Method of two-stage hydrogenation treatment regeneration technology for full-fraction waste mineral oil

A waste mineral oil, hydrogenation treatment technology, applied in the direction of hydrogenation treatment process, hydrocarbon oil treatment products, petroleum industry, etc., can solve the problems of low purity of regenerated lubricating oil, low yield of base oil, low regeneration efficiency, etc. Achieve the effects of improving product viscosity index and oxidation stability, reducing product pour point and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

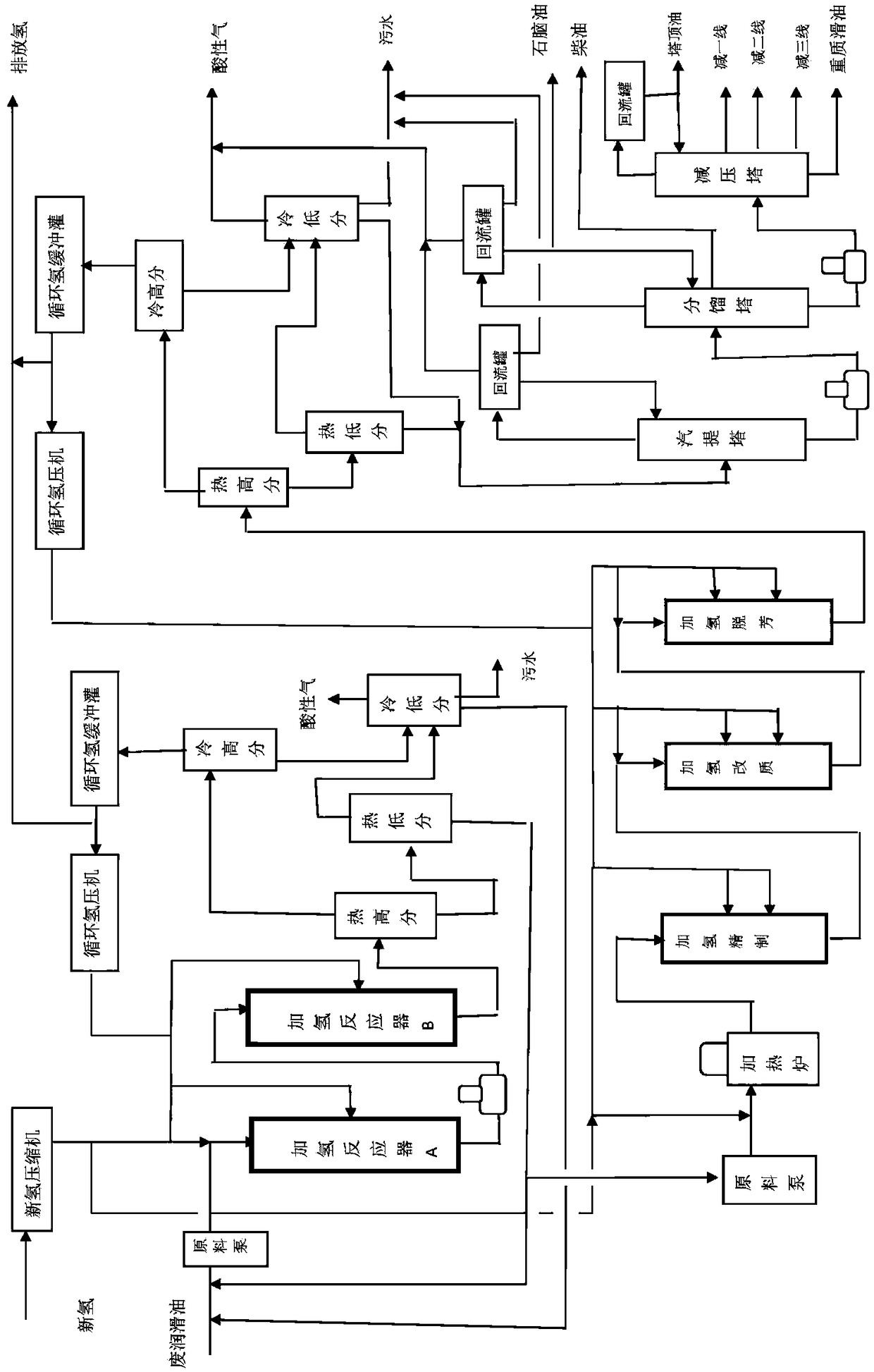

[0068] Such as figure 1 Shown, the method for a kind of full fraction waste mineral oil two-stage hydrotreating regeneration process of the present invention comprises the steps:

[0069] S1. Filtration treatment process unit

[0070] S1-1. Waste mineral oil enters the settling tank first, and settles to remove water, sludge and large solid particles in the oil;

[0071] S1-2. Heat the settled raw materials to 85°C, then add demulsifier and mix to remove water-soluble substances in the oil phase;

[0072] S1-3, and then the materials are sequentially entered into the closed mechanical interception pre-filter and the closed mechanical interception fine filter to further remove solid impurities and water;

[0073] S2. Low-pressure hydrogenation reaction process unit

[0074] S2-1. After heating the filtered waste mineral oil to 330°C, transport it to a low-pressure hydrogenation device with a pressure of 3MPa for low-pressure hydrogenation reaction;

[0075] S2-2. The materi...

Embodiment 2

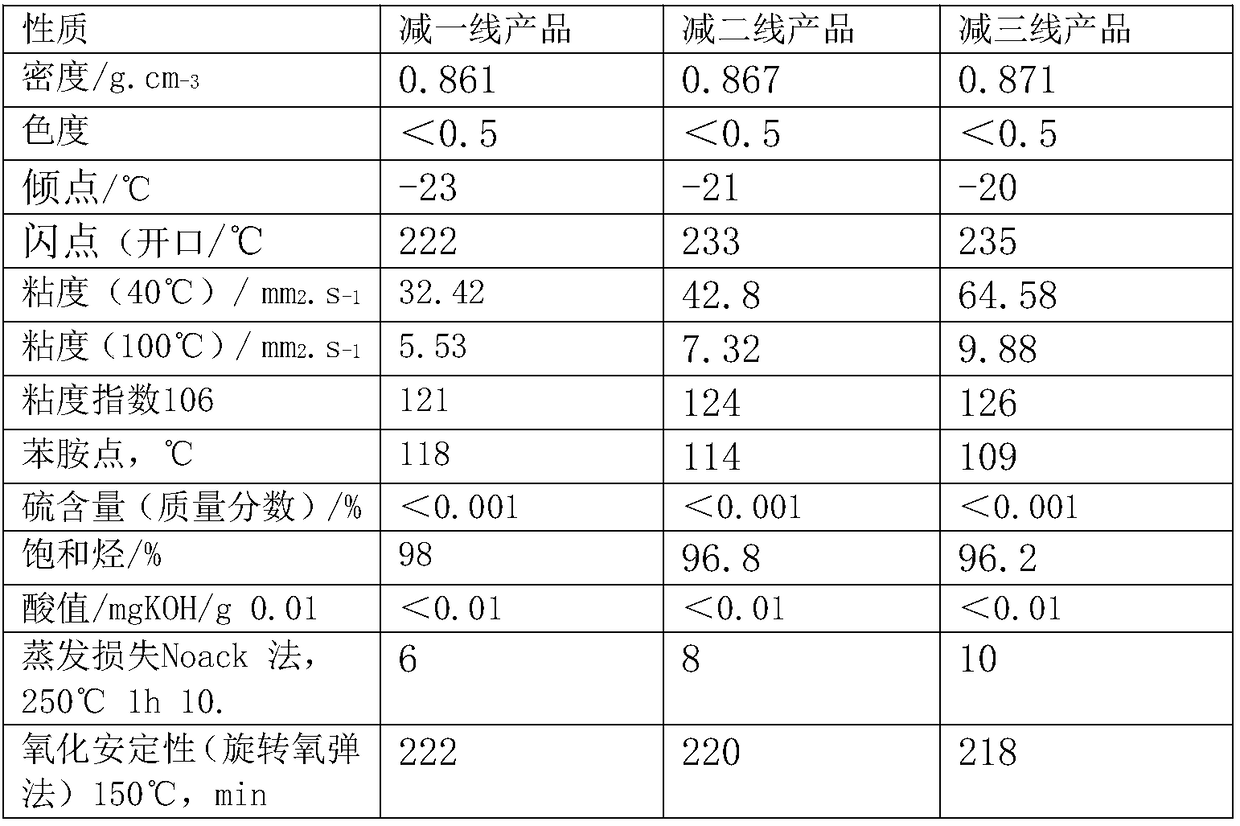

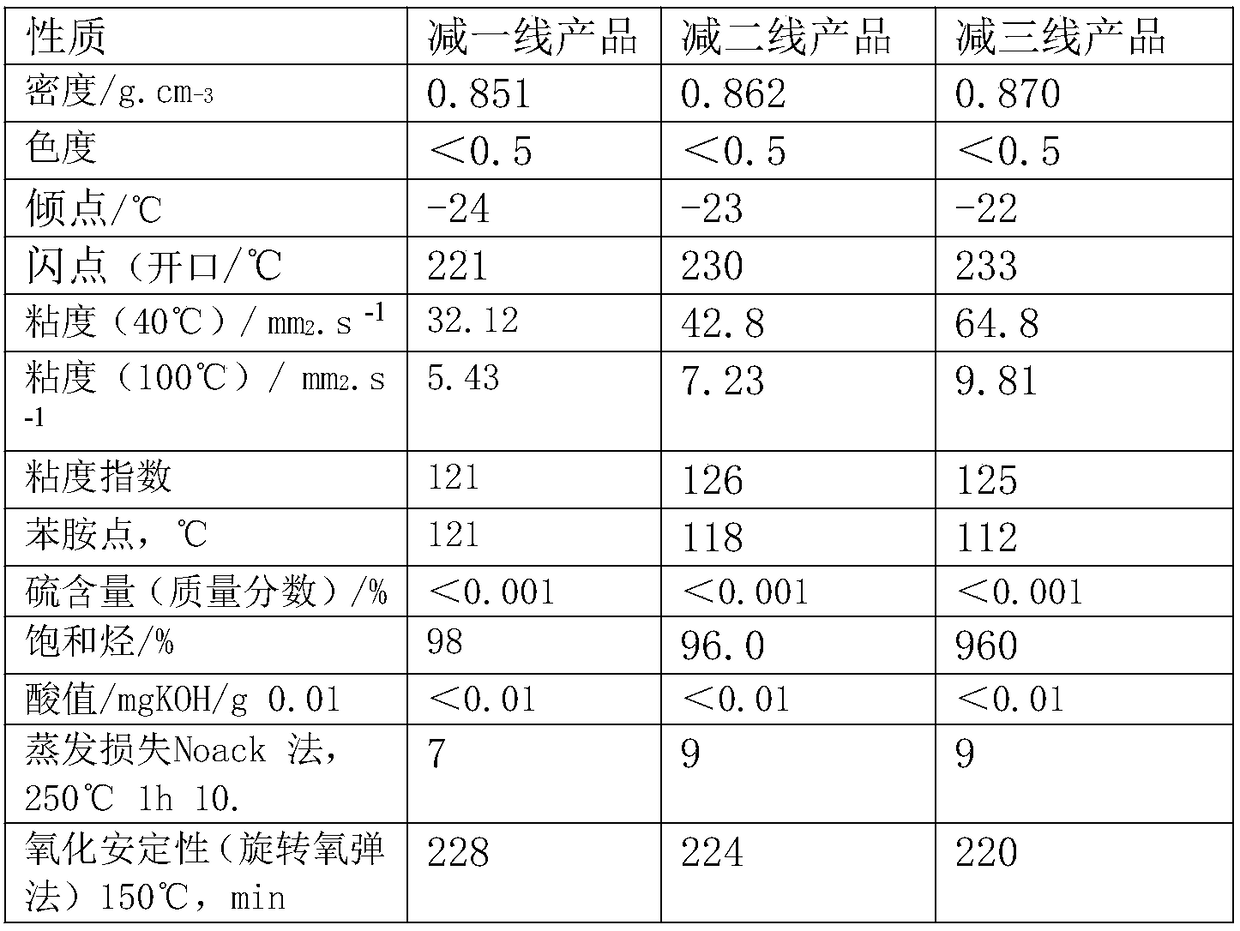

[0104] Repeat embodiment 1, difference is: raw material 2 in table 1 passes through following process condition, and this raw material passes through low-pressure hydroprocessing unit and high-pressure hydroprocessing unit, and the main process condition that raw material enters two processing units is shown in Table 5; Table 6 shows the raw material properties of the lubricating oil base oil produced by the low-pressure hydroprocessing unit. The properties of the product lubricating base oil after high-pressure hydrotreating are shown in Table 7.

[0105] Table 5 embodiment 2 raw material enters the main process condition of two process units

[0106] Process conditions

Low pressure hydrotreating process unit

High pressure hydrotreating process unit

temperature / ℃

Raw materials enter the heating furnace and exit 200 / 320

Raw materials enter the heating furnace outlet 340

Pressure / MPa

4.0

12.0

0.2

1.2

Hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com