Bean curd and bean curd production method

A production method and tofu technology, applied in the food field, can solve the problems of complex equipment, high cost, rough tofu, etc., and achieve the effects of shortening soaking time and fine structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The northern bean curd production method that the embodiment of the present invention one provides, comprises the following steps:

[0044] 1) The crushed soybean cotyledon crumbs from which the germ and bean skin have been removed are used as raw materials; the crushed soybean cotyledon crumb used is to crush the soybean raw material before pulping to remove the germ and bean skin.

[0045] 2) The soybean cotyledon crumbs were mixed with water (water hardness 400mg / l CaCO 3 ) soaked at room temperature, the weight ratio of cotyledon crumbs to soaking water was 1:9 during soaking, the soybean cotyledon crumbs were soaked in water for 30 minutes, and the water absorption reached 1.2 to 1.3 times of the weight of soybean cotyledon crumbs, and the pulping was carried out. Adjust the pH to 6.8 after the slurry, remove the bean dregs to obtain raw soybean milk.

[0046] The bean soaking process of the present invention does not require hot air drying of raw soybeans for pee...

Embodiment 2

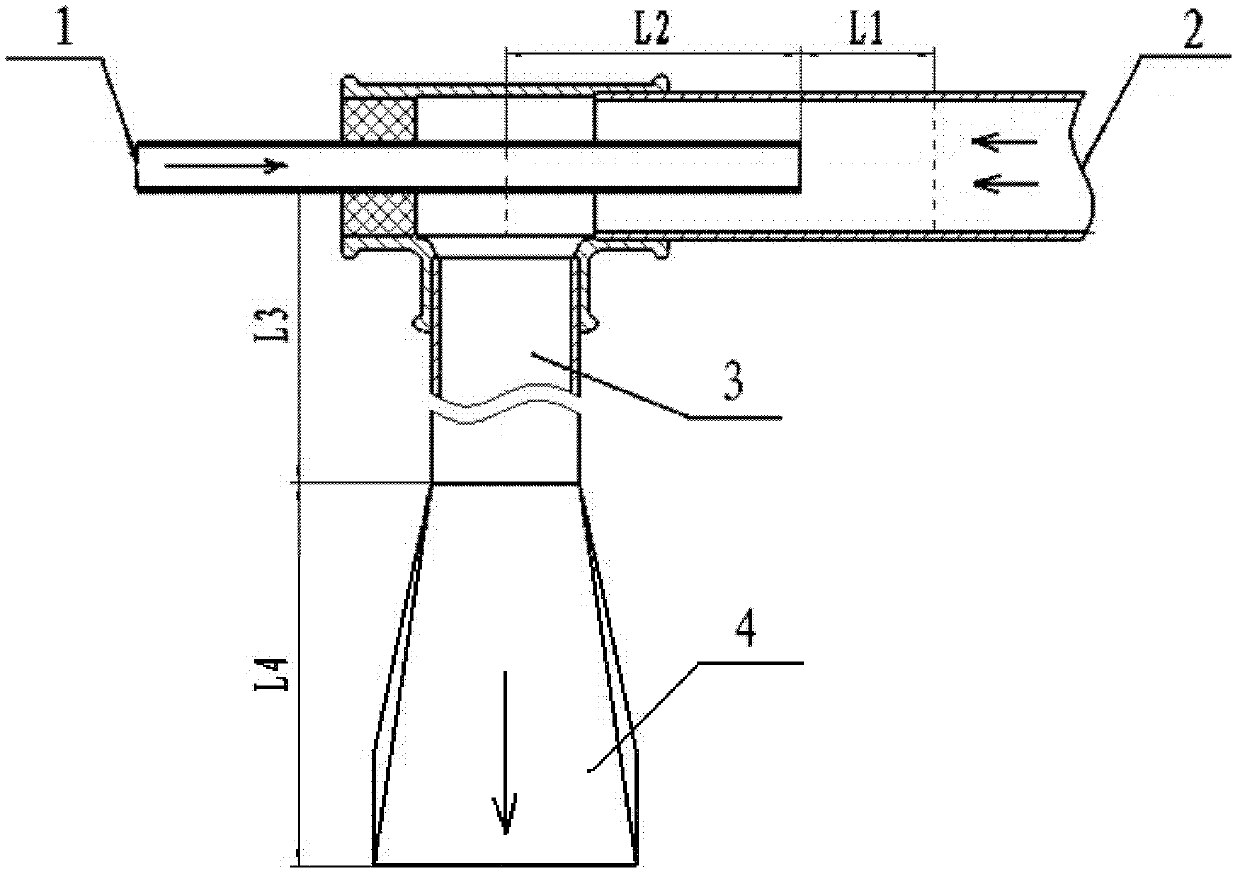

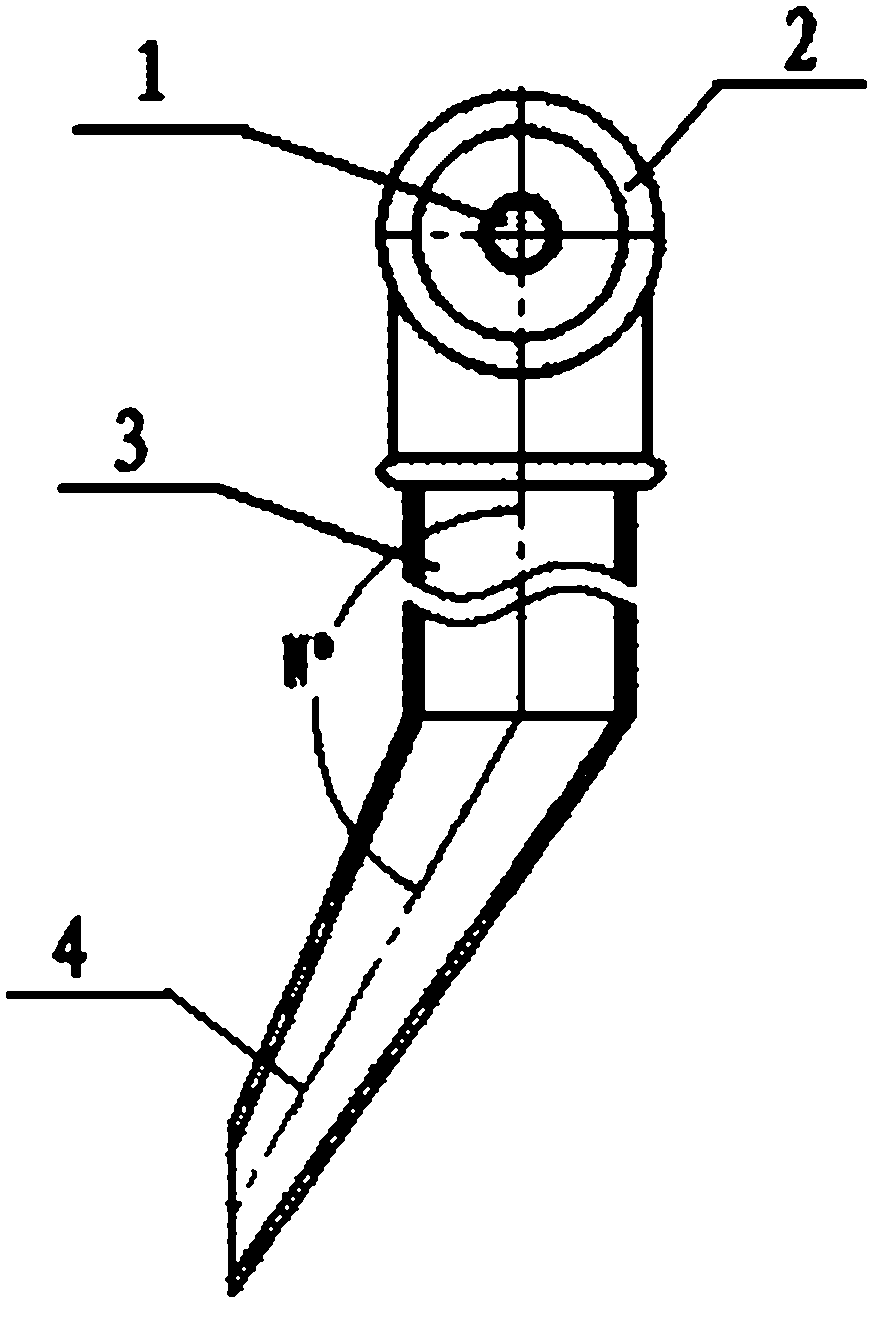

[0052] figure 1 The front view of the soya-bean milk-coagulant mixer that adopts for the embodiment of the present invention two; figure 2 for figure 1 left view of .

[0053] The preparation process of soybean milk is the same as embodiment one. The difference between this embodiment and embodiment one is that the mixing of soybean milk and coagulant adopts such as figure 1 and figure 2 The soymilk-coagulant mixer shown in the soymilk-coagulant mixer has at least one coagulant delivery pipe 1, a soya-bean milk delivery pipe 2 with a pipe diameter larger than the coagulant delivery pipe 1 and one end closed, and a soymilk delivery pipe 2 close to the soymilk delivery pipe 2. The side wall of the closed end communicates with the mixed slurry output pipe 3 that changes the flow direction of the material. The at least one coagulant delivery pipe 1 extends from the closed end of the soybean milk delivery pipe 2, and the coagulant delivery pipe 1 The protruding amount in the...

Embodiment 3

[0067] Adopt soya-bean milk and soya-bean milk-coagulant mixer identical with embodiment two. Mix soybean milk and coagulant at a volume ratio of 20:1, and the coagulant is MgCl 2 + An aqueous solution of glucono-delta-lactone containing 18 g of MgCl per liter of aqueous solution 2 10 g of glucono-δ-lactone (the molar concentrations are respectively: 0.2 mol / L, 0.05 mol / L). After adjusting the flow rate of the coagulant pump to match the soymilk, start the coagulant pump and the soymilk valve, so that the mixed liquid flows directly from the soymilk-coagulant mixer into the tofu box, seals it, and keeps it warm at 75°C for 15 minutes, which is the finished product. The elasticity of the tofu prepared in this example is better than that of the traditional northern tofu, the internal structure is delicate, and no yellow pulp is produced during the production process. Yield rate soybean: tofu = 1:8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com