Guide hole water-permeable brick as well as brick machine mold and method for preparing same

A technology of permeable bricks and guide holes, which is used in molds, manufacturing tools, supply devices, etc., can solve problems such as poor water permeability and low strength, and achieve adjustable strength levels, compact matrix structure, and reduce the generation of invalid pores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention is further described.

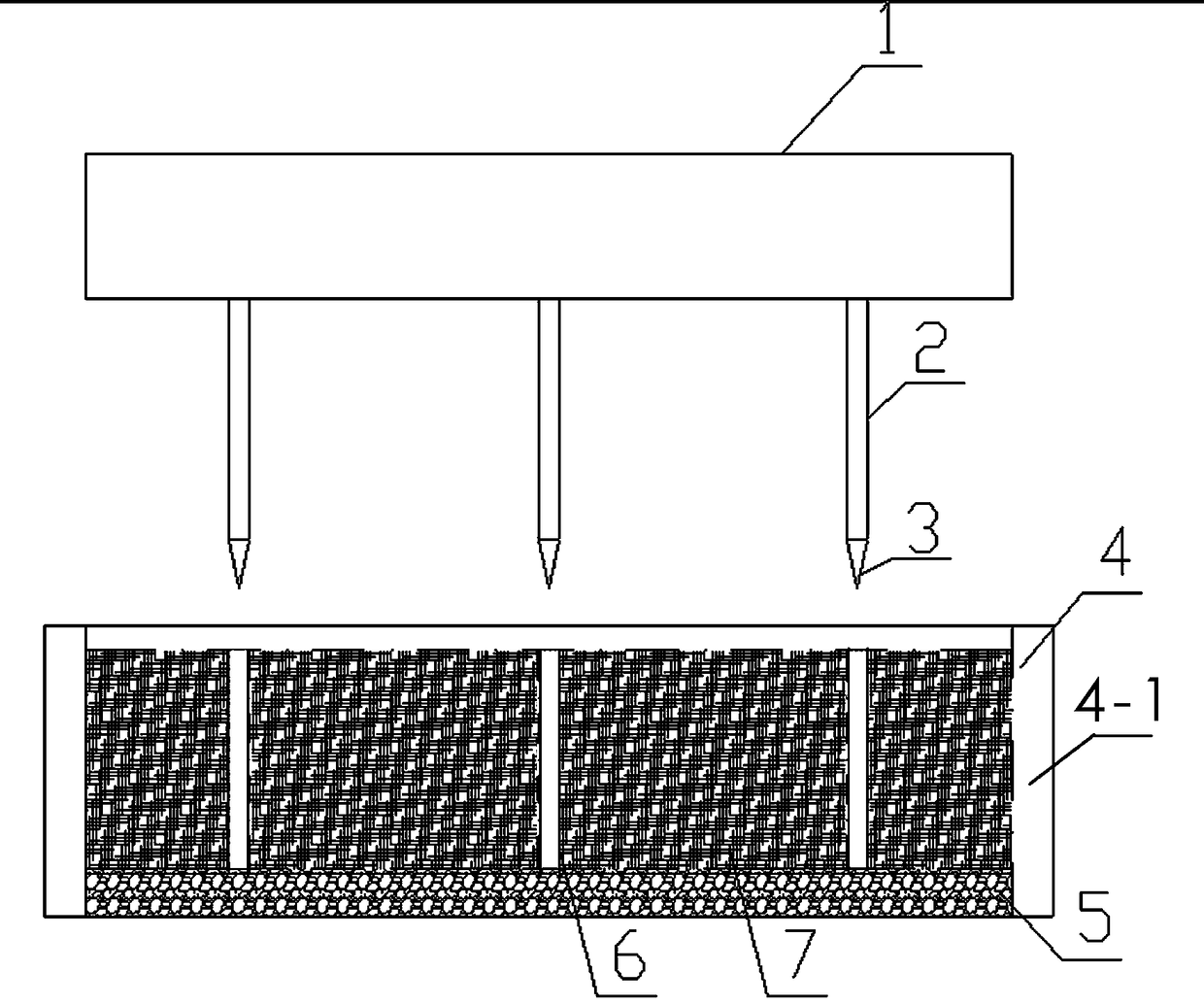

[0027] Such as figure 1 A guide hole permeable brick is shown, the permeable brick is composed of a guide hole permeable structure layer 7 and a porous water permeable surface layer 5, the guide hole permeable structure layer 7 is made with a water permeable guide hole 6, and the guide hole permeable structure layer occupies 80-90% of the thickness of the test piece mainly bears the external load of the test piece; the porous permeable surface layer mainly prevents the blockage of the permeable base of the guide hole.

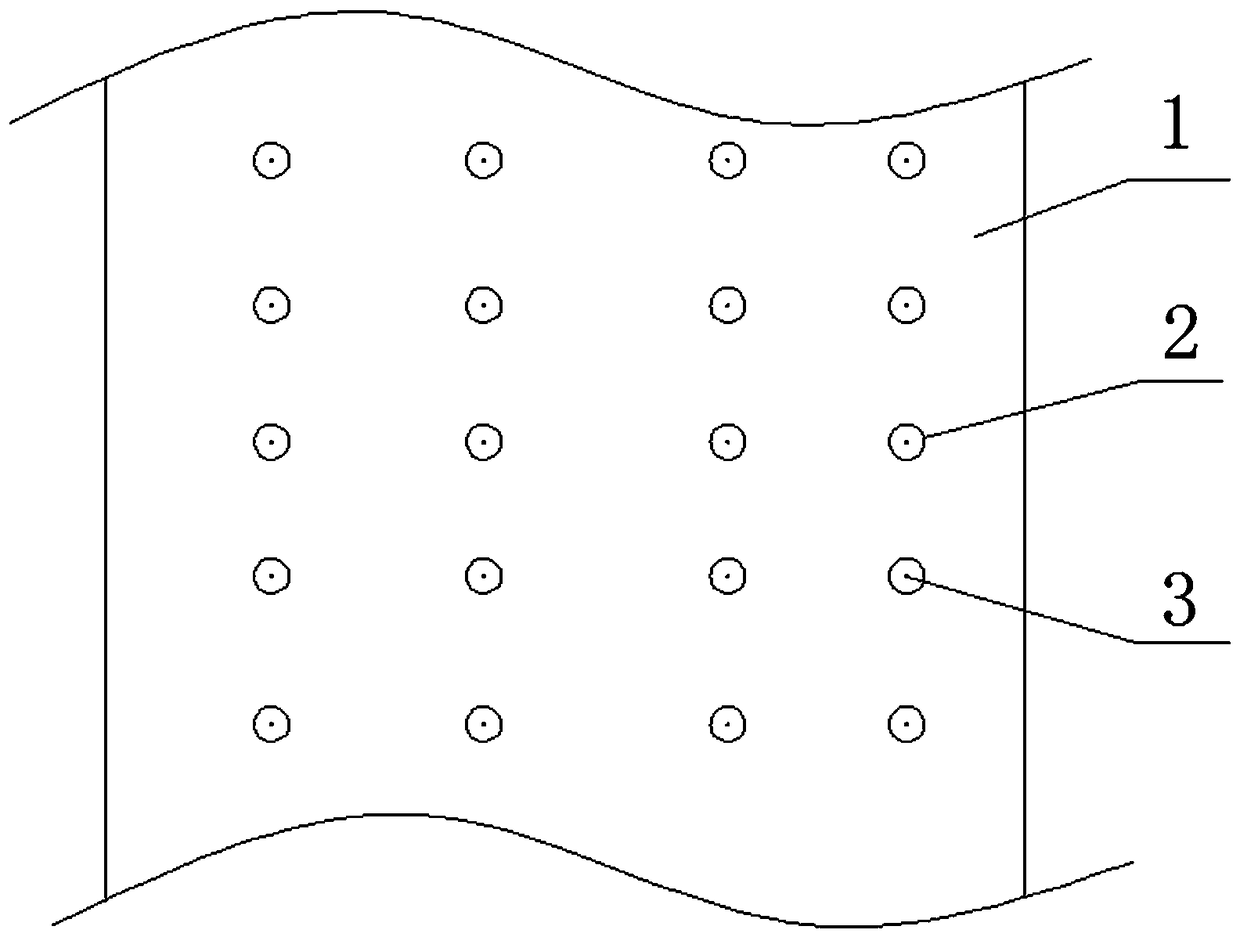

[0028] Such as figure 1 , figure 2 The shown brick machine mold for preparing guide hole permeable bricks with additional guide needles includes a brick machine lower mold 4 surrounded by side templates 4-1, and the upper part of the brick machine lower mold 4 is connected with the brick machine lower mold 4. Coordinated upper mold 1 of the brick machine, the bottom of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com