Jetting Apparatus and Method of Improving the Performance of a Jetting Apparatus

a jetting apparatus and performance technology, applied in the direction of solventing apparatus, manufacturing tools, coatings, etc., can solve the problems of low accuracy, no information provided to the operator and problems such as problems affecting the performance of the jetting devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

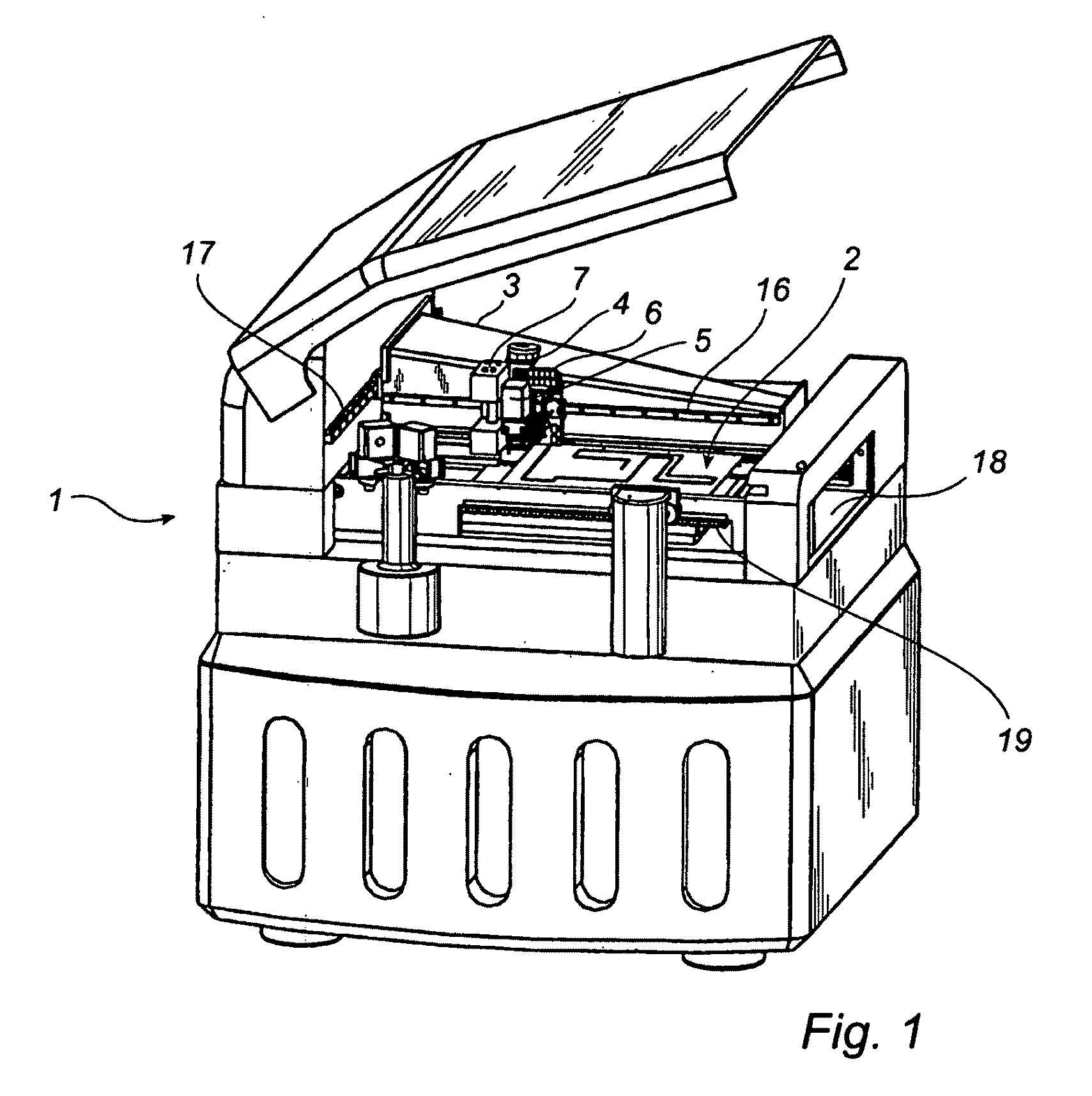

[0039]FIG. 1 illustrates the general outline of a preferred embodiment of an apparatus 1 for providing a substrate 2 with deposits by dispensing droplets of a viscous medium onto the substrate 2, for example, jetting, in accordance with the present invention. For ease of description, the viscous medium will hereinafter be referred to as solder paste, which is one of the alternatives defined above. For the same reason, the substrate will be referred to as an electric circuit board and the gas will be referred to as air. In this embodiment, the jetting apparatus 1 is of a type comprising an X-beam 3 and an X-wagon 4, which is connected to the X-beam 3 via an X-rail and is movable in a reciprocating way along the X-rail. The X-beam, in turn, is movably connected to a Y-rail 17, the X-beam 3 thereby being movable to the X-rail 16. The Y-rail 17 is rigidly mounted in the jetting apparatus 1. Generally, the movements are provided by linear motors (not shown).

[0040]Furthermore, the jetting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com