Glycosylation application of dextransucrase and method for preparing phenyl ethyl caffeate glycoside from dextransucrase

A technology of phenethyl caffeate and dextran, which is applied in the field of enzyme chemistry, can solve problems such as difficulties in the application of phenethyl caffeate, and achieve the effects of rich products, good anti-inflammatory activity, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The preparation of embodiment 1 dextran sucrase

[0074] 1. Strain culture

[0075] The genetically engineered bacteria dex-YG-thMU01 (preservation number CGMCC No.12438) was inoculated into LB medium containing 50 μg / mL kanamycin, and cultured on a shaking table at 37°C and a rotational speed of 250r / min for 16h. Obtain the seed culture solution.

[0076] Use a pipette gun to draw 2ml of bacterial solution in the obtained seed culture solution and add it to medium A (glycerol 5g / L, glucose 5g / L, MgSO 4 ·7H 2 O 0.1mmol / L, peptone 10g / L, KNO 3 10g / L, Na 2 HPO 4 12H 2 O 17.1g, KH 2 PO 4 3g / L, NH 4 Cl 1g / L), cultured on a shaking table at 37°C and 250r / min to obtain a bacterial solution for enrichment culture.

[0077] 2. Induce enzyme production

[0078] Use distilled water to dilute the enriched bacterial solution 10 times. When the OD600 of the diluted solution reaches 0.25, about 3.5 to 4 hours, add 500 μL IPTG to induce enzyme production for about 4 hours ...

Embodiment 2

[0079] The preparation of embodiment 2 caffeic acid phenethyl ester glycosides

[0080] 1. Dextran sucrase catalyzes phenethyl caffeate

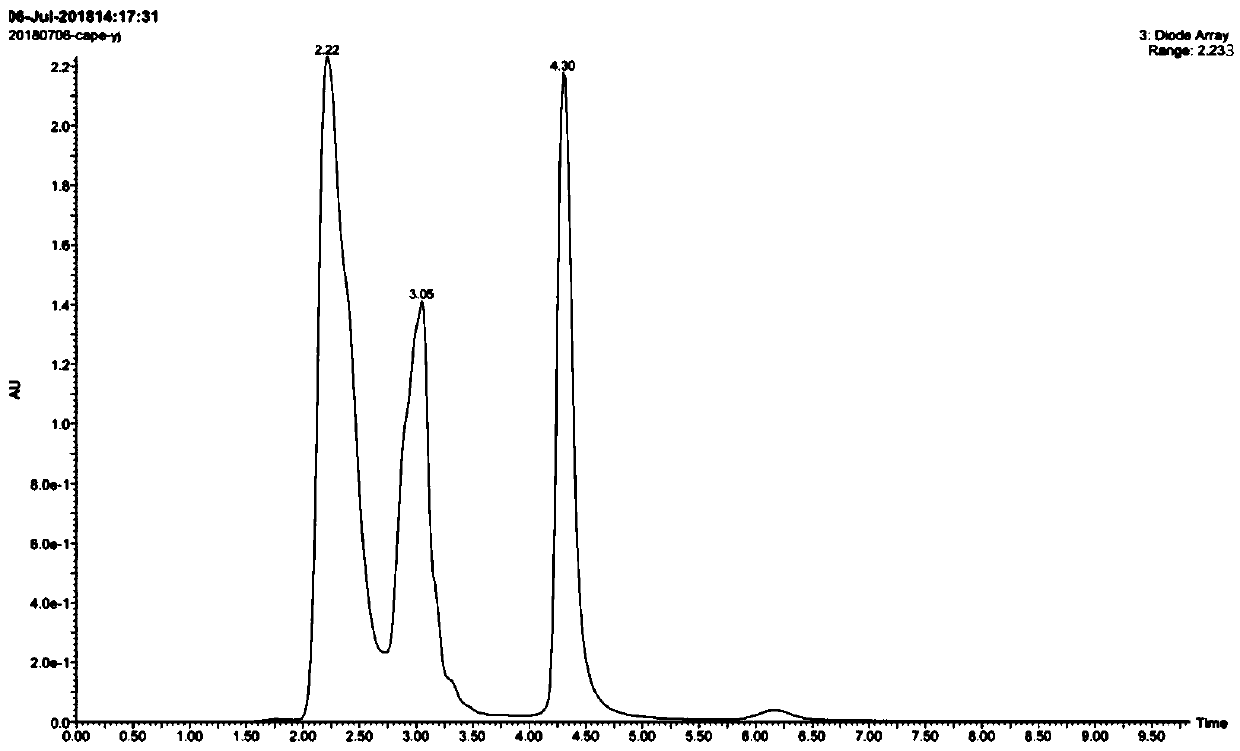

[0081] Add 0.5g (0.5%w / v) phenethyl caffeate and 30g (30%w / v) sucrose to a 250ml Erlenmeyer flask respectively, then add DMSO containing 10% (v / v), 100ml pH5. 5 of the acetic acid-calcium acetate buffer solution, after mixing, add 100 U of the crude dextran sucrase enzyme solution prepared in Example 1 to the conical flask, and catalyze the mixed solution in the conical flask at a temperature of 25°C After 24 hours, the product obtained after catalysis was mixed with an equal volume of ethanol solution for alcohol precipitation treatment, thereby removing the glucan glycoside by-products, collecting the supernatant, and filtering the supernatant through a microporous membrane with a pore size of 0.22 μM Afterwards, obtain the saccharified derivative of caffeic acid phenethyl ester, carry out high performance liquid chromatography analysis b...

Embodiment 3

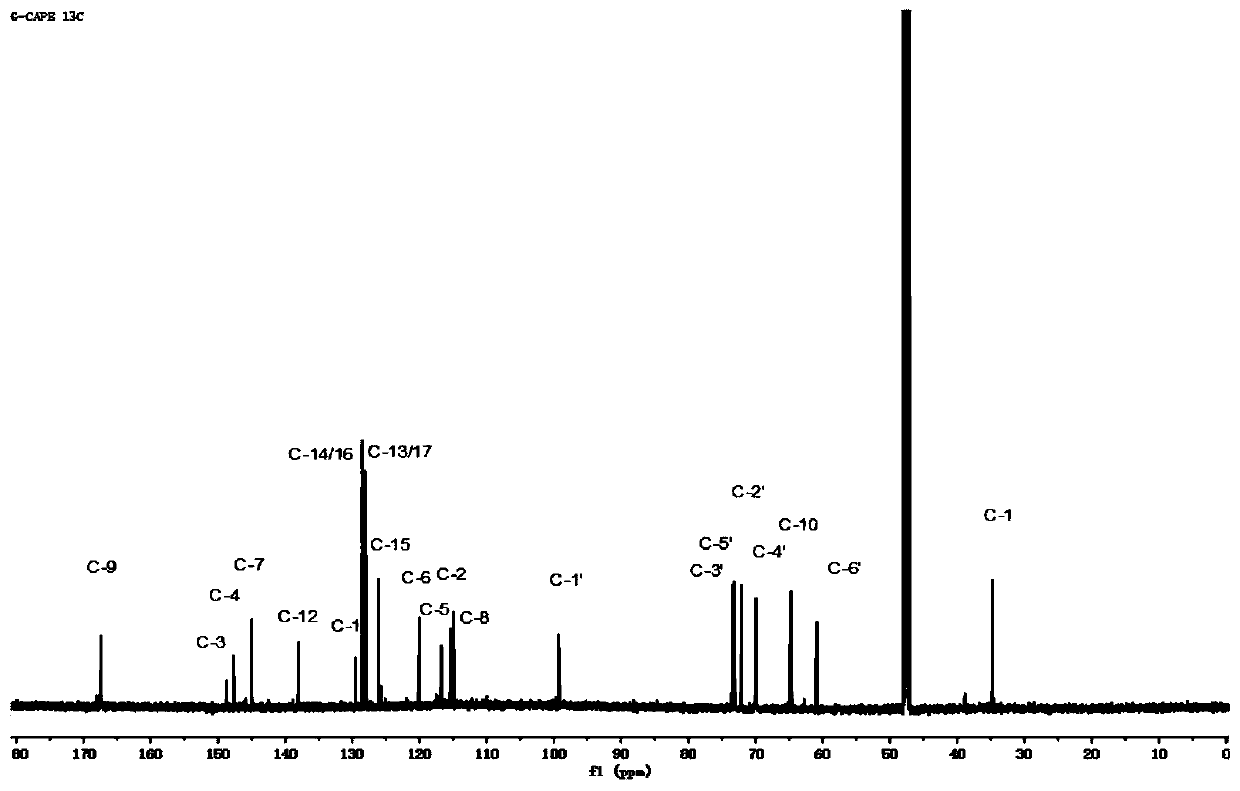

[0085] Identification and structural analysis of embodiment 3 glycoside products

[0086] 1. Identification of glycoside products

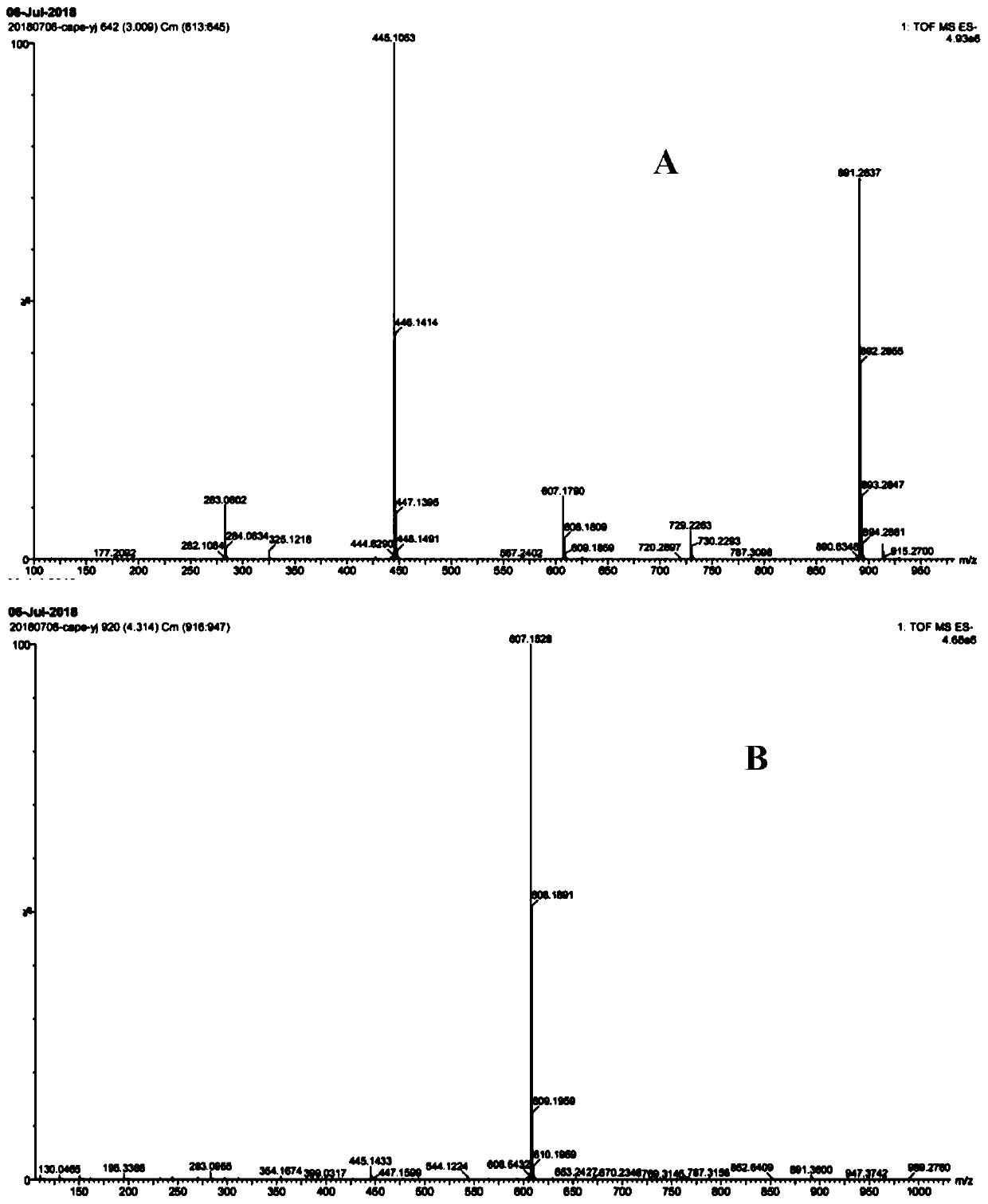

[0087] In order to verify that the obtained glycoside products are caffeic acid phenethyl ester monoglycoside and caffeic acid phenethyl ester diglycoside, the application for the above preparation process reactant caffeic acid phenyl ethyl ester, glucose and reaction product caffeic acid phenyl ethyl ester saccharified derivatives Mass spectrometry was carried out separately, and the results of mass spectrometry were as follows: figure 2 shown.

[0088] according to figure 2 The analysis results show that the molecular mass of phenylethyl caffeate is 283, and the molecular mass of glucose is 180. When the glucose molecule is combined with phenethyl caffeate, a molecule of water will be removed, so the molecular mass of the monoglycoside product is 445. The molecular weight of the glycoside product is 607, which is the same as figure 1 The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com