Electromagnetic force driven soft mold forming device and method for metal bipolar plate of fuel cell

A metal bipolar plate, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficulty in matching, the cost of driving sheets can not be reused, and achieve increased selection range, improved forming limit, and good forming effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

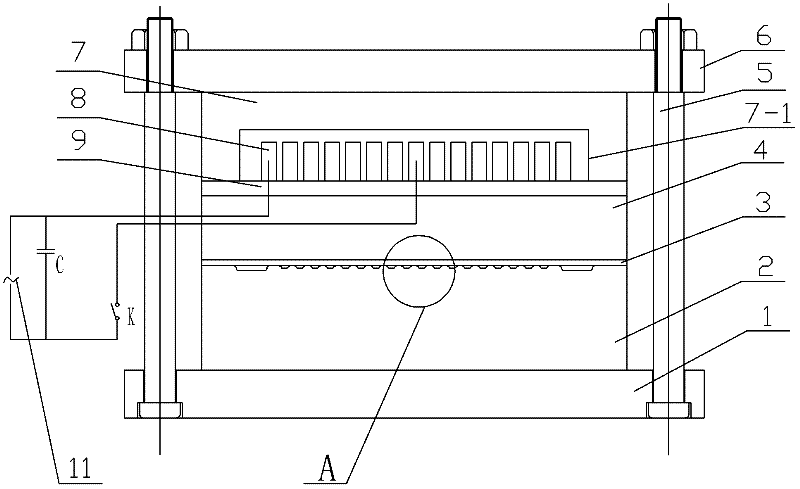

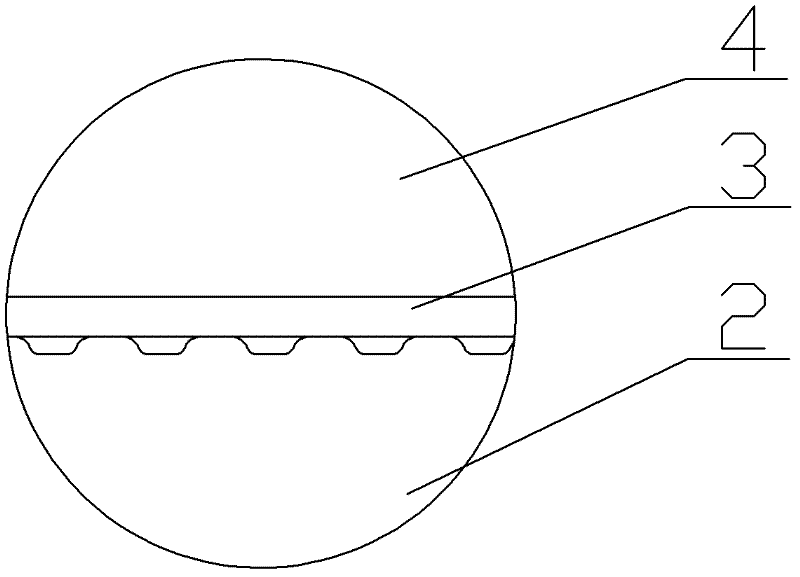

[0015] Specific implementation mode one: combine figure 1 and figure 2 Explain, the electromagnetic force driving soft mold forming device of the fuel cell metal bipolar plate in this embodiment, the device includes a lower fixed plate 1, a forming mold 2, a soft mold 4, a driving plate 9, a coil 8, a support frame 7, an upper Fixed plate 6, capacitor bank C, power supply 11, discharge control switch K and multiple fastening bolts 5;

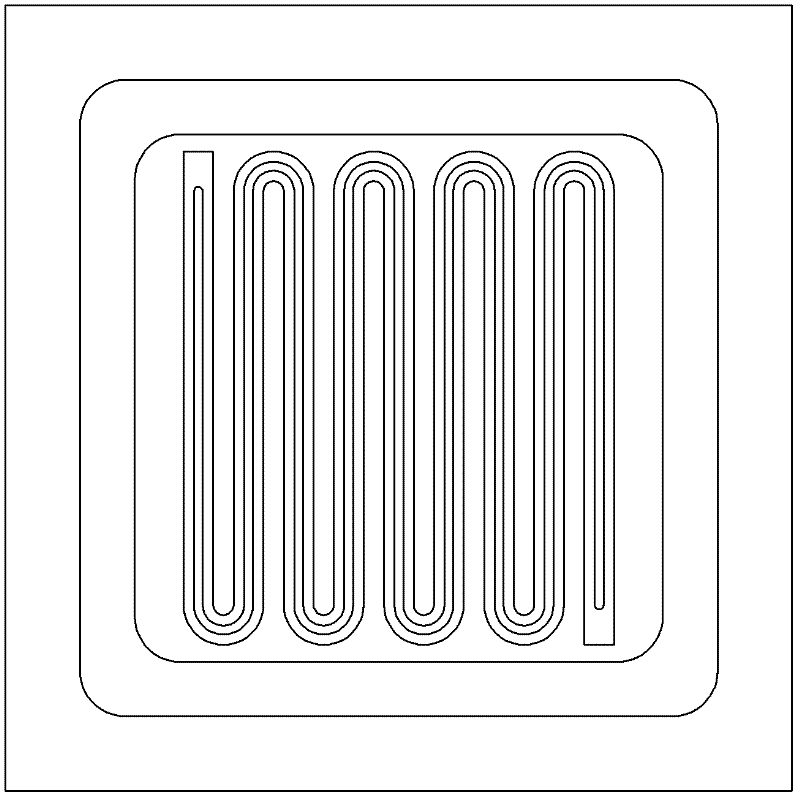

[0016] The lower fixing plate 1 is stacked with forming mold 2, soft mold 4, driving plate 9, support frame 7 and upper fixing plate 6 from bottom to top; the lower end surface of support frame 7 is provided with groove 7-1, and the groove 7-1 is provided with a coil 8. The coil 8 is composed of a single wire wound from the inside to the outside for multiple turns. The adjacent two turns of the wire are separated by a high-voltage insulating material. The surface of 8 is potted with high-voltage and high-strength insulating material to form a...

specific Embodiment approach 2

[0017] Embodiment 2: The cross-sectional shape of a single wire in this embodiment is rectangular. Such a design is beneficial to improve the energy conversion efficiency compared with the circular cross-section wire. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 To illustrate, the driving board 9 of this embodiment is a red copper board. With such a design, the copper plate has a high electrical conductivity, which is conducive to generating high-amplitude eddy currents on its surface, and generating high-intensity magnetic fields in the gap between the drive plate 9 and the coil 8, so that the drive plate 9 is subjected to a greater amplitude pulse magnetic field force, The forming efficiency of the slab 3 is improved by the soft mold 4 acting on the slab 3 . Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com