Sheet metal rigid particles or compressible powder half-module shaping technique

A technology of sheet metal and forming process, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of increasing production cycle and labor intensity, unfavorable automatic industrial production, reducing mold processing cost, etc., to improve the forming limit , The effect of realizing automatic production and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

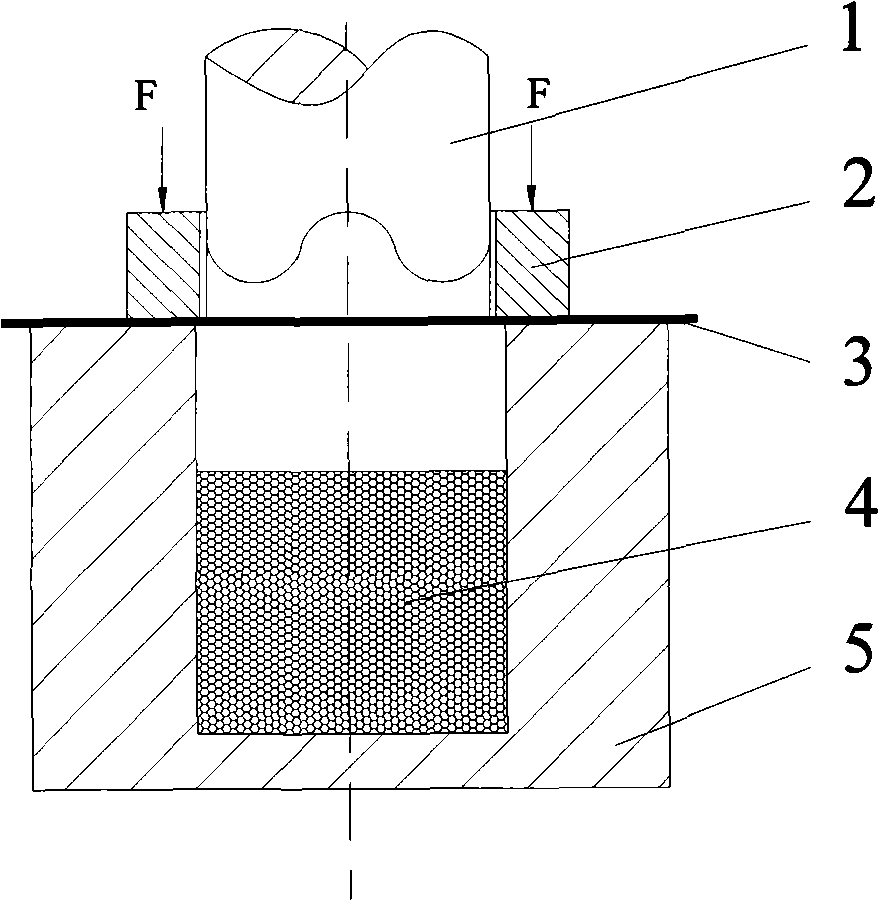

[0020] a. Design a cylindrical mold punch 1 with a diameter of Φ50mm and a height of 100mm; design a box 4 with an inner diameter of Φ62mm, an outer diameter of Φ200mm, and a height of 100mm for rigid solid particles; the inner diameter of the blank holder 2 is Φ52mm, outer diameter Φ150mm, thickness 30mm.

[0021] b. Add rigid solid particles 5 (steel balls) with a diameter of 2mm into the box body 4, and the loading height is 40mm.

[0022] c. Put the 08 steel plate with a diameter of Φ200mm and a thickness of 0.8mm on the box 4 filled with rigid solid particles 5 (steel balls), and load the blankholder 2 with a blankholder force of 2MPa.

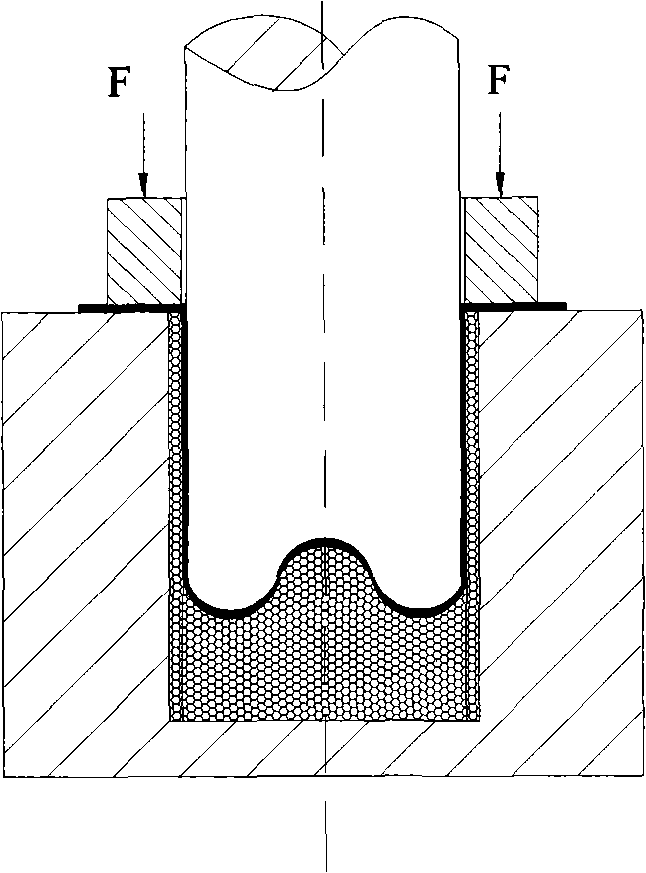

[0023] d. Load 5000-10000N on the mold punch 1, and when the rigid solid particles 5 fill the entire cavity of the concave mold, the drawing of the cylindrical part is completed.

[0024] e. After the mold punch 1 returns, the part is ejected, and the rigid solid particles 5 are automatically reset to form the next part.

Embodiment 2

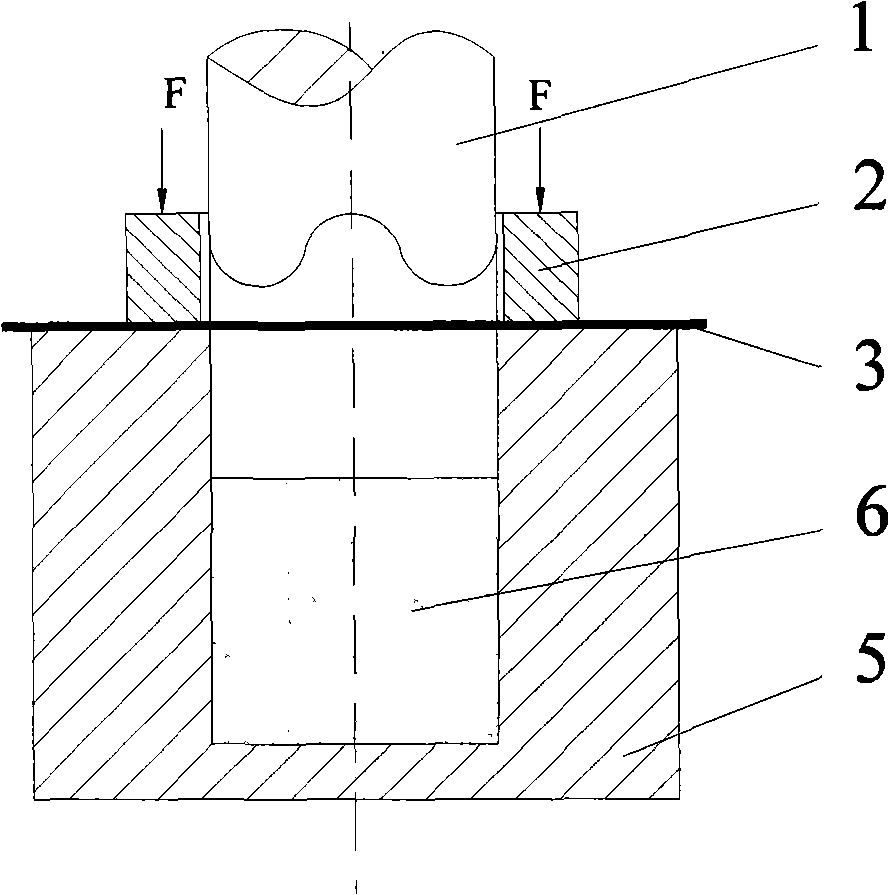

[0026] a. Design a cylindrical mold punch 1 with a diameter of Φ50mm and a height of 100mm; design a box 4 with an inner diameter of Φ62mm, an outer diameter of Φ200mm, and a height of 100mm filled with compressible powder 6; the inner diameter of the blank holder 2 It is Φ52mm, the outer diameter is Φ150mm, and the thickness is 30mm.

[0027] b. Add compressible powder 6 into the box body 4, pre-press the compressible powder 6 with a pressure of 15MPa, and fill it at a height of 40mm.

[0028] c. Put the 08 steel plate 3 with a diameter of Φ200mm and a thickness of 0.8mm on the box 4 filled with compressible powder 6, and load the blankholder 2 with a blankholder force of 2MPa.

[0029] d. Load 5000-10000N to the mold punch 1, when the compressible powder 6 fills the entire cavity of the concave mold, the drawing of the cylindrical part is completed.

[0030] e. Eject the part, add a certain amount of compressible powder 6 again to form the next part, or use a stirring or vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com