Forging process of large tee and large skew tee

An oblique three-way and large-scale technology, applied in the field of forging and pressing production process of large-scale three-way, can solve the problems of high energy consumption, low utilization rate of raw materials, long processing time, etc., achieve energy saving and consumption reduction production efficiency, improve internal quality and mechanics performance, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

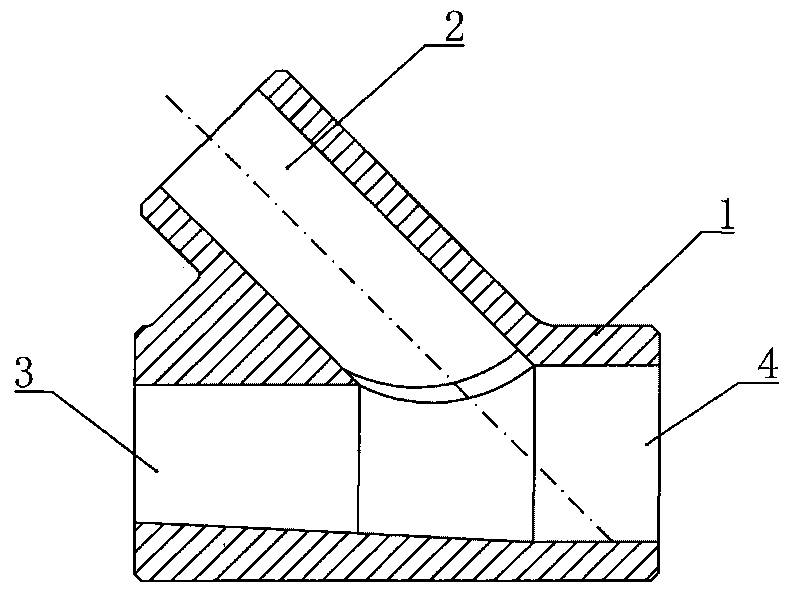

[0024] The structure of a kind of oblique tee that adopts process of the present invention to produce is as figure 1 As shown, the main diameter is 300-325mm, and the wall thickness is about 50-75mm.

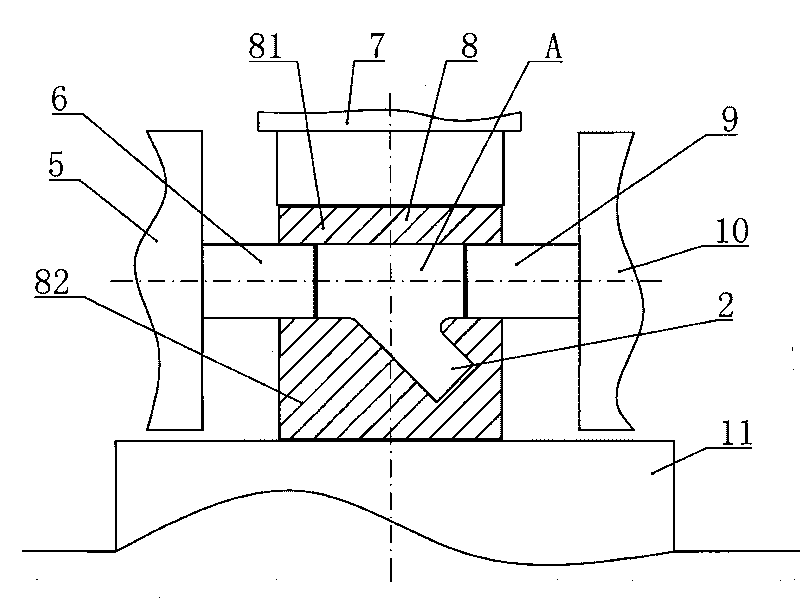

[0025] see figure 2 , the forging process of large-scale tee A produced by forging press of the present invention comprises the following operations:

[0026] 1. Use an electric saw to cut out the forging billet that has passed the re-inspection according to the size of the drawing. The shape of the billet is a cylinder [the material of the billet is given as an example, because the heating temperature below is related to the material].

[0027] 2. Put the billet in the heating furnace, heat up to 1200°C, and the heating rate is 5°C / min.

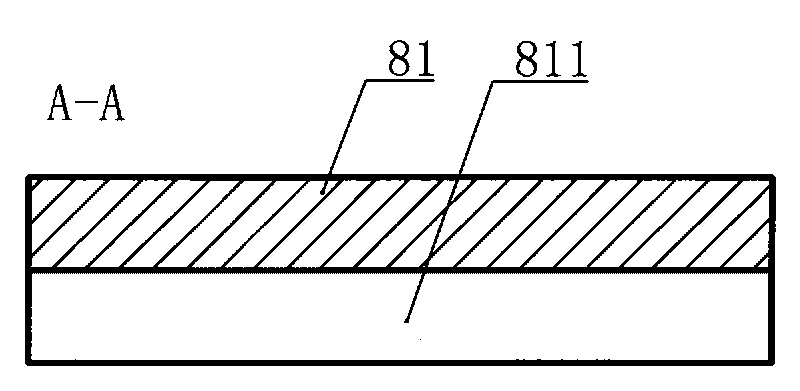

[0028] 3. Install the left push head 6 and the right push head 9 with bolts on the top of the left cylinder 5 and the right cylinder 10 of the 20000T frame type multi-directional mold liquid forging press, and combine the upper and lower di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com