Air separation system for generating liquid oxygen and liquid nitrogen

An air separation and vapor-liquid separator technology, applied in refrigeration and liquefaction, cold treatment separation, liquefaction and other directions, can solve the problems of large power consumption and increased energy consumption, and achieve the effect of large economic benefits and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment:

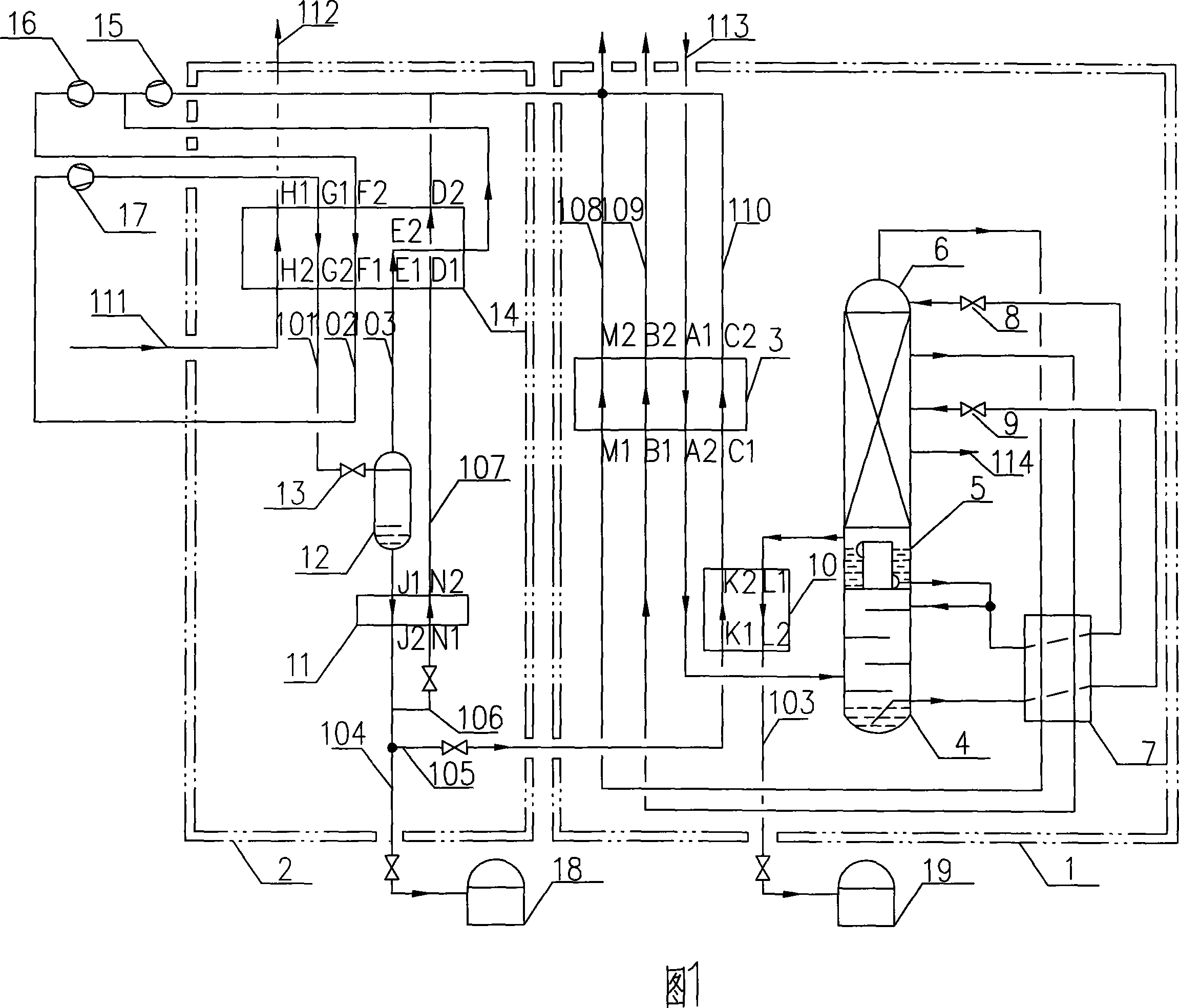

[0022] Main heat exchanger (3), fractionation tower and liquid oxygen heat exchanger (10) are positioned at independent cold box I (1) inside, and fractionation tower is composed of fractionation lower tower (4), fractionation upper tower (6) and main condensation The evaporator (5) is connected to form.

[0023] The feed air (113) that removes carbon dioxide, water, acetylene and other hydrocarbon impurities is sent to the heat exchange channel (A1-A2) of the main heat exchanger (3) in the cold box I (1) to exchange heat with other The reflux gas in the channel exchanges heat, and after cooling down to a suitable fractionation temperature, it is sent to the bottom of the fractionation lower tower (4), and heat transfer occurs on the multi-layer tray with the reflux liquid flowing down from the top of the fractionation lower tower (4). and mass tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com