Patents

Literature

40results about How to "Product diversification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internet of Things method and system

The invention relates to an Internet of Things method and system. Through techniques, complex Internet of Things associated elements are systematically sorted; analysis is carried out from different dimensions; an application-level service referable Internet of Things system architecture model is set, the Internet of Things capability problems of good comprehensive perception, convenient access, reliable transmission, data value, intelligent processing, business closed loop, system guarantee, sustainable development and the like are solved, the fusion of a physical world and a digital world isbetter realized, and the wisdom of a human body is materialized and extended.

Owner:陕西爱尚物联科技有限公司

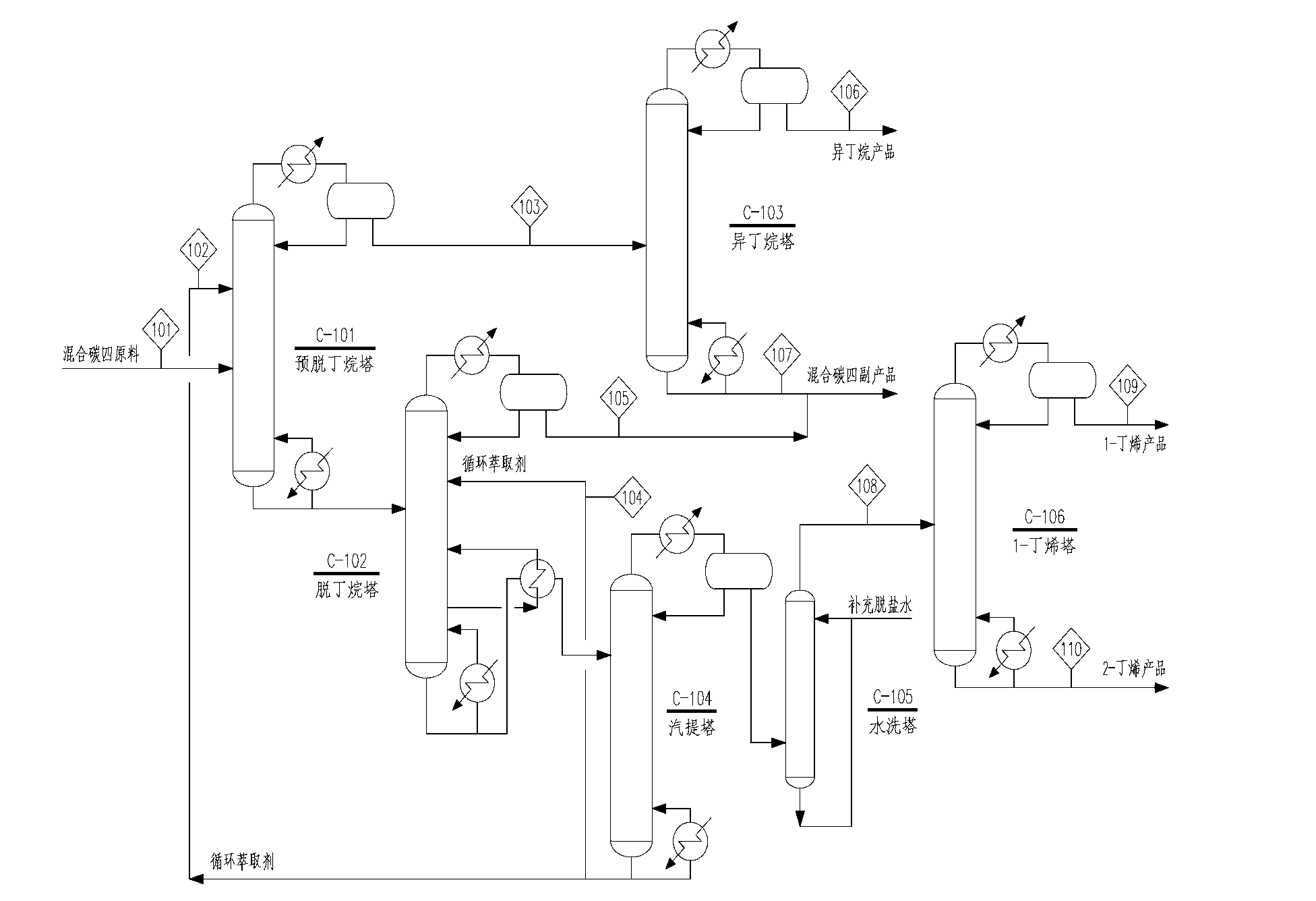

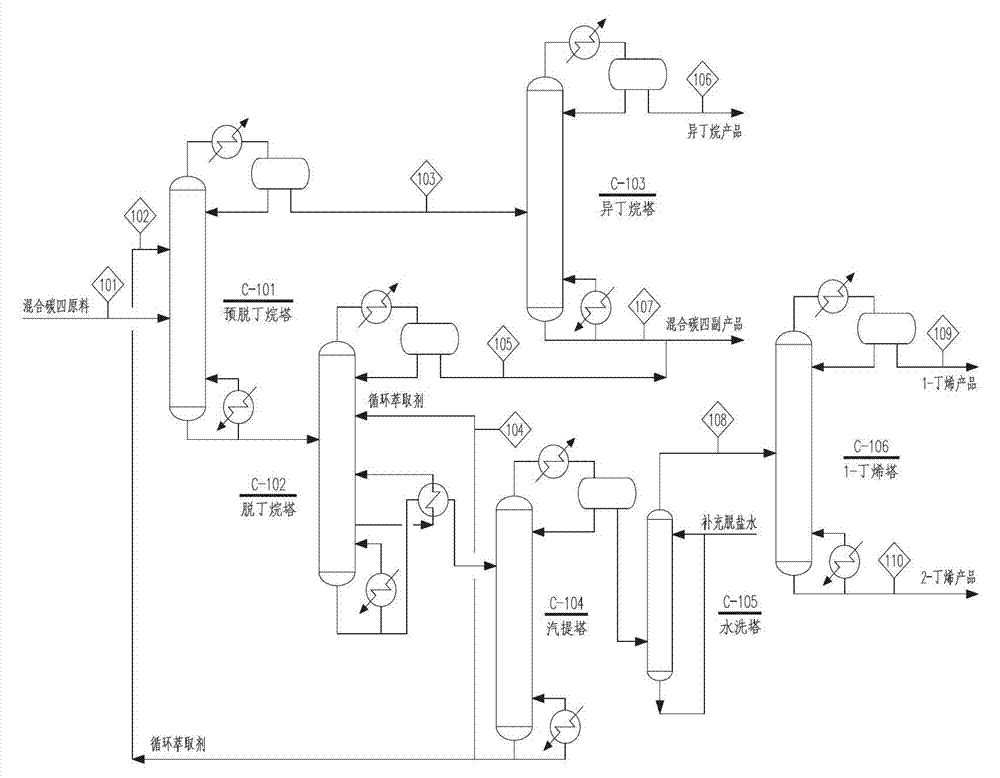

Separation method for mixed C4

ActiveCN102992933AIncrease profitReduce manufacturing costChemical industryDistillation purification/separationButeneHigh concentration

The invention discloses a separation method for mixed C4, which comprises the following steps of separating butene and butane from mixed C4 through extractive distillation, wherein the mixed C4 contains n-butane, iso-butane, 1-butylene and 2-butylene after removal of components such as C3, butadiene, alkyne, isobutene, C5 and the like, furthermore, separating to obtain iso-butane, 1-butylene and 2-butylene and the byproduct of crude n-butane through ordinary distillation, wherein the solvent for extractive distillation is publicly known in the industry, non clear-clear separation method is adopted in extractive distillation technology, namely, the combination of preextraction distillation and extractive distillation. Due to the adoption of the separation method, after the mixed C4 is processed, products of iso-butane, 1-butene and 2-butene of high concentration can be obtained simutaneously, therefore, the separation method has the advantages of being energy-saving, good in economic efficiency, high in resource utilization rate, and the like, reducing the cost and is of great significance in comprehensive utilization of mixed C4 resource.

Owner:EAST CHINA ENG SCI & TECH +1

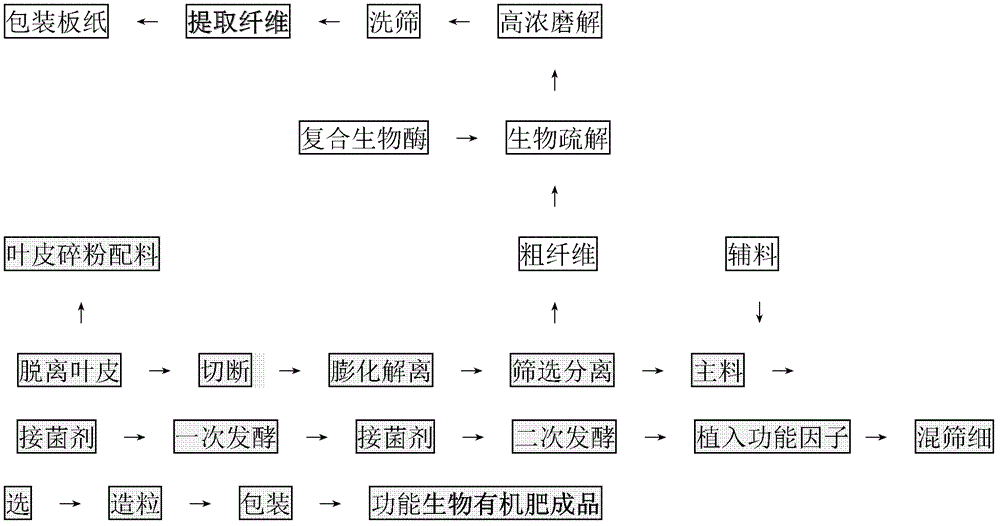

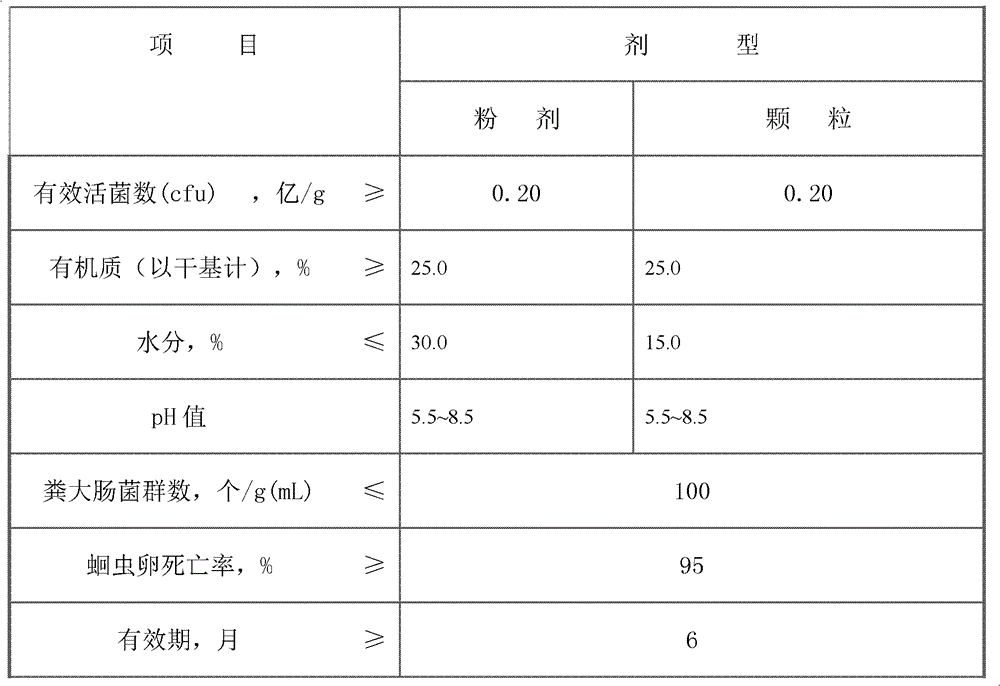

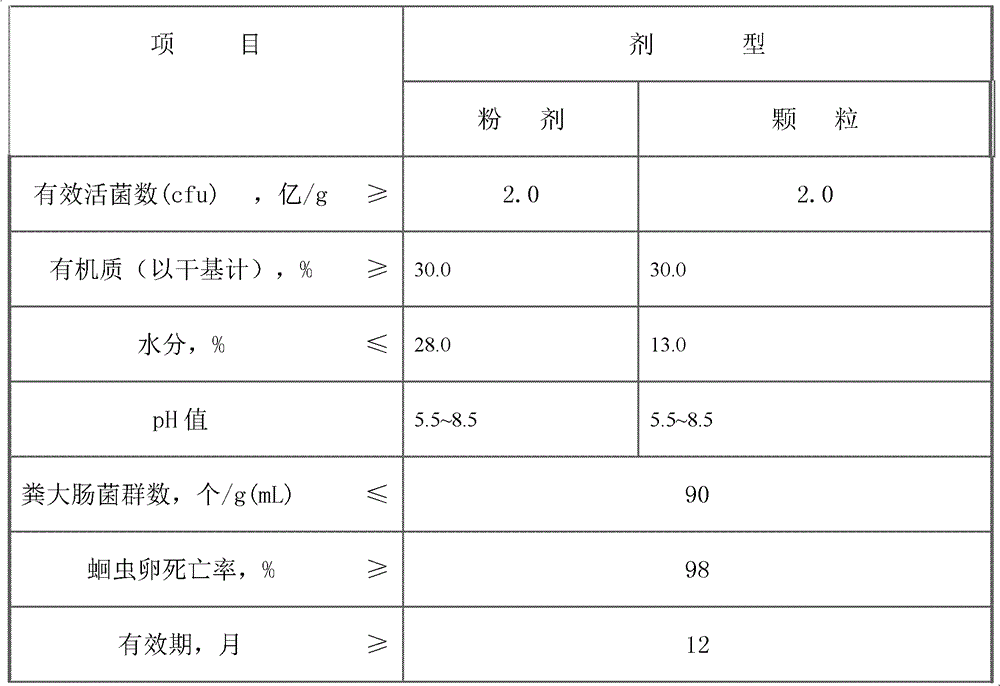

Process for co-producing functional bio-organic fertilizer and plant fibers by using corn straws

ActiveCN102746056AProduct diversificationIncrease valueBio-organic fraction processingOrganic fertiliser preparationCorn stoverPapermaking

The present invention discloses a process for co-producing a functional bio-organic fertilizer and plant fibers by using corn straws. According to the process, raw materials comprise corn straws, breeding excrements, edible fungi culture medium wastes and other organic waste assistant materials, and processes of puffed dissociation, screening separation, fermentation and the like are performed to produce a bio-organic fertilizer, wherein the organic matter content is high, and the bio-organic fertilizer is easily absorbed by plants. With the process of the present invention, plant fibers can be further co-produced, wherein physical performance indicators of the produced fibers completely meet standards of papermaking corrugated base paper, and the fibers can be used for wrapping paper papermaking.

Owner:SHANDONG NATURE AGRI TECH DEV

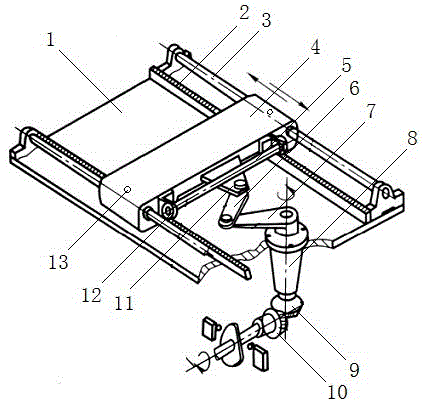

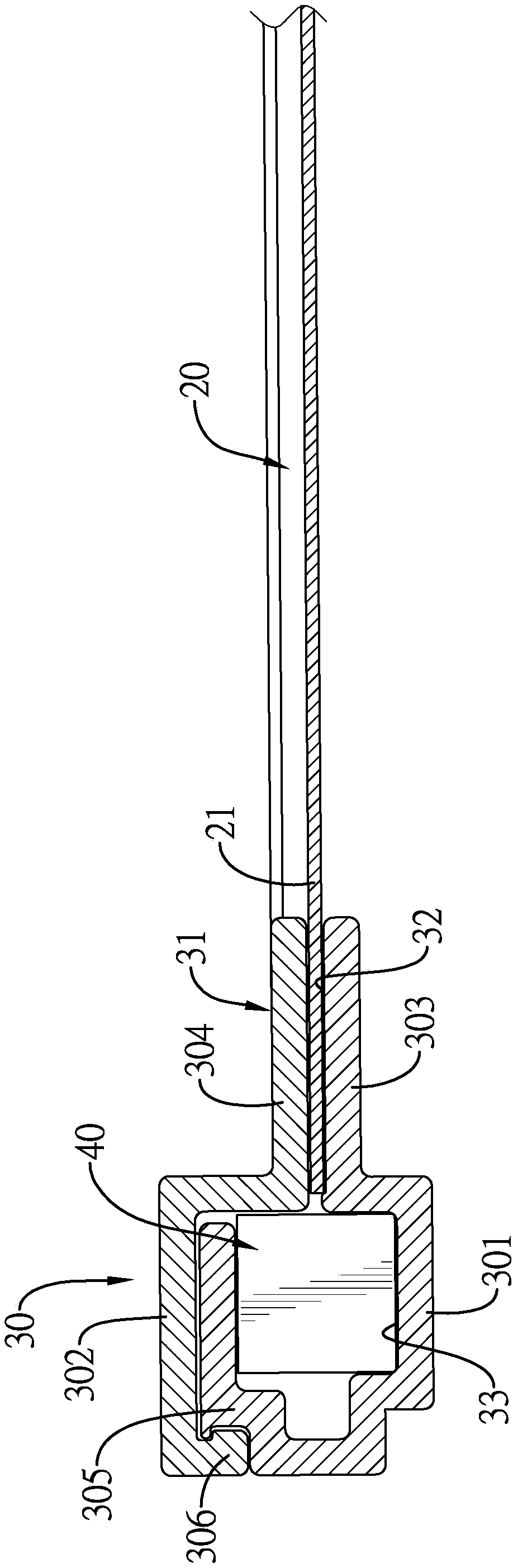

Large stroke pushing device

The invention discloses a large stroke pushing device which comprises a motor, a bottom plate, a driving bevel gear, a driven bevel gear, a vertical shaft, a crank, a connecting rod, a pushing plate, fixed racks, gears, guide rods, a sliding block and a sliding rod. The vertical shaft is rotatably connected with the bottom plate, the lower end of the vertical shaft is connected with the driven bevel gear, the upper end of the vertical shaft is fixedly connected with one end of the crank, the driving bevel gear is connected with the output end of the motor, one end of the connecting rod is hinged to one end of the crank, the other end of the connecting rod is hinged to the sliding block, and the fixed racks and the guide rods which are each arranged in a symmetrical mode are arranged at the two sides of the vertical shaft respectively; the sliding rod is connected with one side of the pushing plate, the sliding block is connected with the sliding rod in a sliding mode, two ends of the sliding rod are provided with the gears, the gears arranged at the two ends of the sliding rod are meshed with the fixed racks arranged at the two sides of the vertical shaft respectively, and the two sides of the pushing plate are connected with the guide rods at the two sides of the vertical shaft respectively. By means of the large stroke pushing device, more products can be pushed out in one time and the process of pushing material is stable.

Owner:南京科院新派设计有限公司

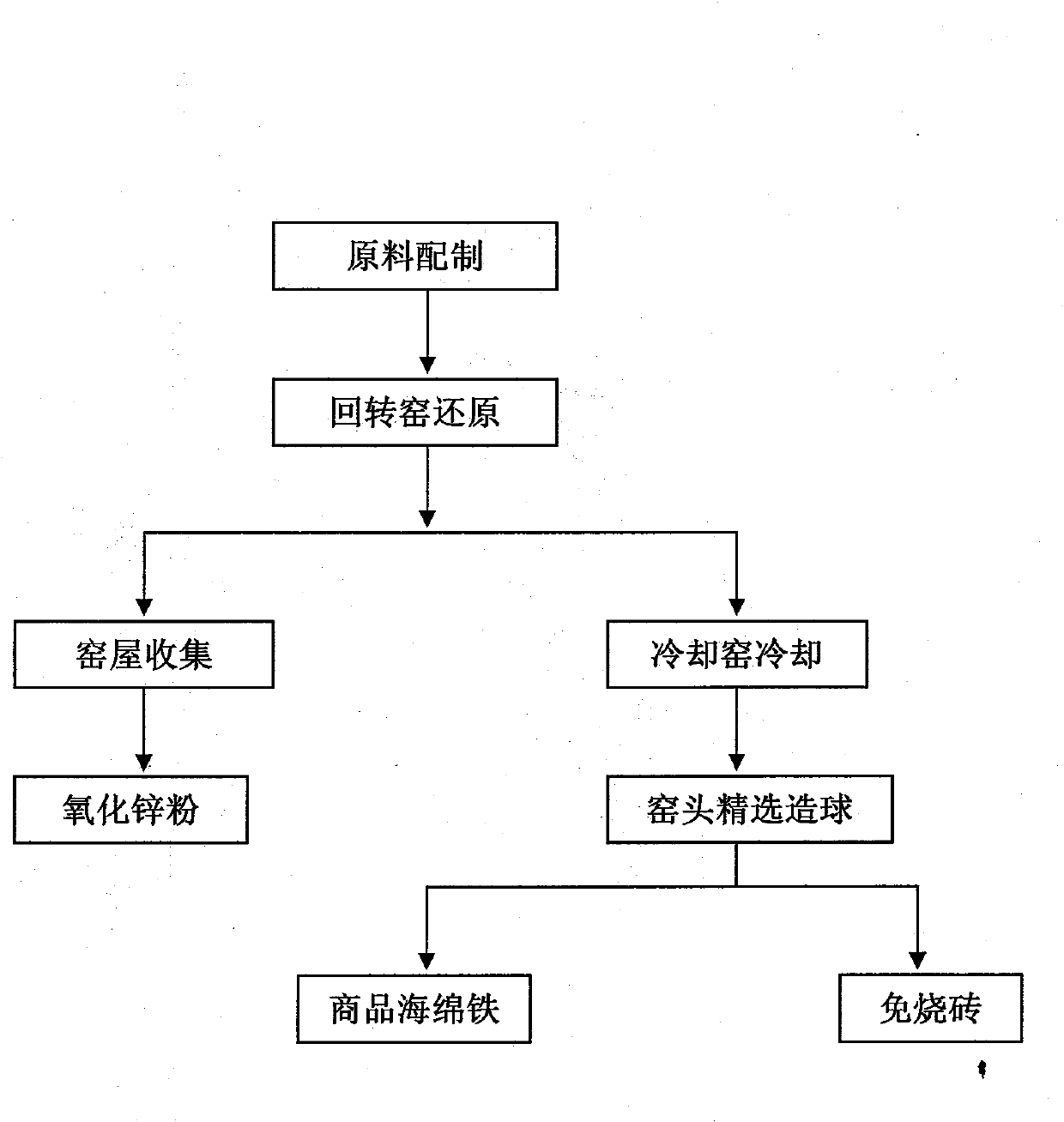

Method for producing zinc oxide and iron by treating zinc ore (slag) in reduction rotary kiln

The invention discloses a production method for producing commercial zinc oxide of a grade of more than or equal to 85 percent from kiln tail and sponge iron and baking-free bricks from kiln head by directly reducing iron-containing zinc ore (slag), reduction coal and lime in a rotary kiln. The process flow of the production method comprises the following steps: raw material preparation, direct reduction in rotary kiln, cooling in cooling kiln, collection at kiln tail and refining pelletizing at kiln head. The required coal particle size is less than 15 millimeters, the particle size of lime is less than 2 millimeters, the coal is burnt by primary air and secondary air, the calcining time is 1.5 to 8 hours, the calcining temperature in the kiln is controlled to be 50 to 1,200 DEG C, materials in the cooling kiln are cooled by water and wind to below a normal temperature of 38 DEG C, the materials are selected and pelletized, the commercial zinc oxide powder is produced at kiln tail, and the commercial sponge iron and baking-free bricks are produced in the kiln head. The method of the invention is simple, energy-saving, emission-reducing, free from waste slag and low in production cost, can produce various products with high quality, represents high degree of mechanization, is favorable for industrial large-scale production, has a large market, is very competitive and environmentally-friendly. The method can create great economic, social and environment-protection effects and solves the economic and technical problems faced by manufacturers of the same industry at home and abroad.

Owner:李维成 +1

Bean curd and bean curd production method

ActiveCN102524418AFully automatedImprove automationCheese manufactureFood scienceEmbryoCotyledon plant

The invention discloses bean curd and a bean curd production method. The bean curd production method comprises the following steps: preparing soybean milk; and mixing the soybean milk with a coagulant, coagulating to obtain bean curd. The preparation of the soybean milk comprises 1) adopting soybean cotyledon particles to serve as a raw material after breaking, embryo removal and soybean skin removal; 2) grinding after soaking the soybean cotyledon particles in water for 30-60 minutes, removing bean dregs after grinding so as to obtain raw soybean milk, and enabling the weight ratio between the cotyledon particles and water for soaking the cotyledon particles to be 1:6-11 during soaking; and 3) boiling the raw soybean milk, maintaining the temperature at over 85 DEG C for 30-45 minutes toobtain the soybean milk. The bean curd production method is scientific and simple, overcomes various shortcomings in the prior art, enables coagulating process of the soybean milk to be effectively adjusted, is favorable for achieving industrialized production of bean curd, and has the advantages of saving energy, simplifying equipment and reducing sewage discharge. Besides, the quality of the produced bean curd is equal to or close to that of northern bean curd.

Owner:FOODSTUFF INST BEIJING

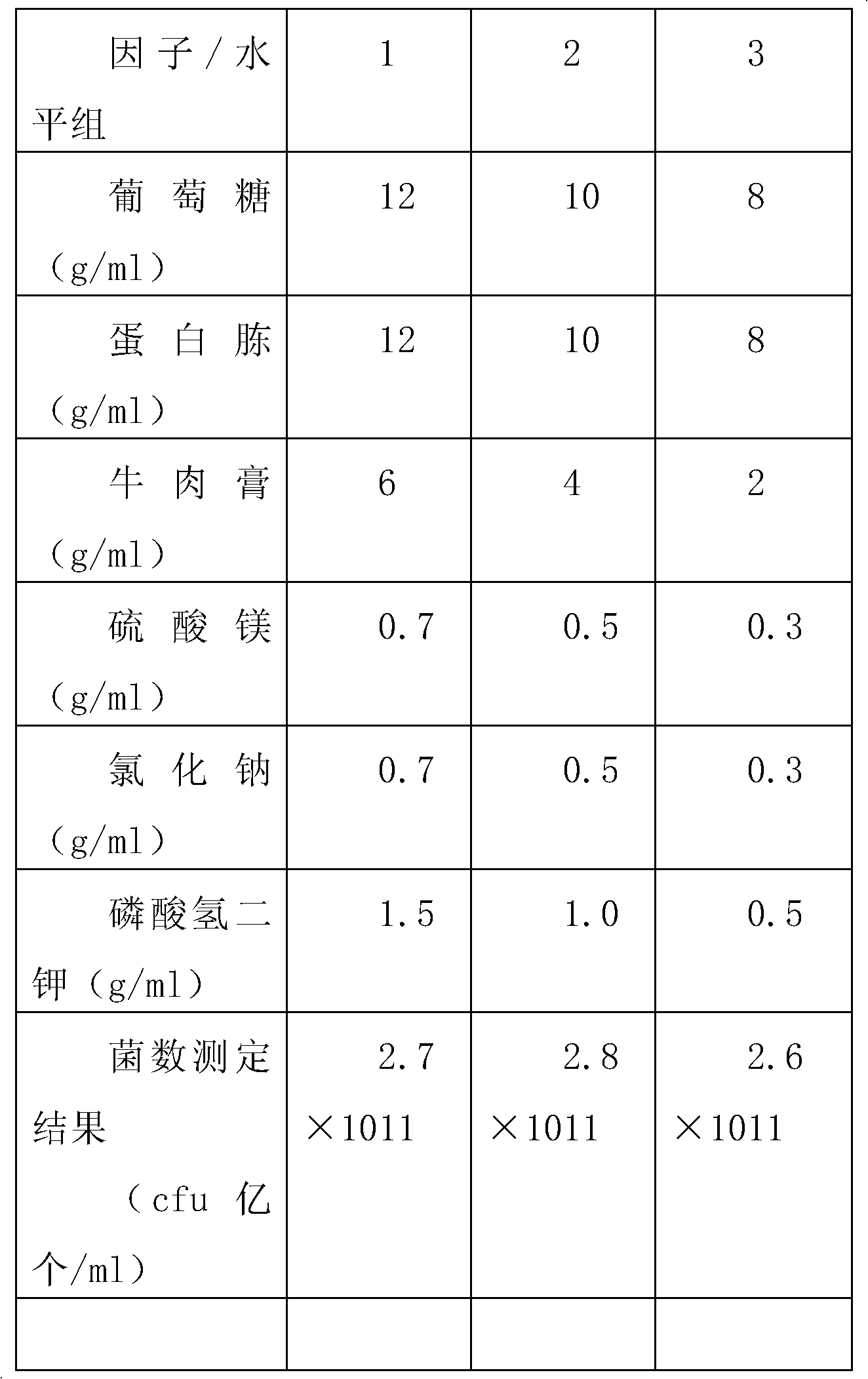

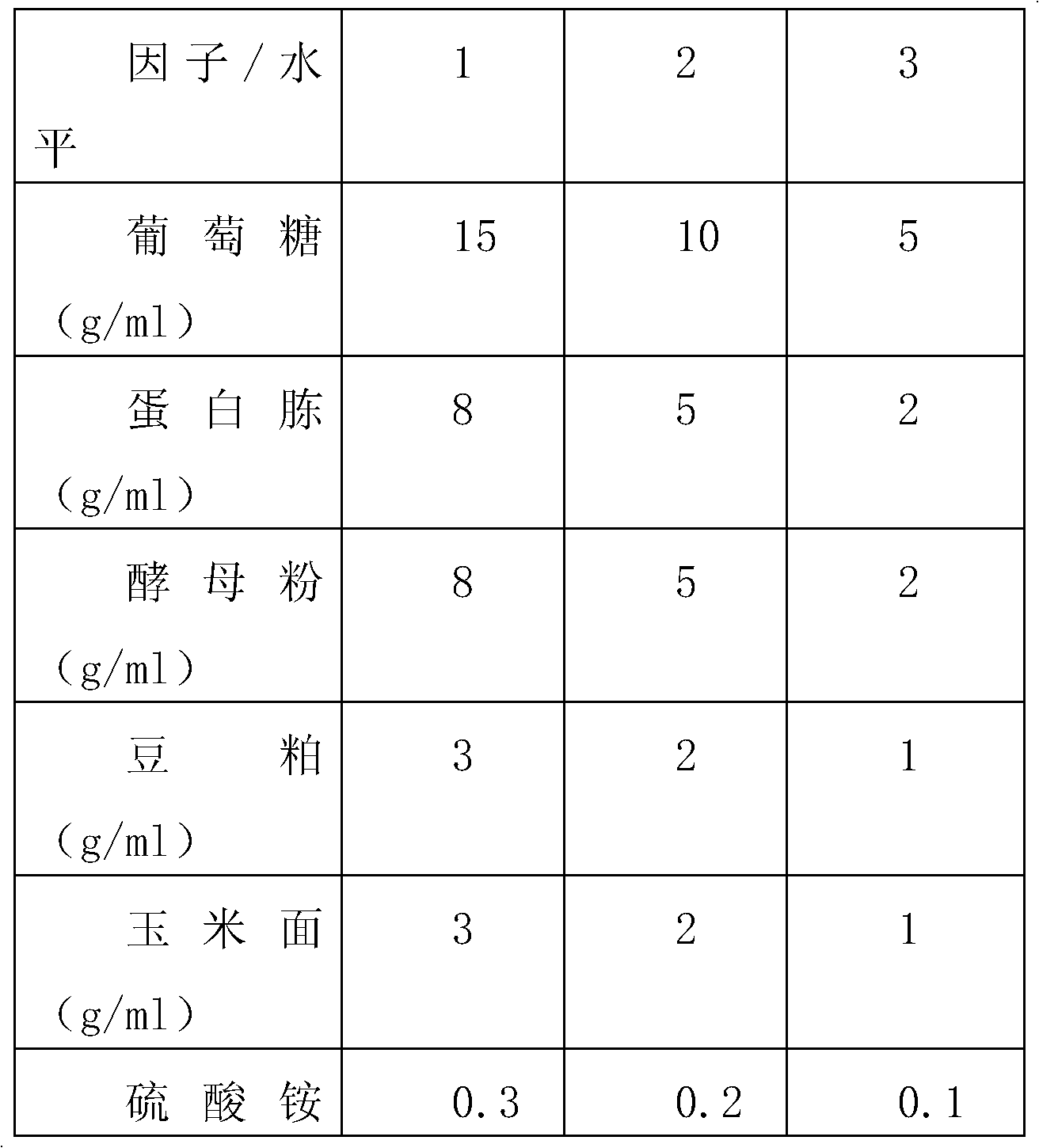

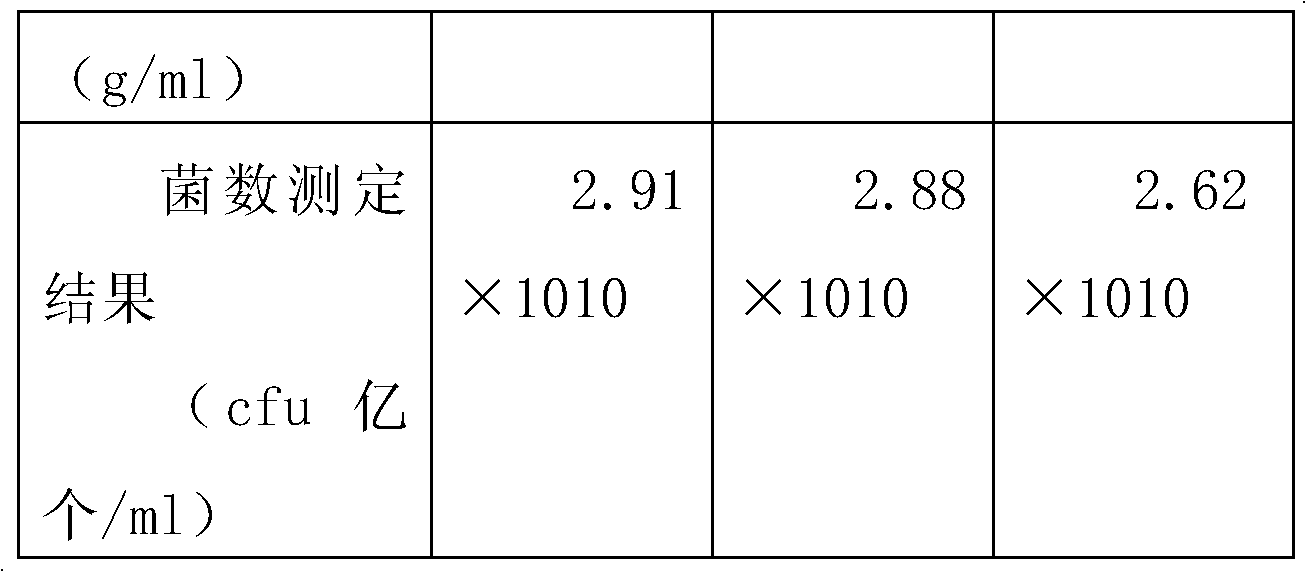

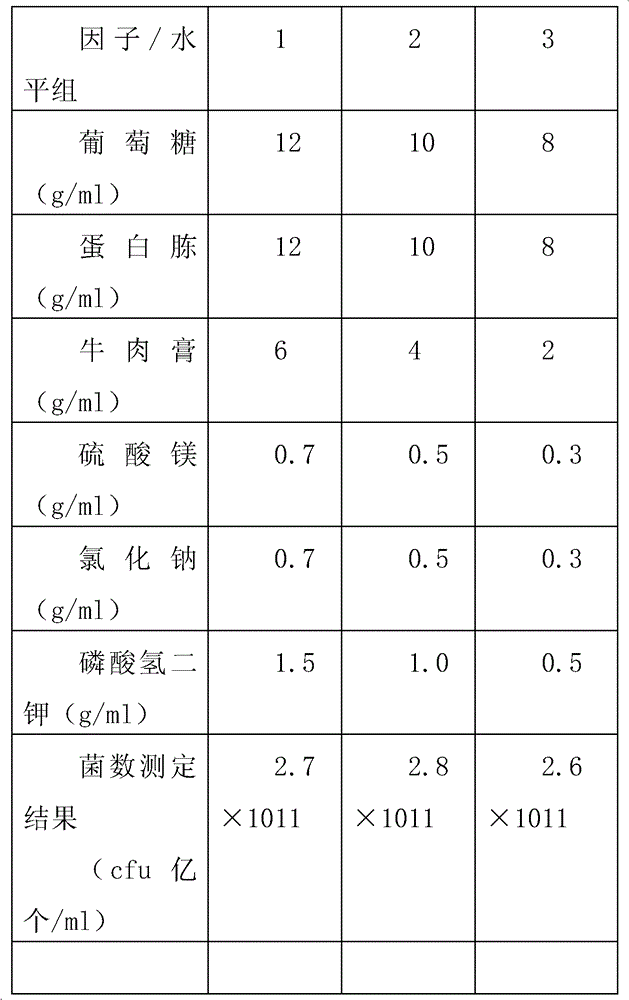

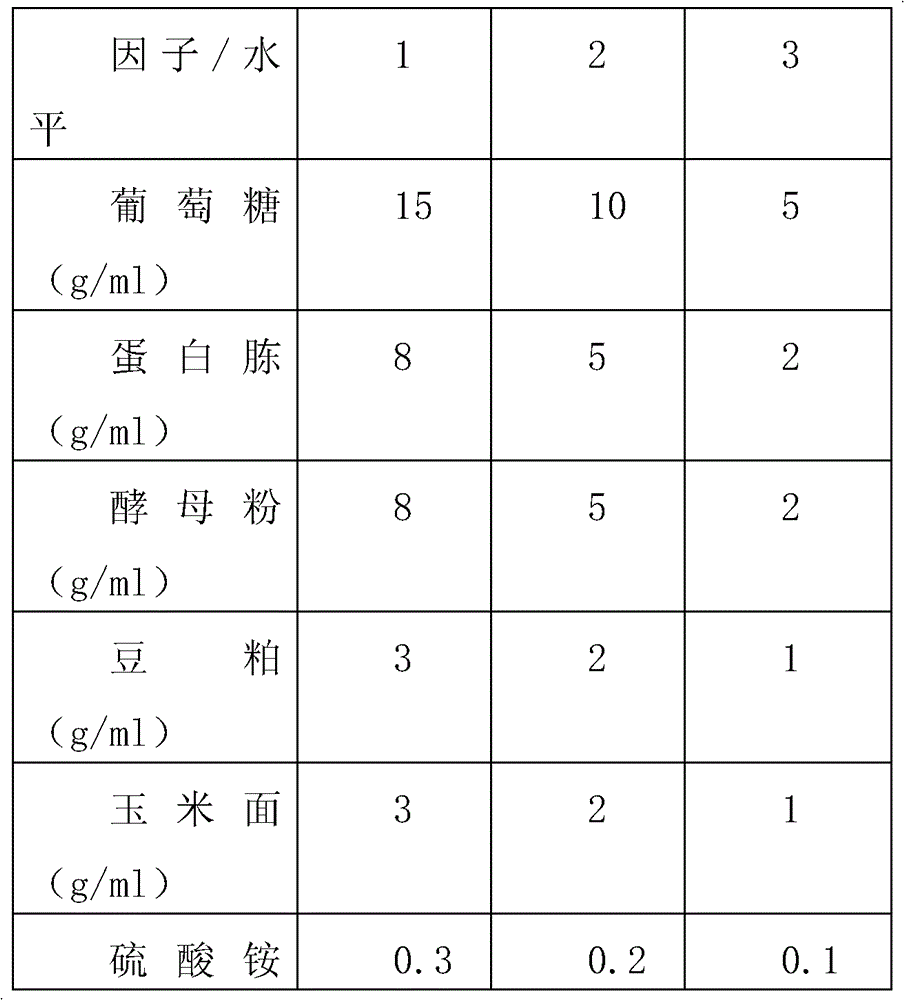

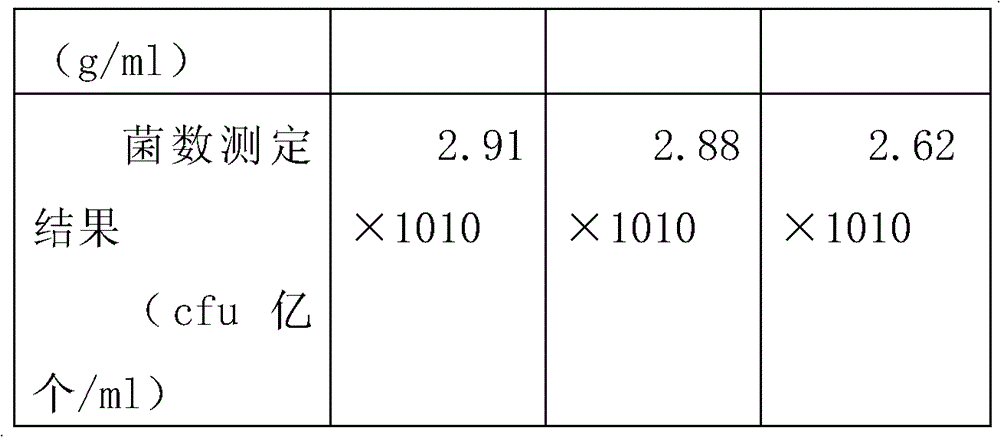

Production method of bacillus subtilis biological agent used for sodium humate-containing feed in medium

ActiveCN103184174AChoose appropriateNew technologyBacteriaAnimal feeding stuffBacterial strainFermentation

The invention relates to a microbe biological agent, and concretely relates to a production method of a bacillus subtilis biological agent used for a sodium humate-containing feed in a medium. The bacillus subtilis bacterial strain is subjected to first-stage solid seed culture and second-stage liquid seed fermentation culture to obtain a bacterial classification liquid. The bacterial classification liquid is inoculated in the medium which takes glucose, sodium humate, soybean meal, corn and wheat bran as raw materials for three-stage solid aerobic fermentation, the culture condition is adjusted to form spore, the spore can be treated, dried, and crushed to produce the bacillus subtilis biological agent. The biological agent contains more than or equal to 200 hundreds million / g of acillus subtilis, the pH value is 5.6-6.6, the moisture is less than or equal to 10%, and the granularity is greater than or equal to 100 meshes, the color presents special shallow grey or grey black, and the shelf life is 18 months. The biological agent can be taken as an additive application in aquatic product, and livestock and poultry culture, can increase the production performance and improve the culture environment.

Owner:SHENYANG BOSHAN YINGSHENG BIOLOGICAL TECH CO LTD

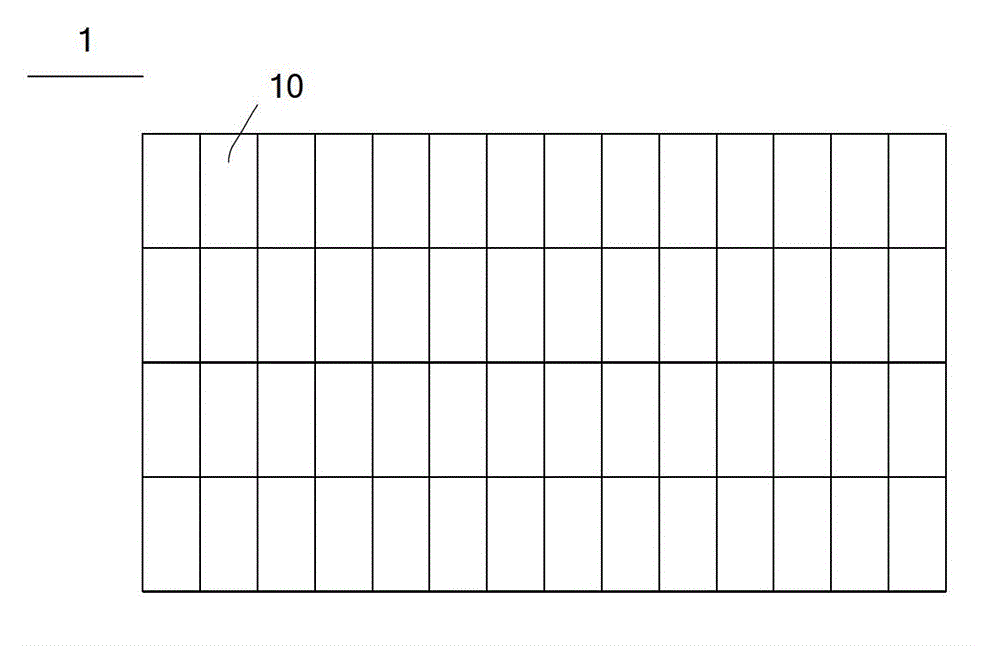

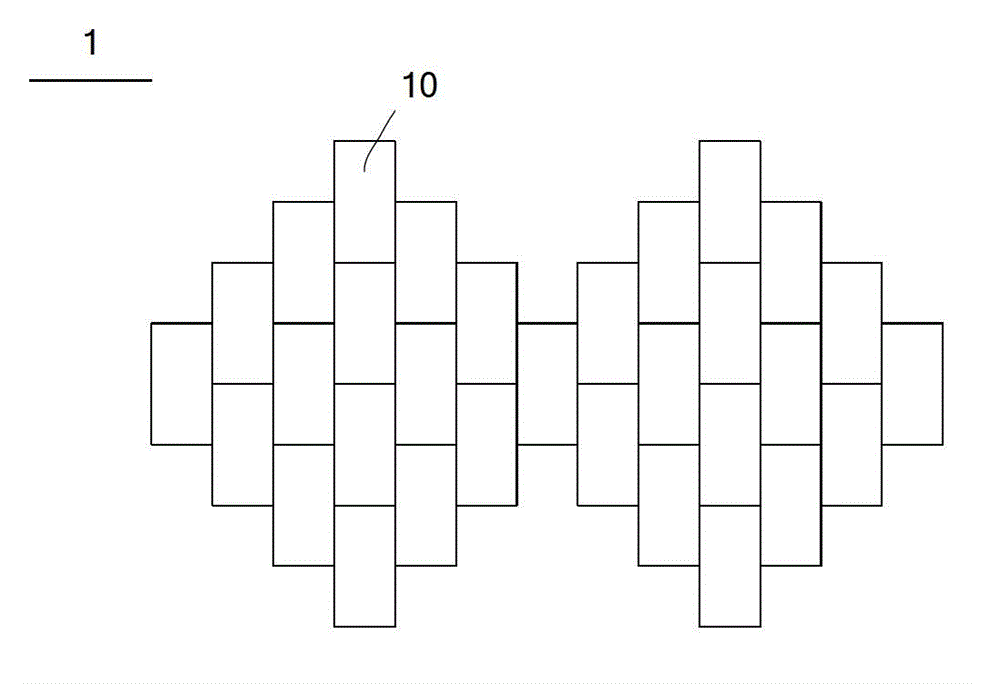

Three-dimensional fabric pattern design method

ActiveCN106777646AProduct diversificationPattern making devicesComputer aided designComputer graphics (images)Two step

The invention relates to the technical field of the textile, in particular to a three-dimensional fabric pattern design method. According to the method, two steps, namely, the three-dimensional stereo image production and three-dimensional image pattern plate production are used for generating the three-dimensional pattern plate. The fabrics which are processed in a jacquard by using the generated three-dimensional pattern plate can render a three-dimensional stereo effect. The method provides the technological foundation to the development of the three-dimensional stereo fabrics.

Owner:ZHEJIANG SCI-TECH UNIV

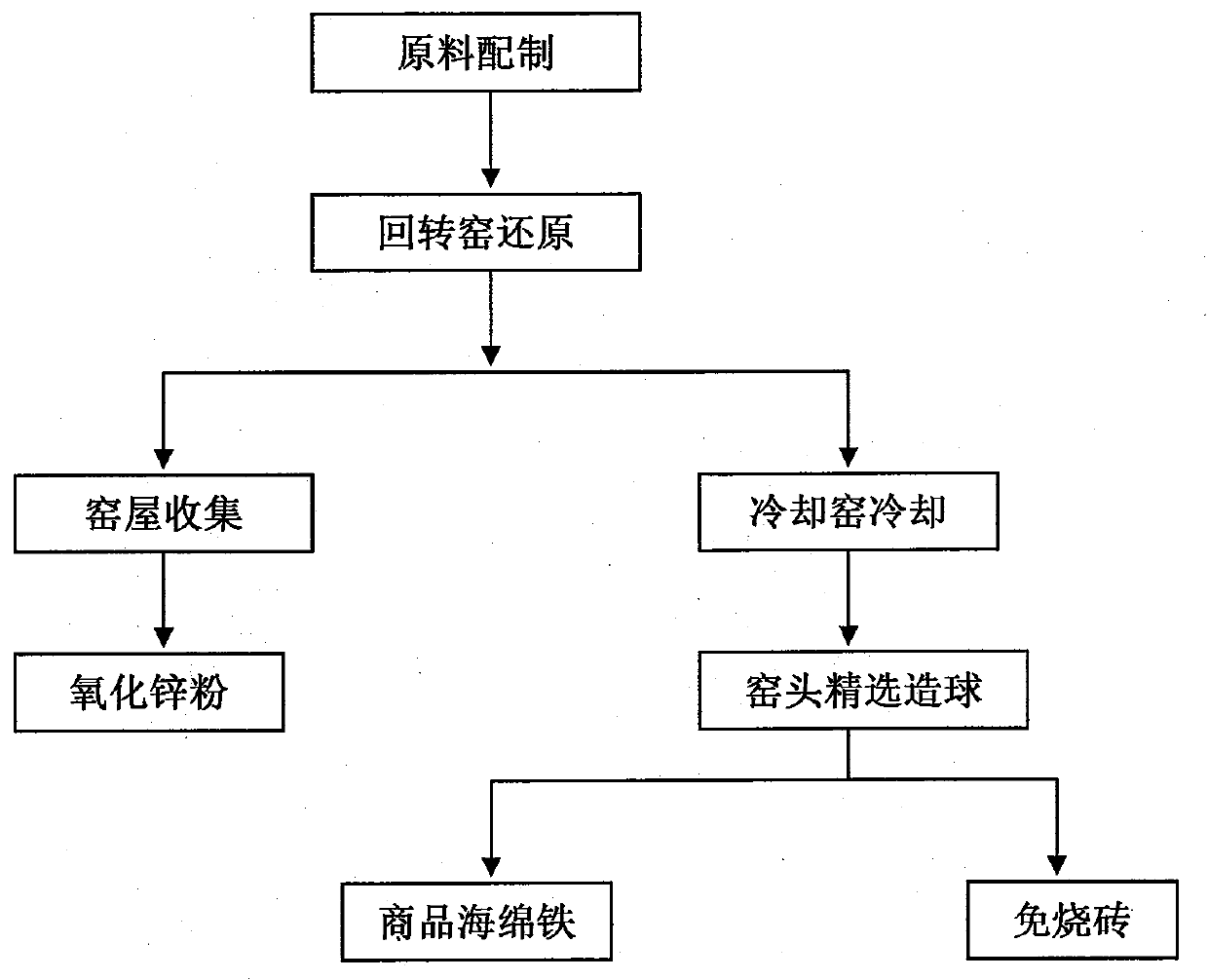

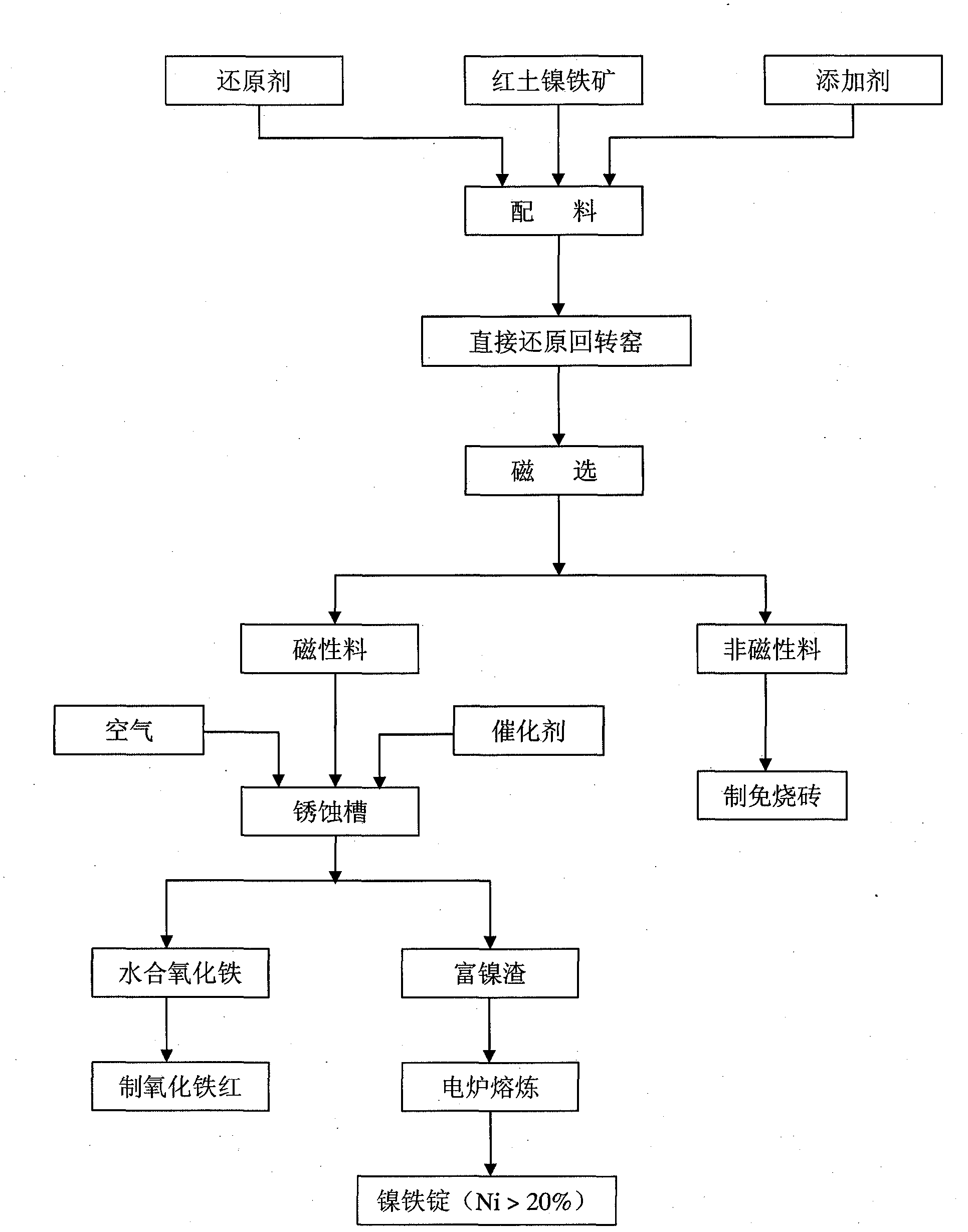

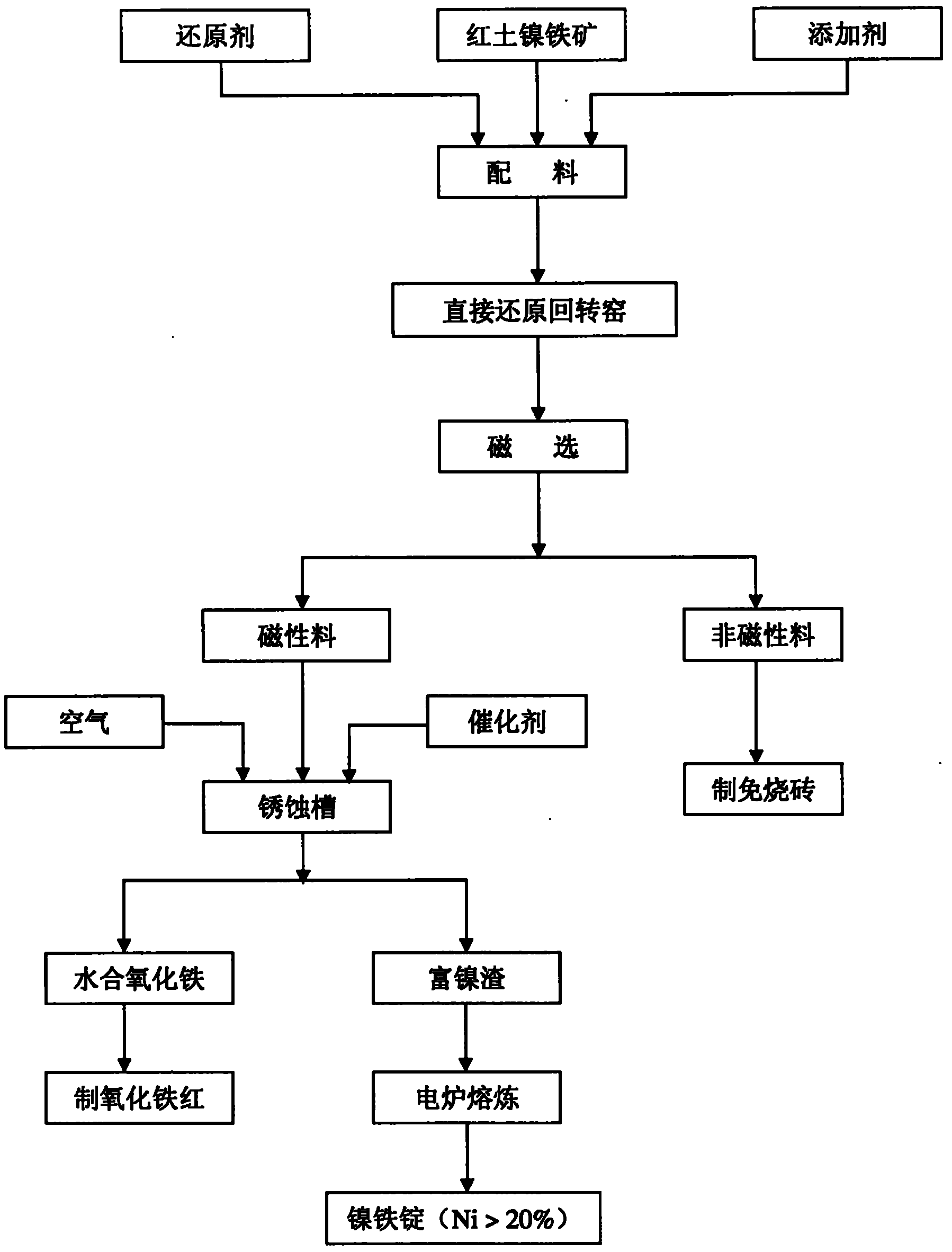

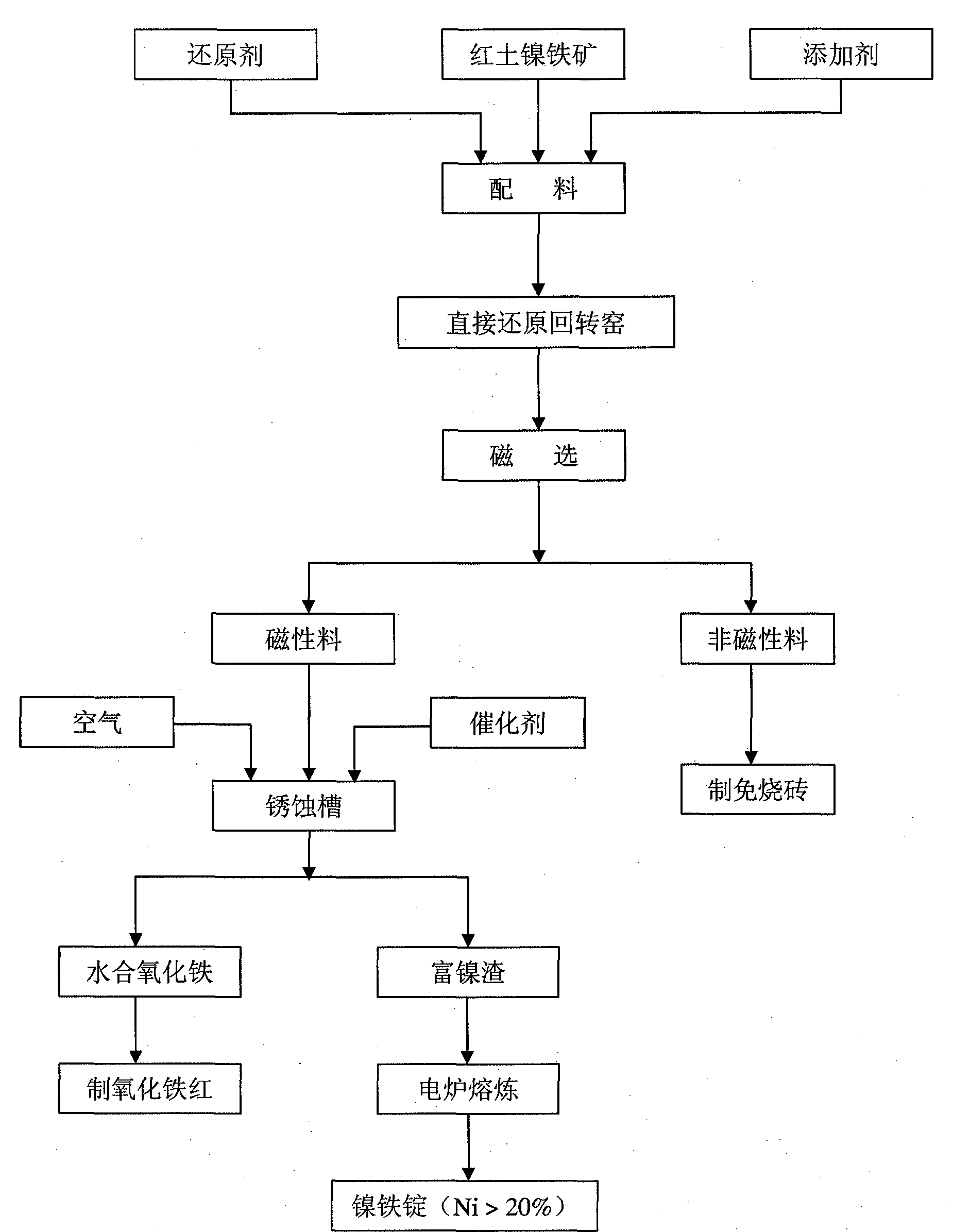

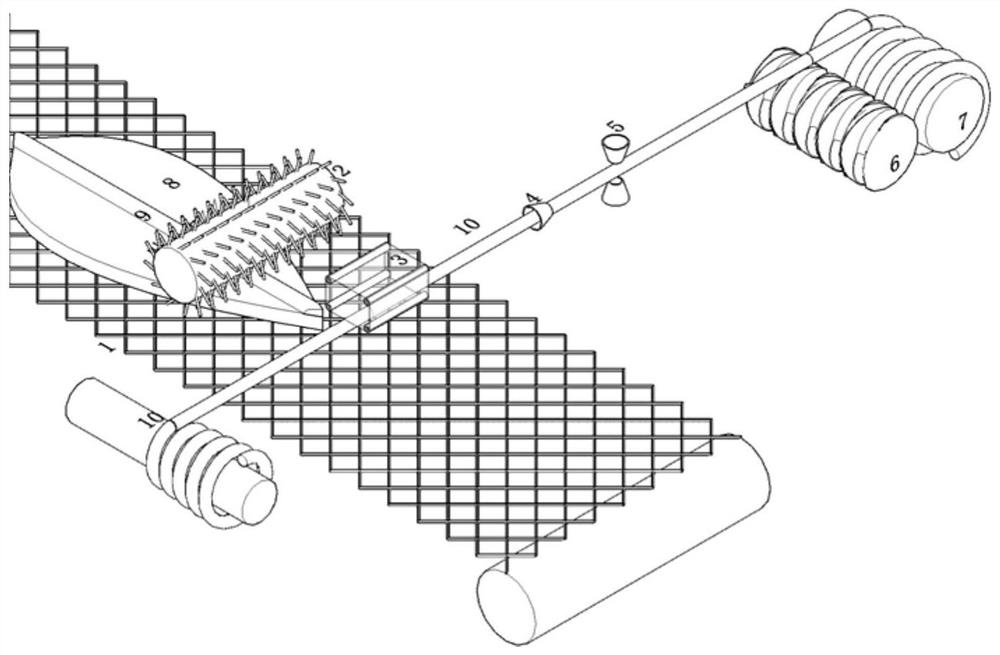

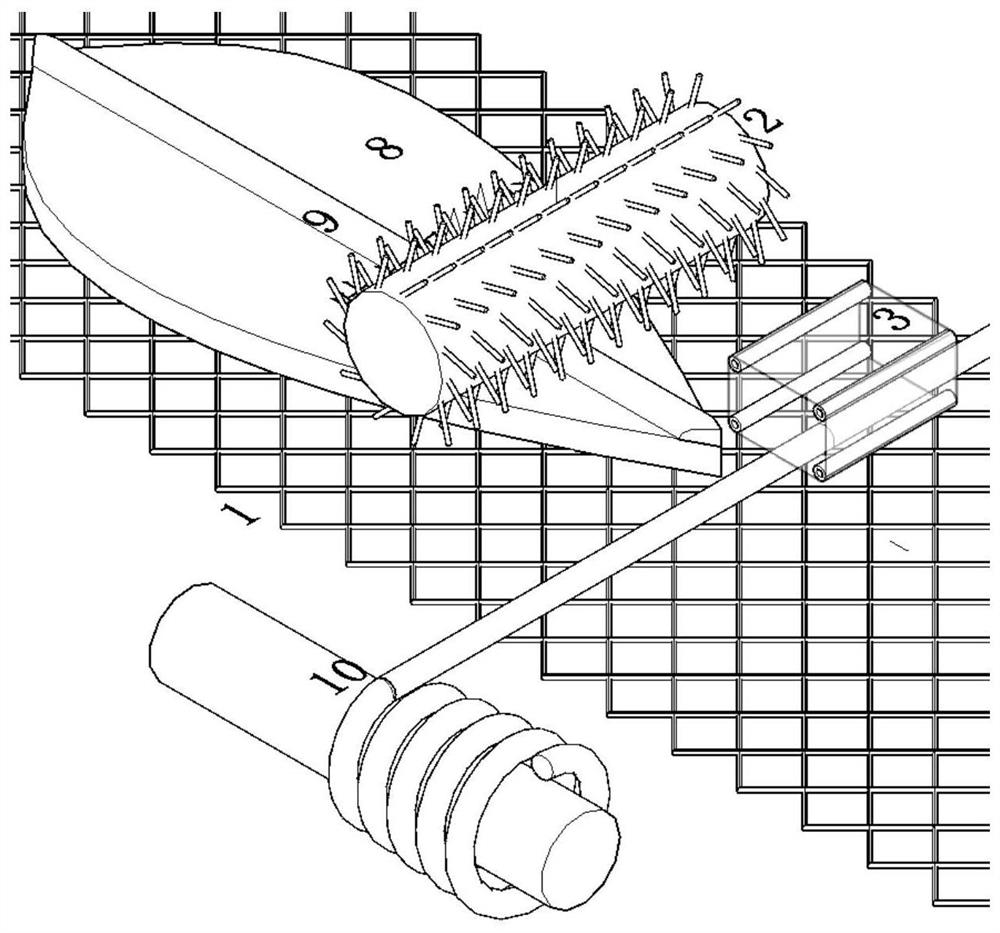

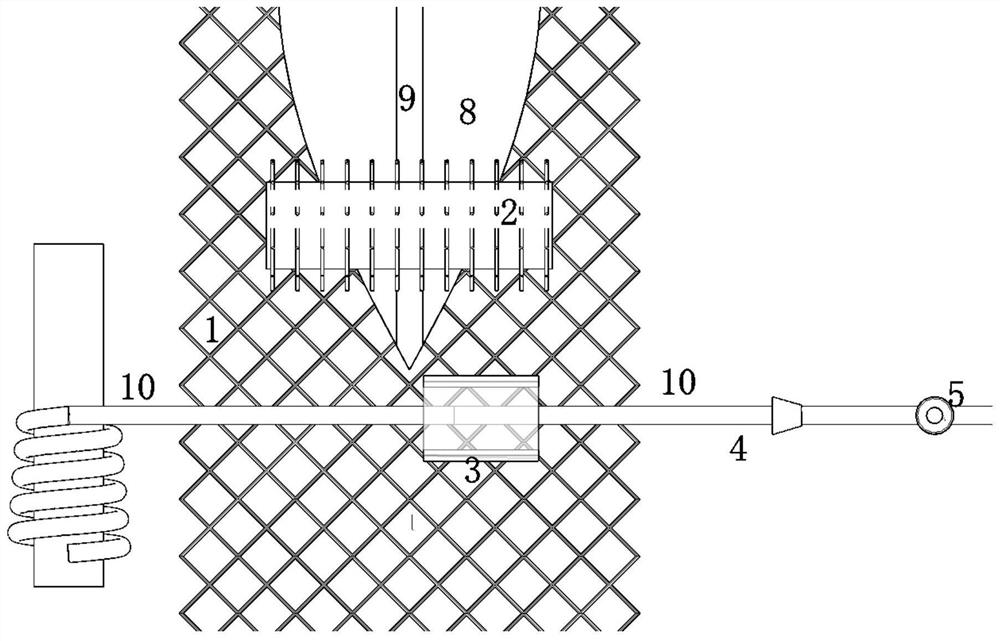

Method for reducing nickel ore by using reducing rotary kiln and producing ferronickel by rusting electric furnace

InactiveCN102168157AAdvanced technologyLow costRotary drum furnacesProcess efficiency improvementEnvironmental resistanceBrick

The invention relates to a method for reducing nickel ore by using a reducing rotary kiln and producing ferronickel by rusting an electric furnace, which comprises the following steps: placing red soil ferronickel ore, reducing coal, a desulfurizing agent and additives into the rotary kiln for direct reduction, further performing selection, rusting, and smelting the high-grade ferronickel by the electric furnace, wherein the nickel grade is not less than 20%; and simultaneously recovering ferric oxide red, and using a waste material to manufacture burning-free bricks. The process flow is as follows: preparing raw materials, directly reducing via the rotary kiln, cooling via a cooling kiln, performing the selection, rusting, and smelting by the electric furnace. The particle size of the coal is required to be not more than 15mm, the particle size of lime is less than 2mm, primary air and secondary air are adopted for burning the coal, the calcination time is 2.5-9 hours, the temperature in the kiln is 500-1180 DEG C, the materials are cooled to below 38 DEG C by the cooling kiln, the selection is performed for removing impurities, the rusting is performed for removing the impurities, the smelting is performed by the electric furnace, and then the nickel content in the ferronickel is not less than 20%. The method is simple, the technology is advanced, the energy conservation and the emission reduction are realized, the cost is low, the quality is high, and the degree of mechanization and the degree of automation are high, large-scale production is benefited, large market is achieved, the competitiveness is strong, environment friendliness is achieved, significant economic benefits is obtained, good social benefits and environment-friendly effect are achieved, and further a new way for refining nickel from the red soil ore is .

Owner:李维成 +1

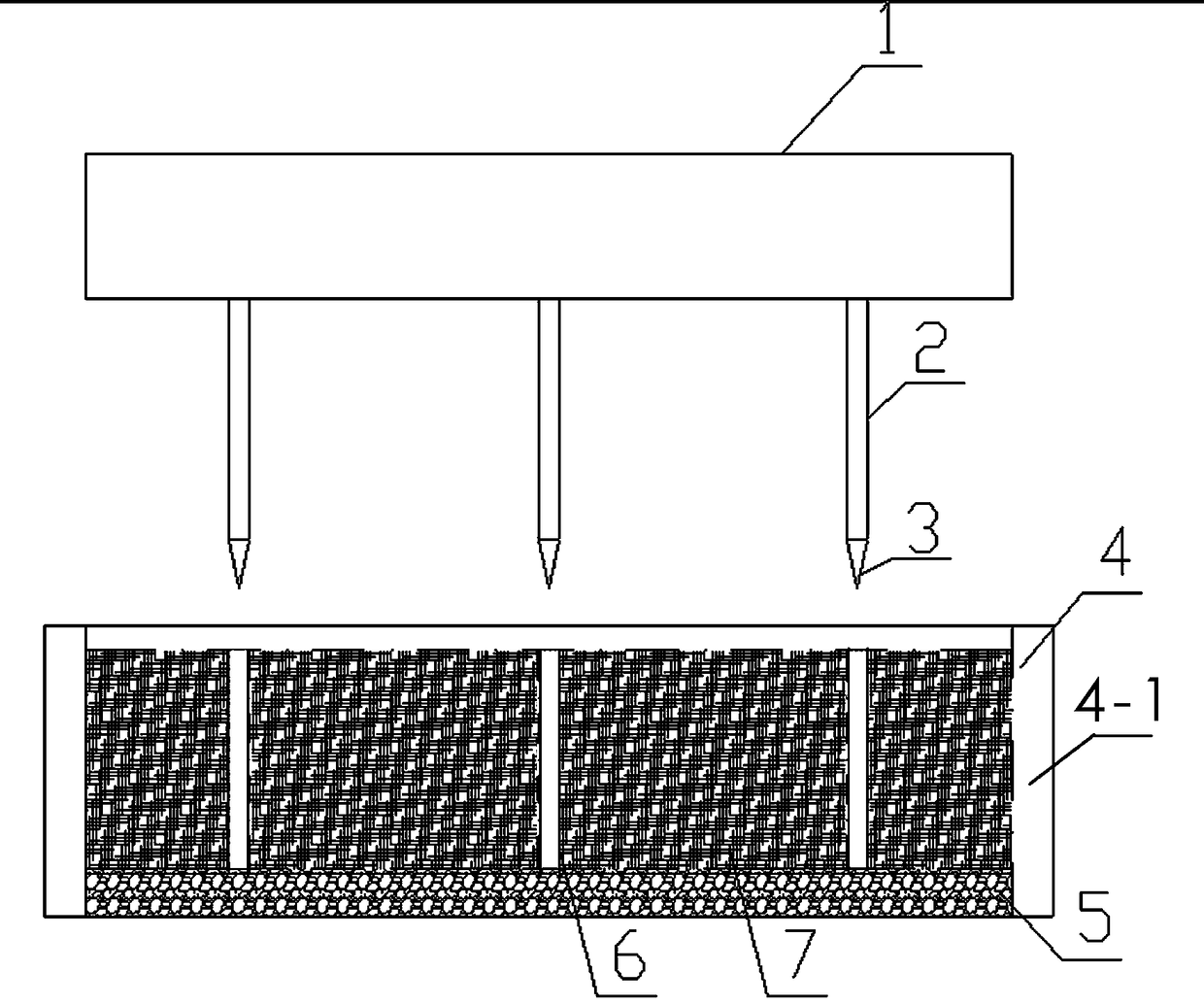

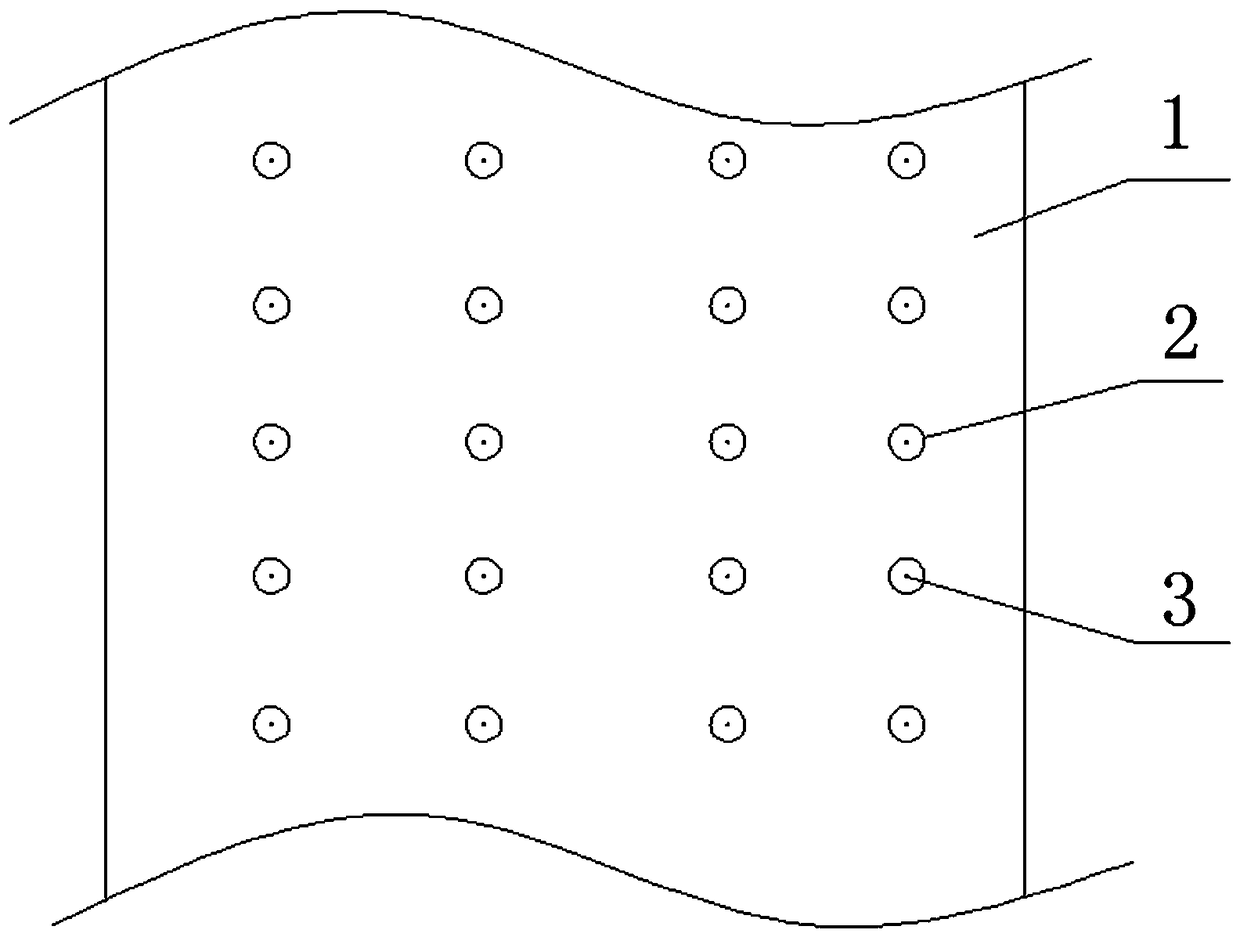

Guide hole water-permeable brick as well as brick machine mold and method for preparing same

InactiveCN108755337ASolve the strength problemFix compatibility issuesMouldsPaving gutters/kerbsBrickSurface layer

The invention discloses a guide hole water-permeable brick as well as a brick machine mold and a method for preparing the same and belongs to the technical field of production of guide hole water-permeable bricks. The produced guide hole water-permeable brick comprises two parts including a guide hole water-permeable structure layer and a porous water-permeable surface layer. Guide hole needles are located at the lower part of an upper mold of a brick making machine, and any ordinary brick mold molds provided with the additional guide hole needles can be used for producing the guide hole water-permeable bricks. The thickness of the guide hole water-permeable structure layer is 80%-90% that of a test piece and the guide hole water-permeable structure layer mainly bears external load of thetest piece; the porous water-permeable surface layer mainly plays a role in preventing blockage of a guide hole water-permeable base layer. The mold is mainly used for forming of the guide hole water-permeable brick, the guide hole water-permeable structure layer is prepared in a manual hole forming manner, forming of ineffective pores is avoided, the problems that conventional water-permeable concrete has incompatible strength and water permeability, and the strength and the water permeability of the produced water-permeable brick are higher.

Owner:CHINA UNIV OF MINING & TECH

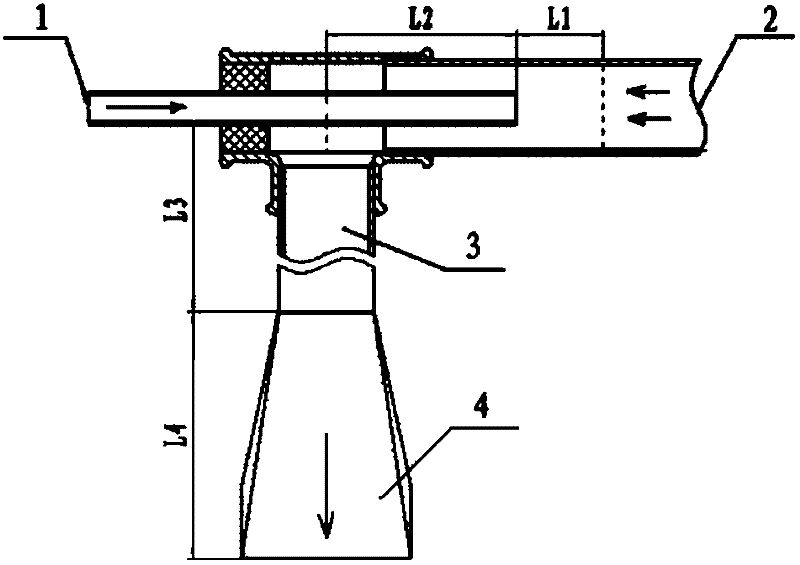

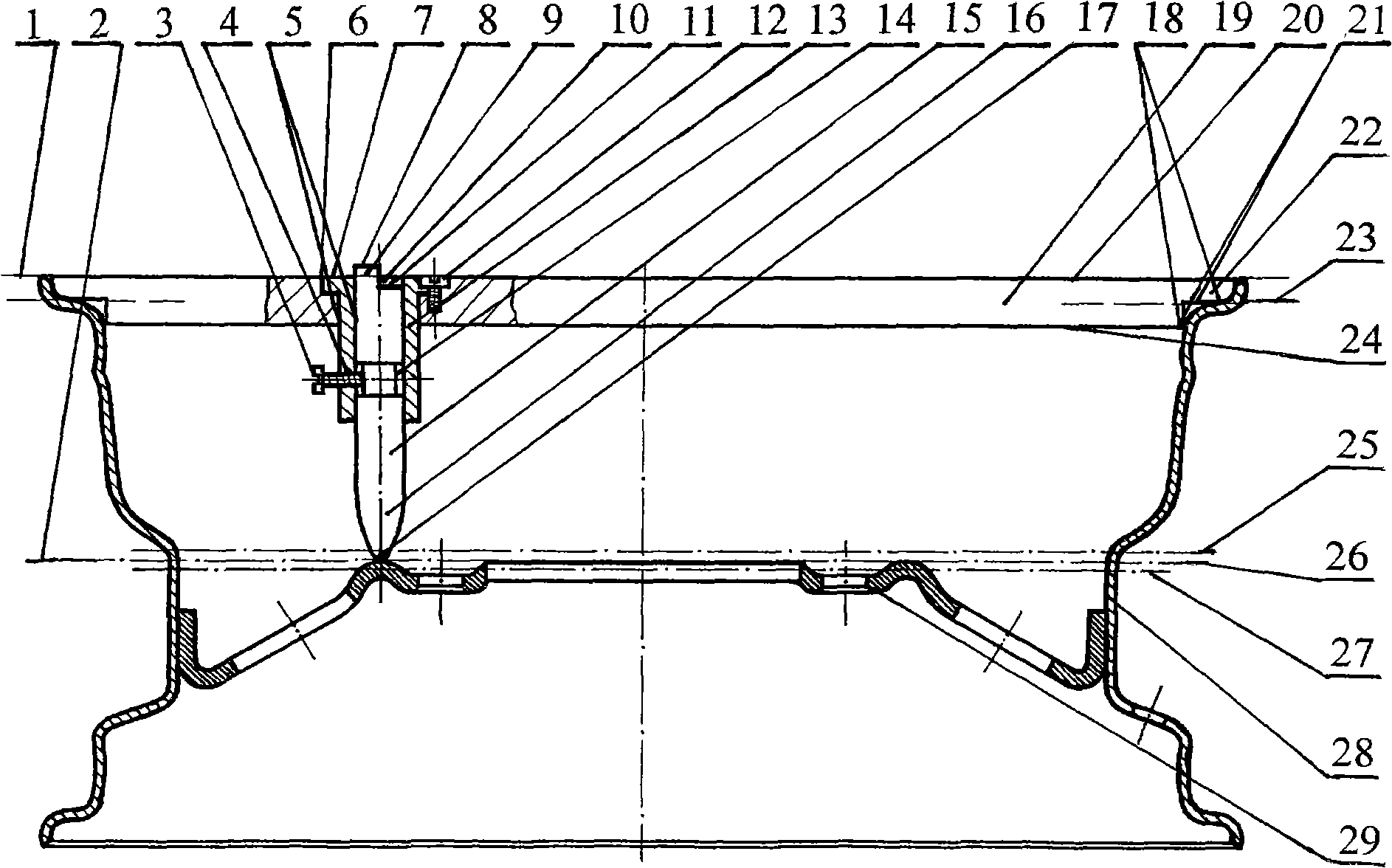

Steel ring deflection distance detection course and instrument construction

InactiveCN101403597AImproving Offset Detection EfficiencyImproving the effect of offset detectionMechanical clearance measurementsDisplay deviceDistance detection

A steel wheel offset checking process and instrument conformation comprise the steel wheel offset checking process and the conformation of a steel wheel offset checking instrument, through the conformation of the steel wheel offset checking instrument, the invention introduces how to manufacture the steel wheel offset checking instrument which can obtain the checking result by single hand operation, touching by hand handle of fingers or intuitionistic steel wheel offset reading by utilizing a checking limit board, a checking rod, and a steel wheel offset reading and display device, or an inner deflection display block and an outer deflection display block, and a checking cover; and through steel wheel offset checking process, the invention introduces each concrete operational step of the checking steel wheel offset. The technical program provides a necessary technical condition to automotive manufacturing corporations to ensure the quality of the steel wheel, reduce scrap rate of finished products and enhance the economic efficiency of corporations, and also provides a necessary technical condition to technical fields of the quality cognizance of automotive steel wheel and the using status detection of the automotive vehicles and the like, and convenient checking of steel wheel offset, and also plays an extremely important role in improving production quality of automotive steel wheels and improving the automotive steel wheel technology.

Owner:徐国林

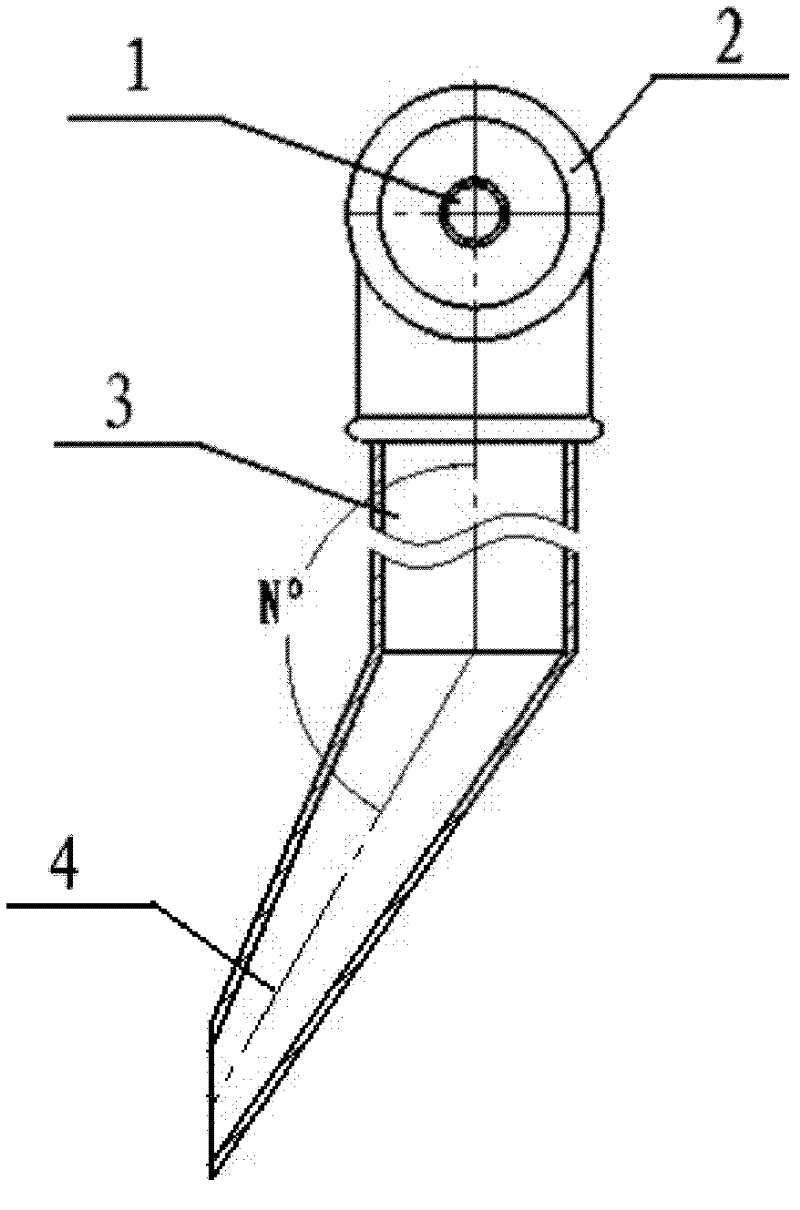

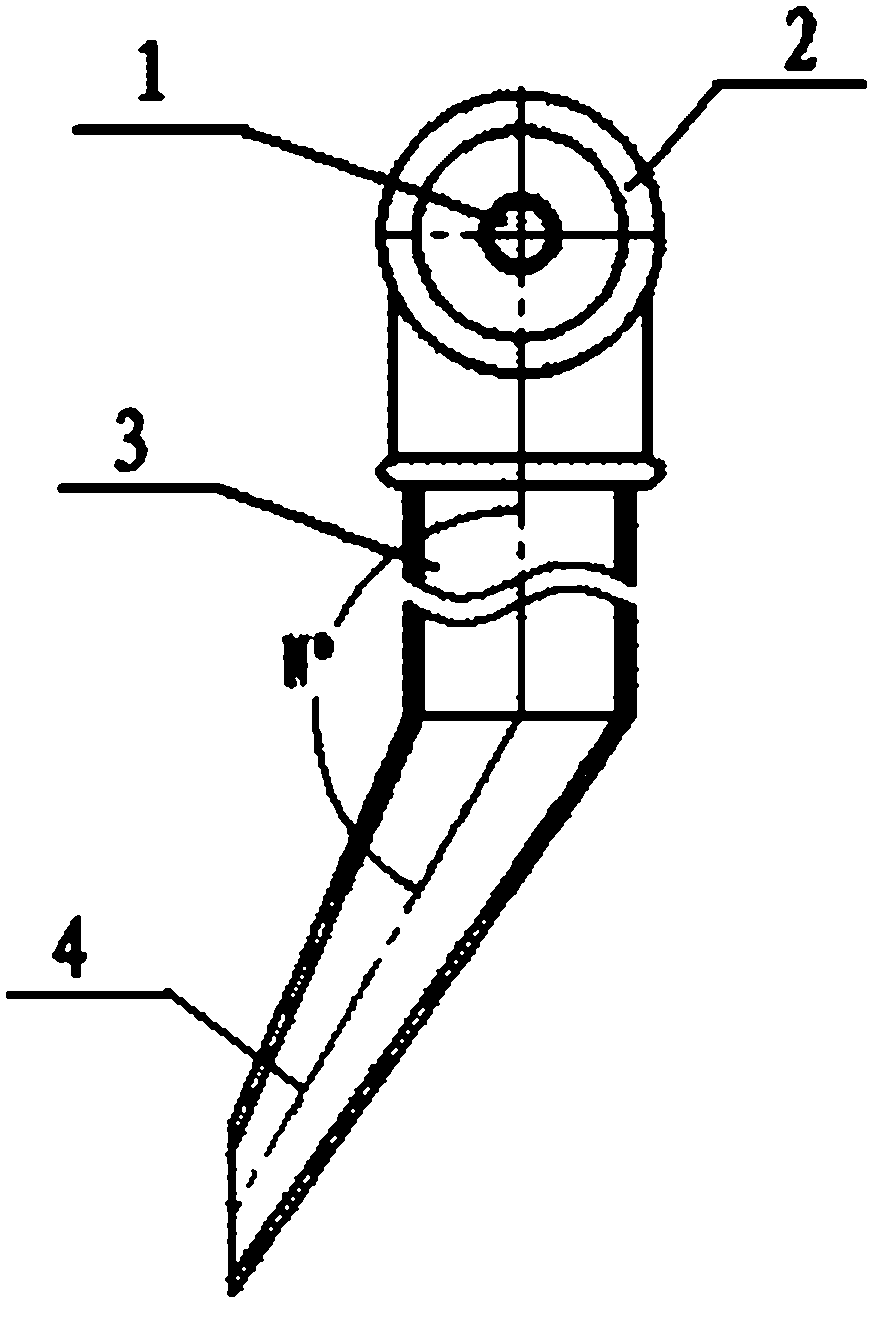

Cutter for machining two sides of building stone slab

InactiveCN102744791AAvoid crackingIncrease productivityFlooringStone-like material working toolsTool bitProduction line

Owner:H & H INT LTD

Antibacterial health-care plastic spectacles frame and manufacturing method thereof

The invention provides an antibacterial health-care plastic spectacles frame and a manufacturing method thereof. The plastic spectacles frame comprises, by weight, 75-95% of polymer, 3%-19% of natural antibacterial agents, 1.2%-3.5% of blueberry seed oil and 0.8%-2.5% of coupling agents. The natural antibacterial agents are made from, by weight, 70%-90% of loess powder, 5%-15% of cedrela sinensis leaf extracts, 2%-5% of persimmon leaf extracts and 3%-10% of betel pepper leaf extracts. In this way, the plastic spectacles frame manufactured through multiple machining means is stable in size, smooth in touch, high in tenacity, resistant to impact, resistant to stain, resistant to wear and good in rebound resilience; in the wearing process, the antibacterial and sterilization functions are achieved while fragrance and health-care ingredients can be released slowly so as to relieve or avoid eye fatigue and prevent shortsightedness and farsightedness; excellent aging resistance ability and better mechanical property are further achieved, and the service life is longer; the microenvironment around eyes can be improved through the far infrared radiation effect, and eye diseases can be prevented and treated.

Owner:陆思烨

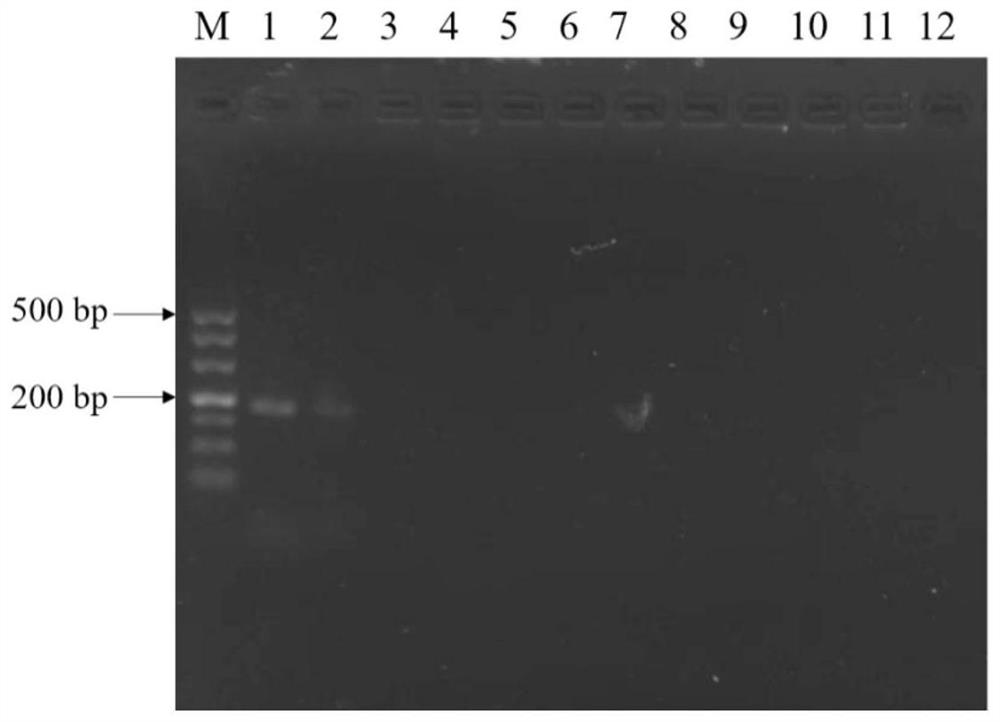

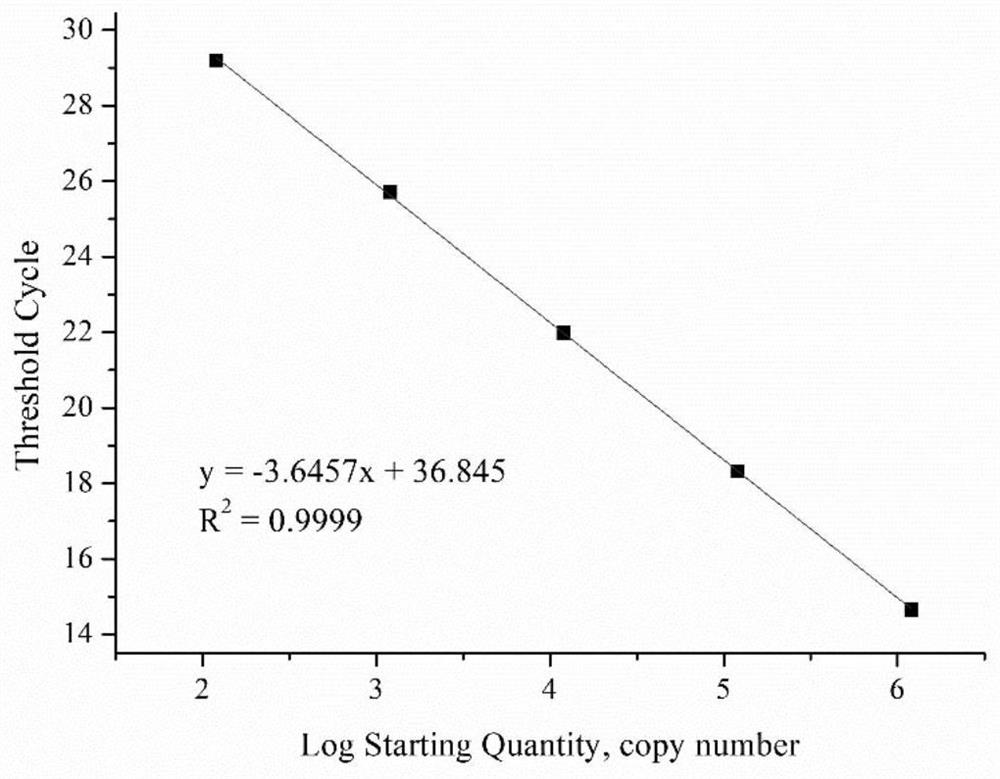

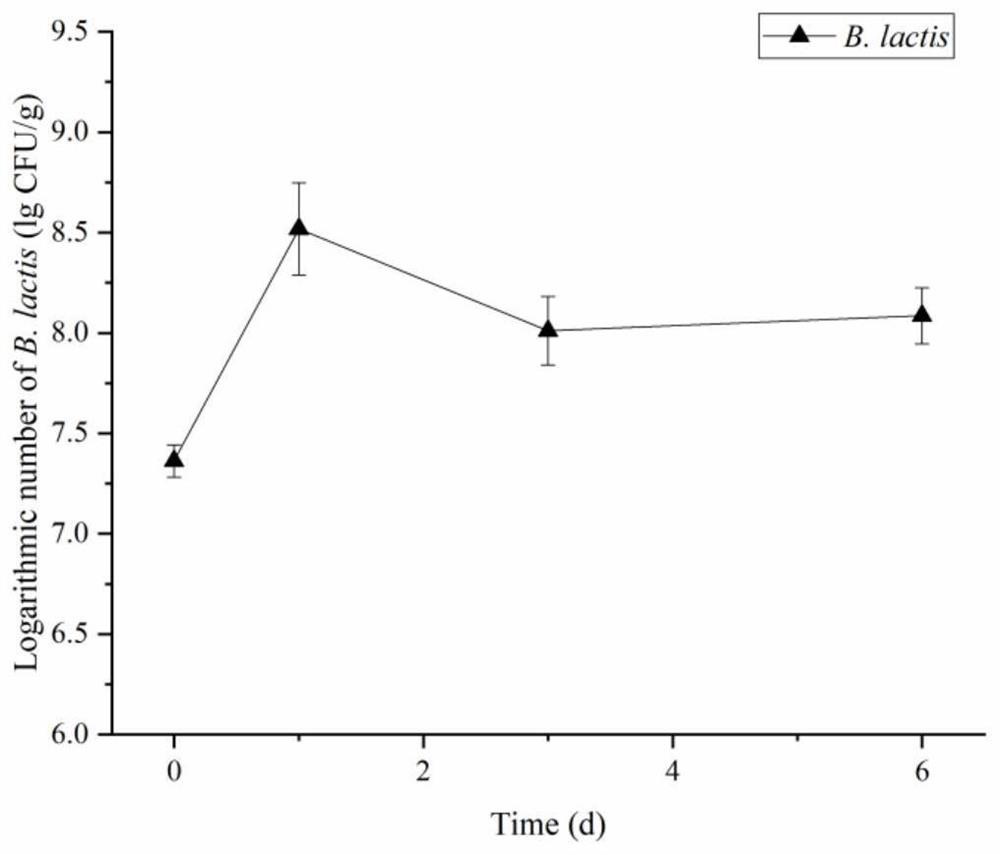

Production method of fermented feed rich in bifidobacterium lactis

PendingCN113475621AReduce lossesReduce manufacturing costFood processingFood preservationBiotechnologyBacilli

The invention belongs to the field of biological feeds, and particularly relates to a production method of a fermented feed rich in bifidobacterium lactis. The method includes the steps of activating strains to obtain a fermentation seed solution of bacillus subtilis, saccharomyces cerevisiae, the bifidobacterium lactis, bacillus coagulans and lactobacillus paracasei; and mixing soybean meal with bean dregs and wheat middlings to obtain a fermentation culture medium, and performing anaerobic fermentation under a sealed condition to obtain a finished product. According to the production method of the fermented feed rich in the bifidobacterium lactis, a mixed bacteria anaerobic fermentation mode is adopted, the bacillus subtilis, the saccharomyces cerevisiae and the bacillus coagulans are used for consuming residual oxygen in the environment at the initial stage of fermentation, the lactobacillus paracasei is rich in acid production, and environment pH suitable for growth is provided for the bifidobacterium lactis. Through the symbiotic synergistic effect of strains, the thallus density is increased, fermentation is thorough, the amount of the bifidobacterium lactis is high, the content of organic acid is rich, the palatability is good, and the economic benefit is high. A qPCR method is used for detecting the number of the bifidobacterium lactis in the fermented feed, so that the detection time is short, and the sensitivity is high.

Owner:浙江康星生物科技有限公司

Bean curd and bean curd production method

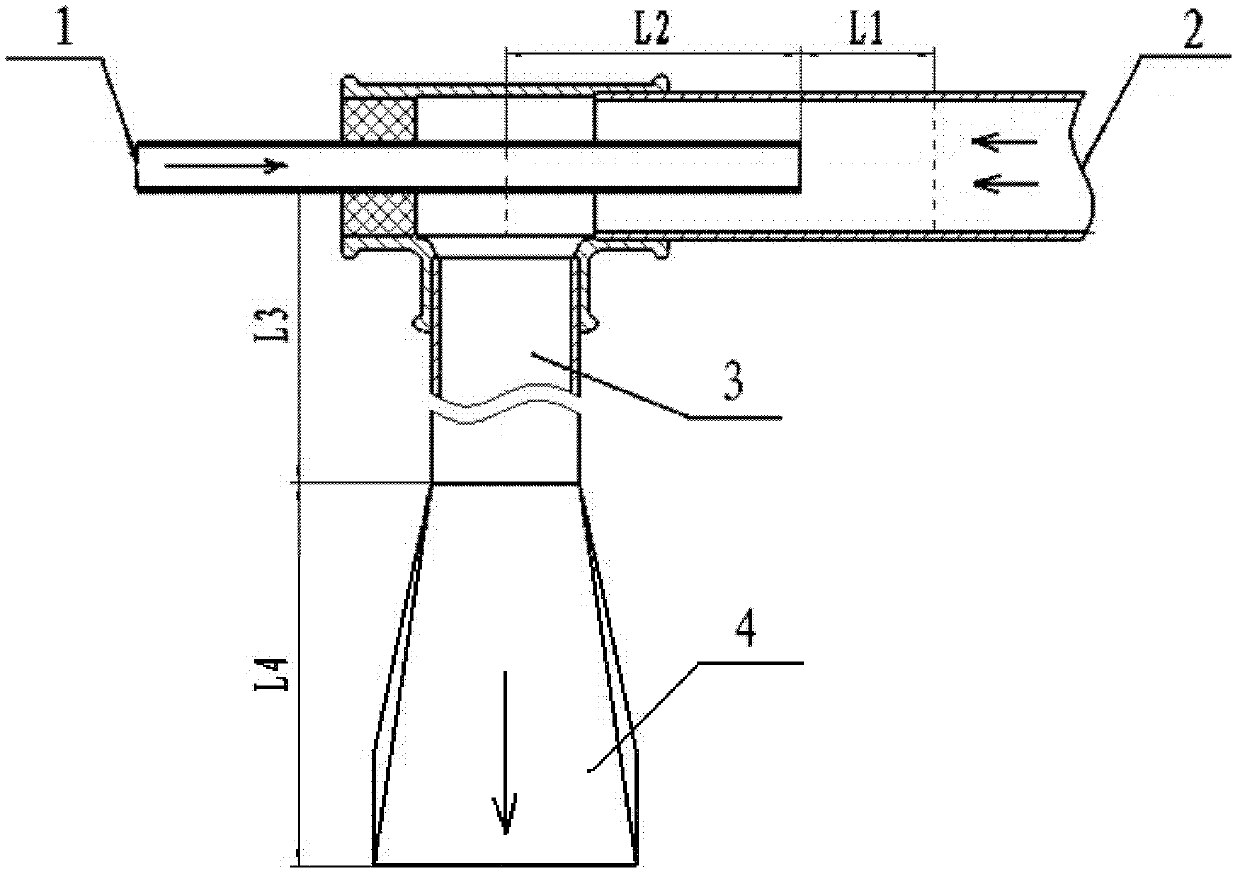

ActiveCN102524418BReduce processing timeShorten the soaking timeCheese manufactureFood scienceSewageMechanical engineering

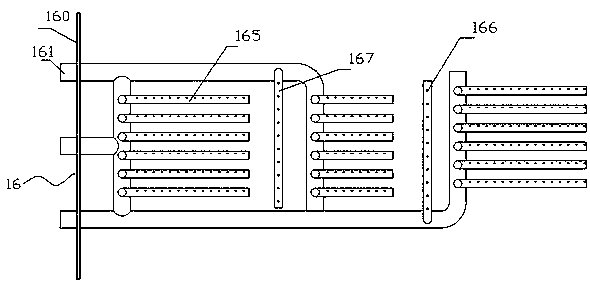

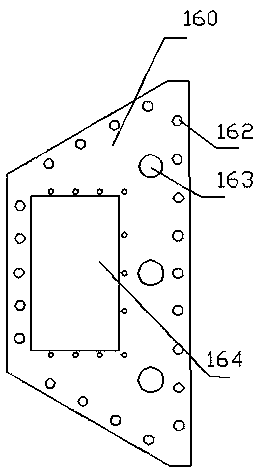

The utility model discloses a mixer, which is provided with at least one thin conveying pipe, a thick conveying pipe and a mixed pulp output pipe, wherein one end of the thick conveying pipe is closed, and the mixed pulp output pipe is communicated with the side wall of the thick conveying pipe close to the closed end and enables material flowing direction to be changed. At least one thin conveying pipe penetrates into the thick conveying pipe from closed end, a part of the thin conveying pipe penetrating into the thick conveying pipe is larger than a communicating port of the thick conveying pipe and the mixed pulp output pipe, and the part of the thin conveying pipe and the thick conveying pipe form partial overlap. The opening diameter formed from the communicating port of the thick conveying pipe and the mixed pulp output pipe to a discharging port is increased. The mixer overcomes a plurality of defects of the prior art and achieves efficient and stable mixing of two fluids with large flow-quantity difference.

Owner:FOODSTUFF INST BEIJING

A kind of separation method of mixed carbon four

ActiveCN102992933BIncrease profitReduce manufacturing costChemical industryDistillation purification/separationButeneHigh concentration

The invention discloses a separation method for mixed C4, which comprises the following steps of separating butene and butane from mixed C4 through extractive distillation, wherein the mixed C4 contains n-butane, iso-butane, 1-butylene and 2-butylene after removal of components such as C3, butadiene, alkyne, isobutene, C5 and the like, furthermore, separating to obtain iso-butane, 1-butylene and 2-butylene and the byproduct of crude n-butane through ordinary distillation, wherein the solvent for extractive distillation is publicly known in the industry, non clear-clear separation method is adopted in extractive distillation technology, namely, the combination of preextraction distillation and extractive distillation. Due to the adoption of the separation method, after the mixed C4 is processed, products of iso-butane, 1-butene and 2-butene of high concentration can be obtained simutaneously, therefore, the separation method has the advantages of being energy-saving, good in economic efficiency, high in resource utilization rate, and the like, reducing the cost and is of great significance in comprehensive utilization of mixed C4 resource.

Owner:EAST CHINA ENG SCI & TECH +1

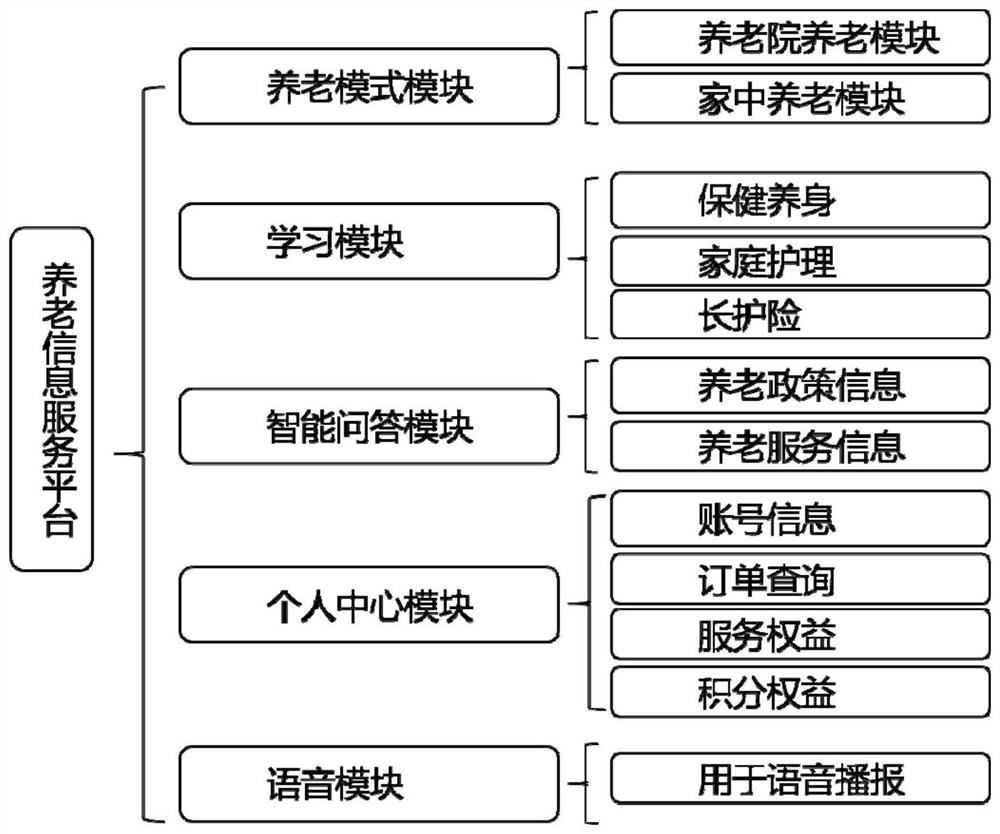

Pension information service platform

PendingCN113361735AEasy to useMeet functional requirementsMedical communicationDiscounts/incentivesDaily livingHome care nursing

A pension information service platform relates to the field of pension informatization platforms. Through a home-based care module and a nursing home care module, home care service, care institution service, meal assisting service, home service and night care service are provided for the elderly. A learning module is used for providing information about health-care and health-preserving home nursing and long-term care insurance; an intelligent question and answer module is used for displaying and answering old-age nursing policy information and old-age nursing service information; a personal center module comprises account information, order query, service rights and interests and point rights and interests. A voice module is used for performing voice explanation on characters in the platform. Through the design of converting daily life of the old people into scene service, functional requirements in different scenes are met, and personalized and diversified products and services are provided for the old people.

Owner:无锡镜子信息技术有限公司

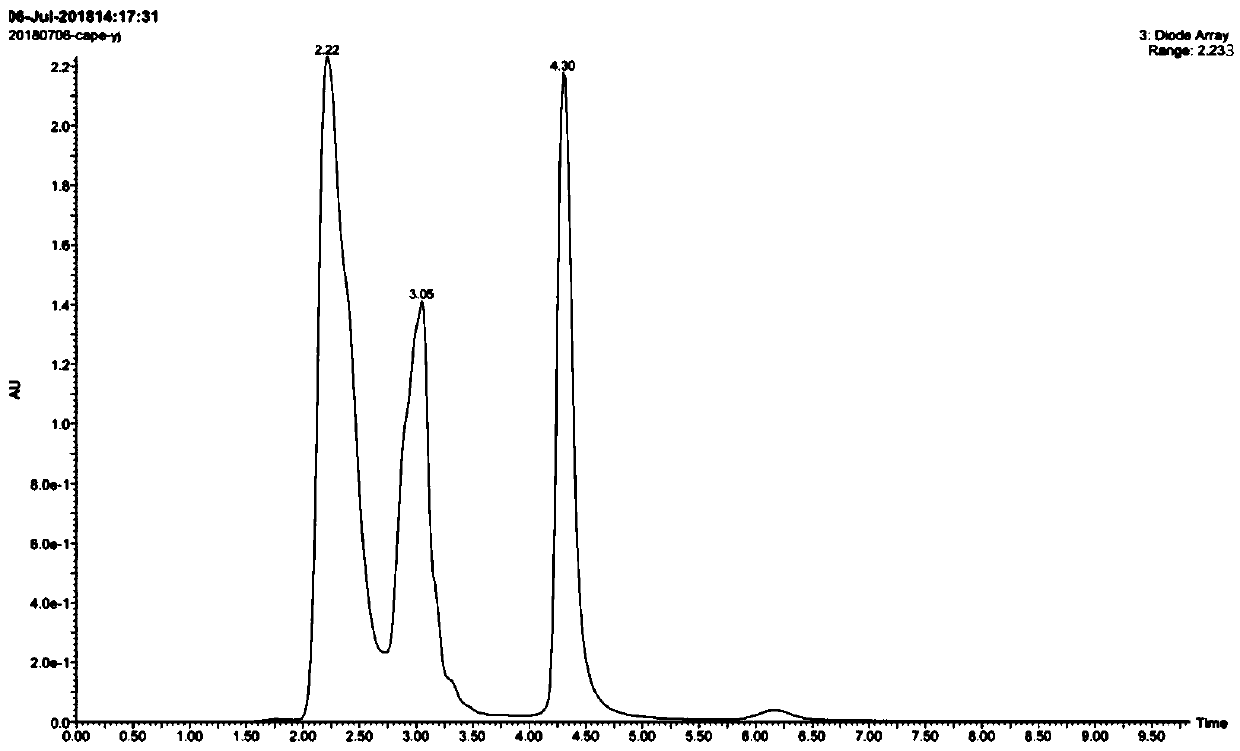

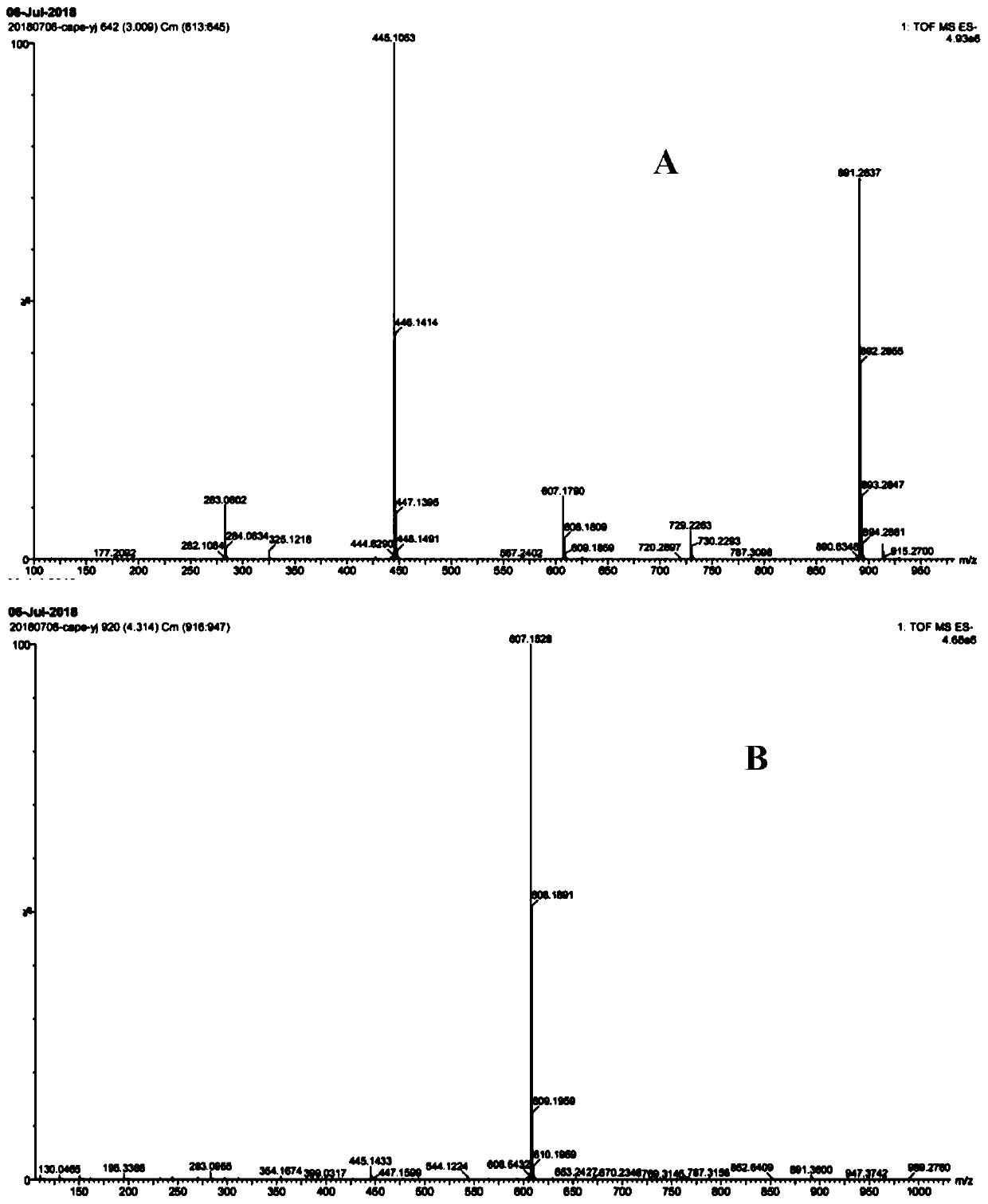

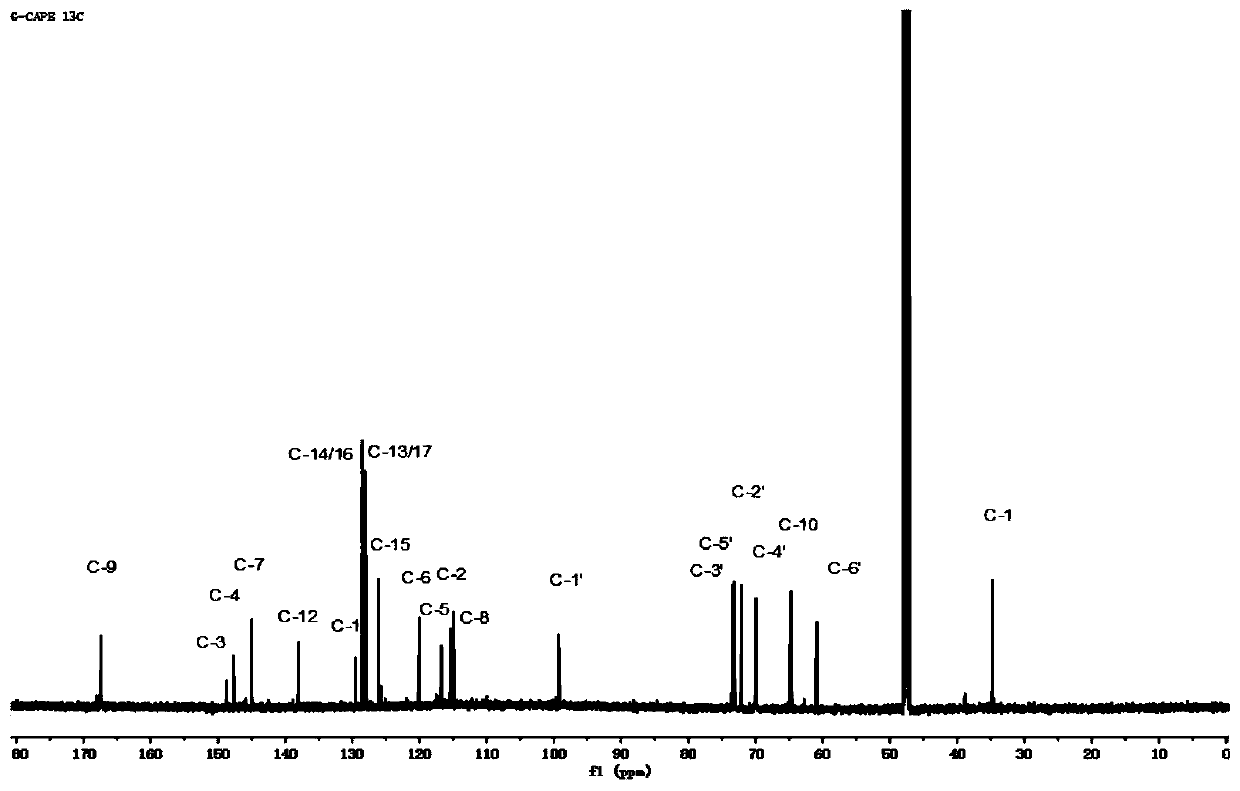

Glycosylation application of dextransucrase and method for preparing phenyl ethyl caffeate glycoside from dextransucrase

PendingCN110117630AImprove biological activityReduced bioavailabilityFermentationChemical industryPhenethyl caffeate

The invention discloses application of dextransucrase to glycosylation of phenyl ethyl caffeate and a method for preparing phenyl ethyl caffeate glycosides from the dextransucrase, and relates to thefield of the enzyme chemical industry. The dextransucrase is added to a buffering solution with the phenyl ethyl caffeate and a glycosyl donor for catalysis treatment, and the phenyl ethyl caffeate glycosides can be obtained after purification. By means of the method, the blank of the application of the dextransucrase to the glycosylation of the phenyl ethyl caffeate is filled up; the prepared phenyl ethyl caffeate glycosides are high in water solubility and anti-inflammation activity, and the problem that phenyl ethyl caffeate is difficult to apply is solved; in addition, by means of the method, the two types of phenyl ethyl caffeate glycosides can be obtained at the same time, the method is simple, products are rich, cost is low, and universality is high.

Owner:HEFEI UNIV OF TECH

Making method for sand rice bean jelly

ActiveCN106360713AIn line with the market demand for developmentEasy to operateFood ingredient as mouthfeel improving agentNutritive valuesHigh volume manufacturing

The invention discloses a making method for sand rice bean jelly. The making method comprises the following steps: cleaning and airing the seeds of the sand rice; performing the peeling treatment to the aired seeds of the sand rice by using a huller, and repeatedly washing the seeds of the sand rice by using clear water after the peeling treatment so as to peel completely; soaking the complete peeling seeds of the sand rice in cold water; pouring the soaked seeds of the sand rice and the soaking liquid into a beater in batches and smashing to be liquid-shaped, and filtering and removing the impurities; pouring the filtered sand rice pulp into a cooker, adding certain amount of the cold water to the cooker, heating to be boiled by using slow fire and adding table salt, using an automatic stirrer to stir to be pasty at the same time, pouring into a container for storing, and obtaining the sand rice bean jelly after cooling to be the room temperature. The provided making method has the characteristics of simple operation, time saving and labor saving, and is capable of producing the sand rice bean jelly in large batch. The sand rice bean jelly made by the making method has the advantages of good taste, fine and smooth feeling and high nutritive value.

Owner:GANSU DESERT CONTROL RES INST

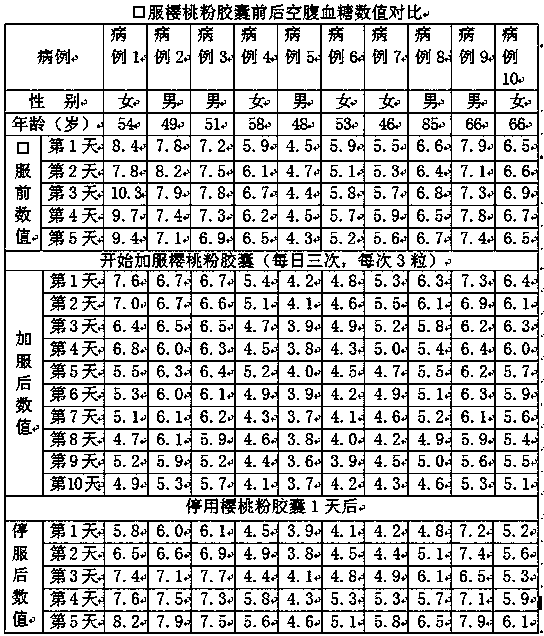

Preparation method and purpose of cherry powder for controlling diabetes

InactiveCN108785411APromote generationFull of nutritionMetabolism disorderAntipyreticPharmacologic actionDistillation

The invention relates to a preparation method and purpose of cherry powder for controlling diabetes. The preparation method is characterized in that the cherry powder preparation steps comprise crushing, fermentation, distillation and desorption drying. The preparation method is used, so that cherry wine with the effects of removing wind and dampness and promoting blood circulation to arrest painis obtained; in the fermentation process, under the condition that other nutritions of fresh cherries are not damaged, partial sugar contained in the fresh cherries becomes ethyl alcohol through conversion and is separated out; the cherry powder which can be trustingly eaten by diabete patients, has rich nutrition, can promote the insulin generation and can reduce the blood glucose is obtained. The preparation method has the advantages that the process is simple; the raw materials are comprehensively used; the yields are many; the yield is high; the cost is low; the preparation method is applicable to scale production, and the like. The cherry powder is used for controlling the diabetes; the prominent biological activity and pharmacologic action are realized in the aspects of treating thediabetes, preventing and controlling angiocardiopathy and the like. The cherry powder is applicable to the fields of food and health care products.

Owner:蔡超

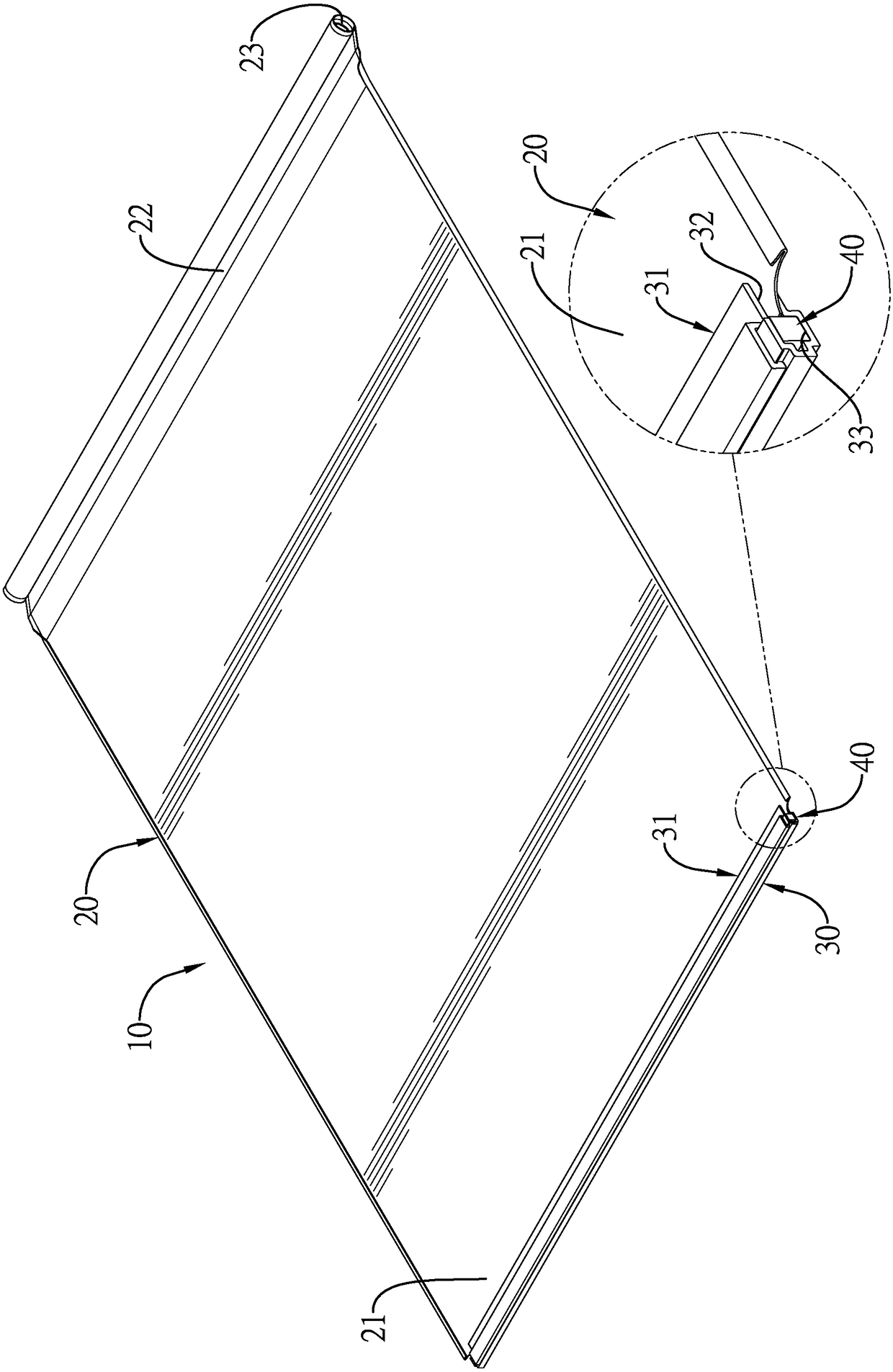

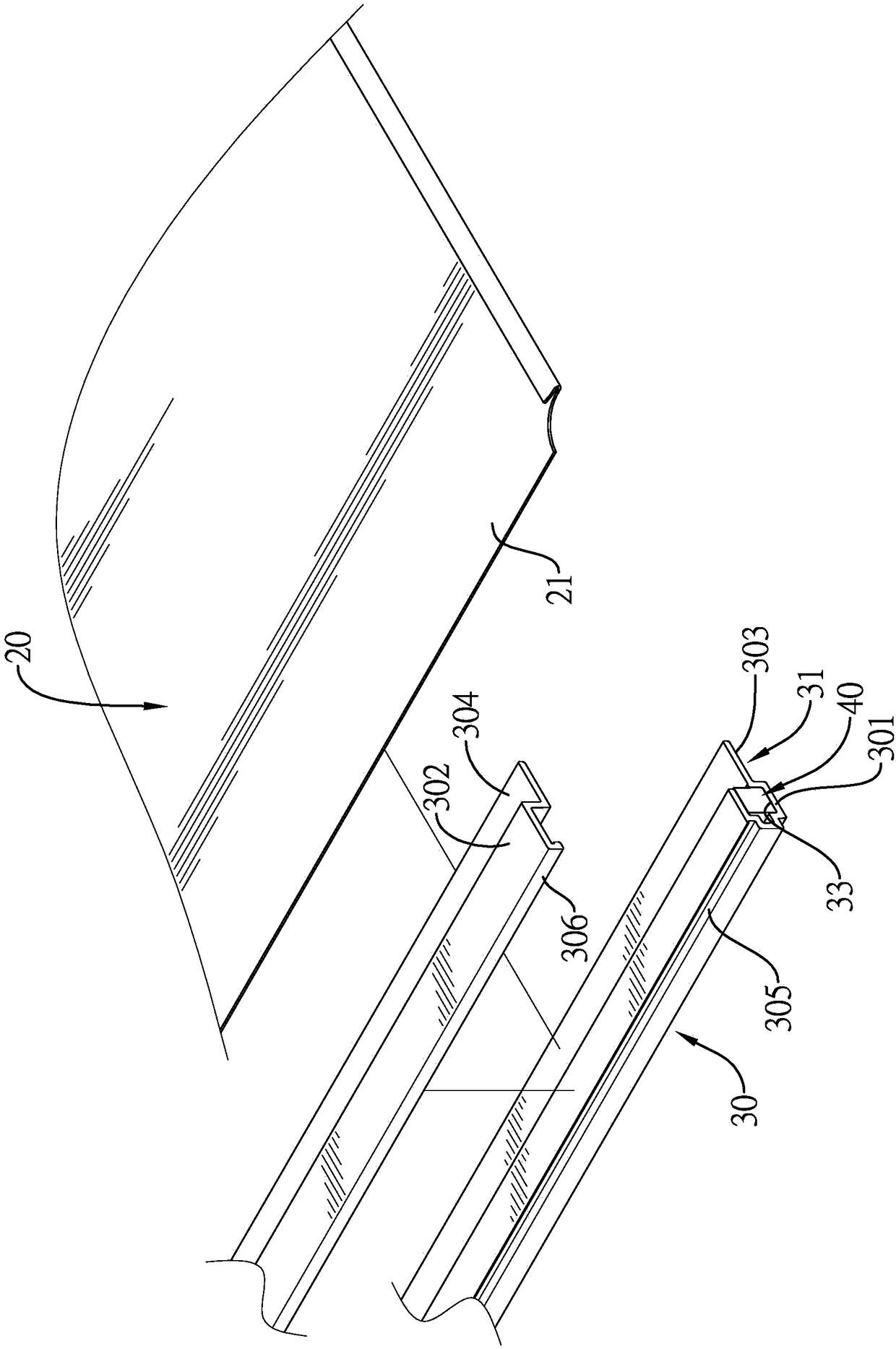

Luminous cloth curtain device

ActiveCN108068591AUnique product differentiationProduct diversificationWindowsWindscreensEngineeringLight guide

The invention relates to a luminous cloth curtain device. The luminous cloth curtain device comprises a piece of luminous curtain cloth provided with a plurality of light guiding fibers, a curtain cloth edge piece and a luminous assembly. The curtain cloth edge piece is arranged on one side of the luminous curtain cloth. The luminous assembly is arranged in the curtain cloth edge piece and can cast light towards the ends of light guiding fibers of the luminous curtain cloth. The luminous cloth curtain device can be applied to products such as an automobile sunshade curtain or an object shade curtain, except providing functions of shading sunlight or covering, the luminous curtain cloth can also make use of light rays emitted from the luminous assembly installed in the curtain cloth edge piece to glow the luminous cloth curtain through the multiple light guiding fibers of the luminous curtain cloth, and illumination and decorative effects are generated. The luminous cloth curtain devicecan also be changed, designed or customized by combining the light guiding fiber layout pattern of the luminous cloth curtain with coloured light of the luminous assembly, so that the purpose of product diversification is achieved.

Owner:MACAUTO IND CO LTD

Meat sandwich chocolate and making method thereof

InactiveCN108420009ANutritious and balancedProduct diversificationFood ingredient as coating agentNutrientTaste Sense

The invention discloses a meat sandwich chocolate and a making method thereof. The meat sandwich chocolate comprises the following raw materials in parts by weight of 100 parts of meat, 100 parts of finished product chocolate, 50 parts of water, 25-26 parts of white granulated sugar, 5-6 parts of sodium lactate, 2-3 parts of table salt, 2-3 parts of first-grade rapeseed oil, 1-1.5 parts of Baijiu,1-1.5 parts of spices and 0.5-0.6 part of monosodium glutamate. According to the meat sandwich chocolate, the chocolate and the meat are combined, so that a new functional leisure food is formed, twofoods having different flavor are matched in a border crossing manner, and bran-new taste sense experience is given to people; and the meat can also be blended into various taste of spiced taste, hottaste and the like according to free choice of personal taste, and the meat sandwich chocolate is good in mouth feel and rich in nutrients.

Owner:唐波

Production method of bacillus subtilis biological agent used for sodium humate-containing feed in medium

ActiveCN103184174BChoose appropriateNew technologyBacteriaAnimal feeding stuffBacterial strainFermentation

Owner:SHENYANG BOSHAN YINGSHENG BIOLOGICAL TECH CO LTD

Method for reducing nickel ore by using reducing rotary kiln and producing ferronickel by rusting electric furnace

InactiveCN102168157BAdvanced technologyLow costRotary drum furnacesProcess efficiency improvementElectric arc furnaceSoutheast asia

The invention relates to a method for reducing nickel ore by using a reducing rotary kiln and producing ferronickel by rusting an electric furnace. The production method comprises the processes of: preparing raw materials, directly reducing via the rotary kiln, cooling via a cooling kiln, selecting, rusting, and smelting by the electric furnace. The method of the invention solves the technology problem of low grade and large beneficiation difficulty in the laterite-nickel ores in the southwest district of China and Southeast Asia district. By using the low grade ore, the ferronickel with nickeliferous grade >= 20-50% can be produced, the iron oxide red can be comprehensively recovered, and baking-free bricks can be produced by using waste slags. The method has high mechanization degree and automation degree, strong roguing performance, low production cost, and high nickel grade of the products, meanwhile the production technology also has characteristic of green and environment protection.

Owner:李维成 +1

A core-spun fireweed yarn and its preparation method and preparation device

ActiveCN112210857BProduct diversificationContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention relates to a core-spun fireweed yarn and its preparation method and preparation device. The core-spun fireweed yarn is composed of a core yarn and a covering yarn, and the covering yarn is twisted from fireweed fiber velvet; the preparation method is as follows: : After the fire grass leaves are conveyed to the bottom of the core yarn with the suede side facing up, the core yarn is pressed to make it contact with the fire grass fiber velvet on the fire grass leaves, and the core yarn is twisted while conveying the fire grass leaves Make it roll on the fire grass fiber velvet on the fire grass blade, cover the fire grass fiber velvet on the surface, twist the core yarn covered with the fire grass fiber velvet on the surface to obtain the core spun fire grass yarn, and collect the core spun yarn at the same time Fireweed yarn; the preparation device includes a transmission assembly (including a mesh conveyor belt and a negative pressure suction device), a hook fiber assembly (including a hook fiber licker-in roller), a core assembly (including a pressure belt), a twisting assembly (for The core yarn that the surface is covered with fireweed fiber suede is twisted) and the winding assembly. The method and device of the invention are simple and can efficiently and automatically prepare the core-spun fireweed yarn.

Owner:DONGHUA UNIV +1

Preparation method of snow pear fermented alcoholic drink and snow pear brandy

InactiveCN111019792AProduct diversificationRich choiceFungiAlcoholic beverage preparationPomaceFermentation

The invention discloses a preparation method of snow pear fermented alcoholic drink and snow pear brandy. The method comprises the steps of sorting, juice-residue separation, enzymolysis, clarification, snow pear juice fermentation, tank pouring, snow pear residue fermentation, distillation, aging, clarification and storage, thereby solving problems of relatively single snow pear wine product, waste of peel and residue resources and low storage stability. According to the invention, the snow pear juice and the peel residues are fermented respectively by yeast screening to obtain snow pear fermented alcoholic drink with characteristics of golden and bright color, elegant fragrance, good typicality and harmonious taste. Meanwhile, the snow pear brandy obtained by fermenting and distilling the peel pomace is rich in fragrance and pure in taste; and the fragrance and nutritional ingredients in the peel pomace are better utilized.

Owner:LUZHOU PINCHUANG TECH CO LTD

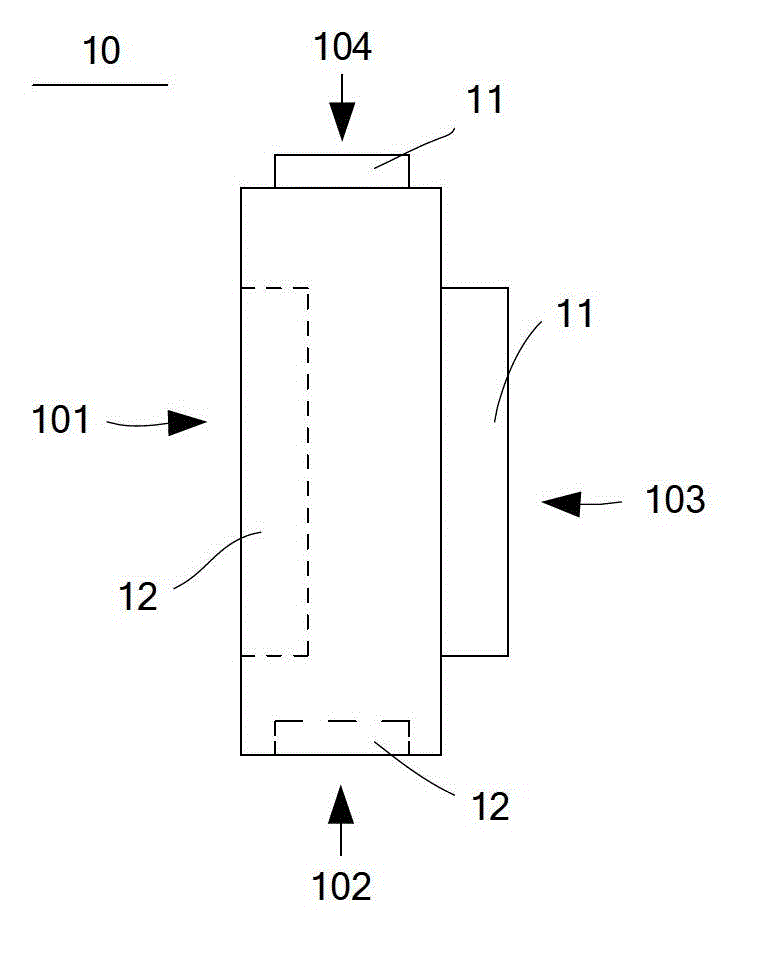

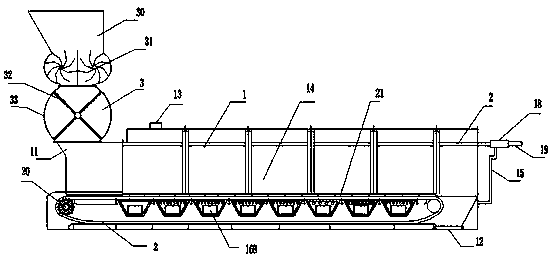

Method and device for biomass aerobic carbonizing and decomposing

The invention discloses a method and a device for biomass aerobic carbonizing and decomposing. The method comprises the following steps of sending the dried biomass raw material into a carbonizing furnace to ignite, carbonize and decompose; leading oxygen gas into the carbonizing furnace, so that the content of oxygen gas in the carbonizing furnace is 8% to 15%; cooling the produced solid, and storing; filtering the produced gas, cooling and decoking. The device comprises the carbonizing furnace and a conveying device, wherein the carbonizing furnace comprises a furnace body and a gas supply main pipe; the conveying device is arranged in the furnace body; the biomass falls onto the conveying device via a material inlet of the furnace body; the conveying device is used for conveying the biomass; in the conveying process, the biomass is carbonized and decomposed; the carbonized and decomposed biomass charcoal is conveyed to a material outlet of the furnace body by the conveying device, and is discharged out by the material outlet of the furnace body; the gas produced in the carbonizing and decomposing process is exhausted out of the gas outlet of the furnace body. The method and thedevice have the advantages that the products are diversified, the carbonizing efficiency is high, the device is simple, the control is easy, the land occupation area is reduced, and the cost is obviously reduced.

Owner:四川大宇中和生物质能源科技有限公司

A kind of compound amino acid nutrition package and preparation method thereof

ActiveCN105379967BNutrient consumption is sufficientFull of nutritionAccessory food factorsBiotechnologyArginine

The invention belongs to the technical field of microorganism fermentation and food nutrition, and particularly relates to a compound amino acid nutrition bag and a preparation method thereof. The compound amino acid nutrition bag is prepared from L-arginine, L-threonine, L-ornithine, L-lysine, L-proline, L-glutamic acid, L-valine, L-phenylalanine, L-leucine, organic protein and reducing sugar. The compound amino acid nutrition bag is rich in nutritional ingredient, green, healthy, fragrant and sweet in taste, diverse in type and capable of being widely applied to feed. The preparation method comprises the processes of L-arginine seed enlarge culturing, fermental culturing, micro-filtering for bacterium removal, concentration cream forming or concentration drying, and the preparation method is simple.

Owner:STAR LAKE BIOSCI CO INC ZHAOQING GUANGDONG

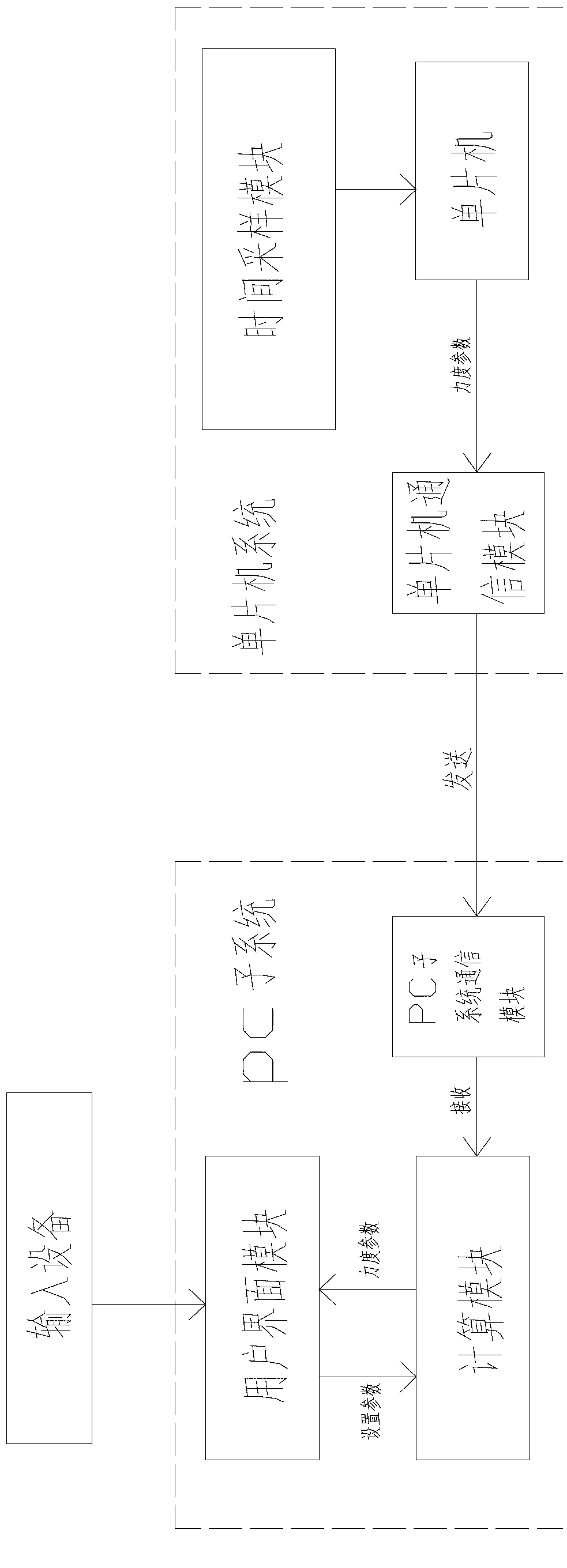

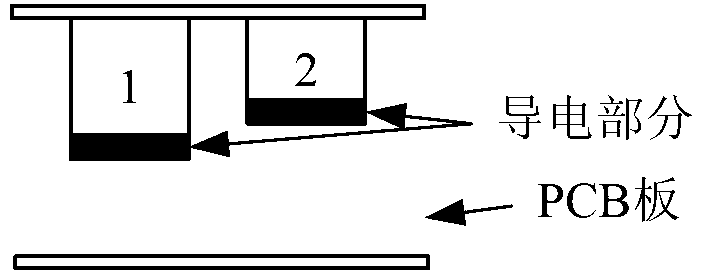

Test system of electronic organ keyboard force conformity

InactiveCN103137113AQuality assuranceProduct diversificationElectrophonic musical instrumentsMicrocontrollerKey pressing

The invention relates to a test system of electronic organ keyboard force conformity. The test system of the electronic organ keyboard force conformity comprises a single chip microcomputer system and a personal computer (PC) subsystem. The single chip microcomputer system is used for collecting button force musical instrument digital interface (MIDI) information of a keyboard and sending the button force MIDI information to the PC subsystem. The PC subsystem is used for receiving the force information of the single chip microcomputer system, comparing the force information of each whole button according to the result needed by a user to be displayed on a user interface so that a force value of each button and the whole comparison force conformity of the electronic organ keyboard are visually displayed. According to the test system of the electronic organ keyboard force conformity, the force conformity of the keyboard can be judged whether to be good or not, the quality is whether up to standard or not, meanwhile inoperative buttons can be also tested whether to exist or not and working conditions of the buttons. Therefore, in certain degrees, the electronic organ keyboard can be maintained beneficially. Through the test, the product quality is further guaranteed, and production and a product are improved.

Owner:RINGWAY TECH JIANGSU

A kind of preparation method of whole rice bud fermented drink

ActiveCN106942549BEnrichment of active substancesTake advantage ofYeast food ingredientsFood ingredient functionsBiotechnologyFood additive

A method for preparing a whole rice bud fermented drink, comprising the following steps: (1) preparation of rice buds; (2) pulping of rice buds; (3) sterilization; (4) saccharification of distiller's yeast; . The invention utilizes the whole grain raw material, transforms it into rice sprouts through germination technology, adopts koji saccharification, probiotic lactic acid bacteria and yeast symbiotic liquid direct-injection fermentation technology, so that the product has low alcohol and gas production, unique taste, sweetness, mellow aroma and flavor Full and soft, the process is simple and easy to control, the production cycle is short, and no food additives are added.

Owner:黑龙江省五常金禾米业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com