Blank-making rolling method for synchronous sliding sleeve of automotive transmission

A technology of automobile transmission and sliding sleeve, applied in metal rolling and other directions, can solve the problems of high material consumption, large processing volume, and yet to appear, and achieve the effect of improving production efficiency, improving internal quality, and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

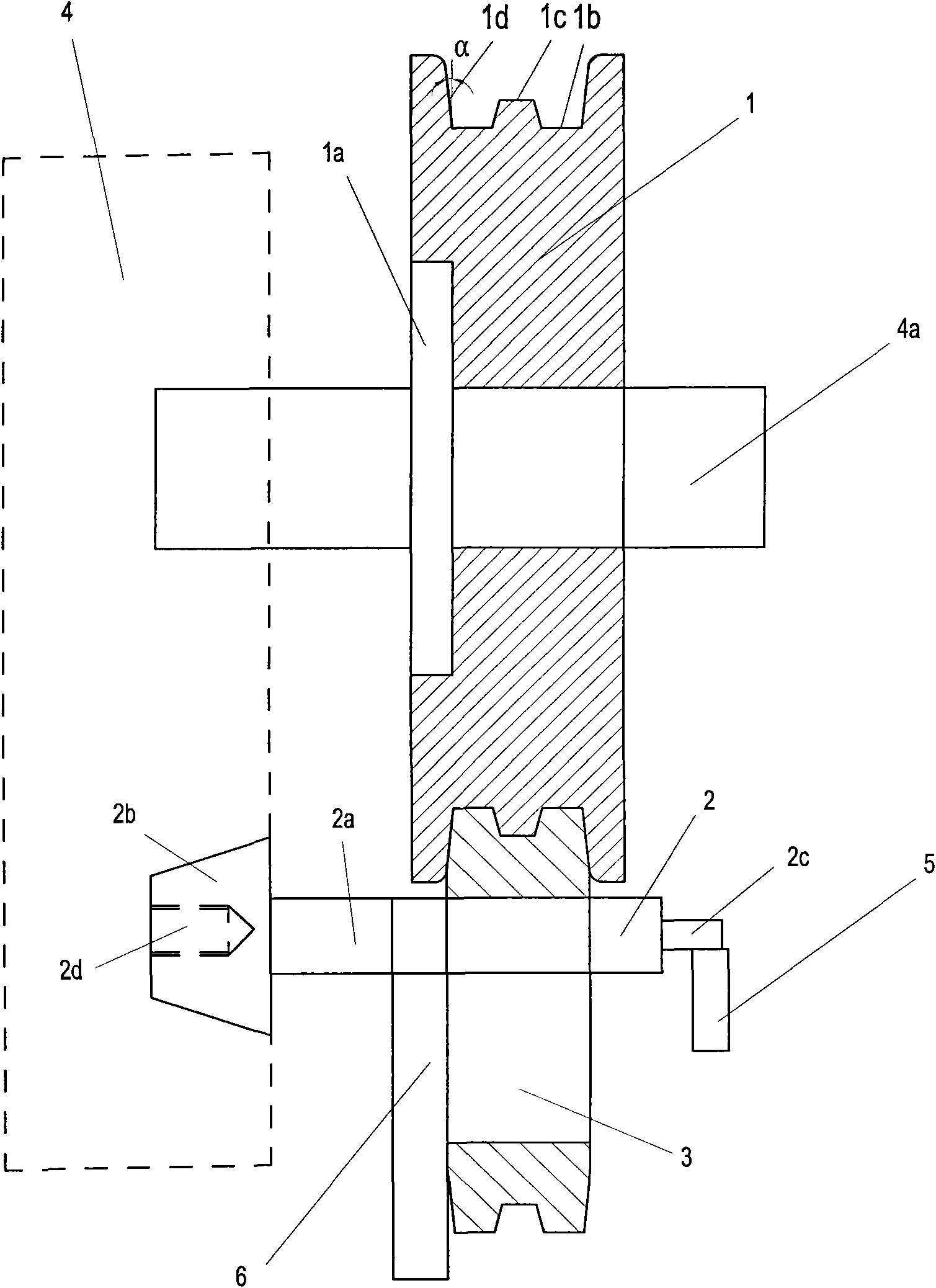

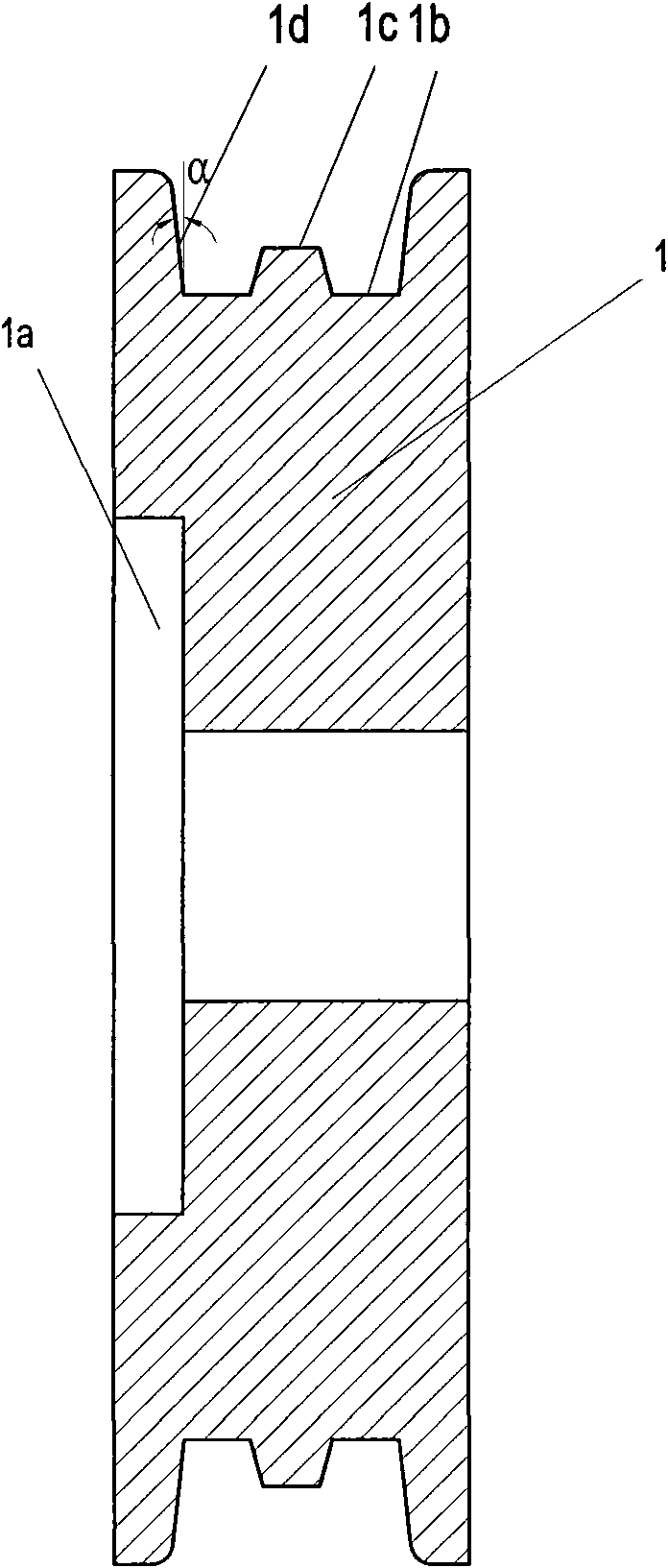

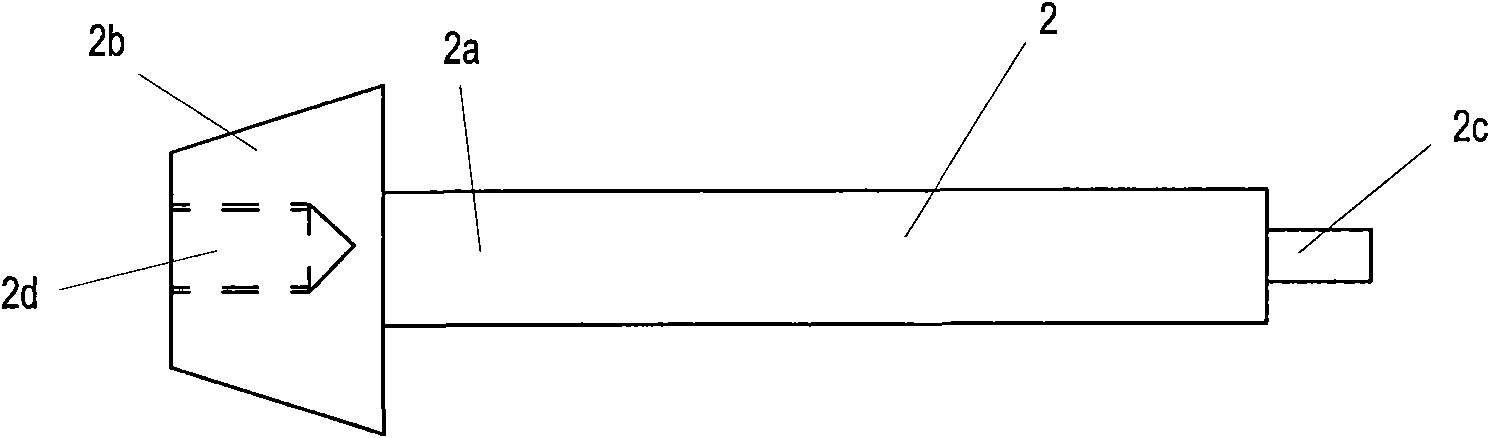

[0051] Embodiment: process outer diameter phi with 20CrMnTi phi 60mm round steel 1 =185mm, inner diameter φ 2 =150mm, height h=28mm, outer diameter groove width h 1 =19mm, outer diameter groove depth h 2 =7.5mm gear synchronous sliding sleeve blank, the processing procedure is as follows:

[0052] a) Blanking, the above size is the finished size of the sliding sleeve after machining, the original forging billet generally needs to increase the machining allowance of 2.5 ~ 5mm on each processing surface, and the billet produced by the ring rolling billet process is due to rolling and expanding. The precision needs to be high, adding 1.5mm machining allowance to each machining end face can fully meet the machining requirements. Therefore, when calculating the weight of blank raw materials, the outer diameter φ 1 =188mm, inner diameter φ 2 =147mm, height h=31mm, outer diameter groove width h 1 =16mm, outer diameter groove depth h 2 = 7.5 mm. In order to make the annular gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com