Fractionation method of hydrocarbon mixtures

A technology of mixed hydrocarbons and fractionation towers, applied in the direction of gasoline stabilization, etc., can solve the problem that the separation method and precision cannot meet the production of chemical raw materials, and achieve the effect of improving efficiency and separation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

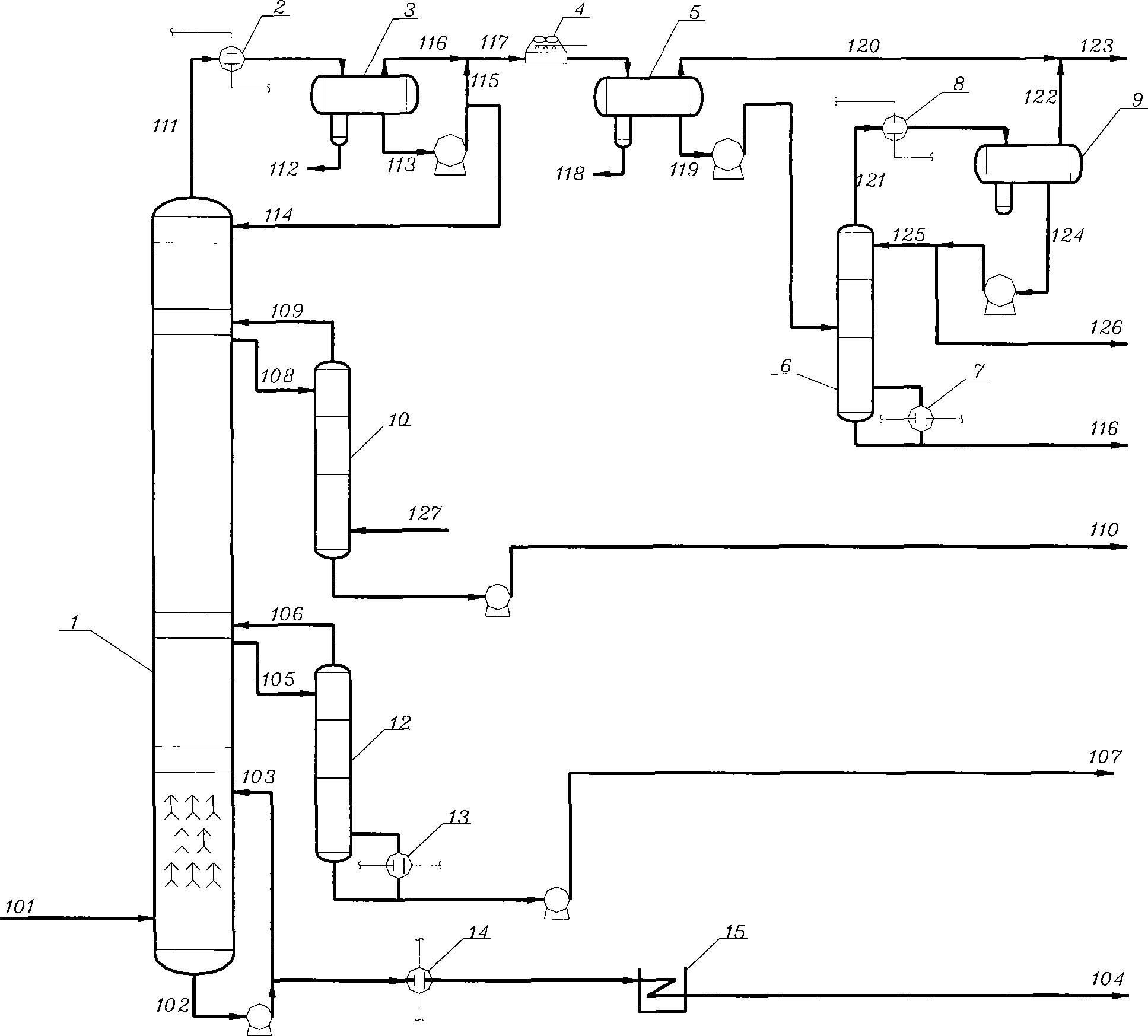

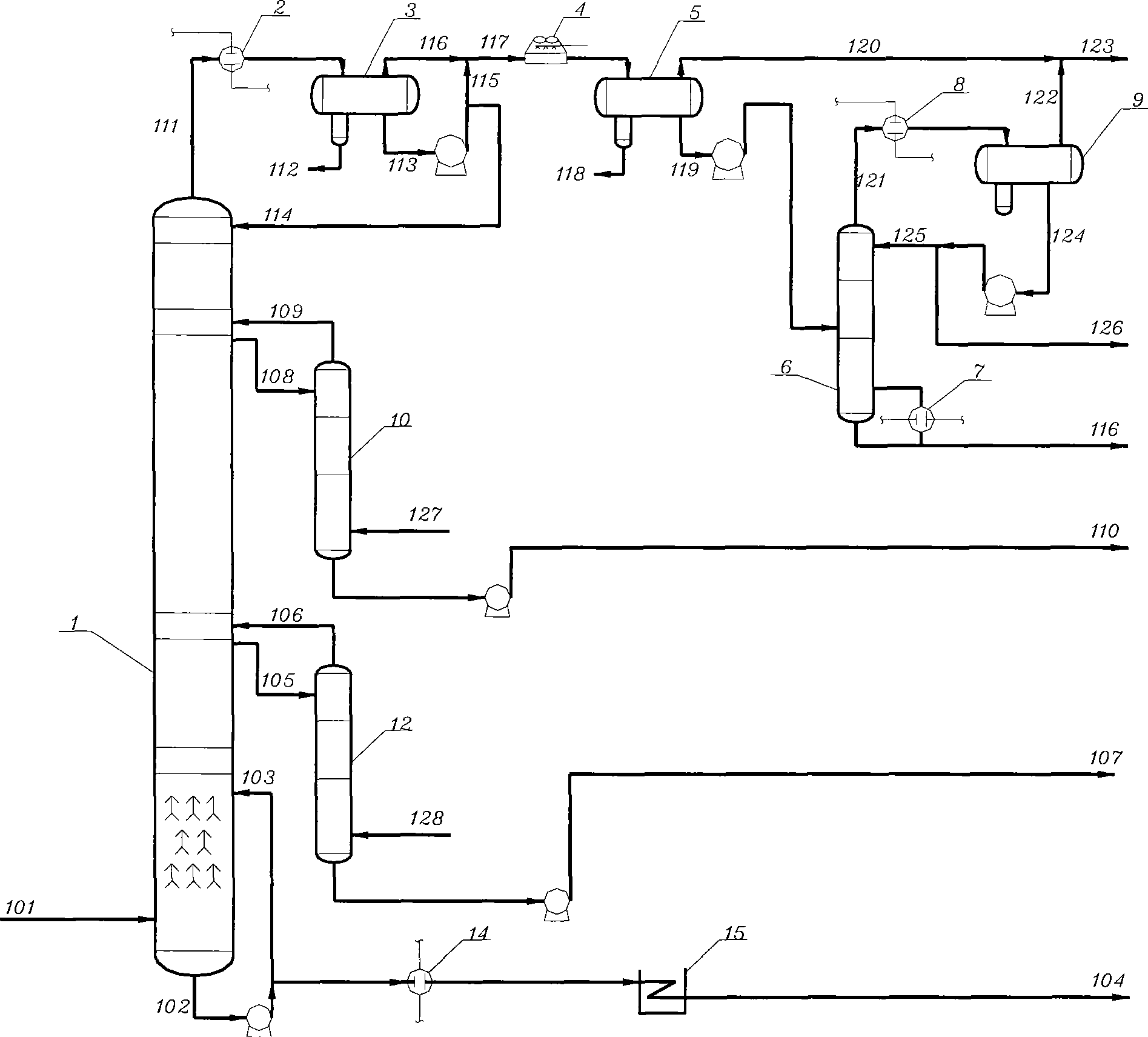

[0040] The present invention is used to fractionate the mixed hydrocarbons produced in the catalytic conversion process of the largest production of small molecular olefins and aromatics, and provide further separation and acquisition of raw materials for small molecular olefins, raw materials for extracting light and heavy aromatics, and recycle raw materials for returning to the cracking unit.

[0041] Feed is the reaction oil gas (pipeline 101 stream) that catalytic cracking unit comes, obtains heavy aromatics extraction raw material (pipeline 107 streams), back refining material (pipeline 110 streams), light aromatics extraction raw material (pipeline 107 streams) through the method provided by the present invention 116 Logistics), C 5 - Distillate (line 126 stream) and rich gas (line 123 stream).

[0042] The composition of each stream is shown in Table 1, and the number of plates and operating conditions of each tower are shown in Table 2.

[0043] It can be seen from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com