Catalysis method for improving quality of gasoline in low quality

A technology for catalytic upgrading and gasoline, applied in the multi-stage series refining process, etc., can solve the problems of difficulty, gas, and large amount of engineering transformation, and achieve easy start and operation, low operating temperature, and construction costs. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

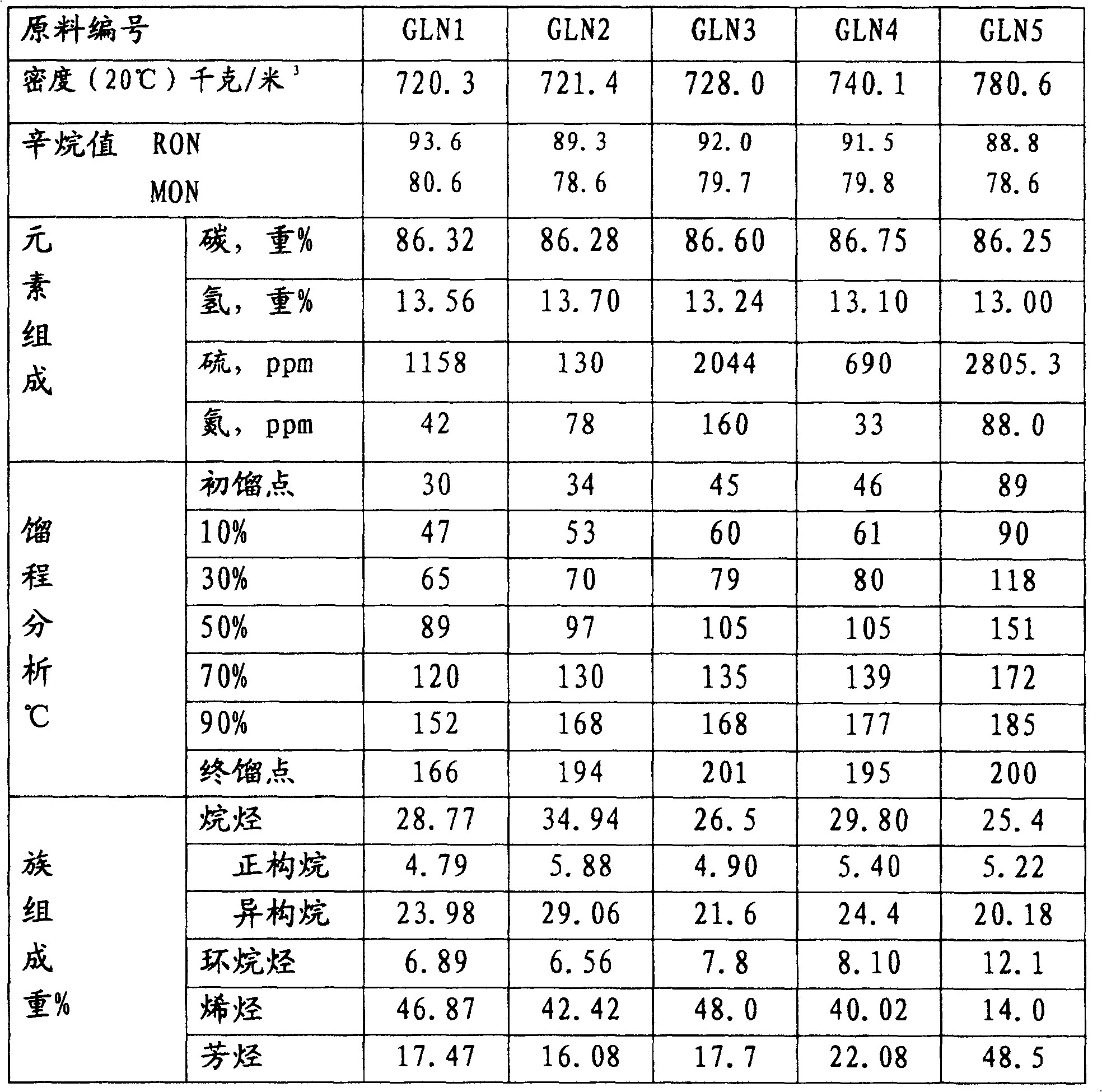

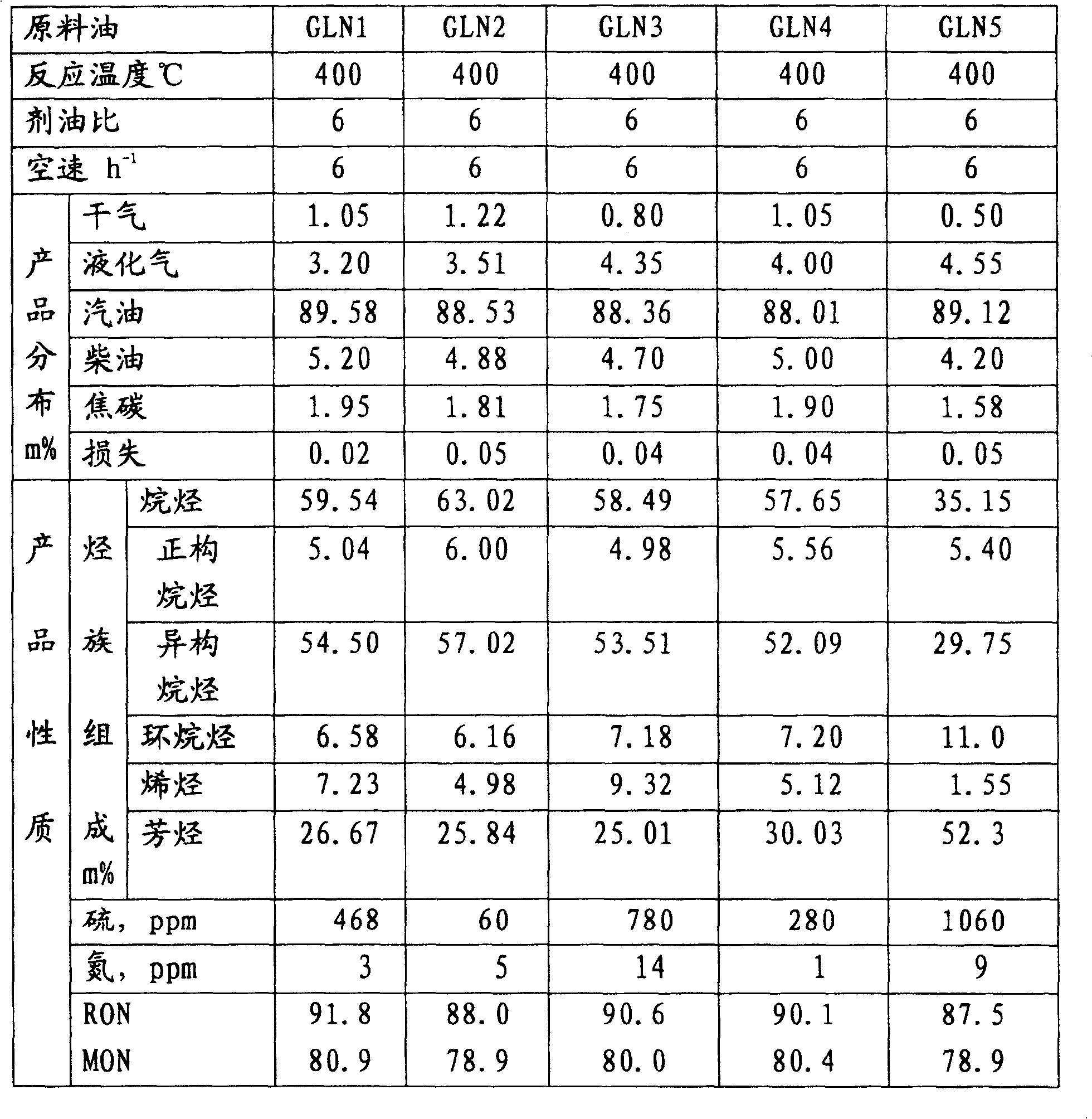

[0043] This example illustrates the results of catalytic conversion of gasoline from different sources using the method provided by the present invention.

[0044] Catalytic upgrading experiments were carried out in a continuous reaction-regeneration small-scale dense-phase uniform velocity fluidized bed reactor with the feed oil listed in Table 1 and the catalyst 2 (CAT2) listed in Table 2. The gasoline raw material is mixed with high-temperature steam and enters the dense-phase uniform-velocity fluidized-bed reactor to contact with the catalyst for reaction. The reaction product, steam and raw catalyst are separated in the settler, and the reaction product is further separated into gas and liquid. The raw catalyst is stripped and then enters the regenerator for burning. After the regeneration is completed, the catalyst is recycled.

[0045] Table 3 shows the experimental conditions, experimental results and gasoline properties. It can be seen from Table 3 that after catalyt...

Embodiment 2

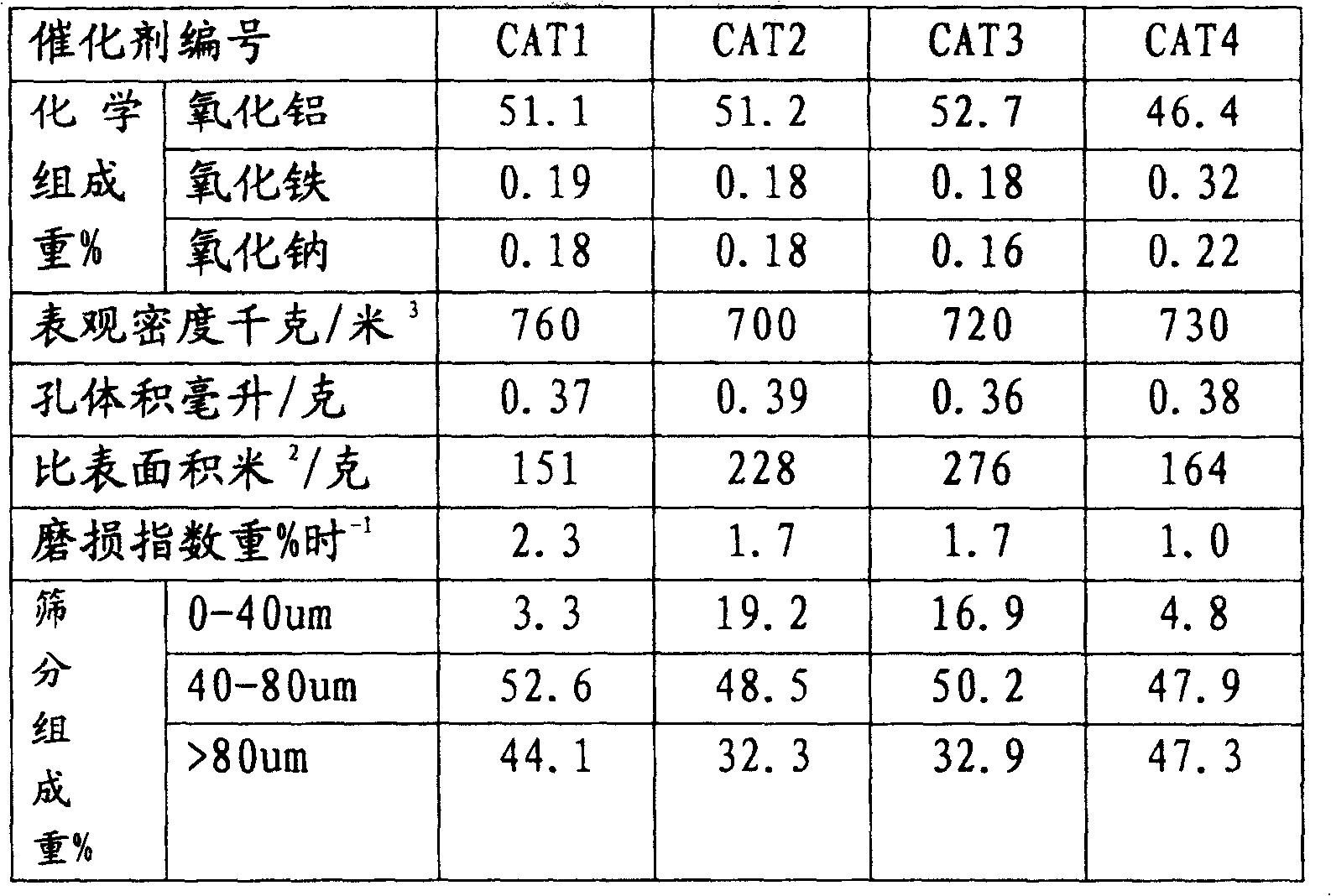

[0047] This example illustrates: adopt the method provided by the present invention, use the catalytic conversion effect of different types of catalysts.

[0048] Catalytic upgrading experiments were carried out in a continuous reaction-regeneration small-scale dense-phase uniform velocity fluidized bed reactor with the feed oil 1 listed in Table 1 and the catalyst listed in Table 2. The gasoline raw material is mixed with high-temperature steam and then enters the reactor to contact and react with the catalyst. The reaction product, steam and raw catalyst are separated in the settler, the reaction product is further separated into gas and liquid, the raw catalyst enters the regenerator after being stripped and burnt, and the regenerated catalyst is recycled for use.

[0049] Table 4 is the experimental conditions, experimental results and gasoline properties. It can be seen from Table 4 that there are certain differences in the effect of the same raw material after being cat...

Embodiment 3

[0051] This example illustrates: using the method provided by the invention, the catalytic conversion effect of gasoline raw materials under different operating conditions.

[0052] Catalytic upgrading experiments were carried out in a continuous reaction-regeneration small-scale dense-phase uniform velocity fluidized bed reactor with feed oil 3 listed in Table 1 and catalyst 1 listed in Table 2. The gasoline raw material is mixed with high-temperature water vapor and enters the reactor to contact and react with the catalyst at a reaction temperature of 250-550°C. The reaction product, steam and raw catalyst are separated in the settler, the reaction product is further separated into gas and liquid, the raw catalyst enters the regenerator after being stripped and burnt, and the regenerated catalyst is recycled for use.

[0053] Table 5 is the experimental conditions, experimental results and gasoline properties. It can be seen from Table 5 that different operating conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com