Method for manufacturing blank of pipe clamp

A manufacturing method and technology for pipe clamps, which are applied in manufacturing tools, casting equipment, molds, etc., can solve the problems of waste of materials and processing costs, troublesome installation and disassembly, irregular shape of pipe clamps, etc., and save materials and labor. , reduce the amount of machining, and realize the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

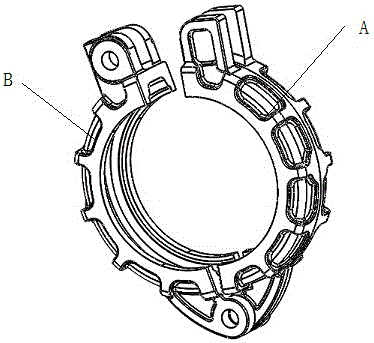

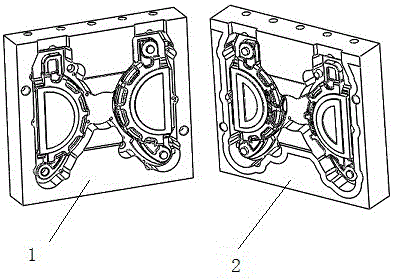

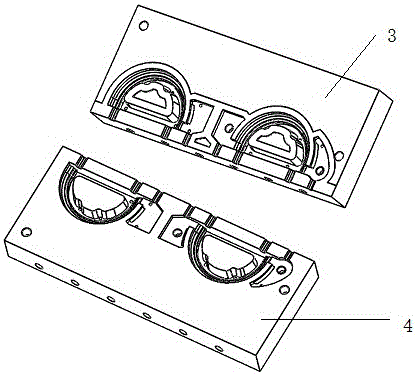

[0034] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as Figure 1 to Figure 8 , according to the design drawing of the pipe clip, in this example, the pipe clip for a steel pipe with a diameter of 125 mm is taken as an example, the pipe clip is divided into the right half A and the left half B, and the two halves are closed and inserted into the locking pin to complete the metal pipe The connection; enlarge the outer dimensions of the pipe clip by 8-12 mm to make the pipe clip sand shell mold C. In this example, the longitudinal center plane of the pipe clip is selected as the pouring parting surface, and the parting surface is used as the boundary. In order to improve work efficiency , in this example, each set of molds is used to make the sand shell and sand core of the left half B and the right half A of the pipe clamp at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com