Leaf-spring type flexible hinge of null-axis shift

A flexible hinge and reed type technology, which is applied in the direction of pivot connection, can solve the problems such as the inability to achieve zero-axis drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

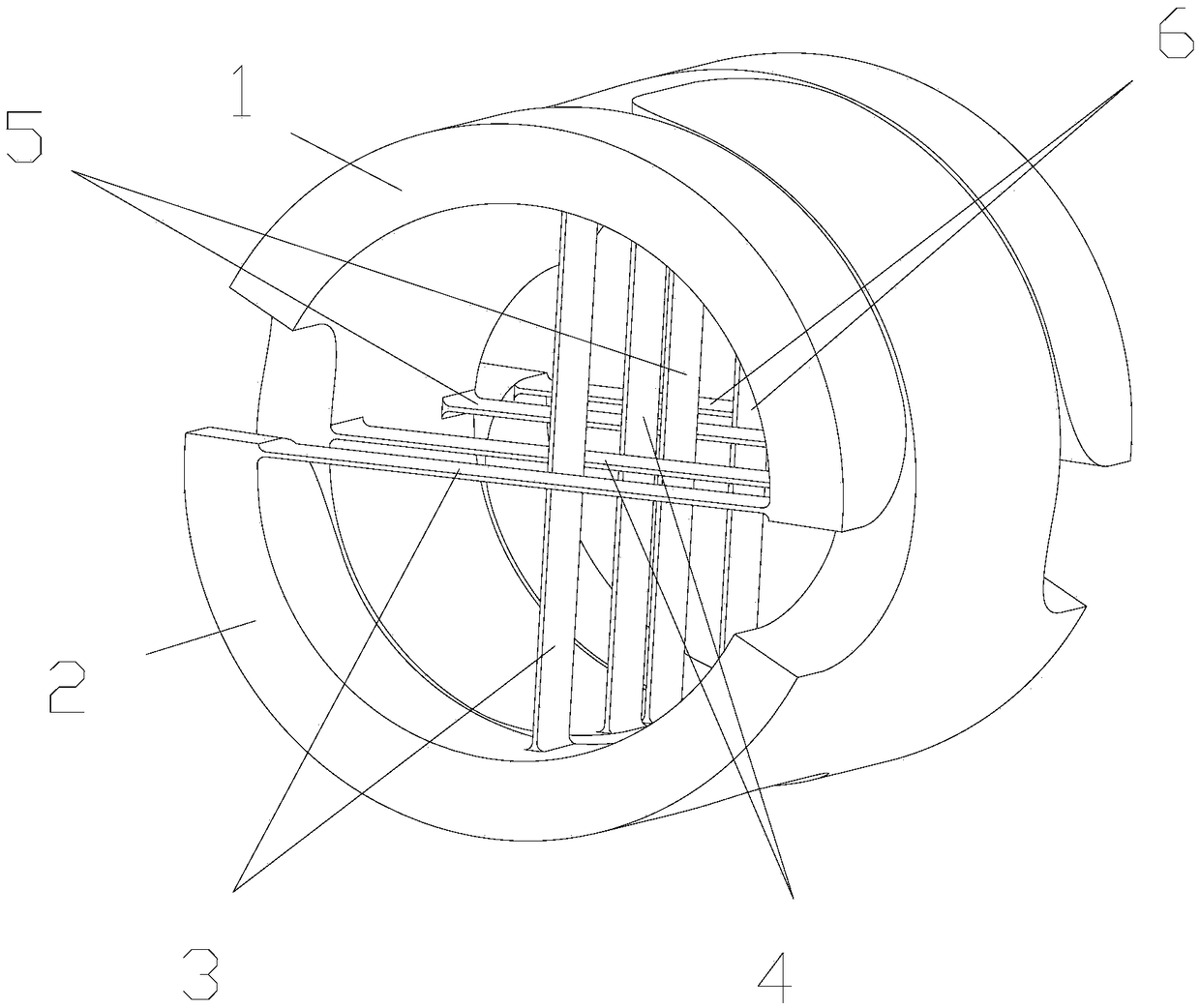

[0020] Such as figure 1 As shown, a zero-axis floating reed type flexible hinge at least includes an upper rotating member 1, a lower rotating member 2, a first cross reed 3, a second cross reed 4, a third cross reed 5, a fourth cross The reed 6; the upper rotating part 1 and the lower rotating part 2 are placed coaxially, and there is a certain gap between them to prevent contact and friction caused by out-of-plane force (abnormal force) during relative movement;

[0021] The first cross reed 3, the second cross reed 4, the 3rd cross reed 5, the 4th cross reed 6 are arranged in the collinear mode of crossing lines; the first cross reed 3, the second cross reed 4 The arrangement of the reeds is symmetrical to that of the third intersecting reed 5 and the fourth intersecting reed 6 along the intersection line;

[0022] The upper or lower end of the first cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com