Cement grouting reinforcement connector

A technology for cement grouting and connecting joints, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of reducing the durability of concrete structures, large size of connecting sleeves, and increasing engineering costs, so as to improve safety. and quality, improve the overall force performance, reduce the effect of cutting amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

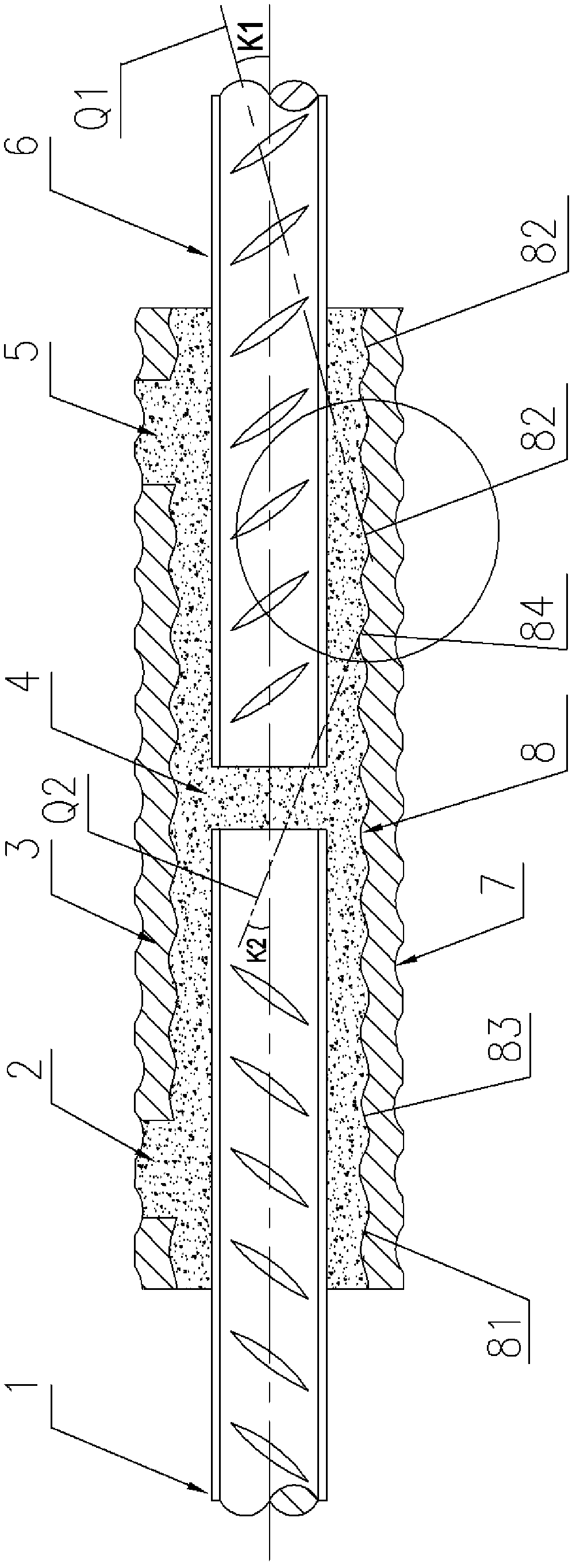

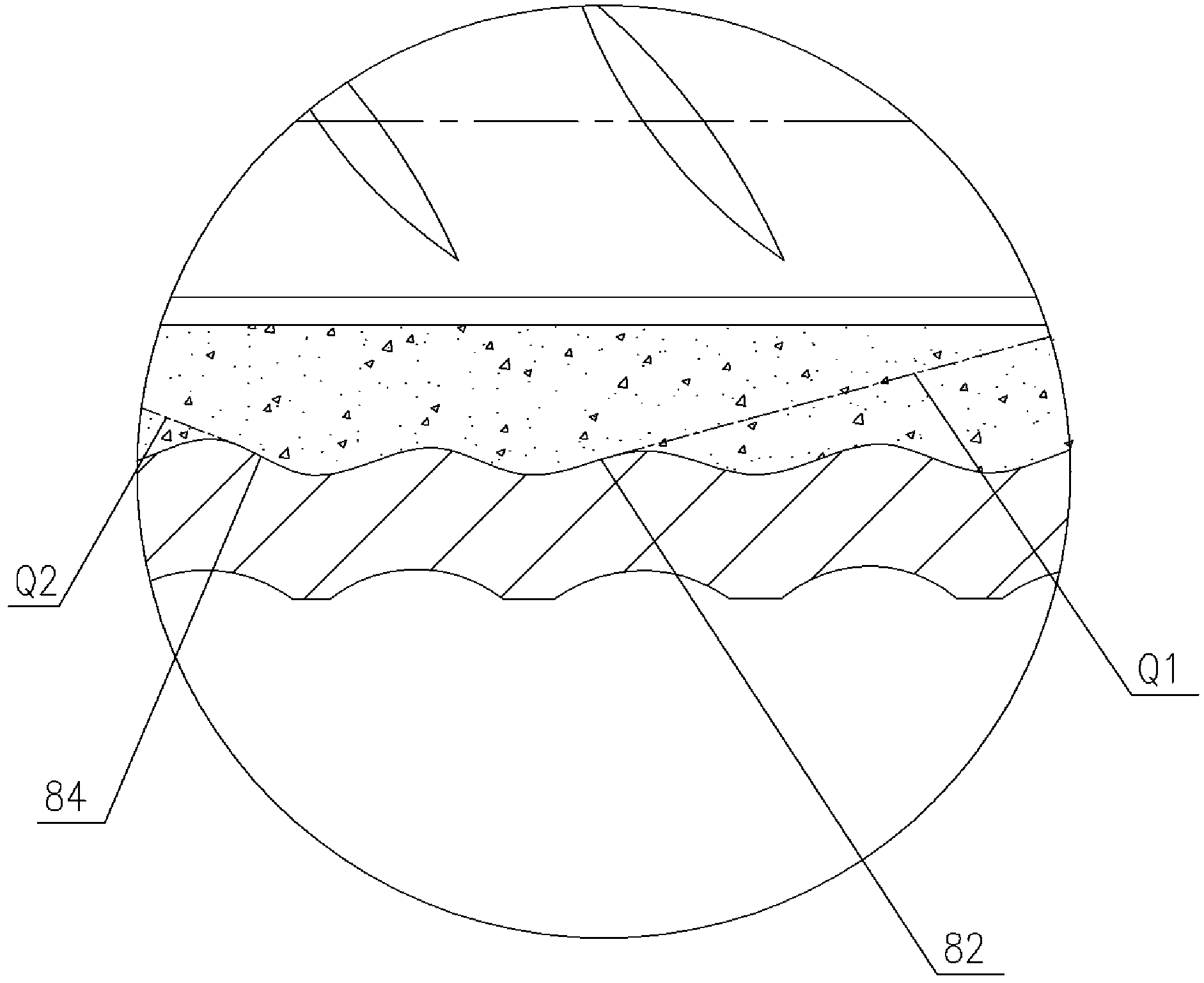

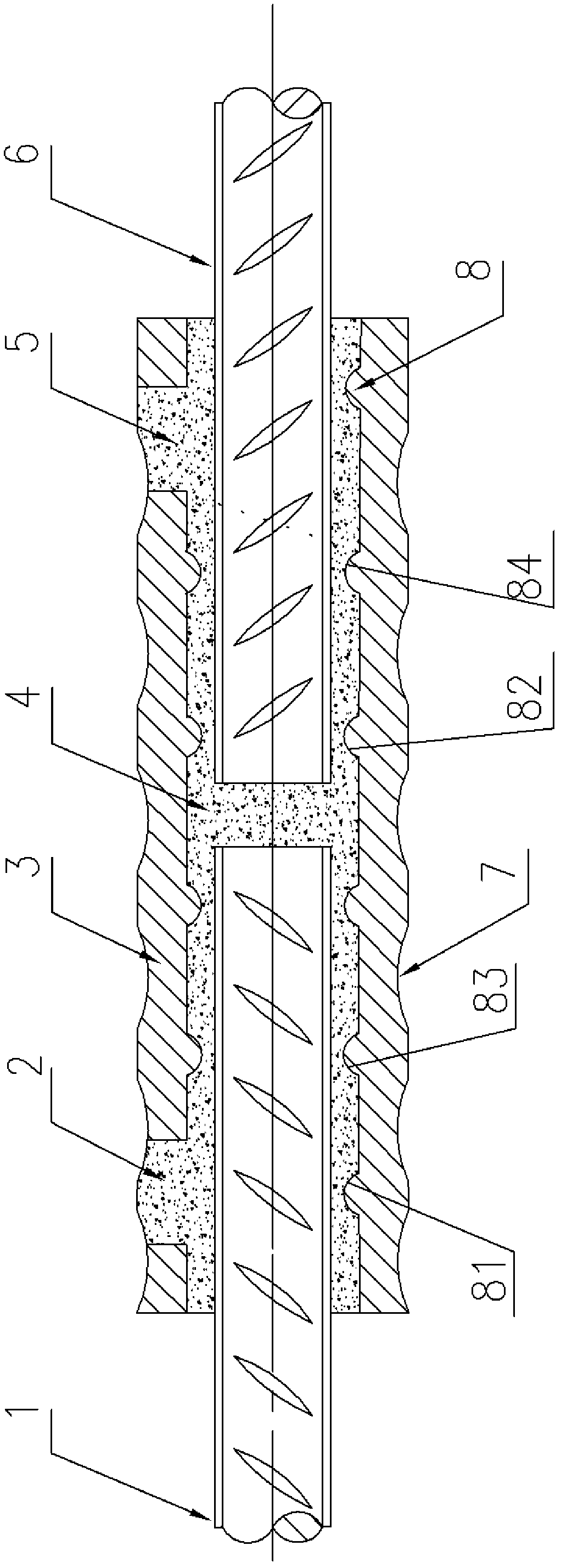

[0030] see figure 1 , the present invention provides a cement grouting reinforcing bar connecting joint, its basic structure includes connecting reinforcing bars 1, 6, metal tubular connecting sleeve 3 and cement mortar 4, wherein: the connecting reinforcing bars are two common ribbed reinforcing bars, The connecting sleeve 3 is tubular, with connecting holes at both ends. The ribbed steel bars 1 and 6 are respectively inserted into the connecting holes at the two ends of the connecting sleeve 3, and pass through the hardened steel bars in the gap between the sleeve and the steel bar respectively. The non-shrinking cement mortar 4 combines to form a connected body; in addition, figure 1 In the described embodiment, a grout hole 2 is provided on the cylinder wall at one end of the connecting sleeve 3, and a grouting hole 5 is provided on the cylinder wall at the other end; A hole is arranged on the tube wall at one end of the connecting sleeve 3, which is used as the grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com