Method for preparing alpha-phenethyl alcohol

A technology of phenylethanol and acetophenone, which is applied in the field of preparation of α-phenylethanol, can solve the problems of high preparation cost of α-phenylethanol, low synthesis selectivity, harsh reaction conditions, etc., and achieve mild reaction conditions and simple post-treatment , the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Catalyst preparation method:

[0029] Taking 0.5wt% MgO / AC catalyst as an example, the preparation method is: weigh 0.16gMg(NO 3 ) 2 ·6H 2 O was dissolved in 50ml of deionized water to obtain an aqueous solution of magnesium nitrate, and then 5 g of activated carbon support was immersed in the aqueous solution of magnesium nitrate, and the water was evaporated to dryness with a rotary evaporator, and then calcined at 600 ° C for 6 hours to obtain a 0.5wt% MgO / AC catalyst.

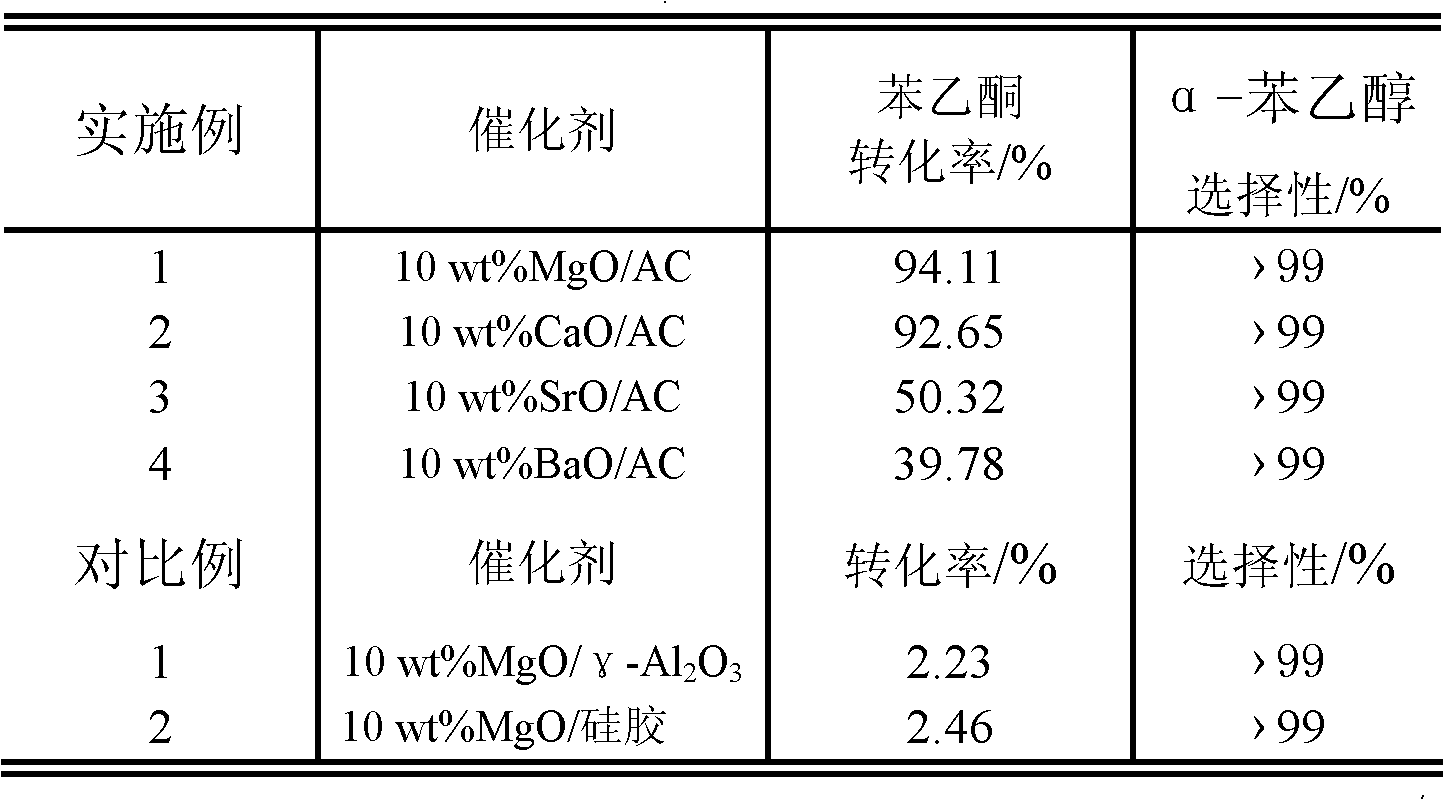

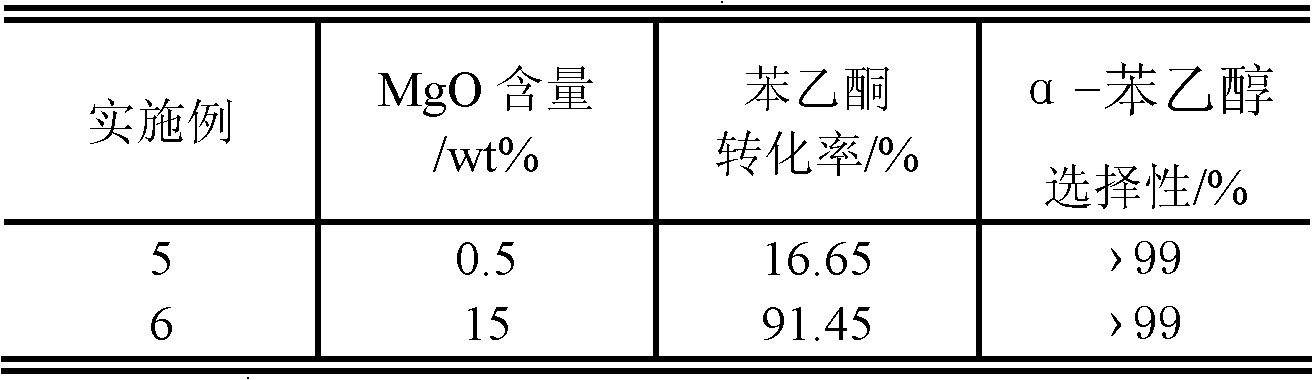

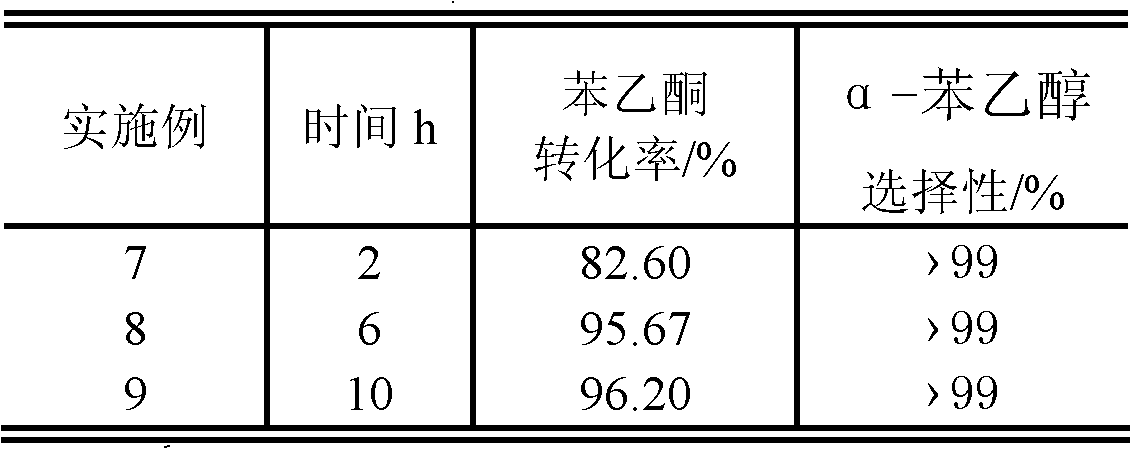

[0030] The preparation methods of various catalysts used in the embodiments of the present invention are all operated according to the above method, the difference is to change the raw materials and consumption, see the following table 1 for details:

[0031] catalyst

[0032] catalyst

Embodiment 1

[0034] Add the 0.5g10wt% MgO / AC catalyst prepared by the above-mentioned catalyst preparation method in the 50mL single-necked round bottom flask, 0.24g acetophenone, 3.6g isopropanol (the material mass ratio of feeding intake is acetophenone: isopropanol=1 : 30), connect a condensing tube, the other end of the condensing tube does not need to be sealed, heat in an oil bath at 85°C, and stir with magnetic force at the same time, after reacting for 4 hours, analyze acetophenone and α-phenylethanol in the reaction solution by gas chromatography content, the results are shown in Table 1, the reaction solution was rectified, and the 200-210 ° C fraction was taken to obtain 0.21 g of α-phenylethanol product, with a yield of 92%.

Embodiment 2-4

[0036]Other reaction conditions are as embodiment 1, difference is that embodiment 2 adopts 10wt%CaO / AC catalyst, embodiment 3 has adopted 10wt%SrO / AC catalyst, embodiment 4 has adopted 10wt%BaO / AC catalyst, with gas chromatography Analyze the content of acetophenone and α-phenethyl alcohol in the reaction solution after the reaction finishes, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com