Separation method of Fischer-tropsch synthesized crude product

A Fischer-Tropsch synthesis and separation method technology, used in the separation of solvent oil and wax, the production of LPG by Fischer-Tropsch synthesis crude products, and the fields of various alkanes. Added value, simple process flow, avoiding the effect of excessive light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

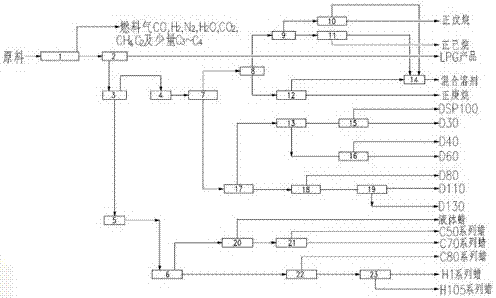

[0048] A kind of separation process of Fischer-Tropsch synthesis crude product, technological process is as figure 1 As shown, the raw material is a high-temperature (130° C.) cobalt-based Fischer-Tropsch synthetic crude oil. The mass fractions of each part of the crude oil are: non-condensable gas 22.06%, normal paraffins 75.71%, isoparaffins 1.69%, olefins 0.52%, Alcohol 0.02%, no sulfur, nitrogen and other impurities in the crude oil, adopt the following separation steps and conditions:

[0049] (1) Coarse separation of raw materials

[0050] The crude product of Fischer-Tropsch synthesis first enters gas removal tower 1, and CO and H are distilled from the top of gas removal tower 1 2 , CO 2 , N 2 、H 2 O, CH 4 , C2 and a small amount of C3, C4 non-condensable gases, the components above C2 are distilled from the bottom of the gas removal tower 1, and the components are sent to the LPG separation tower 2 for separation, and the LPG product is distilled from the top of ...

Embodiment 2

[0085] The raw material is a low-temperature (60°C) cobalt-based Fischer-Tropsch synthetic crude oil. The mass fraction of each part of the crude oil is: non-condensable gas 92.53%, n-alkanes 7.08%, isoparaffins 0.20%, olefins 0.17%, alcohols 0.02%, the separation process parameters are:

[0086] The temperature of the gas removal tower 1 is 355°C and the pressure is 1.9MPa;

[0087] The temperature of the LPG separation tower 2 is 325°C and the pressure is 1.7MPa;

[0088] The temperature of the wax separation tower 3 is 360°C and the pressure is 0.03MPa;

[0089] The catalyst loaded in the oil hydrogenation unit 4 uses alumina-silicon oxide as a carrier, the mass fraction of phosphorus as an auxiliary agent is 5%, the mass fraction of active components tungsten oxide and cerium oxide is 5%, and the mass fraction of alumina is 70%. %, the rest is silicon oxide;

[0090] The reaction pressure of the oil hydrogenation unit is 11-12MPa, the reaction temperature is 320-330°C, ...

Embodiment 3

[0110] The raw material is normal temperature (40°C) synthetic crude oil, the mass fraction of each part of the crude oil is: non-condensable gas 49.73%, n-alkanes 47.03%, isoparaffins 1.32%, olefins 1.81%, alcohols 0.11%. The process parameters are:

[0111] The temperature of the gas removal tower 1 is 350°C and the pressure is 2.1MPa;

[0112] The temperature of the LPG separation tower 2 is 330°C and the pressure is 1.9MPa;

[0113] The temperature of the wax separation tower 3 is 355°C and the pressure is 0.025MPa;

[0114] The catalyst loaded in the oil hydrogenation unit 4 uses alumina-silicon oxide as a carrier, the mass fraction of additives fluorine and boron is 3%, the active component tungsten oxide is 1%, and the mass fraction of cerium oxide is 3%. , aluminum oxide is 80%, and the rest is silicon oxide;

[0115] The reaction pressure of the oil hydrogenation unit is 19-20MPa, the reaction temperature is 260-270°C, and the volume space velocity is 10LHSV -1 ; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com