Integrated encapsulating and potting device for sensor and operation method thereof

A sensor and potting technology, applied in measurement devices, electrical devices, instruments, etc., can solve the problems of limited number of potting and sealing wooden frame shells, waste of labor and material costs, unfavorable process flow, etc., to save labor and materials. , space saving, process saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

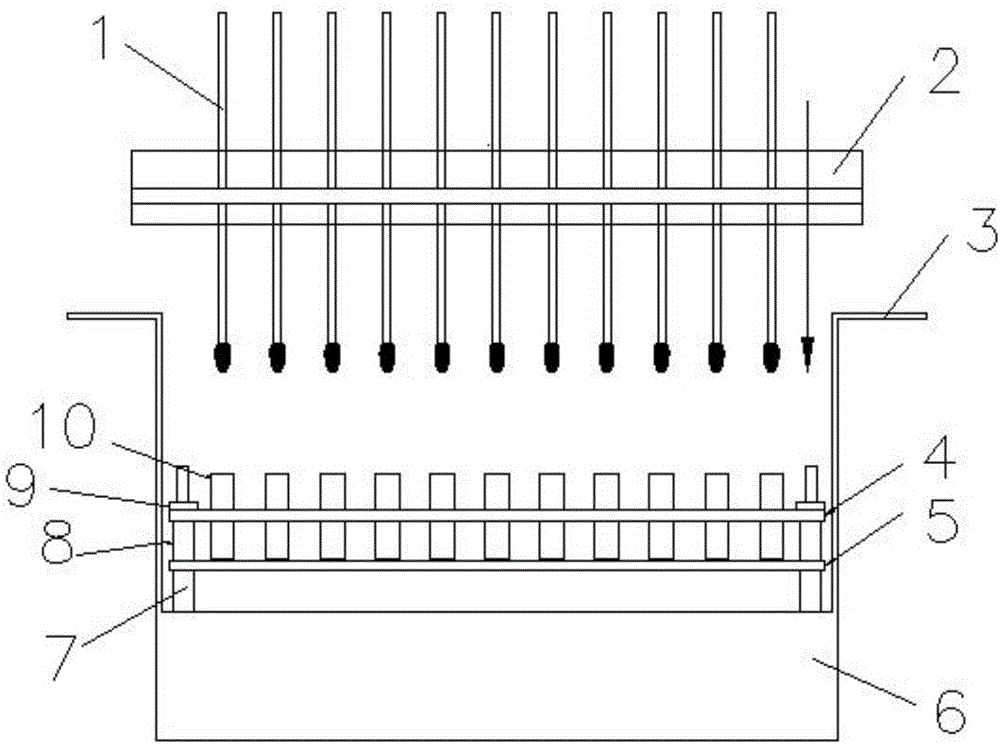

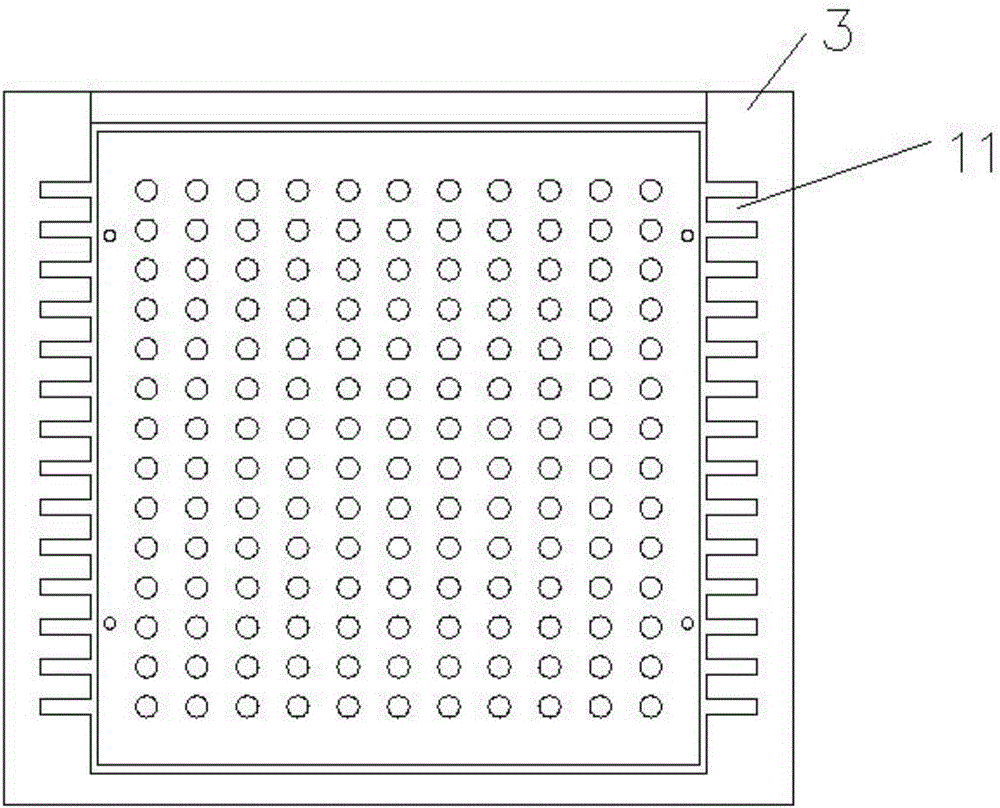

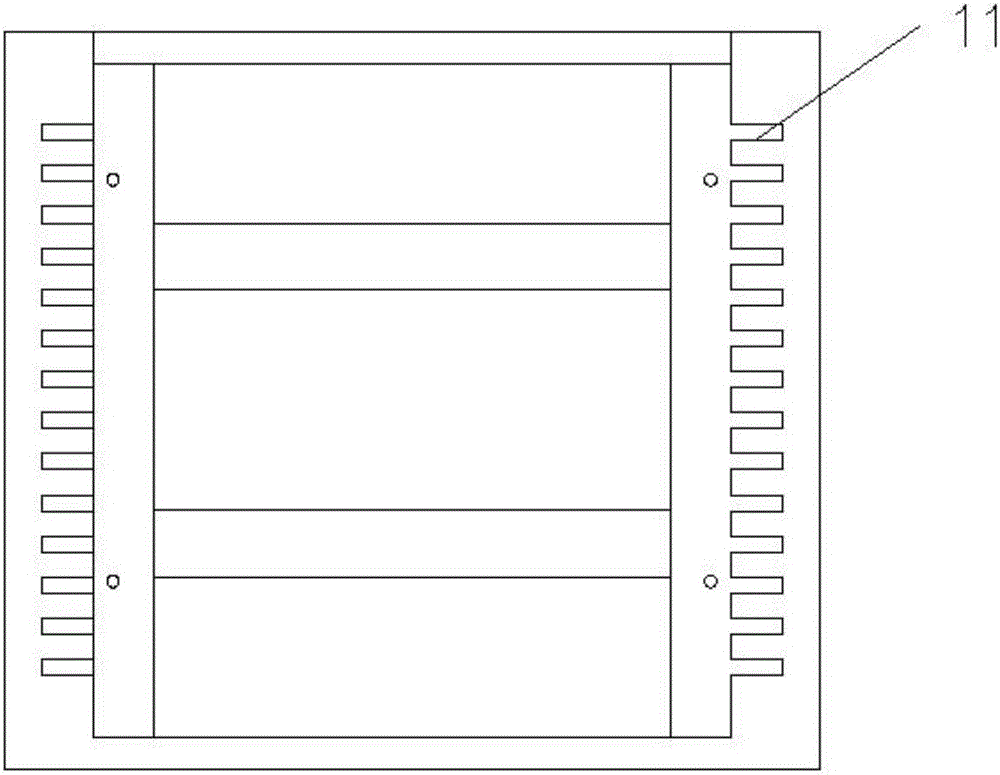

[0033] Embodiment one: if figure 1 and 2As shown, the present invention includes a carrier frame 6 and an encapsulation plate 2. The middle part of the carrier frame 6 is concave and protruding on both sides, and the protruding part is a side structure 3. Several first grooves 11 are provided on the edge structure, and the encapsulation plate 2 Placed in the first groove 11 of the side structure 3, several second grooves 13 are provided on one side of the enveloping plate 2, and the housing placement plate 4 is provided in the middle of the carrier frame 6 and fixed by screws 9. The shell placement plate 4 is provided with no less than 20 holes 12 , and shells 10 are placed in the holes 12 , and each shell 10 corresponds to a component 1 placed in the second groove 13 on the encapsulation plate 2 . Complete the encapsulation by setting the encapsulation plate 2 and the potting by the carrier frame 6, so that the encapsulation and potting can be realized in one device at the s...

Embodiment 2

[0043] Embodiment 2: The present invention includes a carrier frame 6 and an encapsulation plate 2. The middle part of the carrier frame 6 is concave and protruding on both sides, and the protruding part is a side structure 3. Several first grooves 11 are opened on the edge structure, and the encapsulation plate 2 is placed in the first groove 11 of the side structure 3, a plurality of second grooves 13 are arranged on one side of the encapsulating plate 2, and a shell placement plate 4 is arranged in the middle of the carrier frame 6 and fixed by screws 9, so that The housing placement plate 4 is provided with no less than 20 holes 12, housings 10 are placed in the holes 12, and each housing 10 corresponds to a component 1 placed in the second groove 13 on the encapsulation board 2. Complete the encapsulation by setting the encapsulation plate 2 and the potting by the carrier frame 6, so that the encapsulation and potting can be realized in one device at the same time, without...

Embodiment 3

[0055] Embodiment 3: The present invention includes a carrier frame 6 and an encapsulation plate 2. The middle part of the carrier frame 6 is concave and protruding on both sides, and the protruding part is a side structure 3. Several first grooves 11 are opened on the edge structure, and the encapsulation plate 2 is placed in the first groove 11 of the side structure 3, a plurality of second grooves 13 are arranged on one side of the encapsulating plate 2, and a shell placement plate 4 is arranged in the middle of the carrier frame 6 and fixed by screws 9, so that The housing placement plate 4 is provided with no less than 20 holes 12, housings 10 are placed in the holes 12, and each housing 10 corresponds to a component 1 placed in the second groove 13 on the encapsulation board 2. Complete the encapsulation by setting the encapsulation plate 2 and the potting by the carrier frame 6, so that the encapsulation and potting can be realized in one device at the same time, without...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com