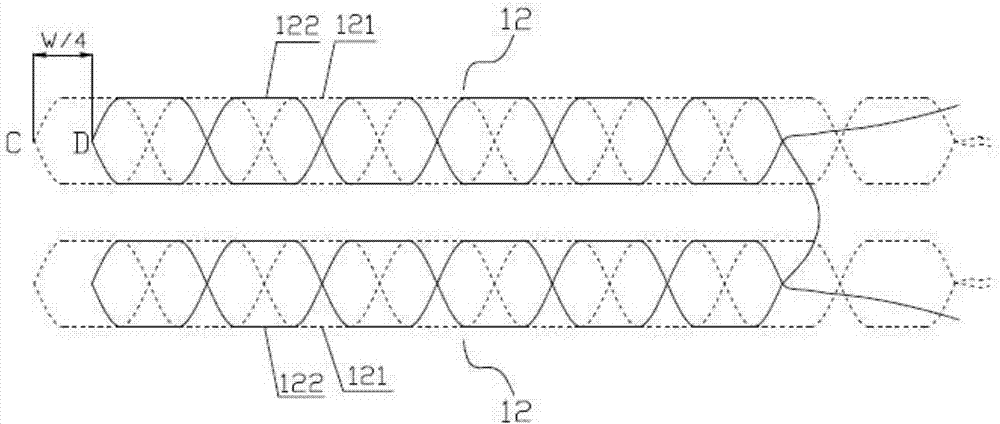

[0028] The fixed length 1 is composed of a fixed length matrix 11 and two identical and parallel sensing units 12 that do not interfere with each other. The distance between the two sensing units 12 is equal to 10 mm. The fixed length matrix 11 is a rectangular parallelepiped iron matrix. Taking the long side direction of the fixed-length substrate 11 as the measurement direction, the sensing unit 12 includes an excitation coil 121 and an induction coil 122. The excitation coil 121 and the induction coil 122 adopt a printed circuit wiring method, and are independently arranged on different parts of the printed circuit board. On the wiring layer, two sets of printed circuit boards with excitation coils 121 and induction coils 122 are fixed parallel to each other on the upper and lower parts of the surface of the scale substrate 11 to form ...

Embodiment 2

[0044] Embodiment 2: as Figure 5 to Figure 7 The time grating linear displacement sensor shown, most of its structure is the same as that of Embodiment 1, the difference is that: the starting position of the exciting coil 121 of the sensing unit 12 on the upper part of the fixed-length substrate 11 is aligned with the fixed-length substrate 11 along the measurement direction. The initial position of the excitation coil 121 of the sensing unit 12 of the bottom is apart from S (S is not equal to 0), and the initial position of the induction coil 122 of the sensing unit 12 of the upper part of the fixed-length substrate 11 is along the measurement direction and the lower part of the fixed-length substrate 11. The initial positions of the induction coils 122 of the sensing unit 12 are separated by S (S is not equal to 0). The initial position of the magnetic conductor 22 embedded in the magnetic conduction unit at the upper part of the dynamic scale base 21 is far from the initia...

Embodiment 3

[0052] Embodiment 3: Most of its structure is the same as that of Embodiment 1, the difference is that the magnetic conduction unit is composed of a rectangular parallelepiped magnetic conduction body 22; Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com