Non contact optical digital guide extension meter

A non-contact, extensometer technology, applied in the direction of material analysis, scientific instruments, measuring devices, etc. by optical means, can solve the problems of measurement accuracy, influence measurement accuracy, complicated auxiliary equipment, etc., to solve permanent damage, Ease of use and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

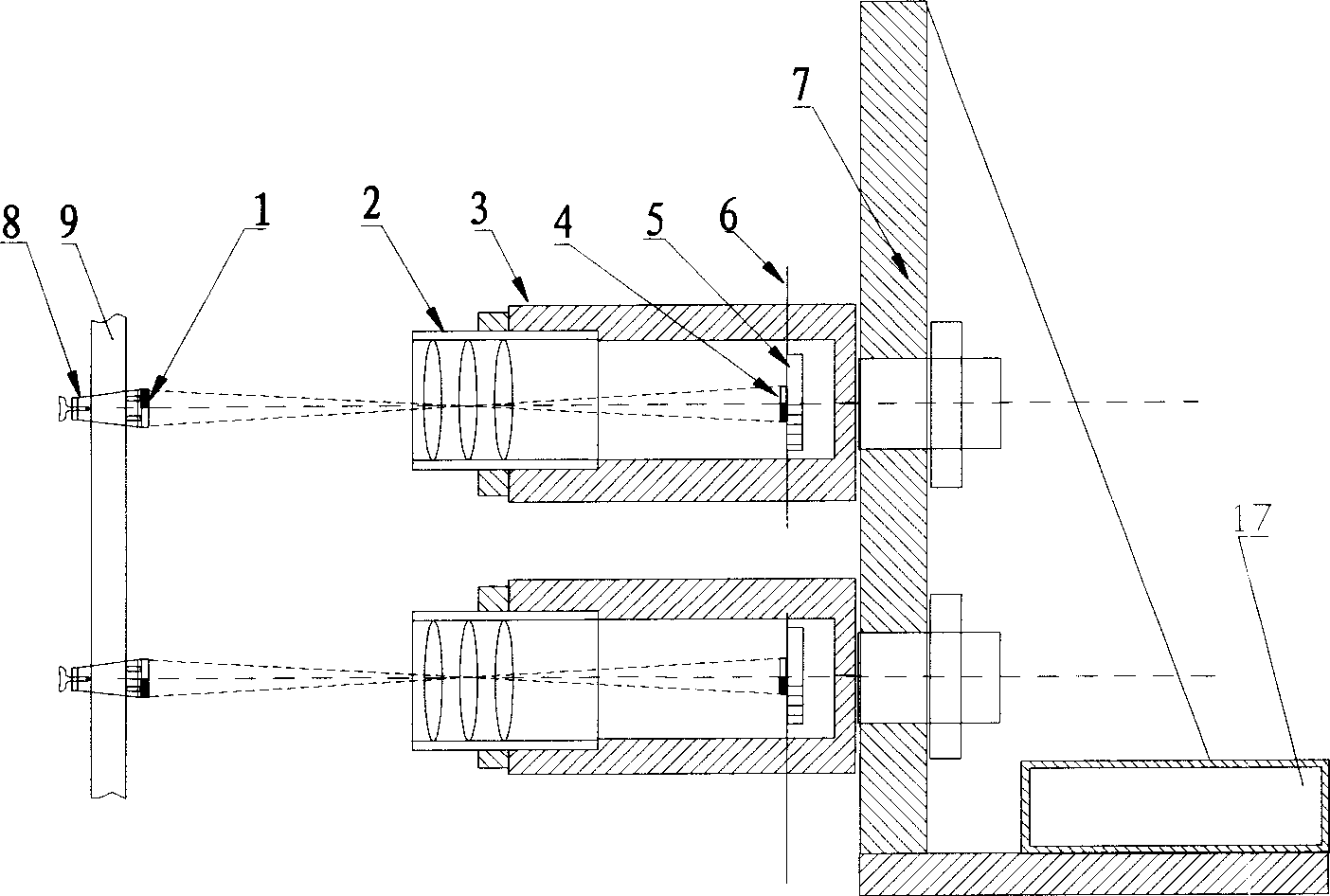

[0018] exist figure 1 Among them, the fastening device 8 fixes two reflective marks 1 with black and white patterns on the two ends of the gauge length of the test piece 9 respectively, connects the lens group 2 with the imager 3, and fixes the image sensor linear array 5 on the imager 3 Inside, the lens group 2 and the imager 3 are connected by thread, so that the distance between the lens and the image sensor linear array 5 can be adjusted. Make the image of the retroreflective mark on the image plane 6 of the image sensor linear array 5 .

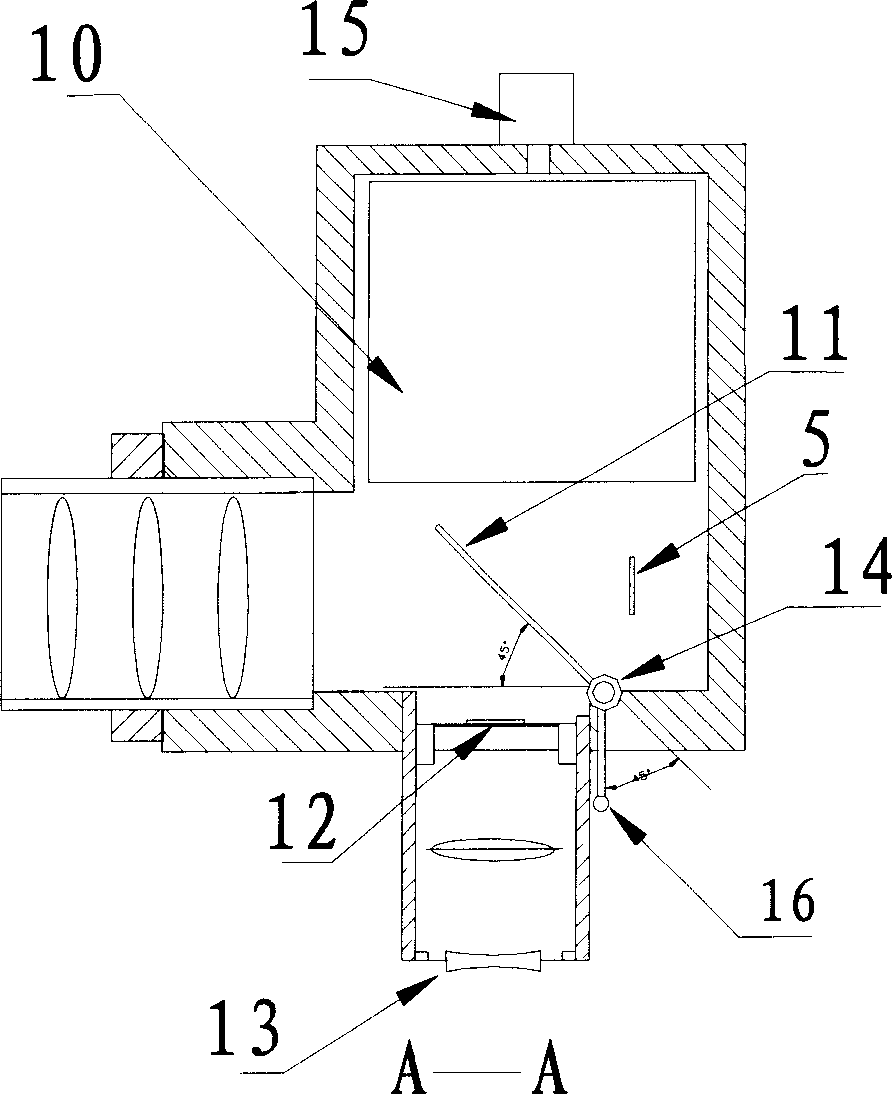

[0019] exist image 3 In the process, the circuit board 10 is installed in the imager 3 , one end of the circuit board is connected to the image sensor linear array 5 , and the other end is connected to the signal connector 15 . The movable plane mirror flap 11 is placed between the lens group 2 and the image sensor linear array 5, and is connected with the imager via the rotating shaft 14. When the connecting line of the plane mirror...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com