Hydrogenation modification method for catalytically cracked gasoline

A technology for catalytic cracking gasoline and hydro-upgrading, which can be used in gasoline stabilization, refining to remove heteroatoms, etc., and can solve problems such as unsatisfactory gasoline yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

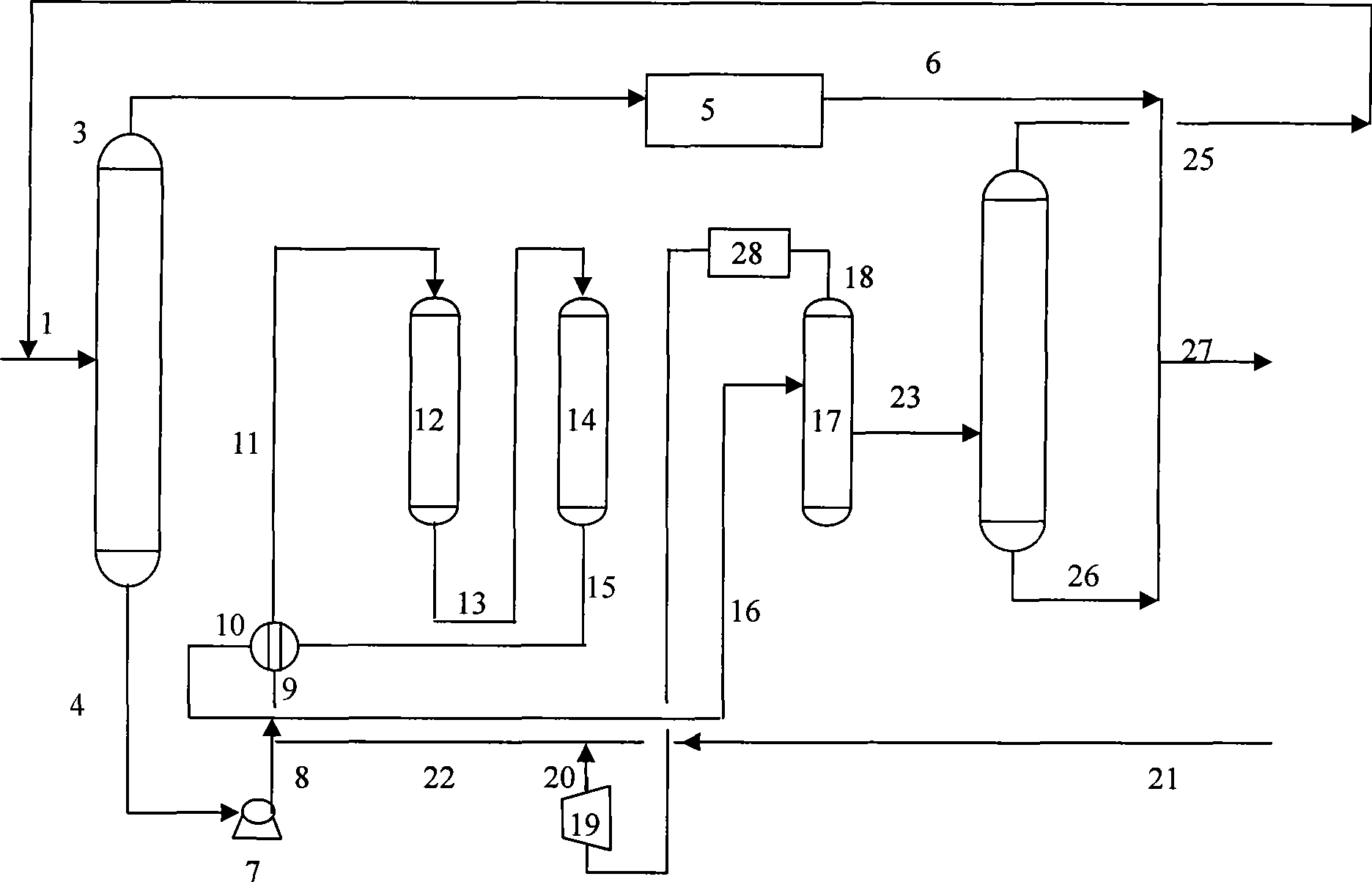

[0035] The method provided by the present invention will be further described below in conjunction with the accompanying drawings. However, the invention is not limited thereby.

[0036] The accompanying drawing is a schematic diagram of the method for desulfurization and olefin reduction while maintaining the octane number provided by the present invention.

[0037] The flow of the method is as follows:

[0038] The gasoline raw material enters the fractionating tower 2 through the pipeline 1 and is cut into light gasoline fraction and heavy gasoline fraction, wherein the light gasoline fraction enters the washing reduction unit 5 through the pipeline 3, the light gasoline fraction after alkali washing is drawn out through the pipeline 6, and the heavy gasoline fraction passes through the pipeline 4 After entering the pump 7, the heavy gasoline fraction after boosting is mixed with the hydrogen-rich gas from the pipeline 22 through the pipeline 8, and then enters the fixed-b...

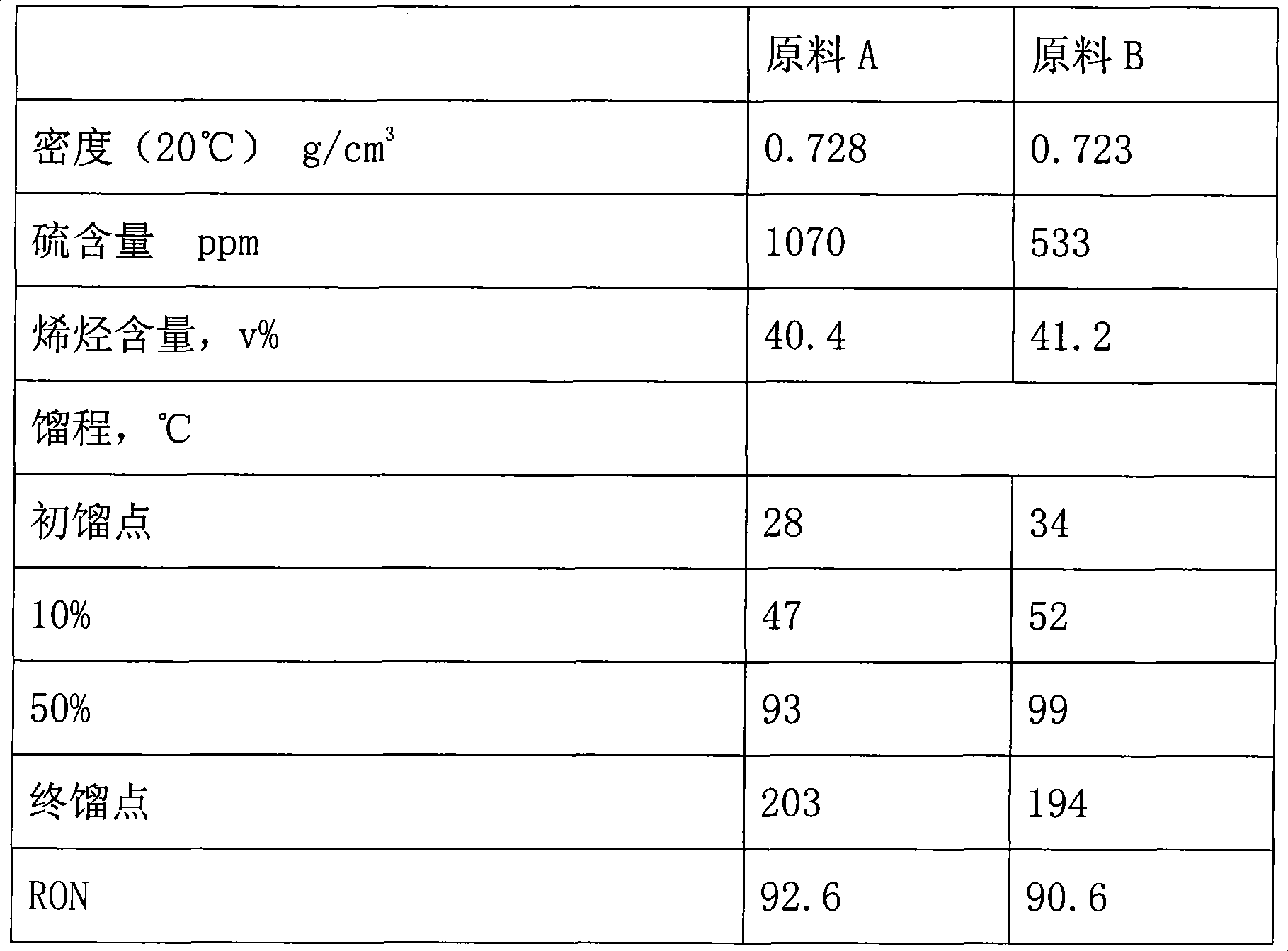

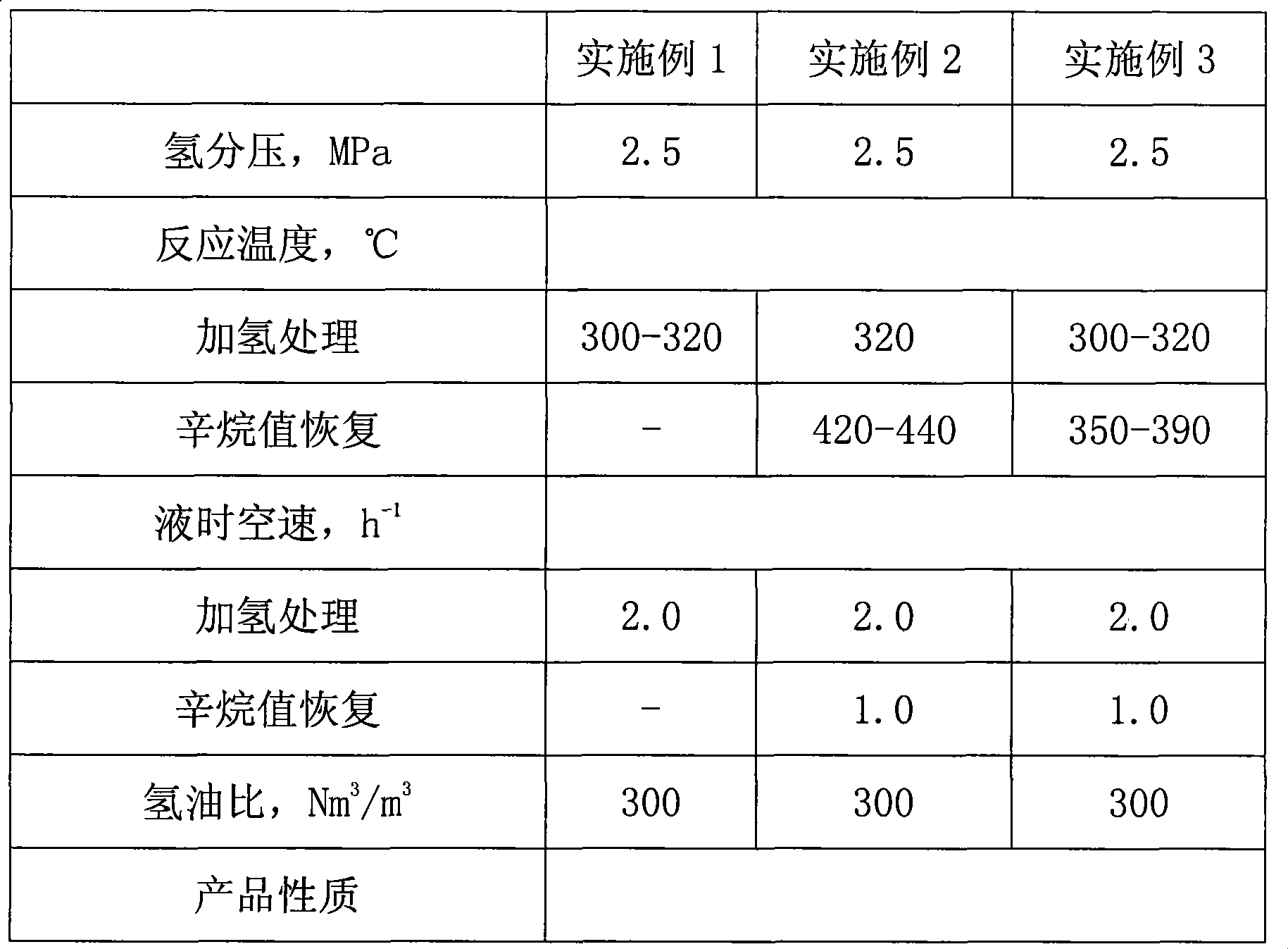

Embodiment 1

[0042] Using FCC gasoline A as the raw material, first cut the raw material, the cutting point is 75°C, the heavy gasoline fraction accounts for 61% by weight of the raw material oil, and its properties are shown in Table 1. The heavy gasoline fraction, hydrogen and hydrotreating catalyst FF-11 The hydrogenation reaction is carried out by contact, and the hydrogenated heavy gasoline fraction is reconciled with the sweetened light gasoline fraction to obtain gasoline products. The hydrogenation process conditions and product properties are shown in Table 2.

Embodiment 2

[0044] FCC gasoline A was used as the raw material to cut according to the method described in Example 1, and the heavy gasoline fraction and hydrogen were contacted with hydrotreating catalyst FF-11 and octane recovery catalyst to perform hydrotreating and octane recovery reactions. The heavy gasoline fraction after hydrogenation is blended with the light gasoline fraction after sweetening to obtain gasoline products. The process conditions and product properties are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com