Combined powder metallurgy hollow camshaft cam material and preparation method

A technology of powder metallurgy and camshaft, which is applied in the field of combined powder metallurgy hollow camshaft cam material and its preparation, can solve the problems of prolonging the production cycle, increasing energy consumption and cost, and achieving the reduction of cutting processing, material saving, durability good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A combined powder metallurgy hollow camshaft cam material, the cam material alloy composition is C 1.5%, Cr 5%, Mo 1%, P 0.6%, Cu 2%, Si 1.5%, Mn 1%, Ti 1.5%, The balance is Fe.

[0025] The preparation method of the above combined powder metallurgy hollow camshaft cam material:

[0026] (1) Weigh the raw material powder according to the alloy composition of the combined powder metallurgy hollow camshaft cam material, wherein: C is added in the form of graphite, Cu is added in the form of electrolytic copper powder, Cr is added in pure Cr powder, Mo is added in the form of ferromolybdenum, and P is added in the form of Ferrophosphorus is added, Si is added as ferrosilicon, Mn is added as ferromanganese, Ti is added as ferrotitanium, Fe is atomized iron powder. The particle size characteristics of various powders used are: graphite particle size is -200 mesh or finer, electrolytic copper powder particle size is -200 mesh or finer, molybdenum iron powder is ≤25μm ultrafi...

Embodiment 2

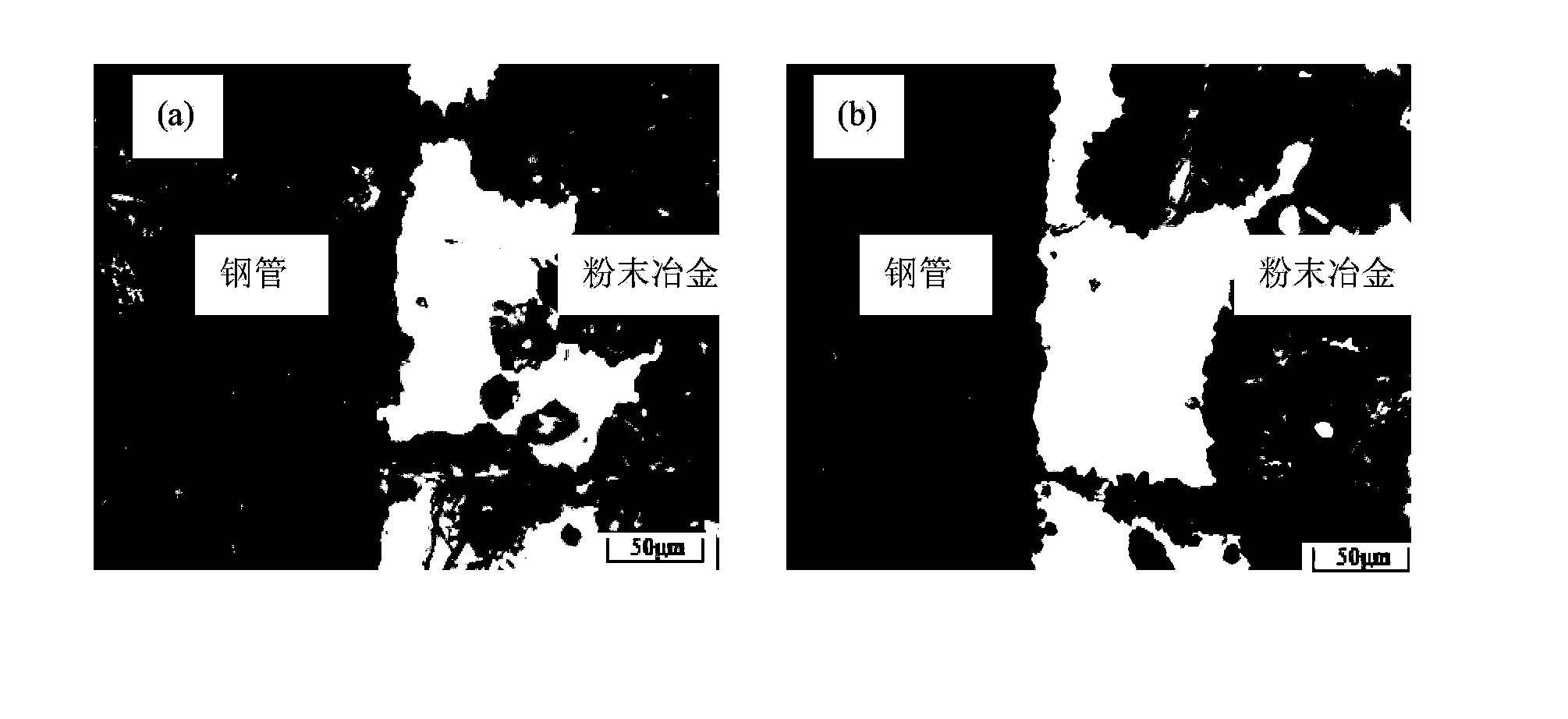

[0031] Through the torsion test, check the connection strength between the steel pipe and the cam, compare the torque value of the sample without Ti addition (other alloy composition points are listed in Example 1) and the sample with Ti addition, and the cam made with 1.5% Ti added, its The torque value can reach 1023 N·m, and the torque value of the sample without Ti addition is 912 N·m. The addition of titanium reduces the diffusion activation energy of elements in the matrix, increases the diffusion speed of elements in the matrix, effectively promotes better and faster diffusion of elements at the interface between the steel pipe and the cam, and makes the performance of the interface joint better.

Embodiment 3

[0033] A combined powder metallurgy hollow camshaft cam material, the cam material alloy composition is C 2.5%, Cr 4.5%, Mo 1%, P 0.6%, Cu 2%, Si 1%, Mn 0.3%, Ti 1.0%, The balance is Fe.

[0034] The preparation method of the above combined powder metallurgy hollow camshaft cam material:

[0035] (1) Weigh the raw material powder according to the above combined powder metallurgy hollow camshaft cam material alloy composition, wherein: C is added in the form of graphite, Cu is added in the form of FeCu alloy, Cr is added in the form of high-carbon ferrochrome with a content of 70%, Mo is added as ferromolybdenum, P is added as ferrophosphorus, Si is added as ferrosilicon, Mn is added as ferromanganese, Ti is added as pure titanium powder, and Fe is added as atomized iron powder. The particle size characteristics of the various powders used are: the graphite particle size is -200 mesh or finer, the high-carbon ferrochrome powder, molybdenum powder, etc. , other raw material po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com