Hydrogenation cracking method of mass production of chemical materials

A technology of hydrocracking and chemical raw materials, which is applied in the field of hydrocarbon oil cracking, and can solve problems such as limiting the role of hydrocracking technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

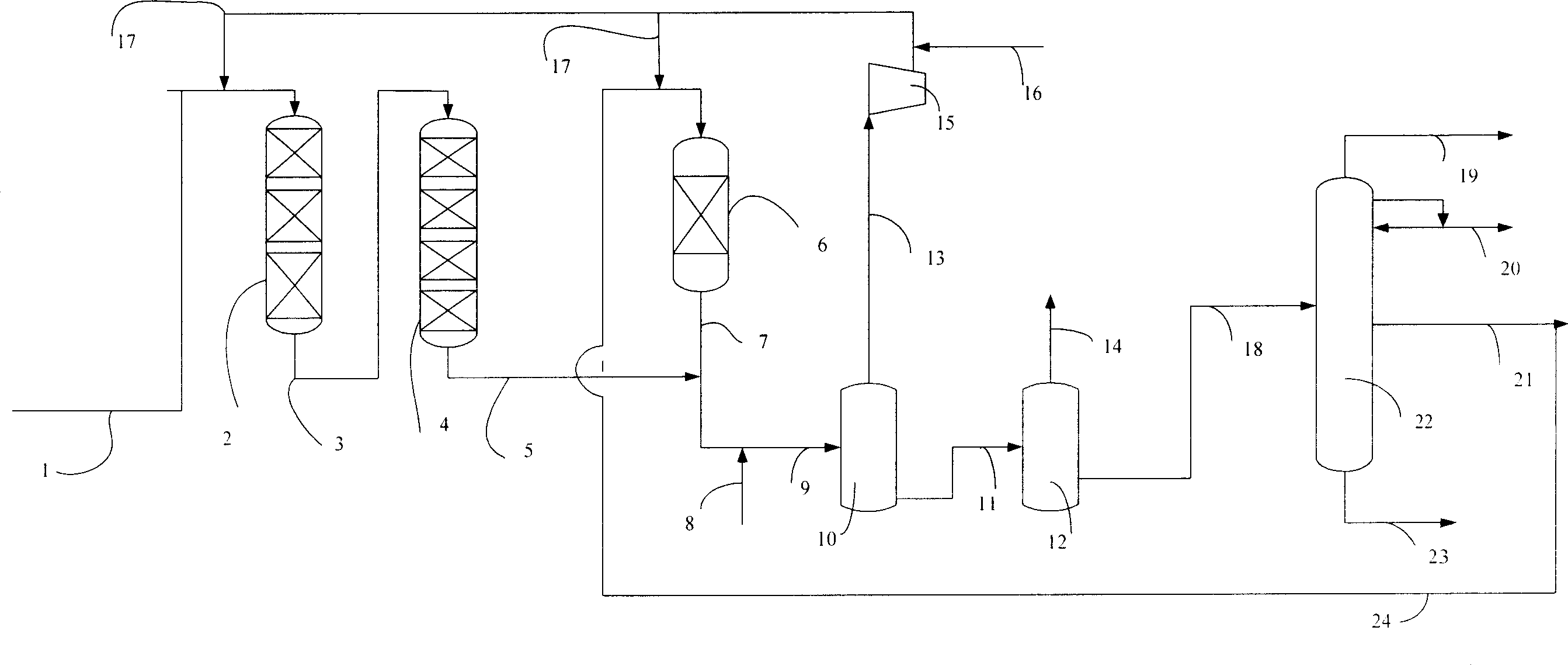

Method used

Image

Examples

Embodiment 1

[0052] Using VGO with a nitrogen content as high as 2516 μg / g as raw material A, the denitrification effects of the refined catalyst M with high denitrification activity and the comparative refined catalyst N are listed in Table 3.

[0053] It can be seen from Table 3 that, under the same reaction conditions, compared with the comparative hydrofinishing catalyst N, the refined oil nitrogen content of the hydrofinishing catalyst M of the present invention is significantly reduced. At 360°C and 380°C, the hydrodenitrogenation activity was increased by 28% and 26% compared with the industrial reference agent, respectively.

Embodiment 2

[0055] Using VGO as raw material B, a hydrocracking test was carried out. In the test, the types of refined catalysts are the same, and the loading amount and loading size are the same. Table 4 is the test results.

[0056] As can be seen from Table 4, under the same situation of conversion depth, that is, under the same tail oil yield, the cracking catalyst O of the present invention can improve product distribution, and has the effect of improving the yield of chemical raw materials, which can be increased by 3 percentage points above.

Embodiment 3

[0058] Using high-sulfur and high-nitrogen heavy VGO as raw material C, a hydrocracking test was carried out according to the catalyst and process flow provided by the present invention. The test results are listed in Table 5-7.

[0059] As can be seen from the data in the table, adopting the method provided by the present invention can reduce the middle distillate yield to the minimum under the condition of hydrogen partial pressure of 12.0MPa, which is 0; The total yield of heavy naphtha and tail oil products reaches 98.7% by weight. It shows that the method can maximize the production of chemical raw materials under relatively mild reaction conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com