Strip-shaped jacketed oil-heat roller

A technology of oil heating rollers and jackets, applied in printing, rotary printing machines, printing machines, etc., can solve problems such as temperature difference on the surface of the roller, large temperature difference on the surface of the roller, affecting the quality consistency of drying or cooling treatment, etc. Achieve the effects of fast replacement speed, small heat loss, and small storage capacity of media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

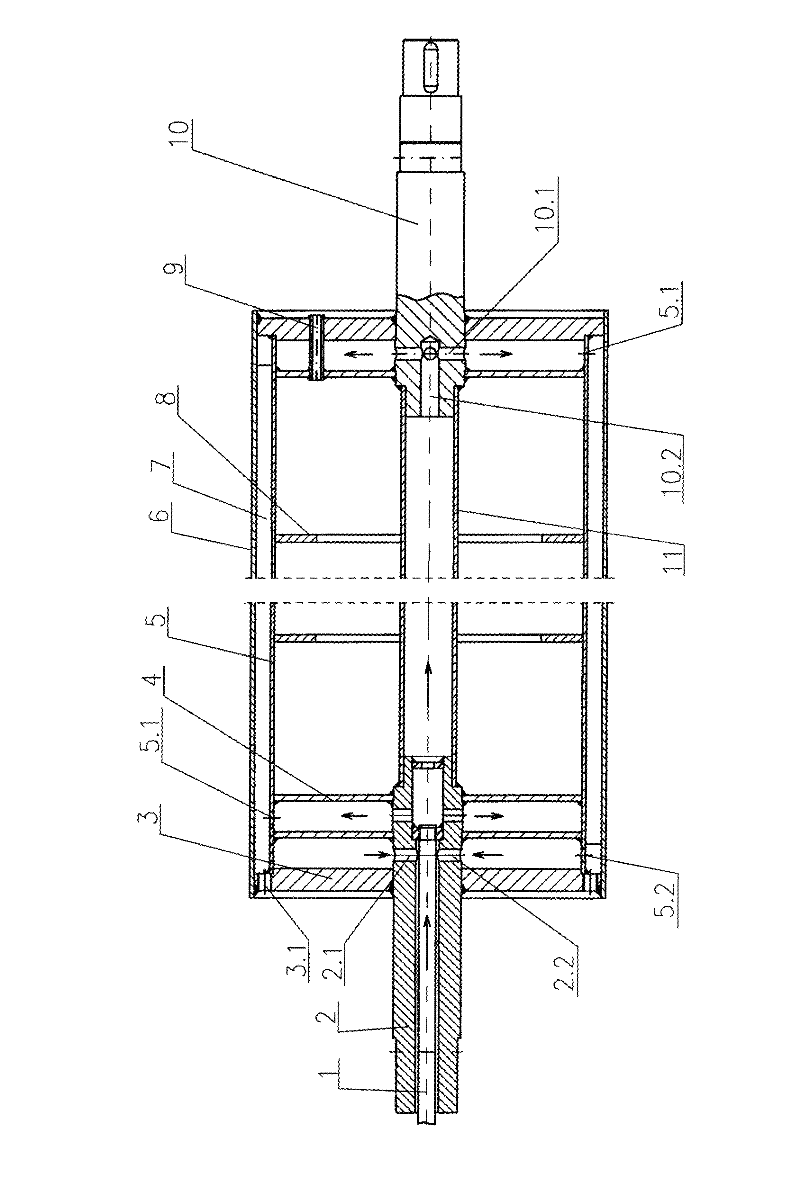

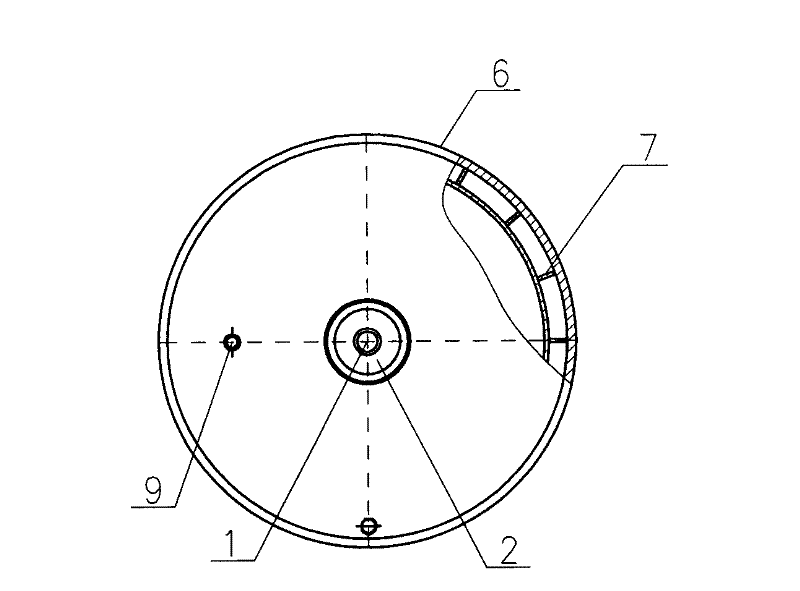

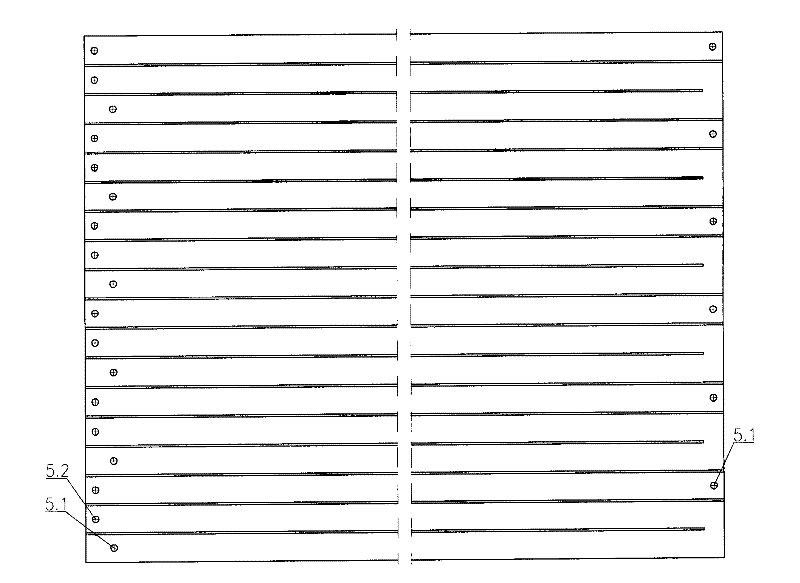

[0016] figure 1 The shown strip jacket oil heating roller includes inner pipe 1, input shaft 2, end cover 3, separator 4, inner cylinder 5, outer cylinder 6, slats 7, inner ring plate 8, ventilation pipe 9. Support shaft 10 and connecting pipe 11. The input shaft 2 is a hollow shaft structure located at the left end, the support shaft 10 is a solid shaft structure located at the right end, and the two ends of the connecting pipe 11 are coaxially fixedly connected to the input shaft 2 and the support shaft 10 respectively. The inner cylinder 5 and the outer cylinder 6 are both cylindrical thin-walled cylinders, and the inner cylinder 5 and the outer cylinder 6 with different diameters fit together to form a jacket structure. The inner wall is fixedly connected with the inner ring plate 8 in the axial direction. The end cover 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com