Hydrodynamic deep drawing equipment for forming deep cavity parts

A technology of liquid-filled deep drawing and forming equipment, which is applied in the fields of liquid-filled deep drawing and forming hydraulic presses and special technical equipment for sheet metal liquid-filled deep drawing and forming. It can solve the problems of surface and internal damage of formed parts, complex shape and structure of sheet metal parts Problems such as the loss of service life of the rubber bag, to achieve the effect of good surface quality of parts, avoid oil pollution, and reduce use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

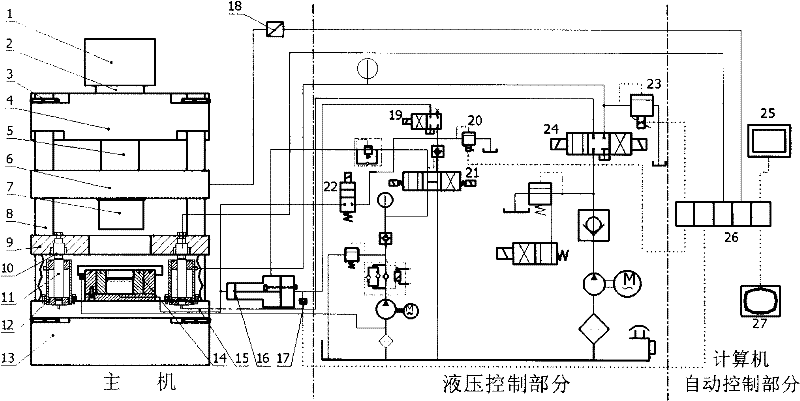

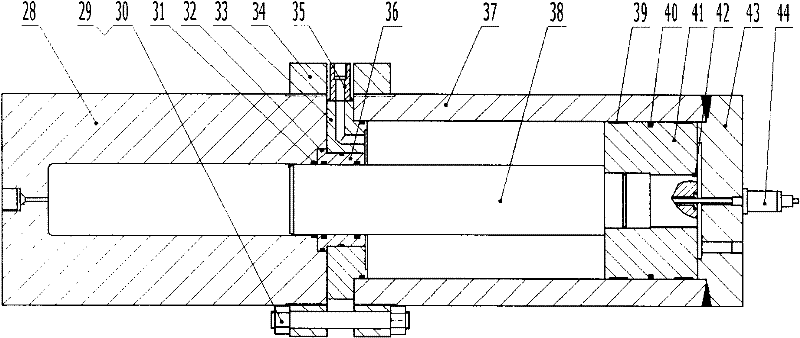

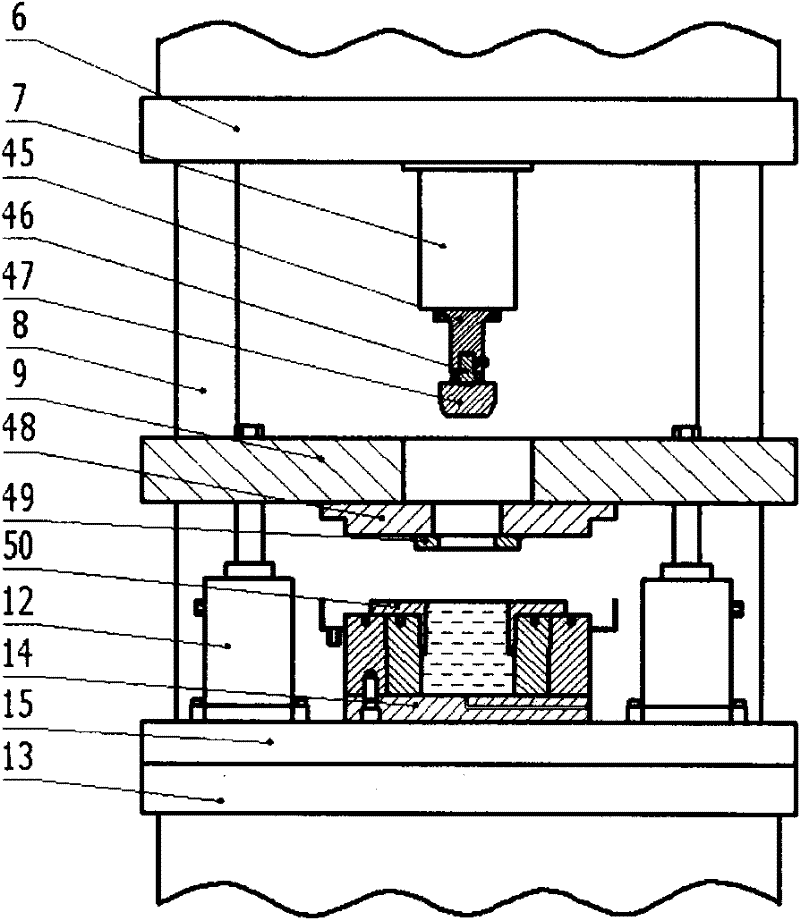

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

[0027] figure 1It shows a schematic diagram of the overall structure of a deep cavity part liquid-filled deep-drawing forming equipment of the present invention. The deep-cavity liquid-filled deep-drawing equipment includes three main components: the main engine, the hydraulic control part and the computer automatic control part, the main engine It mainly includes oil tank 1, main cylinder 2, round nut 3, upper platform 4, main cylinder piston 5, main slider 6, transition block 7, column 8, blank holder slider 9, force sensor 10, press piston 11, press Side cylinder 12, lower platform 13, ultra-high pressure liquid-filled chamber 14, edge-pressing fixed plate 15, booster cylinder 16, pressure sensor 17, grating ruler 18. Upper platform 4, column 8 and lower platform 13 form hydraulic machine frame, master...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com