Waste lubricating oil hydrogenation reproducing method

A technology of waste lubricating oil and hydrogenation regeneration, applied in lubricating compositions, refining to remove heteroatoms, etc., can solve the problems of low quality, limited application scope, incomplete improvement of the smell, color, and corrosiveness of the regenerated oil. , to achieve the effect of improving the properties of regenerated oil, high yield and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

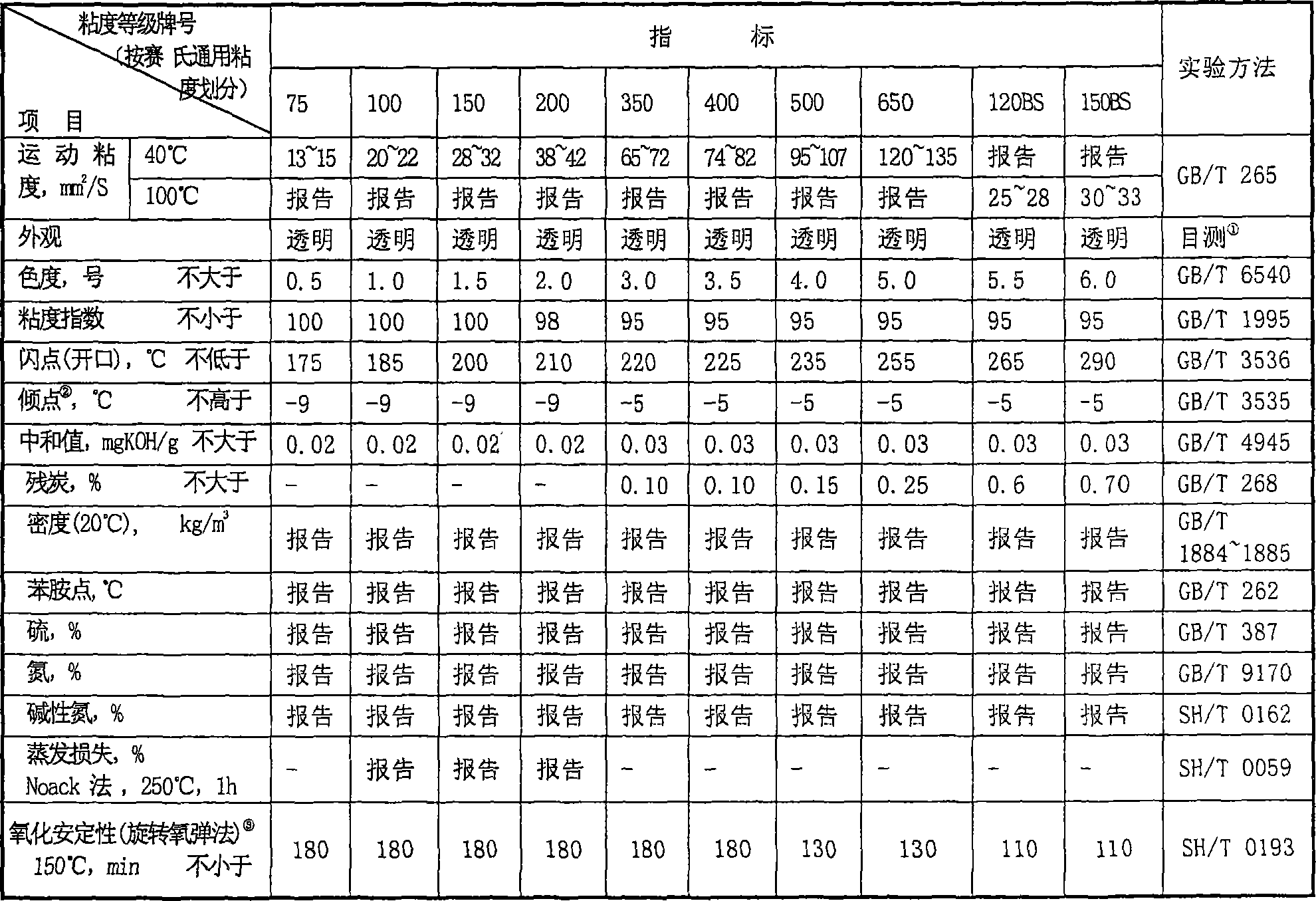

[0043] Take a waste lubricating oil sample (oil sample No. 1), see Table 1 for its specific properties. It can be seen that the waste lubricating oil raw material has the characteristics of dark color, low flash point, high acid value and high content of heavy metals.

[0044] The waste lubricating oil was heated to 85° C. under normal pressure for 4 hours at a constant temperature for dehydration (water content < 0.5 wt %). The dehydrated oil is carried out to remove mechanical impurities.

[0045] The filtered oil is in a fixed-bed reactor equipped with 100ml of adsorbent, the adsorbent is alumina, its shape is spherical or cylindrical, the particle diameter is Φ2.0×(3~8)mm, and the heap ratio 0.50~0.60g / cm 3 , specific surface area 260m 2 / g, pore volume 0.55mL / g. Reaction condition: space velocity 0.5h -1 , pressure 1.0MPa, reaction temperature 320°C, hydrogen to oil volume ratio 80 (the purity of hydrogen used in this example is 99.7%).

[0046] Please refer to Tabl...

Embodiment 2

[0061] Take a waste lubricating oil sample (oil sample No. 2), see Table 1 for its specific properties. It can be seen that the acid value and heavy metal content of the waste lubricating oil raw material are higher than those of the waste lubricating oil sample in Example 1.

[0062] The concrete operating method of oil sample regeneration is the same as embodiment 1. Please refer to Table 5, Table 6, Table 7 and Table 8 for the obtained oil performance measurement results.

[0063] Table 5 shows the main properties of the oil samples in this example after hydroadsorption treatment. It can be seen from Table 5 that most of the heavy metals in the oil sample after adsorption have been removed, and the heavy metal content also meets the requirement of less than 50ppm.

[0064] Table 6 shows the effect of further removing impurities after the oil sample in this example is pre-hydrotreated in a protection tower reactor equipped with a protection agent. It can be seen that the ...

Embodiment 3

[0073] This embodiment adopts the same waste lubricating oil sample (oil sample No. 1) as in Example 1, and the operating conditions of the waste lubricating oil are dehydrated, filtered to remove mechanical impurities, adsorption pretreatment steps, and prehydrotreatment steps. It is the same as in Example 1, and the effect of the process parameter change in the main hydrogenation process on the quality of regenerated oil was investigated and tested.

[0074] Test 1: At an airspeed of 0.8h -1 , pressure 12.0MP, hydrogen-to-oil ratio 700, investigate the yield and properties of fractions > 320°C of refined oil samples at different temperatures. The evaluation results are shown in Table 9.

[0075] As can be seen from the results in Table 9: under the above conditions of space velocity, pressure and hydrogen-to-oil ratio, the temperature of the hydrogenation reaction is controlled under the premise of satisfying the quality of the hydrogenation product, which has a certain inf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com