Method for hydrotreatment of continuous liquid-phase wax oil

A technology for hydrogenation and treatment of wax oil, which is applied in the direction of hydrocarbon oil treatment products, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of hydrogen shortage in hydrocarbon oil, etc., and achieve the goal of increasing processing capacity, reducing operating costs, and low cycle ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The trade name of the hydrogenation catalyst used in Example 1 is RVS-420, both of which are produced by Sinopec Catalyst Company.

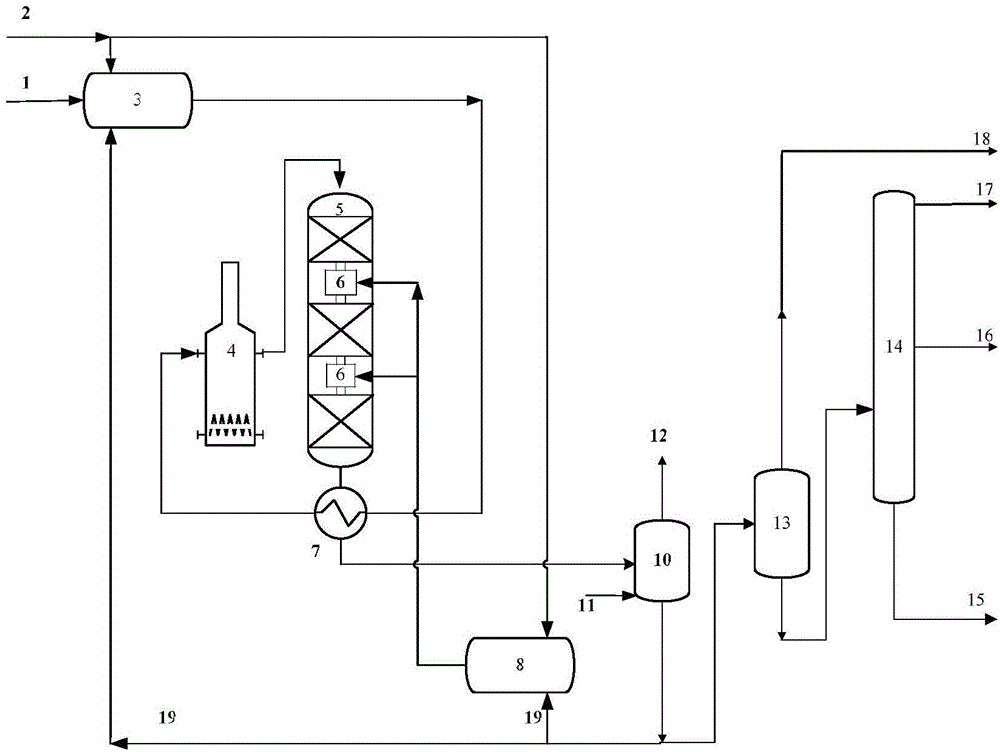

[0043] Example 1

[0044] A high-sulfur vacuum gas oil fraction from the Middle East is used as a feedstock oil, mixed with reactor effluent and hydrogen, and the mixed material is introduced into a reactor equipped with a hydrofining catalyst. The raw material oil undergoes deep hydrodesulfurization reaction under the action of hydrorefining catalyst. The reaction conditions are: reaction temperature 380°C, total liquid hourly volume space velocity 1.68h -1 , the pressure of the reaction system is 8.0MPa, the volume ratio of hydrogen to liquid under standard conditions is 20-30v / v, the catalyst is 3 beds in the reactor, and a mixer is arranged between the two beds, and the reaction The material is mixed again with fresh hydrogen. The reactor effluent enters the high-pressure separator and is fed with hydrogen for stripping. The liquid p...

Embodiment 2

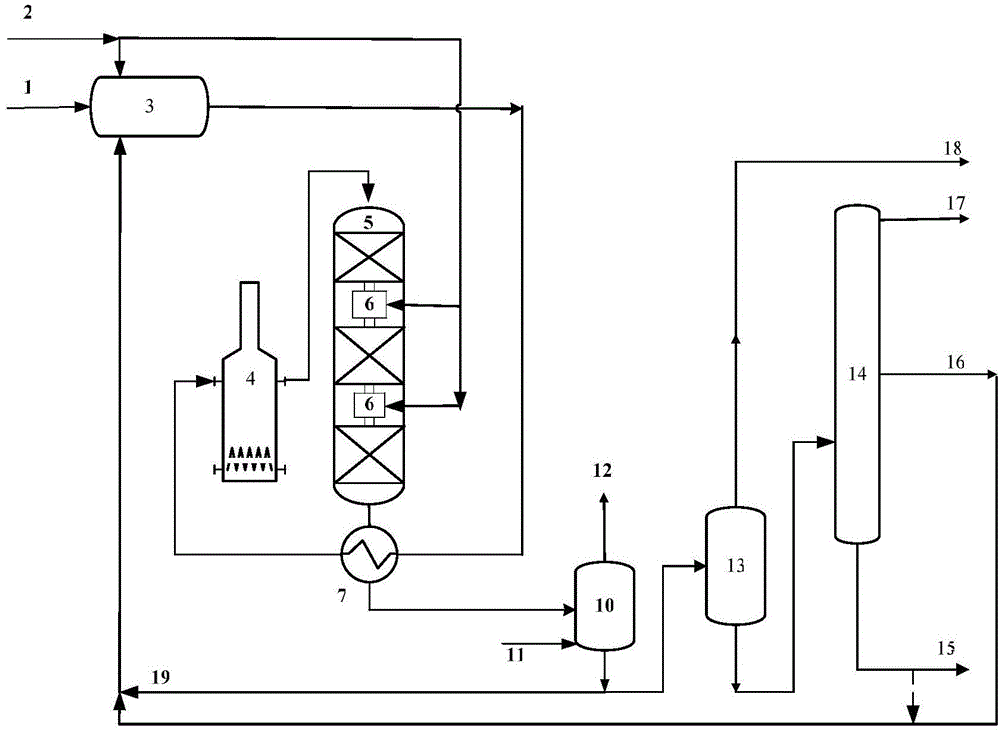

[0049] A mixture of Middle Eastern high-sulfur vacuum gas oil fraction and coker gas oil is used as feed oil, mixed with reactor effluent and hydrogen, and the mixed material is introduced into a reactor equipped with a hydrogenation catalyst. The reactor is filled with a supported hydrorefining catalyst RN-32V, which is produced by Sinopec Changling Catalyst Factory.

[0050] The raw material oil undergoes deep hydrodesulfurization reaction under the action of a hydrorefining catalyst. The reaction conditions are: reaction temperature 363°C, fresh raw material oil liquid hourly volume space velocity 1.62h -1 , the pressure of the reaction system is 8.0MPa, the volume ratio of hydrogen to liquid under standard conditions is 20-30v / v, the catalyst is 3 beds in the reactor, and a mixer is arranged between the two beds, and the reaction The material is mixed again with fresh hydrogen. The reactor effluent enters the first high-pressure separator and is fed with hydrogen for stri...

Embodiment 3

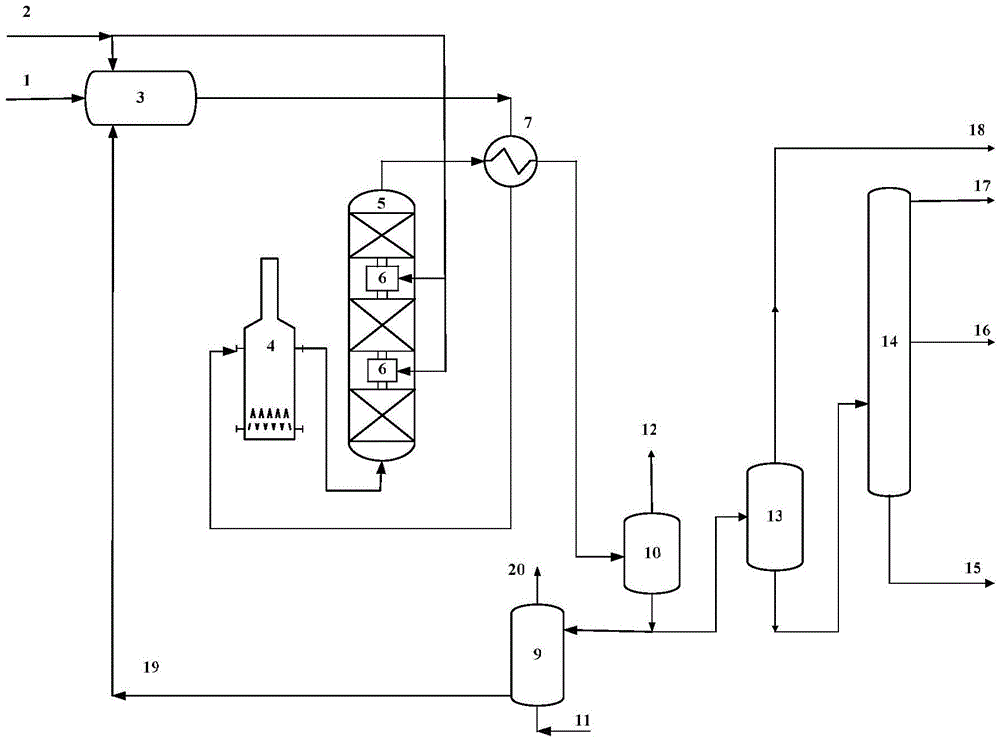

[0053] A mixture of Middle Eastern high-sulfur vacuum gas oil fraction and deasphalted oil is used as feed oil, mixed with reactor effluent, hydrogen, and the mixed material is introduced into a reactor equipped with a hydrogenation catalyst. The reactor is filled with a supported hydrorefining catalyst RN-32V, which is produced by Sinopec Changling Catalyst Factory.

[0054] The raw material oil undergoes deep hydrodesulfurization reaction under the action of a hydrorefining catalyst. The reaction conditions are: reaction temperature 380°C, fresh raw material oil liquid hourly volume space velocity 1.80h -1 , the pressure of the reaction system is 14.0MPa, the volume ratio of hydrogen to liquid under standard conditions is 20-30v / v, the catalyst has 3 beds in the reactor, and a mixer is provided between the two beds, and the reaction The material is mixed again with fresh hydrogen. The reactor effluent enters the first high-pressure separator and is fed with hydrogen for str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com