Preparation method of hydroxypropyl starch

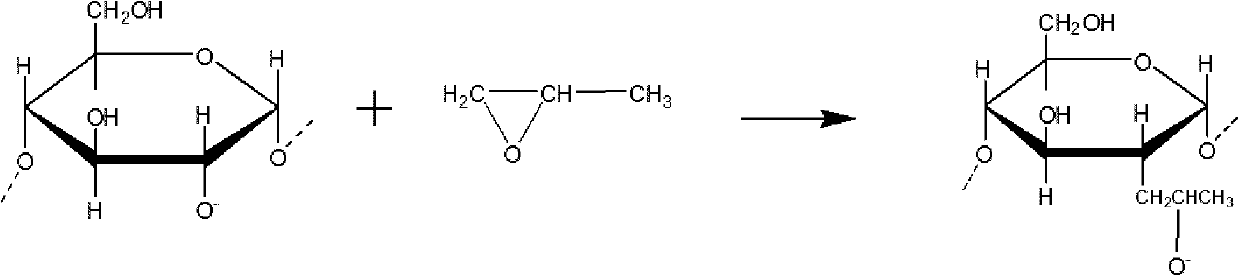

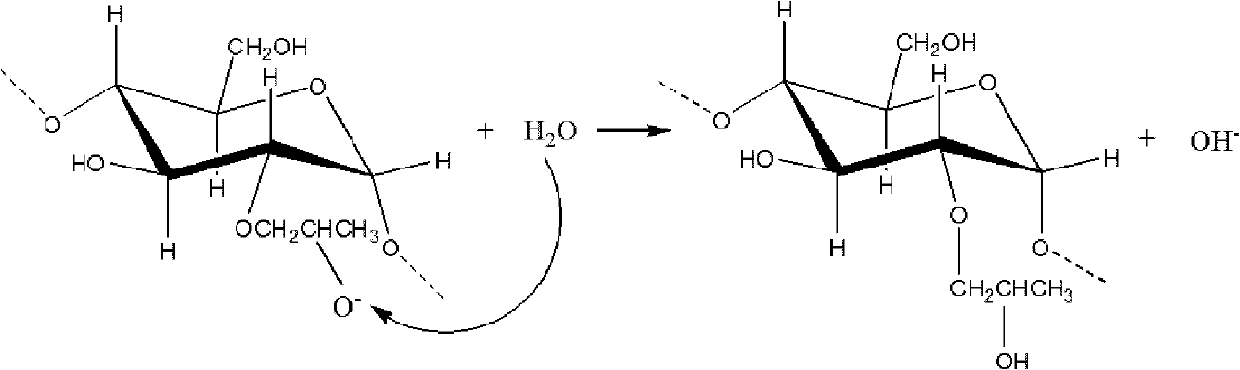

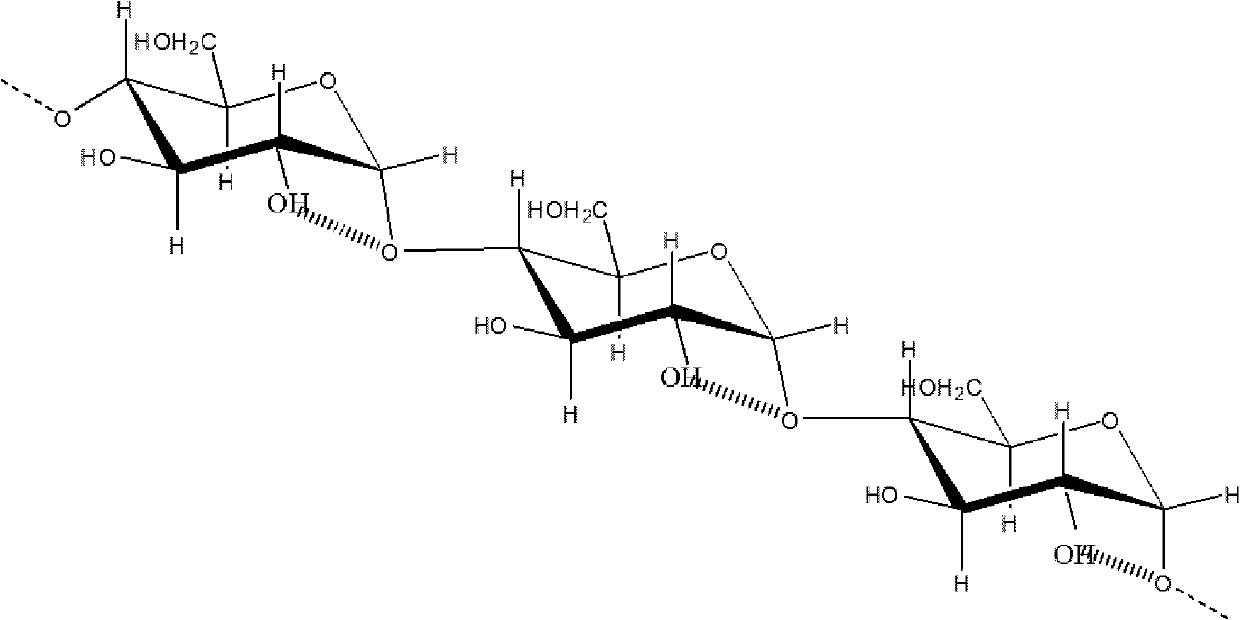

A technology of hydroxypropyl starch and hydroxypropylation, which is applied in the field of preparation of hydroxypropyl starch, can solve the problems such as difficult exposure of reactive points of starch reaction, poor solubility of starch and catalyst, low efficiency of starch hydroxypropylation, and the like, Achieve the effect of shortening the reaction time, mild conditions, and increasing the degree of substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The pre-swelling and hydroxypropylation reactions in this example were carried out in a reaction vessel equipped with an electric stirrer, a thermometer and a reflux condenser.

[0038] Measure 135ml of 90% ethanol solution into the reaction vessel, heat up to 30°C, add 0.6g (3% of the starch weight) sodium hydroxide into it and stir until completely dissolved; weigh 20g of cornstarch and add it into the reaction vessel, stir And heating, when the temperature rises to 78 ° C, there is a reflux phenomenon, after the heat preservation reaction for 120 minutes, the temperature is cooled to room temperature; suction filtration, washing with 300 ml of 95% ethanol in 4 times, to obtain pre-swelled starch in the form of particles;

[0039] Put the obtained pre-swelled starch into the reaction container, and add 185ml 90% ethanol solution, 3g sodium hydroxide, and 100ml propylene oxide, stir and heat, when the temperature rises to 50°C, there will be a reflux phenomenon, and the...

Embodiment 2

[0041] The pre-swelling and hydroxypropylation reactions in this example were carried out in a reaction vessel equipped with an electric stirrer, a thermometer and a reflux condenser.

[0042] Measure 100ml of 85% ethanol solution into the reaction vessel, add 0.6g (4% of starch weight) potassium hydroxide into it and stir until completely dissolved; weigh 15g of corn starch and add it into the reaction vessel, stir and heat, when the temperature rises Reflux occurs at 78°C, keep warm and return to room temperature after 100 minutes; filter with suction, and wash 4 times with 300ml of 95% ethanol to obtain pre-swelled starch in the form of particles;

[0043] Add the obtained pre-swelled starch into the reaction vessel, add 95ml 90% ethanol solution, 2g potassium hydroxide and 75ml propylene oxide, stir evenly and then heat, when the temperature rises to 68°C, there will be reflux phenomenon, keep the temperature for 100 minutes Back to room temperature; use 10% hydrochloric a...

Embodiment 3

[0045]The pre-swelling and hydroxypropylation reactions in this example were carried out in a reaction vessel equipped with an electric stirrer, a thermometer and a reflux condenser.

[0046] Measure 70ml of 90% ethanol solution and add in reaction vessel, get 0.5g (5% of starch weight) sodium hydroxide and add wherein and stir until completely dissolving; Take starch 10g and add in reaction vessel, stir and heat, when temperature rises to Reflux phenomenon occurs at 78°C, heat preservation and reflux for 110 minutes, then drop to room temperature; filter with suction, wash 4 times with 200ml of 95% ethanol to obtain pre-swelled starch in the form of particles.

[0047] The obtained pre-swelled starch is added in the reaction vessel, and 63ml of 90% ethanol solution, 2g of sodium hydroxide and 45ml of propylene oxide are added, heated evenly after stirring, when the temperature rises to 68°C, there is a reflux phenomenon, and the temperature is kept at reflux for 120 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com