Method and device for biomass aerobic carbonizing and decomposing

A technology for biomass and biomass raw materials, which is applied in the fields of biofuels, educts, special forms of dry distillation, etc., can solve the problems of low efficiency, high cost, and different biomass gasification, and achieve good appearance, good quality, and product quality. various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

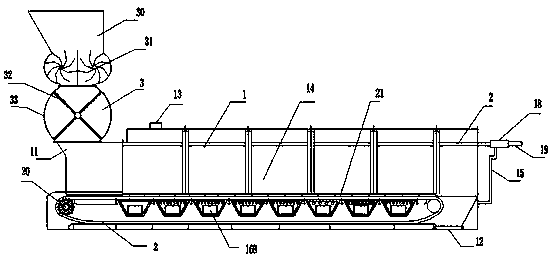

[0066]This embodiment provides a biomass aerobic carbonization decomposition method, which specifically includes: sending the dried biomass raw material into a carbonization furnace for ignition and carbonization decomposition, and introducing oxygen into the carbonization furnace so that the oxygen content in the carbonization furnace At 8%, the solids produced are cooled and stored, and the gases produced are filtered, cooled and decoked.

[0067] The temperature in the carbonization furnace is controlled at 850°C.

[0068] The dried biomass needs to be pulverized to a length of 10 mm before being sent into the carbonization furnace.

[0069] After the gas is filtered, cooled and decoked, the oil-water mixture and combustible gas are obtained. The oil-water mixture is also separated from oil and water to obtain wood vinegar and wood tar.

[0070] The combustible gas is also subjected to gas purification to separate the mixture of water, wood tar and wood vinegar, and the se...

Embodiment 2

[0072] This embodiment provides a biomass aerobic carbonization decomposition method, which specifically includes: sending the dried biomass raw material into a carbonization furnace for ignition and carbonization decomposition, and introducing oxygen into the carbonization furnace so that the oxygen content in the carbonization furnace At 9%, the solids produced are cooled and stored, and the gases produced are filtered, cooled and decoked.

[0073] The temperature in the carbonization furnace is controlled at 120°C.

[0074] The dried biomass needs to be crushed to a length of 1 mm before being sent into the carbonization furnace.

[0075] After the gas is filtered, cooled and decoked, the oil-water mixture and combustible gas are obtained. The oil-water mixture is also separated from oil and water to obtain wood vinegar and wood tar.

[0076] The combustible gas is also subjected to gas purification to separate the mixture of water, wood tar and wood vinegar, and the separ...

Embodiment 3

[0078] This embodiment provides a biomass aerobic carbonization decomposition method, which specifically includes: sending the dried biomass raw material into a carbonization furnace for ignition and carbonization decomposition, and introducing oxygen into the carbonization furnace so that the oxygen content in the carbonization furnace At 15%, the solids produced are cooled and stored, and the gases produced are filtered, cooled and decoked.

[0079] The temperature in the carbonization furnace is controlled at 650°C.

[0080] The dried biomass needs to be crushed to a length of 120 mm before being sent into the carbonization furnace.

[0081] After the gas is filtered, cooled and decoked, the oil-water mixture and combustible gas are obtained. The oil-water mixture is also separated from oil and water to obtain wood vinegar and wood tar.

[0082] The combustible gas is also subjected to gas purification to separate the mixture of water, wood tar and wood vinegar, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com