Sand shell mold for manufacturing blank of vehicle braking disc

A technology for automobile brakes and brake discs, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of long casting cycle, large processing workload, waste of raw materials, etc., to achieve automatic production and reduce mechanical processing. volume, material and labor savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

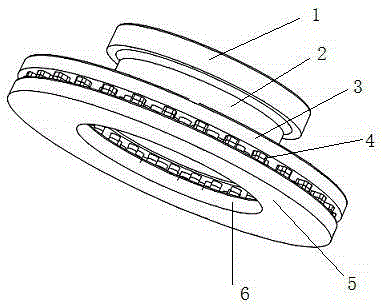

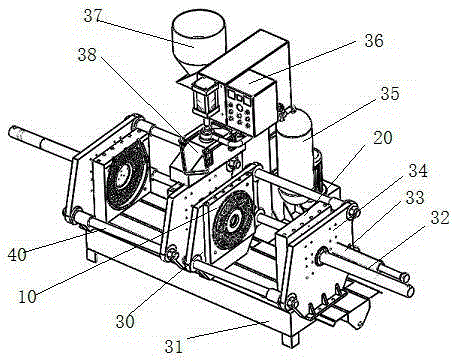

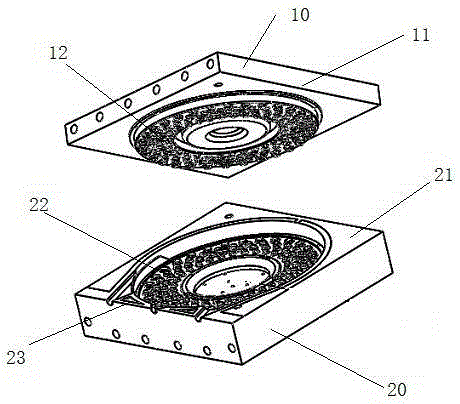

[0019] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as figure 1 , figure 2 , according to the design drawings of the brake disc, enlarge the outer dimension of the brake disc by 8-12 mm to make a sand shell mold. In this example, the middle part of the support block 4 is selected as the pouring parting surface, and the parting surface is used as the boundary to install the disc 1 One side is used as lower mold 20, and one side of left plate surface 5 is used as upper mold 10; Upper template 11 selects the steel plate of thickness 50 millimeters for use, makes upper mold cavity 12 on it, selects the upper mold cavity 12 protruding upper template 11 in this example Form production, the brake disk elements that upper die cavity 12 comprises comprise left disk surface 5, half of support block 4, cavity 6 left half; Select t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com