A core-spun fireweed yarn and its preparation method and preparation device

A fireweed and core yarn technology, applied in yarn, spinning machine, open-end spinning machine, etc., can solve the problems of lack of automation, low efficiency, single product of fireweed yarn, etc., and achieve the effect of abundant products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

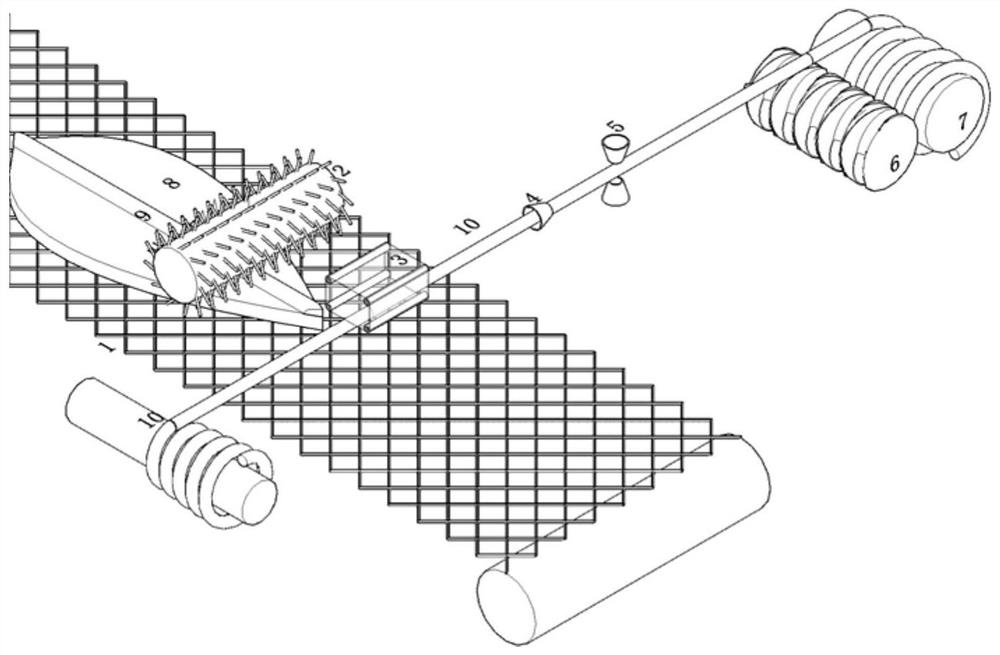

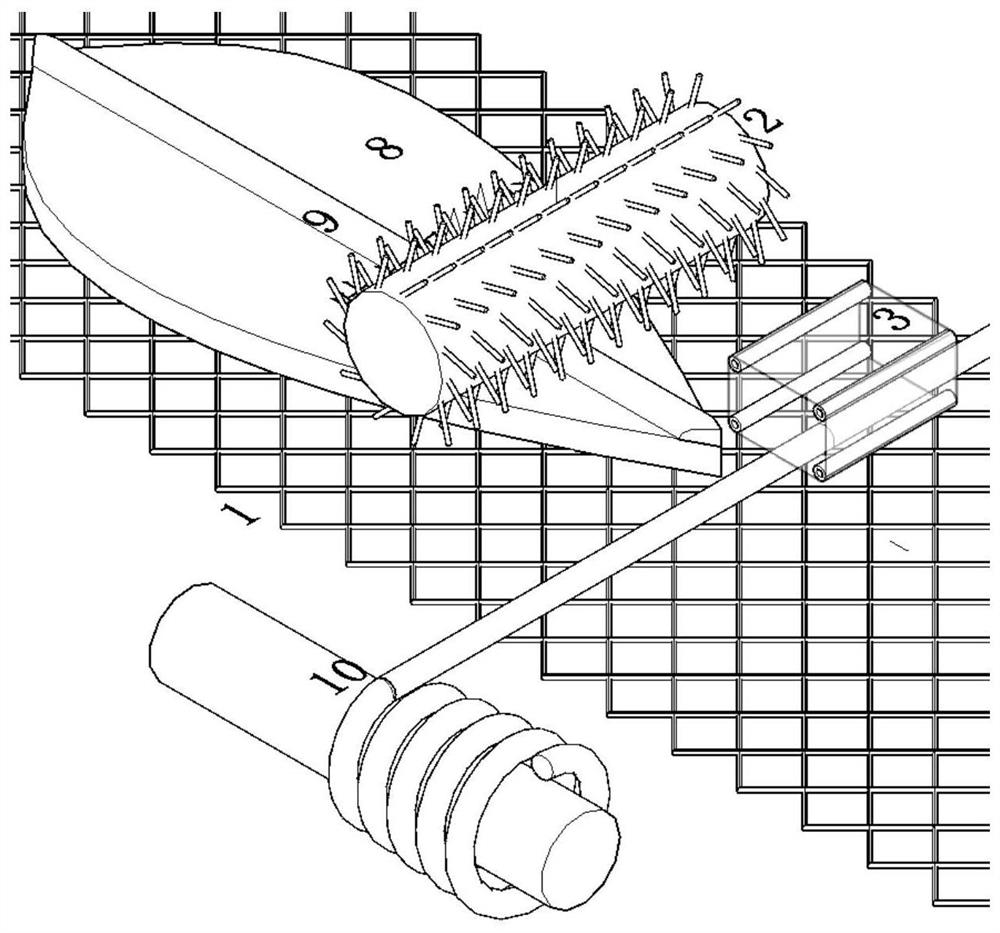

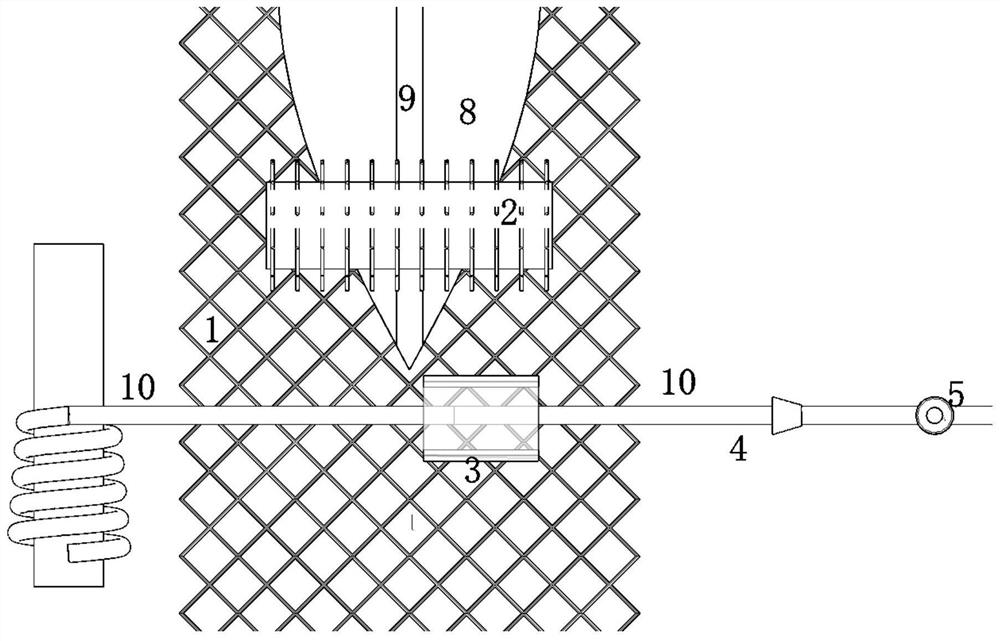

[0064] A kind of preparation method of core-spun fire grass yarn, adopts such as Figure 1~3 For the device shown, the steps are as follows:

[0065] (1) The core yarn system is prepared in advance, the yarn is pulled out from the bobbin as the core yarn 10, which passes through the bottom of the pressure belt 3, the bell mouth 4, the rotary vortex nozzle group 5, and the groove drum 6 in sequence and is wound on the winding On the roller 7, pay attention to ensure that the core yarn 10 is in a straight state;

[0066] (2) Turn on the power, turn on the switch, drive the negative pressure conveyor belt, put the collected, washed and dried fire grass leaves with the suede side up, and place them on the negative pressure conveyor belt in the direction that the midrib 9 of the blade is perpendicular to the core yarn 10 At the same time, the air extractor works, and the fire grass blade 8 is adsorbed on the conveyor belt; the fire grass blade 8 is firmly sucked by the conveyor be...

Embodiment 2

[0074] A kind of preparation method of core-spun fire grass yarn, adopts such as Figure 1~3 The shown device has the same steps as in Example 1, except that the core yarn adopts a soluble vinylon filament yarn with a water melting temperature of 40 degrees Celsius (the core yarn in Example 1 is a non-soluble vinylon filament yarn).

[0075] In the final core-spun fire grass yarn, the fire grass fiber fleece in the yarn is tightly wrapped around the vinylon filament yarn, and the soluble vinylon filament yarn lives inside the fire grass yarn. Then it becomes a pure fire grass hollow structure yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com