Sheet material mold-free multi-point forming device based on viscous medium transfer force and method

A viscous medium, moldless multi-point technology, applied in the field of sheet metal forming, can solve the problems that it is difficult to exert the maximum forming limit of the material, the surface quality of the workpiece cannot be guaranteed, and the sheet metal deformation cannot be processed, so as to save mold design and workpiece Surface quality assurance, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

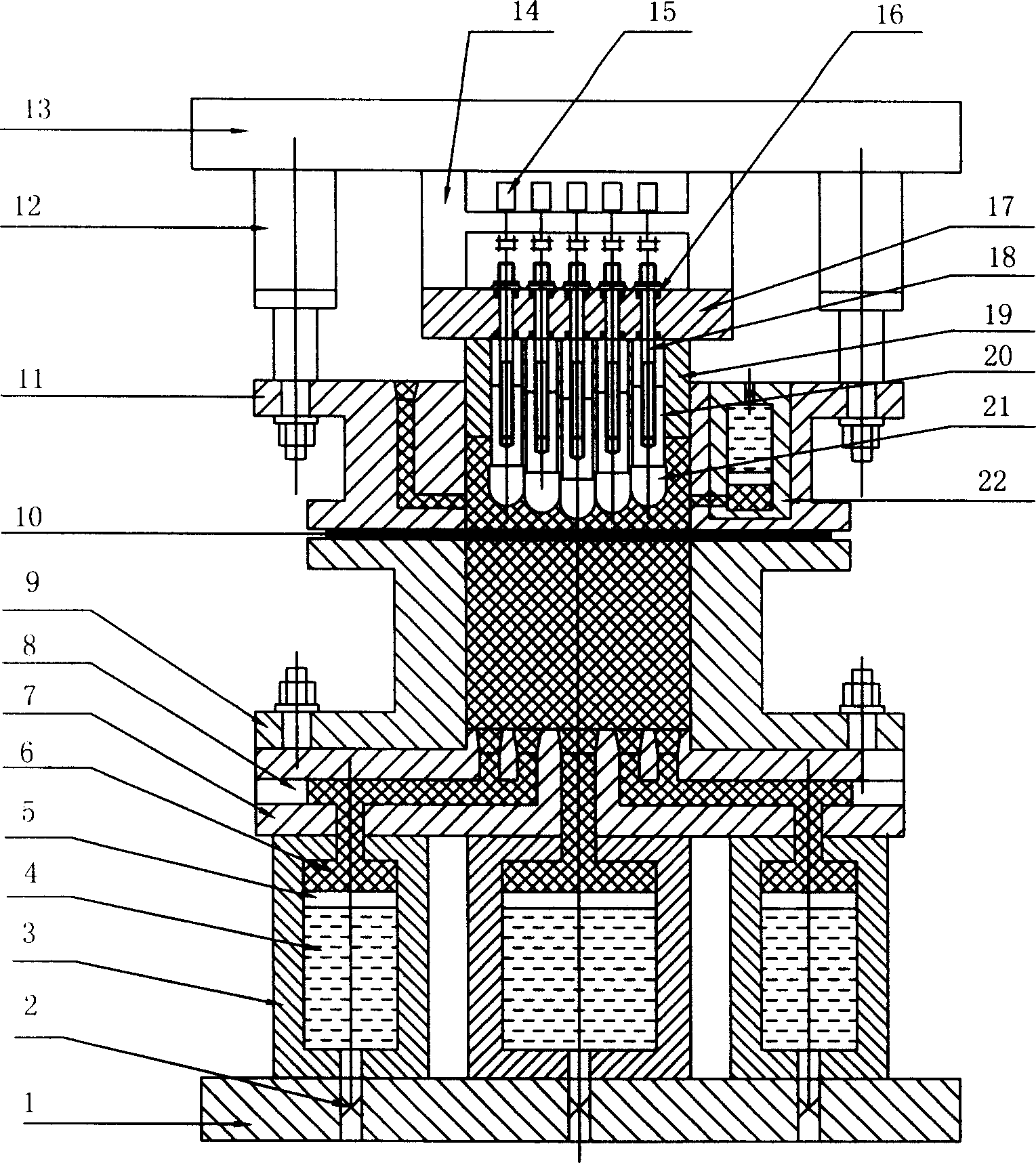

[0030] see figure 1As shown, a sheet metal dieless multi-point forming device based on viscous medium force transmission consists of a base 1, a lower control cylinder 3, an electro-hydraulic proportional overflow valve 2, a die bottom plate 7, a die 9, and a blank holder 11 , Crimping cylinder 12, upper template 13, motor support 14, stepping motor 15, bearing 16, support frame 17, position adjustment screw 18, punch fixing plate 19, telescopic sleeve 20, stamping head 21, upper control cylinder 22 The sheet material 10 is pressed between the die 9 and the blank holder 11, the die 9 and the base plate 7 of the die form the lower cavity, which accommodates the viscous medium 6 and provides back pressure; during the forming process, the medium passes through the base plate of the die The upper discharge hole is discharged; (the plug 8 is set to block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com