Preparation method of aluminium nitride base ceramic copper-clad plate

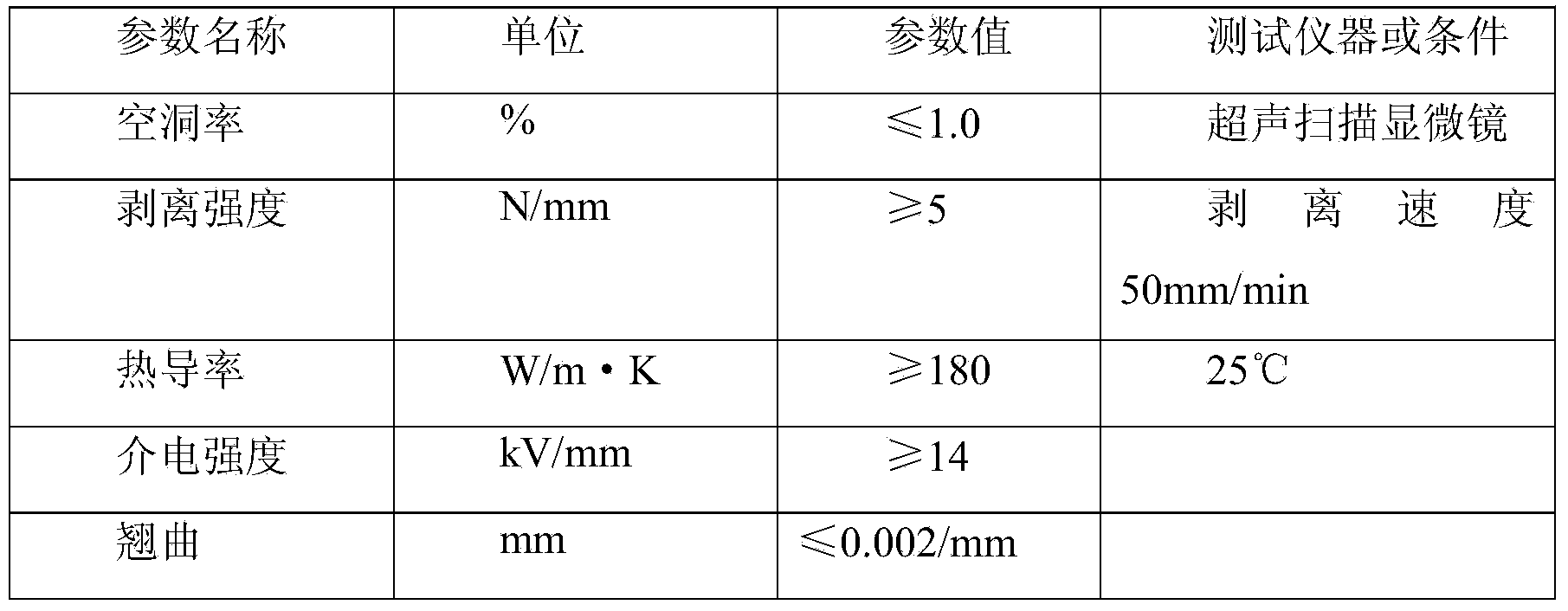

A ceramic copper clad laminate and aluminum nitride substrate technology, which is applied in the field of copper clad laminate manufacturing, can solve the problems of large thermal expansion coefficient, weak local sintering, voids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Chemical oxidation treatment of copper foil

[0049] ①Oxygen-free copper foil size 193mm×145mm×0.2mm, pre-treatment;

[0050] ② Put the copper foil into molten sodium nitrate at 350°C, and the oxidation time is 20 minutes, forming dense and firm Cu on the surface of the copper foil. 2 O film.

[0051] (2) High temperature oxidation of aluminum nitride ceramic substrate

[0052] The size of the aluminum nitride ceramic substrate is 200mm × 150mm × 0.38mm, pre-treatment; the aluminum nitride ceramic substrate is inserted into the Al 2 o 3 The material of the ceramic plate frame is pushed into the three-station high-temperature oxidation furnace tube for oxidation treatment. The parameters are as follows: high-temperature oxidation temperature 1095°C, oxygen flow rate 30ml / min, and holding time 230min.

[0053] (3) Magnetron sputtering of aluminum nitride ceramic substrate

[0054] RF power 76W, working pressure 1.0Pa, Ar flow rate 78ml / min, O 2 The flow rate is ...

Embodiment 2

[0067] (1) Chemical oxidation treatment of copper foil

[0068] ①Oxygen-free copper foil size 193mm×145mm×0.3mm, pre-treatment;

[0069] ② Put the copper foil into molten sodium nitrate at 360°C, and the oxidation time is 18 minutes, forming dense and firm Cu on the surface of the copper foil. 2 O film.

[0070] (2) High temperature oxidation of aluminum nitride ceramic substrate

[0071] The size of the aluminum nitride ceramic substrate is 200mm × 150mm × 0.63mm, pre-treatment; the aluminum nitride ceramic substrate is inserted into the Al 2 o 3 The material of the ceramic plate frame is pushed into the three-station high-temperature oxidation furnace tube for oxidation treatment. The parameters are as follows: high-temperature oxidation temperature 1100°C, oxygen flow rate 25ml / min, and holding time 215min.

[0072] (3) Magnetron sputtering of aluminum nitride ceramic substrate

[0073] RF power 76W, working pressure 1.0Pa, Ar flow rate 77ml / min, O 2 The flow rate is ...

Embodiment 3

[0086] (1) Chemical oxidation treatment of copper foil

[0087] ①Oxygen-free copper foil size 193mm×145mm×0.35mm, pre-treatment;

[0088] ② Put the copper foil into molten sodium nitrate at 370°C, and the oxidation time is 15 minutes, forming dense and firm Cu on the surface of the copper foil. 2 O film.

[0089] (2) High temperature oxidation of aluminum nitride ceramic substrate

[0090]The size of the aluminum nitride ceramic substrate is 200mm×150mm×1.0mm, pre-treatment; the aluminum nitride ceramic substrate is inserted into the Al 2 o 3 The material of the ceramic plate frame is pushed into the three-station high-temperature oxidation furnace tube for oxidation treatment. The parameters are as follows: high-temperature oxidation temperature 1105°C, oxygen flow rate 20ml / min, and holding time 200min.

[0091] (3) Magnetron sputtering of aluminum nitride ceramic substrate

[0092] RF power 76W, Ar flow rate 76ml / min, O 2 The flow rate is 7.6ml / min, and the oxygen par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com