Method for producing zinc oxide and iron by treating zinc ore (slag) in reduction rotary kiln

A technology of rotary kiln and zinc oxide ore, applied in the direction of rotary drum furnace, furnace type, furnace, etc., can solve the problems of no recycling, waste of valuable metals, high production cost, etc., and achieve good environmental protection, good quality and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

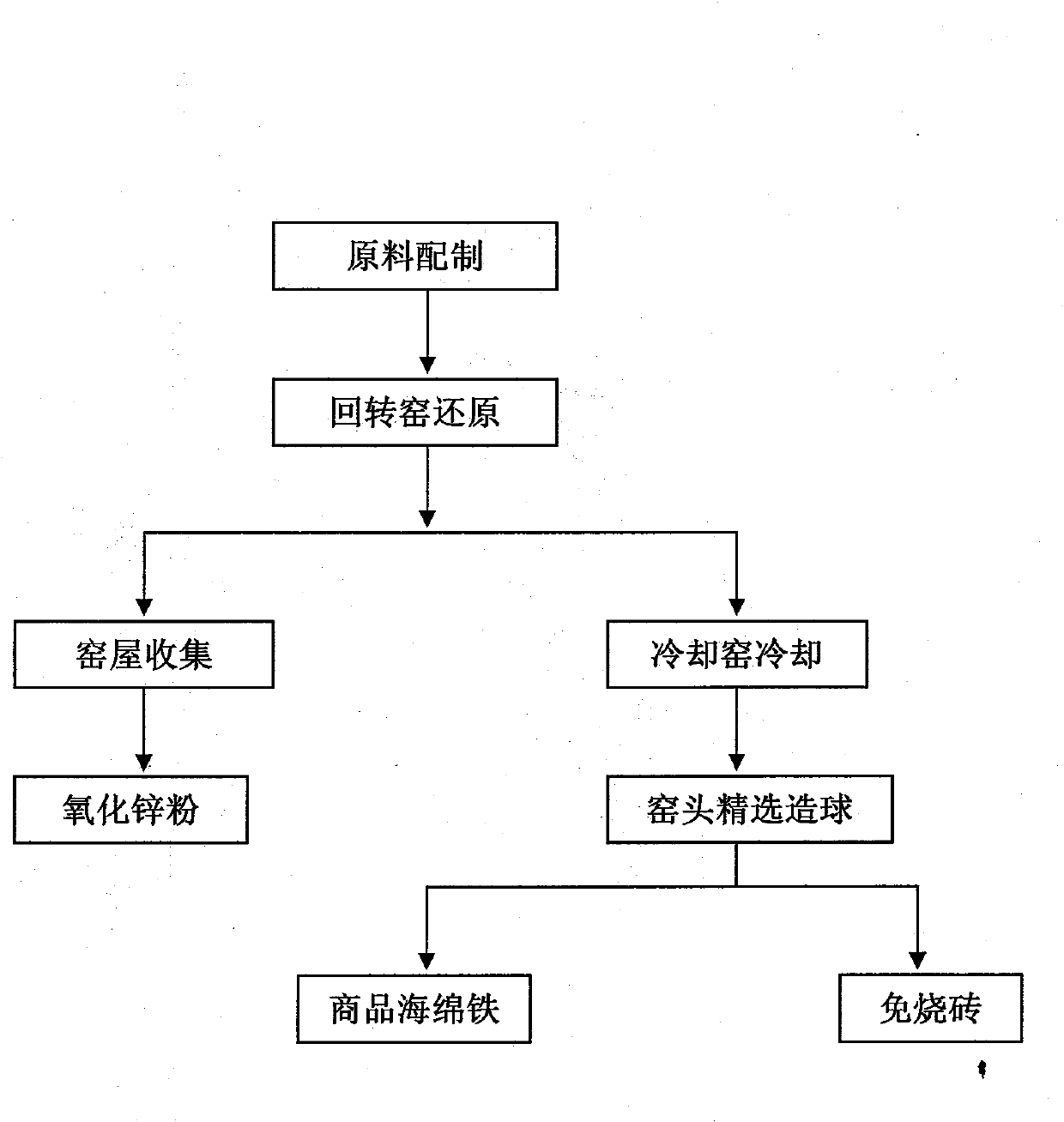

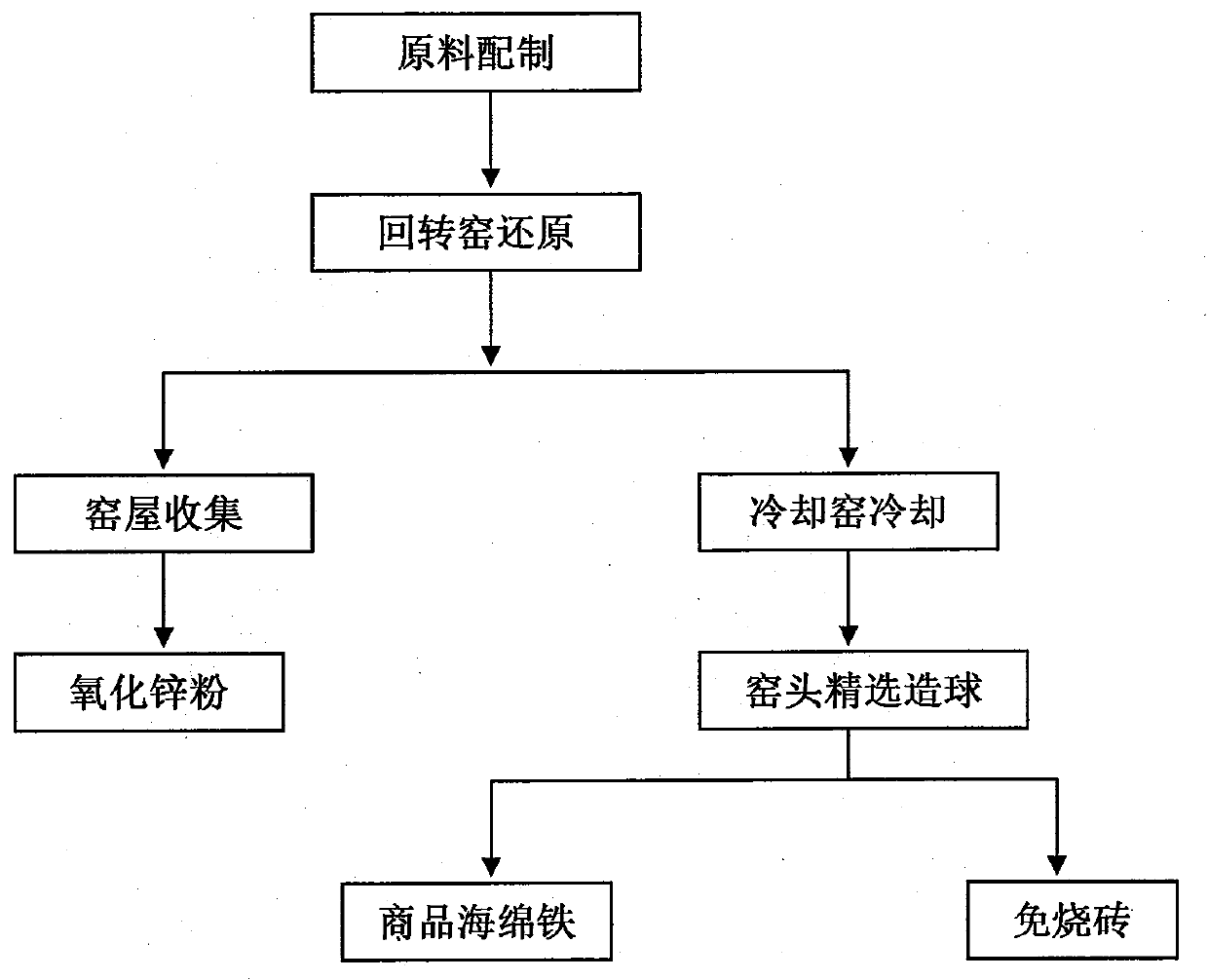

Method used

Image

Examples

Embodiment Construction

[0024] A. Raw material preparation

[0025] The ore (slag) containing S<4%, iron 5-45%, oxide 3-46% and rich in copper, lead and silver is used as the base material.

[0026] Select coal with sulfur content < 0.3%, phosphorus < 0.03%, calorific value ≥ 6000 kcal / kg, coking index < 2-3, volatile matter ≥ 34% as reduction coal and coal injection as fuel, and pulverize the coal with particle size ≤ 15mm .

[0027] Lime containing sulfur<0.3%, phosphorus<0.03% is selected as the desulfurizer, the particle size of lime is less than 2mm, and the weight ratio of iron-containing zinc oxide ore (slag), reduced coal and lime is: ore (slag) 15~ 88 parts, 3 to 16 parts of reduced coal, and 0.15 to 2.5 parts of lime.

[0028] In the present embodiment, 88 parts of raw ore (slag), 8 parts of reduced coal and 1 part of lime are taken.

[0029] B. Direct reduction in rotary kiln

[0030] According to the weight ratio of the components, mix iron-containing zinc oxide ore (slag), reduced co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com