Separation method for mixed C4

A technology of mixing C4 and separation methods, which is applied in the field of isobutane, 1-butene, and 2-butene, can solve the problems of inability to obtain added value, high 2-butene products, and reduce economic benefits, and achieve product Abundance, low production cost, and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

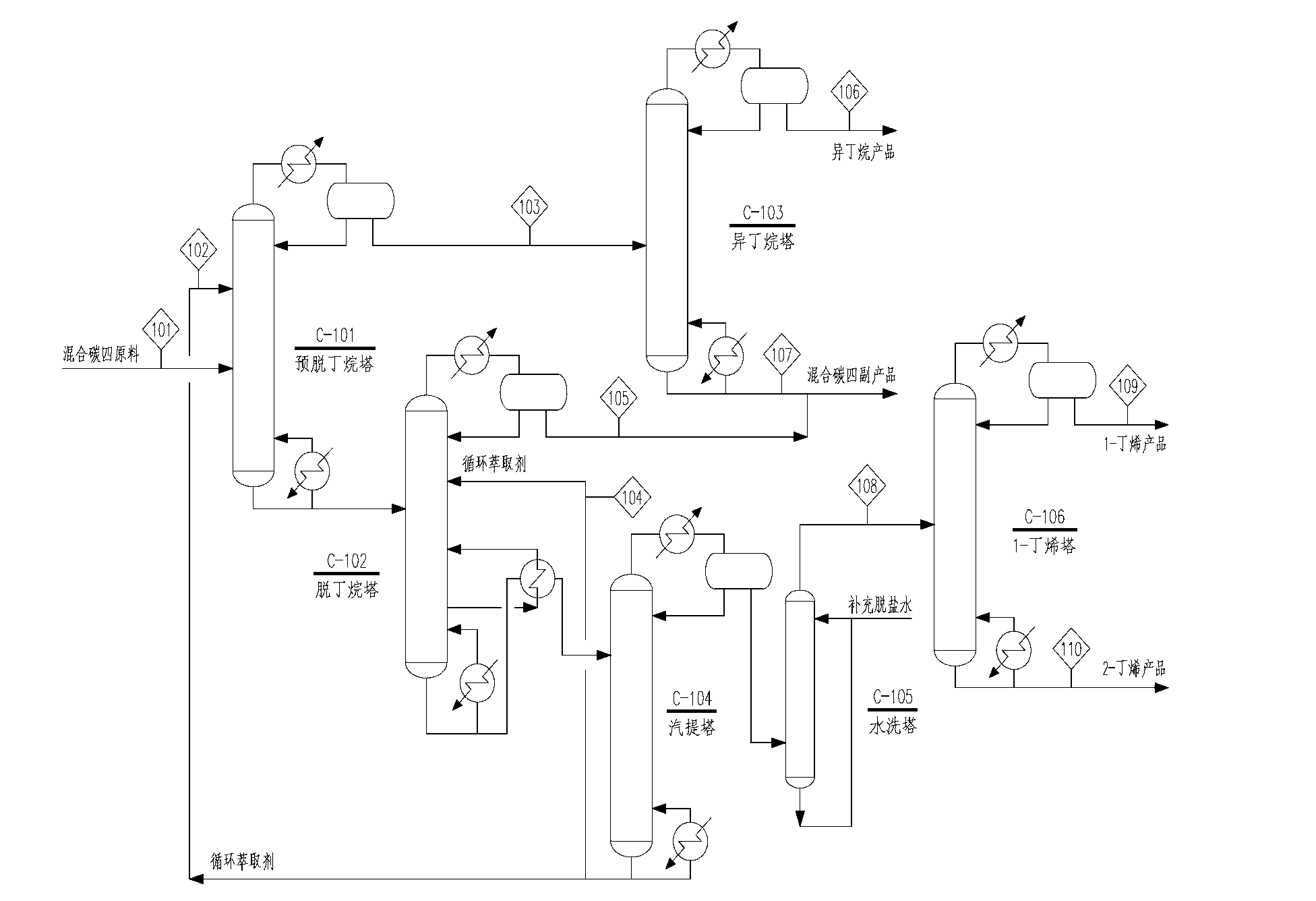

[0049] Such as figure 1 After the pretreatment steps of removing diolefins, alkynes and isobutylene, the mixed carbon four is sent to the process technology of the present invention for treatment under the conditions of 0.7MPaG and 25°C.

[0050] This example adopts the mixed solvent of toluene and carboxyl morpholine as the extraction agent, the solvent ratio of C-101 pre-debutanizer tower is 3.7, the total solvent ratio of C-101 and C-102 two extraction towers is 12.8, each tower reflux See Table 1 for the ratio and Table 2 for the calculation results.

[0051] As can be seen from the calculation result table 2, after the pretreated mixed carbon four is processed by the process technology of the present invention, three kinds of products of isobutane, 1-butene and 2-butene and mixed carbon four by-products can be obtained simultaneously . The product concentration of isobutane is 97.08%wt; the product concentration of 1-butene is 99.59%wt, and the product concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com