Viscous medium bidirection press cold shaping method of titanium and titanium alloy plate material parts

A viscous medium and two-way pressure technology, which is applied in the field of pressure cold forming, can solve the problems that titanium and titanium alloy plate parts cannot be formed, and achieve the effects of improving forming accuracy, reducing springback and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

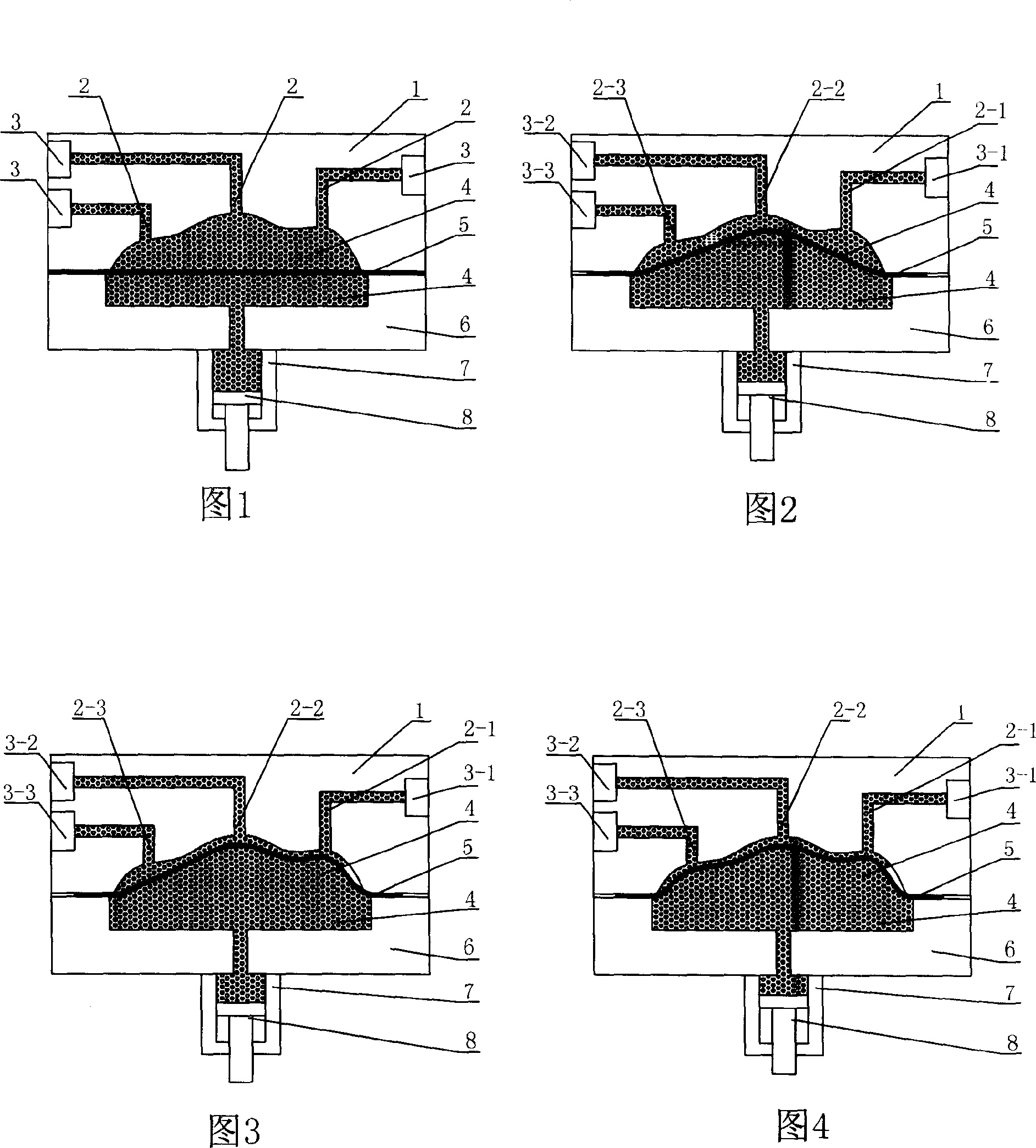

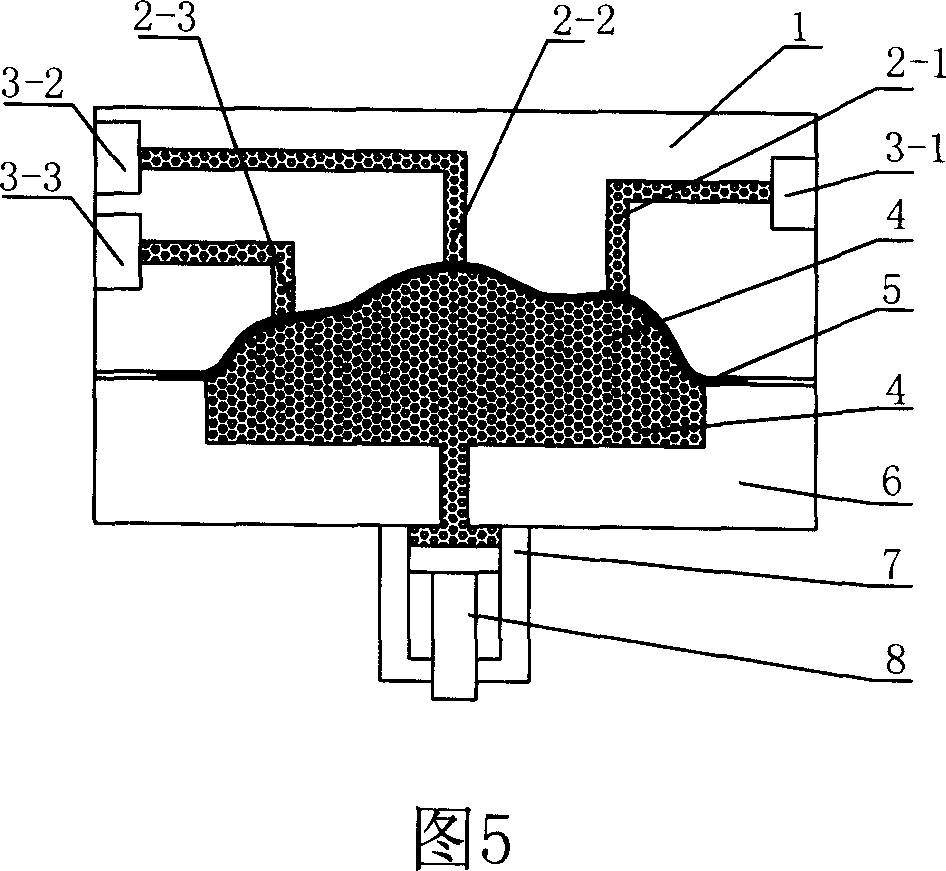

[0008] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 . This embodiment consists of the following steps: 1. Put the blank 5 on the viscous medium bin 6, and press the blank 5 with the die 1 filled with semi-solid viscous medium 4 in the cavity to close the mold cavity; 2. The viscous medium 4 injected into the cylinder 7 by the plunger 8 is filled with the viscous medium chamber 6; 3. The plunger 8 continues to inject the viscous medium 4 into the medium chamber 6 to apply forming pressure to the blank 5; 4. Adjust medium discharge The pressure control valve 3 at the port 2 allows the viscous medium 4 in the die 1 to flow out in a controlled manner and exerts reverse pressure on the blank 5; the blank 5 is gradually pulled in under the bidirectional pressure of the viscous medium 4 on both sides In the cavity of the die 1; 5. Finally, the viscous medium 4 is discharged out of the cavity of the die 1, and the blank 5 ...

specific Embodiment approach 2

[0009] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 2 to FIG. 4 . The difference between this embodiment and Embodiment 1 is that in step 4, the pressure control valve 3-2 is first adjusted so that the viscous medium 4 in the die 1 can controllably flow out from the medium discharge port 2-2 and press the plate blank 5 Apply reverse pressure; the slab blank 5 is gradually pulled into the cavity of the die 1 under the bidirectional pressure of the viscous medium 4 on the upper and lower sides, and is first deformed at the medium discharge port 2-2; After the mold is pasted at the medium discharge port 2-2, close the pressure control valve at the medium discharge port 2-2, and open the pressure control valve 3-1 at the medium discharge port 2-1, so that the viscous medium 4 flows out from there, The billet flows to the medium discharge port 2-1 under the action of two-way pressure, and finally sticks the mold here; clo...

specific Embodiment approach 3

[0013] Specific Embodiment Three: The present embodiment will be specifically described below with reference to FIG. 2 to FIG. 4 . The difference between this embodiment and the second embodiment is that the forming sequence is different. In step four, first open the pressure control valve 3-1 at the medium discharge port 2-1, then open the pressure control valve 3-2 at the medium discharge port 2-2, and finally open the pressure control valve at the medium discharge port 2-3. Pressure control valve 3-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com